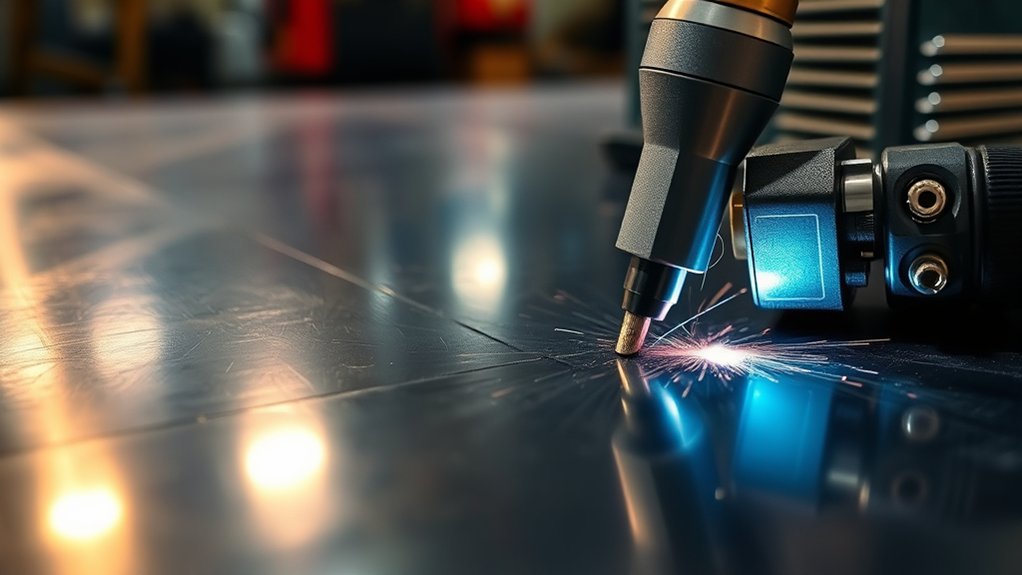

When considering whether you can TIG weld with a plasma cutter, it’s crucial to understand the fundamental differences between these two processes. Plasma cutting involves high voltages and rapid gas flow for slicing through metal, while TIG welding requires precise control of lower voltage and a stable, inert atmosphere for quality welds. These differing requirements mean each tool is purpose-built, and using them interchangeably can lead to challenges. So, how do these differences impact your welding tasks?

Understanding Plasma Cutting and TIG Welding

When it comes to understanding plasma cutting and TIG welding, it’s essential to recognize the distinct electrical and operational differences between these two processes. Plasma cutting operates at a notably higher open circuit voltage (OCV) of 250-300V, vital for sustaining the arc in air. In contrast, TIG welding typically utilizes an OCV of 60-80V, relying on an inert gas like argon to stabilize the arc. This highlights the varying plasma characteristics and welding techniques of each process.

Plasma cutting necessitates higher gas flow rates, complicating ionization but enabling efficient metal cutting. TIG welding, however, benefits from lower gas flow, enhancing arc stability for precision work.

Each technique demands specific equipment; a plasma cutter can’t perform TIG welding tasks and vice versa. Proper understanding of these parameters guarantees effective implementation and prevents issues like dross and oxidation from compromising weld quality.

Key Differences Between Plasma Cutting and TIG Welding

Although both plasma cutting and TIG welding are rooted in the manipulation of electric arcs, their operational criteria distinctly differ. Plasma applications demand higher open circuit voltages (OCV) and load voltages. You’re looking at plasma cutting with an OCV of 250-300V and load voltage of 90-130V. In contrast, TIG techniques require a more modest OCV range of 60-80V and load voltage of 12-24V, underscoring different energy demands.

Plasma cutting demands higher voltages than TIG welding, reflecting their distinct energy requirements.

- Gas Flow Rate: Plasma cutting requires a higher gas flow rate, which complicates ionization and demands higher voltage, whereas TIG welding uses argon with less voltage to maintain the arc.

- Power Source Design: Both processes use constant current/drooping voltage power sources, but the equipment setups are incompatible.

- Application Focus: Plasma cutting excels in slicing through materials, while TIG welding shines in joining metals, each tailored to specific operational needs and material interactions.

Voltage, Current, and Ionization in Welding Processes

When comparing TIG welding and plasma cutting, you’ll notice a stark contrast in voltage requirements, with plasma cutting needing markedly higher voltage to sustain the arc due to air resistance.

The current level is vital as it directly affects ionization and temperature, with plasma cutting capable of delivering more power at the same gas temperature than TIG welding.

Additionally, understanding gas flow dynamics is essential, as TIG welding relies on argon shielding, which demands lower voltage compared to the open-air operation of plasma cutting.

Voltage Requirements Explained

Understanding voltage requirements is essential when comparing TIG welding and plasma cutting. Both processes have distinct voltage characteristics due to their different operational needs.

