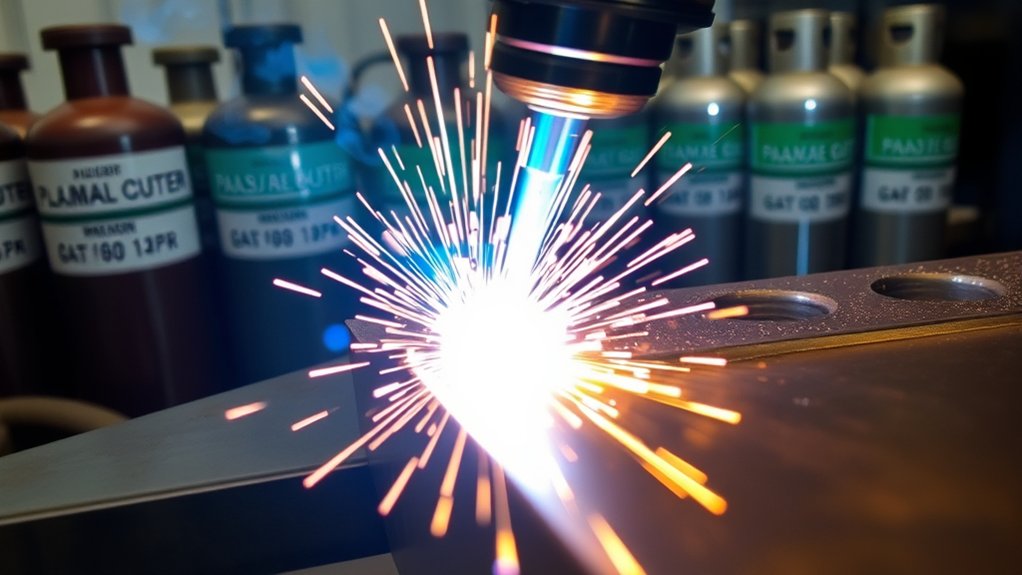

Cutting brass with a plasma cutter can be surprisingly effective if you master the right techniques. You’ll need to manage heat input carefully to avoid warping, using low amperage and a steady cutting speed between 20 to 60 inches per minute. Opting for nitrogen as your shielding gas minimizes oxidation, enhancing edge quality. Precision is key, so employing a narrow nozzle guarantees cleaner cuts. Curious about mastering these methods for a flawless brass finish?

Exploring the Suitability of Plasma Cutting for Brass

When considering the suitability of plasma cutting for brass, it’s vital to understand brass’s unique thermal properties. Brass is known for its high thermal conductivity, which means heat spreads quickly and can lead to uneven cuts and distortion if not managed correctly.

Brass’s high thermal conductivity demands careful heat management to avoid uneven cuts and distortion.

As you explore cutting tools like plasma cutters, precise control over heat input becomes important. Employing nitrogen as a shielding gas effectively reduces oxidation, ensuring cleaner surfaces.

To achieve the best results, adjust the plasma cutter’s settings to accommodate brass thickness. Lower amperage settings prevent excessive heat damage, preserving the material’s integrity.

In addition, brass’s reflectivity necessitates careful attention; familiarizing yourself with its properties enhances cut quality and accuracy.

Dross formation is another challenge. By experimenting with cutting speed and power settings, you can minimize this issue and improve the finish.

Embrace the liberating potential of plasma cutting, armed with knowledge of brass properties and the right cutting tools.

Key Techniques for Effective Brass Cutting

When cutting brass with a plasma cutter, you must optimize heat input by setting the machine to low amperage, minimizing the risk of thermal distortion due to brass’s high thermal conductivity.

It’s vital to maintain a steady cutting speed to reduce dross formation and guarantee smooth, clean edges.

Optimize Heat Input

To optimize heat input when cutting brass with a plasma cutter, focus on using low amperage settings, which helps minimize heat damage and distortion. Effective heat management is essential, and one of the key cutting techniques involves adjusting the plasma cutter’s settings to match the brass’s thickness.

This precision guarantees controlled heat application, preserving the material’s integrity. Use a narrow nozzle to further refine your cuts, allowing for accurate control over the heat directed at the brass.

