Lotos Plasma Cutter: How to Use, Setup, and Troubleshooting Guide

Master the Lotos Plasma Cutter with our setup and troubleshooting guide, and discover the secrets to flawless cuts and efficient operation.

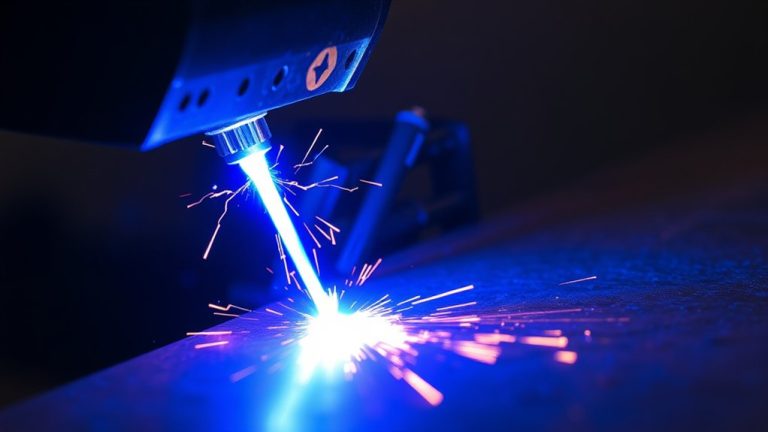

Run clean, dry air and set the regulator with flow on. Attach the work lead to bright metal, install fresh consumables, and power on. For pilot-arc torches, let the pilot establish, then move to the work to transfer; for contact-start, touch the shield to the edge to strike and lift to cut height. Start from an edge when possible; for pierces, use the charted pierce height/delay, hold vertical, and begin with a short lead-in. Maintain cut height with a drag shield, stand-off gauge, or THC and keep a steady travel speed—look for even drag lines and minimal dross. At cut end, pause briefly, overlap 1–2 mm, then let post-flow cool the torch.

Master the Lotos Plasma Cutter with our setup and troubleshooting guide, and discover the secrets to flawless cuts and efficient operation.

Navigate the world of plasma cutting with pilot arc technology—discover its unmatched benefits and ideal applications that will elevate your metalworking projects.

Curious about achieving flawless plasma cuts? Discover essential torch settings and techniques for arc starting a plasma cutter effectively to enhance your cutting skills.

Cut through metal like a pro with our plasma cutting guide; discover the secrets to achieving clean edges effortlessly.

Master the art of plasma cutting by setting up safely and making those first cuts with precision—are you ready to transform metal into masterpieces?

Learn the key differences between pilot arc and non-pilot arc plasma cutters and discover which one is ideal for your metal cutting needs.