- Voltage Stability: Plasma cutting operates at a high open circuit voltage (OCV) of 250-300V, vital for maintaining an arc in air, while TIG welding uses a lower OCV of 60-80V, benefiting from argon’s shielding properties for arc stability.

- Amperage Control: Amperage influences ionization and temperature. Plasma cutters deliver more power to the metal at the same gas temperature compared to TIG, necessitating precise amperage control.

- Load Voltage: Plasma cutting’s load voltage ranges from 90-130V, whereas TIG welding maintains a load voltage between 12-24V, underscoring the power requirements for each technique.

Current Influence on Ionization

To explore the impact of current on ionization in welding processes, it’s crucial to examine how current levels directly influence the arc’s stability and efficiency.

In TIG welding, lower load voltages of 12-24V mean that the current impact is less intense, allowing for more precise control over ionization efficiency. This precision results from using argon gas, which requires less voltage to maintain the arc, enhancing ionization efficiency.

Conversely, plasma cutting requires higher load voltages of 90-130V, meaning a stronger current impact is necessary to achieve effective ionization. This is due to the need to overcome increased resistance from higher gas flow rates.

Ultimately, the amperage plays a significant role in determining ionization efficiency and maintaining arc stability in both processes.

Gas Flow Dynamics

Examining the interplay between voltage, current, and ionization reveals essential insights into gas flow dynamics in both TIG welding and plasma cutting.

You’ll notice that plasma cutting demands higher voltages to maintain its arc due to increased gas flow rates, which complicate ionization. In contrast, TIG welding operates at lower voltages and utilizes more efficient ionization processes owing to its reduced gas flow.

Here’s a breakdown of key differences:

- Voltage Requirements: Plasma cutting uses 250-300V for OCV, while TIG welding needs just 60-80V.

- Gas Flow and Resistance: Higher gas flow in plasma cutting increases resistance, necessitating higher voltage.

- Ionization Efficiency: TIG welding achieves better ionization efficiency with lower amperage and temperature settings.

Understanding these factors enhances the effective application of each welding method.

Equipment Design and Requirements for Each Process

When setting up for plasma cutting or TIG welding, you’ll notice distinct differences in power source requirements and equipment configurations.

Plasma cutters demand higher open circuit voltages, typically between 250-300V, and a robust gas supply system to handle the increased flow rate necessary for ionization.

In contrast, TIG welding, utilizing argon with lower voltage needs, requires a dedicated TIG torch and gas cylinders to maintain a stable arc.

While inverter machines can accommodate both processes, each setup must be precisely tailored to its specific application.

Power Source Differences

While both TIG welding and plasma cutting rely on power sources that feature a constant current and drooping voltage design, their equipment design and power requirements diverge considerably.

Plasma cutting requires notably higher open circuit voltage (OCV) levels, ranging from 250-300V, whereas TIG welding operates with an OCV of 60-80V. This illustrates the distinct power requirements each process demands.

In addition, plasma cutters utilize a unique electronic design, incorporating specialized components to handle the high load voltage of 90-130V, compared to TIG welding’s 12-24V.

Here’s a breakdown of key differences:

- Open Circuit Voltage (OCV): Plasma: 250-300V, TIG: 60-80V

- Load Voltage: Plasma: 90-130V, TIG: 12-24V

- Electronic Design: Distinct for each process, requiring unique components.

Torch and Gas Setup

Understanding the power source differences between TIG welding and plasma cutting lays the groundwork for analyzing their torch and gas setup.

Plasma cutters utilize a plasma torch requiring a high voltage of 250-300V OCV and a gas supply system for ionized gas. This setup demands higher gas flow rates to maintain ionization, contrasting with TIG welding’s torch types that operate at a lower 60-80V OCV using a tungsten electrode.

TIG welding typically employs argon, a gas mixture that allows precise control over heat input with reduced flow rates. While both processes rely on constant current power sources, their distinct electronic configurations reflect unique operational requirements.

Ensuring the correct torch and gas setup is essential for efficient cutting or welding results.

Challenges of Welding Over Fresh Plasma Cuts

Although plasma cutting is a highly efficient method for shaping metal, welding over fresh plasma cuts presents several challenges that can’t be ignored.

First, there’s the issue of welding contamination; residual dross and impurities from the cuts can compromise weld integrity. This contamination often leads to oxidation issues that further degrade the quality of your welds.

Secondly, TIG welding over these fresh cuts frequently results in poor penetration. The impurities present create barriers that prevent a strong weld joint, making it difficult to achieve the desired level of structural robustness.

Lastly, both stick welding and TIG welding struggle with unattractive, weak outcomes on freshly cut surfaces.

Here’s a breakdown of what you’ll face:

- Welding contamination: Dross and oxidation issues are prevalent.

- Poor penetration: Impurities hinder strong joint formation.

