Did you know that approximately 80% of plasma cutting processes encounter issues with dross formation? This is just one of the challenges you face when using plasma cutting, alongside bevel angles that can affect assembly precision, and the heat-affected zone (HAZ) that might compromise material integrity. Add to this the regular maintenance and consumable replacement, and it’s clear there’s more to contemplate for ideal operation and safety. What’s the real impact on your projects?

Understanding Dross Formation

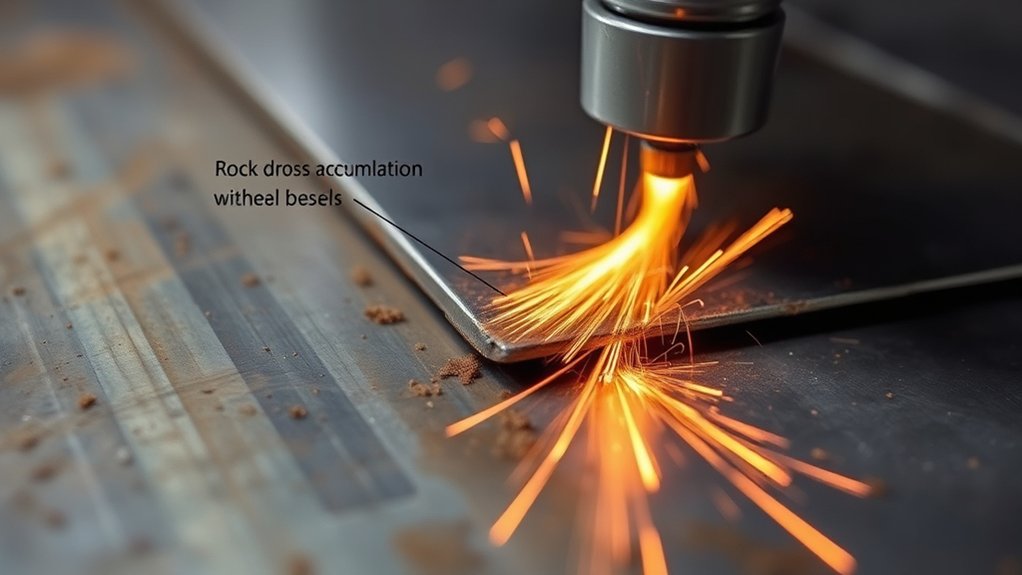

Dross is a common challenge in plasma cutting, manifesting as residue on the cut edge of metal due to solidified molten metal.

Dross, a byproduct of plasma cutting, appears as residue from solidified molten metal on the cut edge.

When cutting slower or at incorrect torch angles, you may notice increased dross formation, particularly with mild steel thicker than 1/4 inch. These conditions complicate achieving a clean cut and necessitate dross removal to maintain quality.

To minimize dross, adjust cutting speed and torch angle to ideal settings. Advanced systems offer technologies like True Hole to enhance edge quality and reduce dross.

However, when dross forms, it demands post-processing, such as grinding or sanding, which can elevate production costs and time.

Impact of Bevel Angles

You’ll encounter precision challenges with bevel angles in plasma cutting, as the process often produces sloped edges rather than perfectly vertical cuts.

Adjusting bevel angles becomes necessary to guarantee components fit correctly, especially when working with tight tolerances in industries like automotive and aerospace.

To achieve the best results, you’ll need to calibrate equipment and adjust cutting parameters based on material properties and thickness.

Precision Challenges in Beveling

When precision is paramount, the inherent challenges in achieving exact bevel angles with plasma cutting can’t be overlooked.

Bevel angle calibration is critical, as variances up to 5 degrees can compromise the fit and assembly of components in precision machining. Plasma cutting typically results in bevel angles between 2 to 5 degrees, often necessitating additional machining for tighter tolerances.

High-definition plasma cutting has improved accuracy, but deviations still occur, influenced by material thickness and cutting speed. Cutting thicker materials exacerbates issues, increasing the heat-affected zone (HAZ) and causing warping and distortion.

Maintaining ideal parameters like amperage and speed minimizes bevel angles, yet balancing these with productivity demands remains a challenge for operators aiming for precision.

Bevel Angle Adjustment Necessities

Addressing the precision challenges in beveling, you’ll find that bevel angle adjustments play a significant role in ensuring the accuracy of plasma cuts. Variability in cutting parameters often necessitates precise angle calibration. This is vital because typical bevel angles, ranging from 2 to 8 degrees, directly influence the fit-up quality in assembly processes.

When cutting speeds increase, so do bevel angles, potentially compromising structural integrity and leading to more machining to meet tolerances. To achieve tight tolerances, meticulous bevel adjustments are essential. Excessive bevel can cause misalignment in joints and welds, adversely affecting cut quality.

