When using an angle grinder, choose a cutoff wheel for precise cuts in metal sheets and pipes. Its thin profile minimizes warping and enables clean, narrow cuts. Opt for a grinding wheel when you need to remove material or prepare surfaces, as it provides effective shaping and smoothing. Remember, using the correct wheel boosts safety and performance. If you’re curious about details like common mistakes or maintenance tips, there’s more to explore.

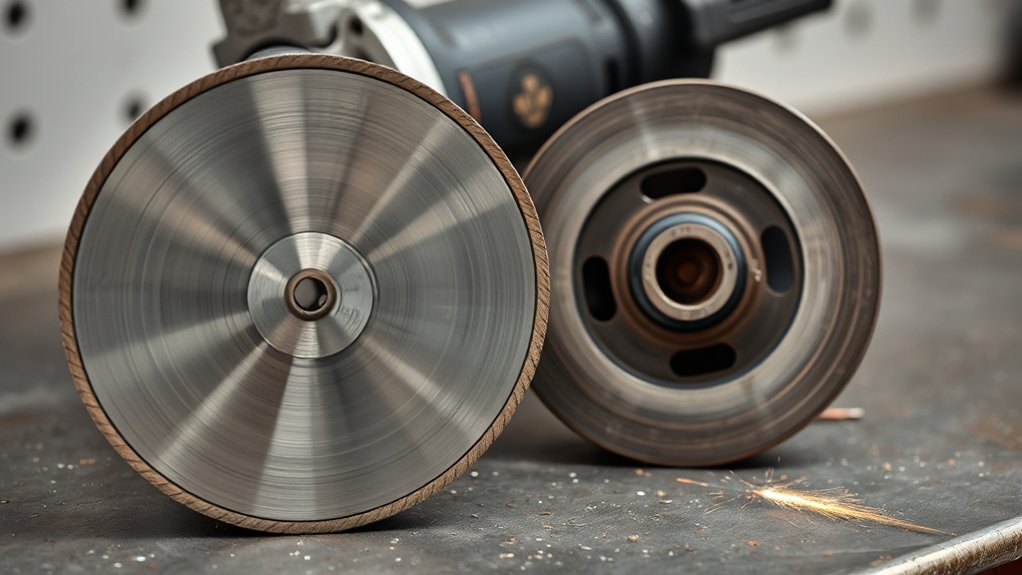

Understanding Cutoff and Grinding Wheels: Key Differences

When you’re choosing between cutoff wheels and grinding wheels, it’s crucial to understand their distinct functions and designs. Cutting wheels, typically thinner at .045 inches, excel at making narrow cuts with precision, especially at 90° angles. Their primary purpose is to cut through metal efficiently, but this thin profile increases the risk of shattering during use. You’ll need to handle them with care and always wear safety gear.

On the other hand, grinding wheels, often 1/4 inch thick or more, focus on material removal and surface preparation. They’re designed to smooth surfaces and prepare materials for welding, making them less prone to shattering. Different types of cutting wheels, like Type 41 (flat) and Type 42 (raised hub), offer varied visibility and capabilities, emphasizing their specific cutting functions. Understanding these differences will help you choose the right tool for your task effectively.

Ideal Scenarios for Using a Grinding Wheel

Grinding wheels shine in scenarios where material removal and surface preparation are essential. These tools excel at removing excess material and shaping surfaces, making them ideal for preparing metal for welding. When you need to smooth edges or deburr rough surfaces, grinding wheels with coarse grit will quickly handle the task. For finer finishes, simply switch to higher grit numbers, which are effective in blending welds and achieving smoother results.

In metalworking and fabrication applications, grinding wheels are invaluable. Their thicker design guarantees they stand up to significant wear and tear, providing durability in heavy-duty tasks. Remember, grinding wheels aren’t meant for cutting; using them for that purpose can lead to damage or injury. Stick to their intended uses for peak performance and safety. Whether you’re fabricating or finishing, these wheels are your go-to solution for efficient, effective results.

When to Use a Cutoff Wheel for Precision Cuts?

When you need to make precision cuts, a cutoff wheel is your go-to tool, especially for materials like metal sheets and pipes. Its thin kerf and minimal thickness allow for quick, accurate cuts that reduce the risk of warping. Consider using a cutoff wheel for applications like notching before welding, where precision is essential.

