Spring is a great time to tackle metalwork projects, and the right plasma cutter can save you hours while improving your results. You get faster, cleaner cuts, less grinding and a lot more control whether you are repairing equipment, building garden structures, or making art. Choosing a cutter that matches your workspace, air supply, and material thickness helps you avoid downtime and expensive mistakes, so you can spend more time creating and less time correcting.

Top Picks

| Category | Product | Score |

|---|---|---|

| 🏆 Best Power | LOTOS LTP8500 | 93/100 |

| 💰 Best Value for Thick Cuts | LOTOS LTP6300 | 88/100 |

| 🎯 Best for Hobbyists | SILATU STC750P | 84/100 |

| ⭐ Most Affordable Starter | YESWELDER CUT-55DS | 80/100 |

| 🚀 Best Garage Workhorse | YESWELDER CUT-60DS | 85/100 |

| 🔰 Best Accessory Bargain | PLAXCON AG-60 | 75/100 |

Selection Criteria

You want a plasma cutter that fits the work you actually do, so we prioritized power and cut thickness, usable duty cycle, and whether a unit supports pilot arc or drag cutting for rough or thin surfaces. We looked at dual-voltage flexibility and on-machine controls because those affect setup time and precision, and we checked torch ergonomics, cable lengths, and included accessories so you know what’s ready out of the box. Air demands and the need for dryers or shop air were factored in because a cutter is only as good as its compressed air, and we weighed price, consumable availability, and common reliability issues to help you avoid surprises down the road.

If you want a capable cutter that tackles thicker homeowner and small-shop jobs, this LOTOS gives you real cutting muscle without the pro price. You get pilot‑arc and drag‑cut modes so you can handle painted or rusty metal and thin sheet work alike, plus a comfortable torch and a long lead that makes setup easier. For everyday fence, trailer, or gate work it speeds through cuts and reduces grinding, though you should plan for solid compressed air and, for heavy runs, a 240V circuit.

It’s a practical choice when you want commercial‑style results without stepping up to industrial gear.

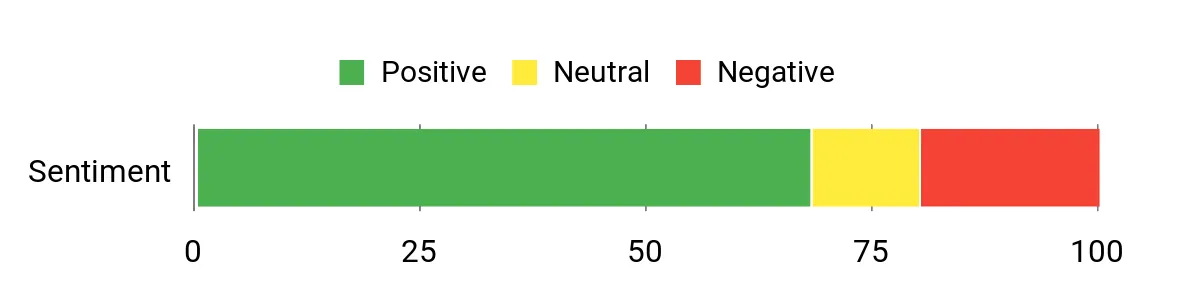

What People Say

You’ll notice most users praise how quickly and cleanly this unit cuts thicker material compared with entry‑level machines. Common notes point to the comfortable torch and long lead, strong duty cycle, and reliable consumables, while many call out the need for a robust air supply and a proper 240V circuit for full performance.

A few mention minor setup quirks or shipping issues, but overall people report it holds up under regular use.

Overall Sentiment: Positive

Long-Term Cost Benefits

Because the machine cuts faster and reduces prep and grinding time, you save on labor and finishing supplies. Consumables wear with heavy use, so stocking spares is sensible, but the unit’s durability and consistent consumable availability tend to lower total cost compared with higher‑priced professional systems.

Return On Investment

If you do occasional heavy projects or frequent repairs, the LOTOS pays back in saved time and subcontracting costs; users often find it recoups its cost after several medium‑size jobs thanks to faster, cleaner cuts and fewer reworks.

Situational Benefits

| Situation | How It Helps |

|---|---|

| Weekend Fabrication | You can knock out gate frames, brackets, and small trailers faster than with grinders, and the long torch reach keeps you working without constant repositioning. |

| Rusty or Painted Metal | Pilot arc starting gets you through coatings without tedious prep, so you spend less time cleaning before cutting. |

| Shop With Limited Space | Compact but heavy‑duty design gives you serious cutting capability without taking up the footprint of an industrial unit. |

Versatility

This is versatile for hobbyists, auto repair, and light fabrication; it tackles thin sheet and heavier plate well but isn’t designed for nonstop industrial duty or CNC table integration.