As a result, careful calibration of plasma cutting parameters is necessary to optimize performance and reduce post-processing requirements, ultimately ensuring that final products meet design specifications efficiently.

Exploring the Heat-Affected Zone (HAZ)

As you explore the intricacies of plasma cutting, understanding the Heat-Affected Zone (HAZ) becomes paramount. The HAZ effects are a critical factor since the heat generated can alter material properties, potentially leading to warping or weakening.

Thinner metals are especially vulnerable, compromising structural integrity around the cut edges. Effective HAZ mitigation involves balancing cutting speed, amperage, and material thickness. You need to grasp this balance to guarantee minimal HAZ in high-precision applications, preventing defects that might require further processing.

Key points to take into account:

- Material Properties: Alterations due to heat can affect strength and ductility.

- Susceptible Materials: Thinner metals face greater risk of HAZ-related issues.

- Cutting Parameters: Speed and amperage greatly influence HAZ size.

- Precision Impact: Excessive HAZ can introduce defects in precise applications.

- Mitigation Strategies: Adjust cutting parameters to minimize HAZ and maintain quality.

Understanding these elements is essential for achieving ideal plasma cutting outcomes.

Maintenance Requirements for Plasma Cutting Machines

Understanding the intricacies of plasma cutting isn’t complete without considering the importance of maintenance for the machinery involved. Regular maintenance schedules are vital for performance optimization.

Begin by routinely inspecting and replacing consumables like electrodes and nozzles, as they greatly impact cut quality. Cleaning internal components prevents dross and slag buildup, which can impair cutting efficiency and lead to extended maintenance downtime.

Properly aligning and calibrating the plasma torch is essential to maintain cutting accuracy, minimizing bevel angles and heat-affected zones (HAZ) on your workpiece. Make sure these checks are part of your regular maintenance routine.

Adequate ventilation is also critical since plasma cutting generates harmful fumes. Regularly inspect and service ventilation systems to maintain a safe working environment.

Consumable Replacement and Costs

When operating a plasma cutting machine, you must consider the regular replacement of consumables like electrodes and nozzles, as they directly influence your operational costs.

These consumable types are essential for maintaining ideal cutting performance and quality. A cost analysis reveals several factors impacting their replacement frequency and expense:

- Material Type and Thickness: Cutting thicker or harder materials wears out consumables faster.

- Cutting Speed: High-speed operations may increase the wear rate, necessitating more frequent changes.

- Electrode and Nozzle Costs: Prices vary, with electrodes ranging from $5 to $20 and nozzles from $10 to $30.

- Inventory Management: Efficiently managing consumables reduces downtime and guarantees consistent workflow.

- Quality Maintenance: Timely replacement prevents excess dross and maintains precision, keeping performance high.

Challenges in Achieving Precision Cuts

While managing consumable costs is significant, achieving precision cuts with plasma cutting presents its own set of technical challenges. Dross formation, bevel angles, and the heat-affected zone (HAZ) can all impede achieving precise cuts. Using advanced cutting techniques and precision tools becomes essential to mitigate these issues.

The table below outlines key challenges and potential solutions:

| Challenge | Solution |

|---|---|

| Dross Formation | Optimize cutting speed and amperage |

| Bevel Angle | Use secondary machining processes |

| Heat-Affected Zone | Control heat input and cutting speed |

| Inconsistent Cuts | Regular maintenance of consumables |

Careful control of parameters like cutting speed and amperage is critical. Variations can lead to inconsistent kerf widths and edge quality, affecting fit and structural integrity. Regular maintenance of precision tools, such as electrodes and nozzles, is essential to maintaining accuracy. By addressing these technical challenges, you can enhance the precision of your plasma cutting processes.

Safety Concerns and Compliance

When operating a plasma cutter, you must address safety concerns such as excessive noise and hazardous fumes, which demand the use of protective gear and effective ventilation systems.

Compliance with guidelines from agencies like OSHA guarantees you mitigate risks and adhere to necessary legal standards.

Proper training on equipment handling and the use of safety measures is essential to protect against potential health hazards and operational risks.

Noise and Fume Hazards

- Monitor and control workplace noise levels.

- Install effective ventilation and fume extraction systems.

- Regularly maintain equipment for maximum safety.

- Conduct thorough safety training sessions.

- Guarantee adherence to OSHA standards.

Neglecting these factors can lead to serious health issues, emphasizing the importance of safety measures.

Protective Gear Necessity

Addressing noise and fume hazards is only one aspect of guaranteeing safety in plasma cutting environments. Equally critical is the use of protective equipment to safeguard operators from multiple risks. High noise levels necessitate hearing protection to adhere to safety protocols and prevent hearing loss. The intense light from plasma cutting demands ANSI-standard safety goggles or face shields to avert eye damage. Additionally, flame-resistant clothing and gloves are essential to shield against burns and sparks. Regular safety training guarantees all personnel comprehend these requirements, enhancing compliance and safety.

| Hazard | Protective Equipment |

|---|---|

| Noise | Hearing protection |

| Intense light | ANSI-standard goggles/shields |

| Burns and sparks | Flame-resistant clothing/gloves |

Implementing rigorous safety protocols is indispensable for safe plasma cutting operations.