Experiment with different power settings to achieve a balance that minimizes dross while maintaining the integrity of intricate designs. By doing so, you’ll make certain the brass maintains its desired shape and finish, freeing you from the constraints of excessive heat and distortion.

Maintain Steady Speed

Achieving precise cuts in brass with a plasma cutter hinges on maintaining a steady speed throughout the process. Inconsistent speed compromises the efficiency of your cutting techniques, leading to uneven cuts and excessive dross.

Aim for a cutting speed between 20 to 60 inches per minute, adjusting according to brass thickness and your plasma cutter’s settings. A narrow nozzle focuses the plasma arc, granting you precise speed control and enhancing cut quality.

Additionally, calibrating power settings to lower amperage minimizes heat distortion, enabling a consistent cutting rate. By regularly practicing and closely monitoring your speed, you’ll master the skill to maintain the ideal pace, liberating you to execute high-quality, clean-edge cuts with confidence and precision.

Selecting the Right Gas for Optimal Results

When cutting brass with a plasma cutter, selecting the right gas is essential to achieving ideal results.

Utilizing nitrogen as the shielding gas minimizes oxidation due to its inert properties, ensuring cleaner cuts and a reduced heat-affected zone.

Additionally, combining compressed air with nitrogen can enhance efficiency, particularly for thicker brass materials, by balancing cut quality and dross formation.

Gas Types for Brass

Selecting the right gas for plasma cutting brass is essential for achieving ideal results, with several options to evaluate. Understanding gas properties directly impacts plasma efficiency and your final cut quality.

Nitrogen is a popular choice due to its ability to reduce oxidation and guarantee cleaner cuts, while compressed air is less effective, increasing oxidation risks.

Oxygen excels with thicker brass, yet demands careful management to prevent surface oxidation and dross.

For a hotter plasma flame, consider an argon-hydrogen mix, which enhances cutting performance and edge precision.

Each gas type influences cutting speed, edge quality, and finish, so aligning your gas selection with brass thickness liberates you to achieve peak results.

Your choice dictates the success of your plasma cutting endeavors.

Nitrogen Benefits Explained

Nitrogen stands out as a premier choice for plasma cutting brass, offering unmatched benefits that optimize your cutting process.

With nitrogen advantages, you can achieve cleaner cuts and minimal oxidation, vital for maintaining pristine surface quality. This gas reduces dross formation, preserving intricate designs and enhancing cutting performance.

Nitrogen’s inert properties stabilize the plasma arc, granting you precise control over reflective materials like brass. When tackling thicker brass, nitrogen improves cutting quality and minimizes the heat-affected zone, guaranteeing less distortion and superior dimensional accuracy.

Opting for nitrogen guarantees smoother finishes, making it ideal for projects demanding high-quality aesthetics.

Reducing Oxidation Risks

Achieving high-quality cuts in brass requires selecting the right shielding gas to minimize oxidation risks. Opt for nitrogen, which excels in oxidation prevention by shielding the metal from atmospheric oxygen. This choice guarantees a cleaner cut, reducing the potential for dross formation.

For thicker brass, oxygen can improve cutting efficiency, but beware of its increased oxidation risk. A dual-gas approach, using nitrogen with air, can enhance plasma stability and cut quality, providing cleaner edges with minimal post-processing.

Fine-tune the power settings and gas flow rates to match brass thickness, assuring minimal heat input and oxidation. Regular monitoring and adjustments of the gas mixture maintain a stable plasma arc, vital for achieving the best results in brass cutting.

Achieving a High-Quality Finish on Brass

When aiming for a high-quality finish on brass using a plasma cutter, start by setting the machine to low amperage to reduce heat input and minimize material distortion. This approach respects the material properties of brass, allowing for precise finishing techniques.

Utilize a narrow nozzle, which enhances cut accuracy, resulting in cleaner edges and a smoother finish. Adjust the cutting speed meticulously; maintaining a steady pace is essential to prevent uneven edges and dross formation.

Opt for a narrow nozzle to achieve precision cuts with cleaner edges and a smoother finish.

Employ nitrogen as your shielding gas to effectively reduce oxidation, ensuring that the cut edges remain clean and presentable. This choice greatly contributes to the overall quality of the finish.