Ideal Materials for Cutting

Although you might think any wheel can handle cutting tasks, using a cut-off wheel is crucial for achieving precision cuts in metalwork. Cut-off wheels excel in cutting metal bars, sheets, and tubes at 90° angles, minimizing unnecessary material removal. For thin metal applications, the .045 cutting wheel is ideal, while the .090 wheel works well for accurate notching before welding. These cutting wheels reduce the kerf, resulting in cleaner cuts with less waste compared to grinding wheels. When precision and minimal burrs matter, cut-off wheels outperform grinding wheels, which are designed primarily for material removal. Always prioritize safety, as cut-off wheels have a higher risk of shattering; proper handling and protective gear are important.

Thickness and Kerf Considerations

Selecting the right wheel for your cutting tasks hinges on understanding thickness and kerf considerations. Cut-off wheels, with a kerf around .045 inches, excel at making precise cuts with minimal material removal, ideal for tasks like cutting metal bars. In contrast, grinding wheels are thicker, generally 1/4 inch or 1/8 inch, and focus on material removal rather than clean cuts.

| Wheel Type | Thickness | Application |

|---|---|---|

| Cut-off Wheel | ~.045 inches | Precise cuts, minimal waste |

| Grinding Wheel | 1/4 inch | Material removal |

| Cut-off Wheel | .090 inches | Cutting and notching |

| Grinding Wheel | 1/8 inch | Not suitable for cutting |

| Cut-off Wheel | Variable | Reduces overheating risk |

Using the appropriate wheel not only guarantees precision but also mitigates safety hazards.

Applications Requiring Precision Cuts

For tasks that demand exceptional accuracy, utilizing a cut-off wheel is essential. These wheels are engineered for narrow, precise cuts at 90° angles, making them ideal for trimming metal bars and sheets without excessive material removal. The thinner .045 cut-off wheels produce minimal kerf, ensuring cleaner cuts and reducing heat generation, which is vital for maintaining material integrity. Unlike grinding wheels, which shape and smooth materials, cut-off wheels are specifically designed for cutting applications. When selecting a wheel, choose one with ceramic or zirconium grain for durability. Always wear proper safety gear, including goggles and gloves, to protect against flying debris and potential wheel shattering during use with an angle grinder.

Identifying Key Features of Cutoff Wheels

Cutoff wheels boast several key features that set them apart from grinding wheels, making them essential for precise applications. Their thinner profile, often around .045 inches, allows for efficient metal cutting with minimal kerf, ensuring cleaner cuts. You’ll find two configurations: Type 41, designed for maximum depth, and Type 42, which offers better visibility for flush cutting.

Consider these essential features:

- Precision: Narrow cuts at 90° angles enhance your project’s accuracy.

- Safety: Higher risk of shattering necessitates proper safety gear to protect against flying debris.

- Material Variety: Different abrasive grains, like ceramic and zirconium, improve cutting speed and longevity across various metal types.

Understanding these features will empower you to choose the right cut-off wheel for your needs, ensuring safety and efficiency in your metal cutting tasks.

Understanding Grinding Wheel Characteristics

When you’re selecting a grinding wheel, understanding its types and grit size is essential for effective material removal. Each grit size affects the wheel’s hardness and suitability for different applications, impacting your project’s finish. Choosing the right grinding wheel will guarantee peak performance in smoothing and shaping metal surfaces.

Grinding Wheel Types

Grinding wheels come in various types, each tailored for specific applications and materials. Unlike cutting wheels, grinding wheels are thicker—typically around 1/4 inch—and designed for aggressive material removal rather than precise cuts. They feature higher grit numbers for smoother finishes, making them ideal for tasks like surface leveling and preparing surfaces for welding. Common abrasive grains include:

- Aluminum Oxide: Durable and effective for general grinding.

- Ceramic Aluminum Oxide: Ideal for tougher materials, offering extended life.

- Thickness: Greater thickness increases material removal efficiency.

Keep in mind that grinding wheels generate more friction and heat, so be cautious to avoid overheating your workpiece. Choosing the right type enhances your ability to achieve the results you desire.

Grit Size Importance

Selecting the right grit size is key to optimizing the performance of your grinding wheel. Grit size, measured numerically, affects both material removal and surface finish. Coarser grits, like 24 grit, are designed for aggressive material removal, making them ideal for heavy tasks. In contrast, finer grits, such as 120 grit, are perfect for achieving a polished look. The hardness of the grinding wheel also plays a role; harder wheels endure longer but may struggle with softer materials. Understanding the relationship between grit size and application guarantees efficiency in your work. Choose the appropriate abrasive grain based on your needs to enhance your results, whether you’re using a grinding or cutting wheel.

