Do You Need a Compressor for a Plasma Cutter

Mulling a plasma cutter purchase but unsure about compressors, airflow, and PSI—discover the must-know specs that prevent ruined cuts and wasted cash.

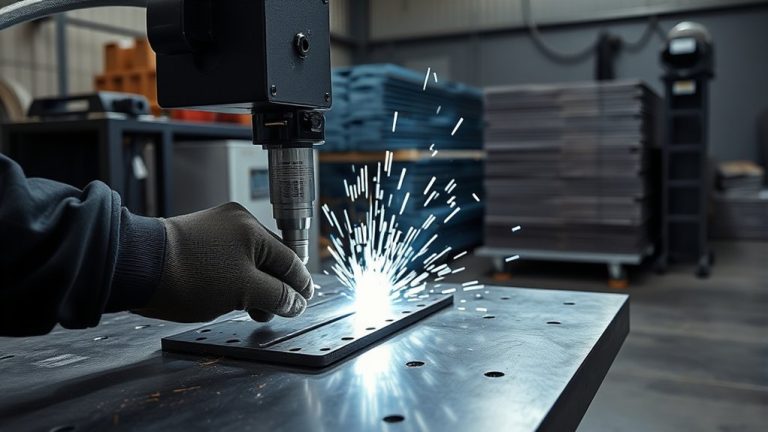

Clean, dry air—or the right process gas—is essential for quality plasma cuts. Most handheld units run on compressed air; advanced systems may use nitrogen or oxygen for faster steel cutting and argon–hydrogen blends for thick stainless and aluminum. Size your compressor by CFM at pressure, not tank size: ~4–6 CFM @ 90–120 PSI suits many 30–40A units; 6–9+ CFM fits 50–65A machines (confirm in your manual). Set regulated pressure around 60–90 PSI at the torch, maintain steady flow, and add moisture/oil filtration or an air dryer to prevent double-arcing. Built-in-compressor models simplify mobile work; match duty cycle and CFM, especially when running from a generator.

Mulling a plasma cutter purchase but unsure about compressors, airflow, and PSI—discover the must-know specs that prevent ruined cuts and wasted cash.

Skipping gas with a plasma cutter risks arc failure, poor cuts, and damage—discover which gases matter, why, and what happens if you try anyway.

Seeking cleaner cuts and longer consumable life, many plasma systems run nitrogen—discover when it’s the best choice and when it isn’t.

Teasing the truth about plasma cutter shielding gas, this guide reveals when air suffices and when specialty gases matter—discover the hidden pitfalls before you cut.

Learn whether plasma cutters require compressed air, the exact PSI/CFM specs that protect consumables, and how filtration impacts cut quality—before your next cut goes wrong.

Curious about which gas—compressed air, oxygen, nitrogen, or argon‑hydrogen—delivers the best plasma cuts for your materials and budget?

Unlock the secrets of plasma cutter gases—oxygen, nitrogen, air, and more—so you choose perfectly for clean cuts, lower costs, and longer consumable life.