Regular maintenance and the use of high-quality consumables, such as torches and electrodes, are imperative for achieving consistent, superior results.

- Low Amperage: Minimizes heat input, reducing material distortion.

- Narrow Nozzle: Provides precision, creating cleaner, smoother cuts.

- Nitrogen Shielding Gas: Reduces oxidation, enhancing edge quality.

Addressing Common Challenges in Brass Cutting

Although brass’s high thermal conductivity presents a challenge in plasma cutting, understanding its properties allows you to manage these difficulties effectively. The key lies in precise control of your cutting tools.

Adjust the plasma cutter’s heat input carefully to prevent bending and distortion. By understanding brass properties, you can mitigate surface oxidation with shielding gases like nitrogen, ensuring a cleaner cut.

Dross formation is another common issue, tackled by experimenting with cutting speed and power settings. Finding the sweet spot minimizes excess material, allowing for smoother results.

Don’t overlook the vital aspect of ventilation; brass contains zinc, releasing toxic fumes during cutting. Adequate ventilation liberates you from health hazards, ensuring a safer workspace.

Ultimately, mastering these challenges requires a balance of technical adjustments and an intimate understanding of brass properties. This knowledge empowers you to achieve precise, high-quality cuts every time, transforming obstacles into opportunities for excellence.

Enhancing Precision and Safety in the Workshop

Understanding the challenges in brass cutting sets the stage for enhancing precision and safety in your workshop. By employing low amperage settings and a narrow nozzle, you can achieve cleaner cuts with minimal distortion.

Adjust the cutting speed and power settings based on brass characteristics to maintain accuracy and avoid uneven cuts. Regularly inspect and maintain consumables such as nozzles and electrodes to guarantee peak performance and longevity.

Safety protocols are non-negotiable. Proper ventilation is vital to mitigate harmful fumes, particularly due to zinc content in brass. Always equip yourself with protective gear, including masks and goggles, to prioritize your well-being.

To further enhance your workshop’s precision and safety, consider the following:

- Ventilation: Ensure proper airflow to reduce exposure to harmful fumes.

- Protective Gear: Always wear masks and goggles during operations.

- Maintenance: Regularly check and replace nozzles and electrodes as needed.

Frequently Asked Questions

How Does Brass Thickness Affect Plasma Cutting Settings?

Brass thickness directly influences your cutting settings. For thicker brass, increase the amperage and adjust travel speed to guarantee a clean cut. Thinner brass requires lower power settings, allowing precise control without overheating or warping the material.

Is It Necessary to Preheat Brass Before Plasma Cutting?

Preheating brass is like warming up before a run; it’s not necessary but offers benefits. By preheating, you stabilize cutting temperature, ensuring precision and reducing thermal shock, ultimately achieving a cleaner, more liberated cut.

Can You Use a Standard Plasma Cutter for Brass Jewelry Making?

Yes, you can use a standard plasma cutter for brass jewelry making. Choose a cutter type that offers fine control for intricate jewelry design. Guarantee precision by adjusting settings for cleaner cuts, achieving creative freedom in your work.

Does Plasma Cutting Brass Produce Harmful Fumes?

Plasma cutting brass does produce potentially harmful fumes. Prioritize protective practices by employing effective fume extraction systems. Follow strict safety precautions to guarantee safe, liberating work environments, minimizing inhalation risks and maximizing your creative freedom in metalwork.

Are There Alternative Cutting Methods for Intricate Brass Designs?

You can explore laser cutting and water jet techniques for intricate brass designs. Laser cutting provides precision and speed, while water jet offers flexibility without heat distortion. Both methods liberate you from design limitations and guarantee detailed craftsmanship.

Conclusion

Cutting brass with a plasma cutter is like steering a well-tuned orchestra; precision, technique, and the right tools are essential. By carefully managing heat, using nitrogen gas, and maintaining a steady speed, you’ll achieve clean, high-quality cuts. Employ a narrow nozzle to enhance control, minimizing oxidation for a polished finish. Address challenges methodically, and always prioritize safety. With these strategies, your workshop will be well-equipped to handle brass like a pro.