Plasma Cutter Vs MIG Welder: When to Cut Vs When to Weld

Cutting-edge techniques await as we explore when to choose a plasma cutter over a MIG welder for your next project. Discover the art of decision-making.

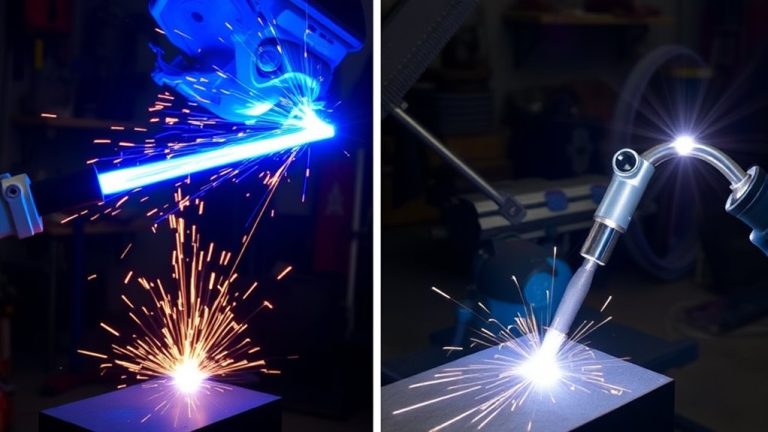

How does plasma stack up against welding and other cutting tools? This section contrasts plasma cutters with MIG/TIG welders (joining vs cutting), oxy-fuel, laser, angle grinder, and band saw. We explain where plasma wins—fast cuts on conductive metals, narrow kerf, minimal prep, CNC compatibility—and its trade-offs: HAZ, bevel on thick plate, air/CFM needs, and consumable costs. You’ll learn when a welder is the right tool for joining, when oxy-fuel excels on very thick carbon steel, and when laser offers the tightest tolerance and smallest kerf. We also cover safety, power requirements, fume extraction, and typical operating costs so you can choose the best process for each job.

Cutting-edge techniques await as we explore when to choose a plasma cutter over a MIG welder for your next project. Discover the art of decision-making.

Navigate the intricacies of plasma and TIG welding, uncovering how they differ in precision and heat control—discover which is best for your project.

Keen to discover which welding method offers the best speed, penetration, and cost-effectiveness for your project? Find out more inside!