Ventilation and Regulations

Guaranteeing proper ventilation and adhering to regulations are paramount in plasma cutting operations. You need effective ventilation systems to control harmful fumes and gases and maintain air quality. OSHA compliance demands these systems to mitigate risks and protect workers’ health.

Consider these critical points:

- Harmful Emissions: Plasma cutting releases fumes needing efficient extraction.

- OSHA Compliance: Adhering to regulations guarantees a safer work environment.

- Noise Levels: Plasma cutting noise can exceed 85 dB; use hearing protection.

- Light and Heat Hazards: Train operators to handle intense light and heat safely.

- Maintenance: Regularly maintain ventilation systems for ideal function and compliance.

Prioritize these measures to guarantee safety and regulatory conformity in plasma cutting operations.

Noise and Fume Management

How does one effectively manage noise and fumes in plasma cutting operations?

Start by prioritizing noise reduction and fume extraction. Plasma cutting typically generates noise levels above 85 decibels, potentially harmful without proper hearing protection. To mitigate this risk, guarantee operators are equipped with adequate ear protection.

For fume extraction, implement local exhaust ventilation (LEV) systems to capture and filter hazardous fumes and metal dust at the source. This not only maintains air quality but also aligns with health regulations.

Routine maintenance checks are essential to confirm that ventilation systems are functioning efficiently, reducing the presence of airborne pollutants effectively.

Adhering to OSHA standards for noise and fume exposure is vital. By doing so, you guarantee a safe working environment, minimizing health risks associated with plasma cutting.

Balancing these strategies effectively addresses noise and fume challenges, safeguarding both operator health and compliance with regulatory requirements.

Energy Consumption Considerations

When considering plasma cutting operations, it’s vital to analyze energy consumption due to its direct impact on operational costs and efficiency.

Plasma cutting machines, particularly high-power models, can greatly increase energy expenses. To accurately evaluate your energy efficiency and perform a detailed cost analysis, consider the following:

- Electricity Usage: Plasma cutters demand substantial electricity, contributing to higher operational costs, especially in smaller shops.

- Additional Equipment: Air compressors and fume extraction systems amplify overall energy consumption.

- Efficiency Evaluation: Evaluating the energy consumption patterns helps optimize cost efficiency and sustain operational viability.

- Budget Constraints: Smaller operations may find plasma cutting’s energy requirements a financial burden compared to other methods.

- Long-term Impact: Understanding energy costs is vital for evaluating both the initial investment and ongoing expenses.

Frequently Asked Questions

How Does Plasma Cutting Compare to Laser Cutting in Terms of Edge Quality?

In comparing plasma to laser cutting, you’ll find laser cutting offers superior edge precision and a narrower kerf width. Plasma cutting, though effective, can’t match the fine detail and minimal material loss laser cutting achieves.

What Materials Are Least Suitable for Plasma Cutting?

Aluminum alloys and stainless steel act like stubborn mules in plasma cutting. They’re less suitable due to their reflective surfaces and thermal conductivity. You’d face challenges like poor edge quality and increased dross, affecting precision and efficiency.

How Can Plasma Cutting Affect the Structural Integrity of Materials?

Plasma cutting can alter material properties by introducing distortion effects, especially in thin materials, compromising structural integrity. You should consider how heat-affected zones might impact strength and performance in your specific application, ensuring minimal adverse effects.

Are There Alternatives to Plasma Cutting for Reducing Operational Costs?

Yes, you can reduce operational costs by using alternatives like water jet and oxy-fuel cutting. Water jet offers precision without heat distortion, while oxy-fuel is cost-effective for thicker materials, despite slower cutting speeds.

What Advancements Are Being Made to Improve Plasma Cutting Technology?

Automation advancements and high frequency innovations enhance plasma cutting efficiency. You’ll notice smoother cuts and reduced dross due to precise programming. These technologies greatly speed up operations, ensuring you’re always at the forefront of cutting-edge capabilities.

Conclusion

In the domain of plasma cutting, you’re like a blacksmith wielding a lightsaber, maneuvering through dross, bevel angles, and heat-affected zones. These challenges demand your attention to detail, guaranteeing precision and safety. Regular maintenance, including consumable replacement, becomes your routine mission to optimize performance and manage costs. Don’t overlook noise, fumes, and energy consumption in this high-tech craft. Balancing these elements guarantees your operation remains efficient and compliant, sharpening your edge in the modern industrial landscape.