Application Suitability

Understanding the characteristics of grinding wheels is essential for any metalworking task, as their specific design influences application suitability. Unlike cutting wheels, grinding wheels are thicker, typically ranging from 1/8 to 1/4 inch. They excel in material removal but fall short in delivering clean, precise cuts.

Consider these factors when selecting your tool:

- Thickness: Grinding wheels reduce visibility and control during operations.

- Grit Size: Coarse grits work for aggressive material removal; finer grits prepare surfaces.

- Safety: Using grinding wheels for cutting can lead to overheating and injury.

For tasks requiring clean cuts, always opt for cutting wheels. This choice guarantees effective results while prioritizing safety and precision with your Angle Grinder.

Safety Tips for Using Cutting and Grinding Wheels

When working with cutting and grinding wheels, safety should always be your top priority. Always wear appropriate safety gear, including safety glasses, gloves, and face shields, to protect against flying debris. Verify that your cutting or grinding wheel is correctly mounted and undamaged before use to prevent wheel failure, which can lead to serious injuries. Use the right wheel type for your task—cutting wheels are thinner for precise cuts, while grinding wheels are thicker for material removal. Be mindful of the operational speed; the wheel’s maximum RPM rating must match or exceed your grinder’s speed to prevent accidents. Maintain a stable grip and control of the tool, especially with cutting wheels, as they can shatter under excessive pressure, leading to kickback. By following these safety tips, you’ll greatly reduce the risk of accidents while using cutting and grinding wheels.

Common Mistakes to Avoid With Cutting and Grinding Wheels

Many users make critical mistakes when working with cutting and grinding wheels that can lead to inefficiencies and safety hazards. To guarantee peak performance and safety, be mindful of the following:

- Using the wrong wheel type for a task, like a grinding wheel for cutting, can lead to improper material handling.

- Misusing cutting wheels can cause shattering, sending debris flying and risking serious injury.

- Failing to check wheel specifications and configurations, such as Type 41 versus Type 42, may limit visibility and cutting efficiency.

Always select thinner cutting wheels (.045) for metal cutting tasks and reserve thicker grinding wheels for their intended purpose. Regularly consult application charts to match wheel specifications with the material you’re working with. By avoiding these common mistakes, you’ll enhance your efficiency and, more importantly, maintain a safer workspace.

How to Maintain Your Angle Grinder for Optimal Performance

To keep your angle grinder performing at its best, regular maintenance is essential. Start by cleaning the air vents and housing frequently to prevent dust buildup that can cause overheating and reduce performance. Make it a habit to inspect and replace any worn or damaged brushes; neglecting this can harm the motor. Always verify that your cutting wheels and grinding wheels are securely mounted and properly aligned to minimize vibration, enhancing the tool’s longevity.

Lubricate moving parts as per the manufacturer’s guidelines for smooth operation and to prevent wear. Finally, store your angle grinder in a dry place to avoid moisture exposure, which can lead to rust and corrosion. By following these maintenance steps, you’ll guarantee that your angle grinder remains a reliable ally in your projects, delivering peak performance every time.

Frequently Asked Questions

When Can a Cutting-Off Wheel Be Used for Grinding?

You can use a cutting-off wheel for very light grinding tasks, ensuring you follow safety precautions. However, prioritize project suitability and performance comparison to avoid common mistakes, maximizing tool maintenance and application versatility for cost efficiency.

What Is the Difference Between Grinding and Cutting on an Angle Grinder?

Cutting on an angle grinder uses thinner wheels for precise cuts, while grinding employs thicker wheels for shaping surfaces. Prioritize angle grinder safety, tool maintenance, and project planning to guarantee peak performance and finish quality.

What’s the Difference Between a Grinding Wheel and a Cutoff Wheel?

A grinding wheel smooths surfaces, while a cutoff wheel makes precise cuts. Consider wheel materials, shapes, sizes, and application techniques. Prioritize safety tips and tool compatibility for peak performance with your angle grinder.

What Do You Use a Cutoff Wheel For?

You use a cutoff wheel primarily for cutting metal materials with precision. Make certain you follow ideal usage techniques and safety precautions, considering blade thickness variations and wheel compatibility for effective performance and longevity in common applications.

Conclusion

In the world of angle grinders, using a cutoff wheel for precision contrasts sharply with relying on a grinding wheel for shaping. Each serves a unique purpose—cutting through materials versus refining surfaces. Recognizing these distinctions guarantees your projects are efficient and effective. Proper maintenance and adherence to safety protocols further enhance performance, preventing costly mistakes. Embrace the right tool for the task, and you’ll achieve best results while safeguarding both your equipment and well-being.