- Weak, unattractive welds: Surface impurities affect weld quality.

Address these challenges to enhance your welding results.

Importance of Surface Preparation Before Welding

Tackling the challenges of welding over fresh plasma cuts starts with proper surface preparation. Removing surface contaminants like dross and oxidation is vital for ensuring effective welding. Without this step, you risk poor weld quality and compromised joint integrity.

Clean surfaces are essential for smoother weld puddles and better arc control, leading to consistent bead sizes and improved aesthetics.

To achieve this, employ effective cleaning techniques. Tools such as grinding wheels or flap discs are excellent choices for preparing metal surfaces before welding. They not only enhance the strength and appearance of the final weld but also help in avoiding contamination issues.

Welding on freshly plasma-cut surfaces without preparation can result in unattractive and weak joints due to leftover dross and oxidation.

Neglecting surface preparation can lead to brittle welds and increased porosity, making it a significant step in achieving high-quality welds.

Don’t overlook this essential process.

Comparing Weld Quality: TIG Vs Plasma Cuts

When comparing weld quality between TIG welding and plasma cuts, it’s crucial to recognize the distinct advantages each method offers.

TIG welding excels in weld aesthetics and strength, especially on clean surfaces. Plasma cuts, while efficient, often introduce surface contamination like dross and oxidation, which can lead to poor penetration and weak joints.

Here’s what you should consider:

- Surface Contamination: Welding over fresh plasma cuts risks contamination, leading to brittle welds due to unremoved dross and oxidation.

- Weld Aesthetics: TIG welding on clean metal yields polished, consistent beads, while dirty surfaces from plasma cuts result in inconsistent and unattractive welds.

- Craftsmanship: Unprepared surfaces lead to increased porosity and compromised joint integrity, highlighting the importance of surface preparation for quality welding.

Ultimately, prioritizing clean, prepared surfaces before TIG welding guarantees superior welds in both appearance and durability.

Plasma cuts require meticulous cleanup to avoid quality issues, making TIG welding the preferred choice for high-quality results.

Expert Tips for Achieving Strong and Appealing Welds

Achieving strong and appealing welds requires attention to detail and a methodical approach, especially after understanding the differences in weld quality between TIG welding and plasma cuts.

Start by ensuring proper material preparation; clean surfaces free of dross and oxidation are essential for weld aesthetics and process efficiency. Dirty surfaces compromise bead consistency and joint integrity, so meticulous cleaning is non-negotiable.

Adjust your TIG welding parameters, including current, arc travel speed, and gas flow rates, to control heat input and penetration. These adjustments directly affect the weld’s quality and aesthetics. Clean surfaces result in smoother puddles and better arc control, yielding polished, consistent welds.

Conduct regular quality checks. Visual inspections and tools like X-rays help detect defects early, enhancing weld aesthetics and strength.

Stay updated with new technologies and techniques, maintaining detailed project records to refine your skills and achieve superior weld quality across applications.

Frequently Asked Questions

Can You Use the Same Gas for Both TIG Welding and Plasma Cutting?

You can’t use the same gas for both TIG welding and plasma cutting. Gas compatibility is essential. TIG welding techniques require an inert gas like argon, while plasma cutting needs compressed air or nitrogen for effective and precise cutting.

How Does Plasma Cutting Affect Metal Thickness for TIG Welding?

When you plasma cut, envision a sculptor crafting a masterpiece. Plasma cut quality directly impacts metal thickness for TIG welding, with precision guaranteeing smoother edges. Analyzing these details guarantees ideal welding, enhancing your final creation’s integrity.

Are There Specific Safety Risks When Combining Plasma Cutting and TIG Welding?

Yes, combining plasma cutting and TIG welding poses safety risks. You must handle equipment properly to prevent electric shocks. Always wear appropriate protective gear to shield against intense light, heat, and harmful fumes, ensuring a safer working environment.

What Materials Are Best for TIG Welding After Plasma Cutting?

Think of TIG welding like a dance; aluminum alloys and stainless steel are your perfect partners after plasma cutting. Their clean edges and consistent heat response guarantee smooth, precise welds, minimizing imperfections and enhancing structural integrity.

How Do You Choose Consumables for TIG Welding Post-Plasma Cutting?

Choose consumables by first evaluating your material’s thickness and type post-plasma cutting. Opt for an electrode selection that matches the base metal. Select a filler rod complementary to the alloy, ensuring strong, precise TIG welding results.

Conclusion

In the domain of metalworking, think of TIG welding and plasma cutting as two distinct dance partners, each with their own rhythm and style. You can’t interchange them without stumbling. Plasma cutting slices through metal with high-voltage intensity, while TIG welding demands a gentle, precise touch. Mixing them leads to welds marred by dross and inconsistency. So, embrace the art of preparation and choose the right partner for pristine, strong welds every time.