Durability

The unit feels solid and users report long runs with few failures; consumables are the expected wear items and are readily replaceable, though proper air drying and maintenance are important for longevity.

Problem Solving

It solves common cutting problems like dealing with painted or rusty surfaces and provides cleaner edges on thicker stock, but you’ll need adequate air and the right tip choice for fine detail work.

Speed

Cutting speed is notably faster than basic hobby units, especially on 240V; continuous heavy work depends on air supply and cooling, so performance is best with shop air and dryers.

Key Benefits

- Cuts up to 3/4″ clean and 1″ severance for heavier DIY work

- Pilot arc and drag cut handle rusty or painted surfaces and thin sheet

- Dual 110/220V lets you use it in different shops

- Long torch lead improves reach and comfort

- Durable consumables and solid build for frequent use

Rating: 4.5 (total: 53+)

You get a serious step up from hobby cutters without wrestling with industrial gear. The LTP8500 combines high amperage, pilot‑arc reliability and a drag‑cut mode that makes freehand and stencil work smoother, so you spend less time fighting burrs and more time shaping parts.

Its LED display and front regulator speed setup, and the ergonomic torch keeps longer sessions comfortable. It shines for garage fabrications, HVAC duct work, small shop production and metal art where consistent, clean edges matter. If you want a no‑nonsense, capable cutter that’s approachable even if you’re not a pro, this one fits the bill.

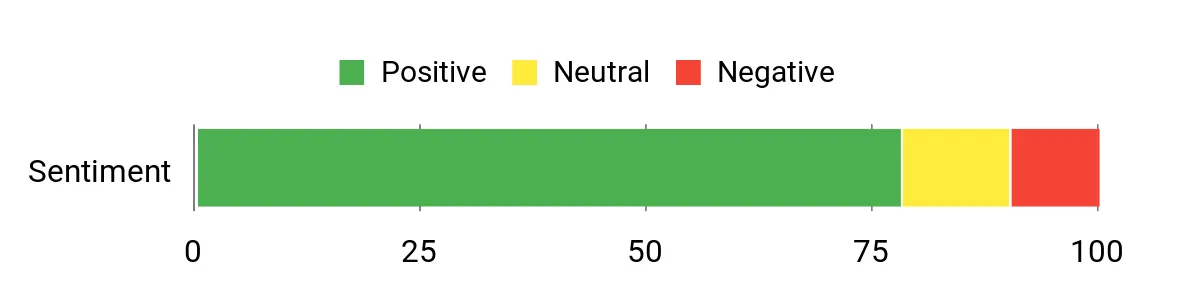

What People Say

Most users highlight how capable and easy to use this cutter feels for garage and small‑shop projects. Folks often praise the intuitive controls, the improved torch ergonomics, and the drag‑cut behavior for clean edges on thin sheet work.

The need for a reliable, dry air supply and 240V for peak performance comes up regularly, but people say it delivers consistent, precise cuts when those basics are in place.

Overall Sentiment: Positive

Cost Benefits

You’ll save time on prep and finish work, and the cleaner cuts reduce grinding and rework. Consumables do wear with heavy use, but the machine’s efficiency and reduced labor often outweigh those recurring costs over multiple projects.

ROI

If you regularly do fabrication, auto repairs, or small production runs, the LTP8500 repays itself through faster, cleaner cuts and lower finishing time compared with entry‑level machines.

Situations

| Situation | How It Helps |

|---|---|

| Metal Art & Signmaking | Drag cut support lets you run the torch on the surface for smooth curves and fewer burrs, so your shapes come out cleaner with less filing. |

| HVAC and Duct Work | Front regulator and easy controls speed repetitive cuts and adjustments, keeping your workflow tight on site. |

| Garage Fabrication | High amperage and pilot arc let you cut painted or slightly rusted parts without excessive prep, saving time on repairs and upgrades. |

Versatility

Designed for a variety of light‑to‑medium tasks, it handles thin sheet, structural brackets and moderate plate well but is not aimed at nonstop industrial table use.

Durability

Build quality feels robust and users report solid performance under regular shop use; regular maintenance and dry air help keep consumables and internals lasting longer.

Problem Solving

It addresses common cutting headaches like coating and surface rust with pilot arc, and drag‑cut reduces burrs on thin materials, though very fine detail still depends on tip choice and operator control.

Speed

Cuts are noticeably quicker than entry‑level units at 240V, and the LED/readout plus regulator make dialing in settings fast so you can get back to cutting.

Key Benefits

- High 85A output for thicker clean and severance cuts

- Pilot arc plus drag cut for painted, rusty, or thin materials

- Front regulator and LED display for quick setup and tuning

- Ergonomic torch and safety trigger for extended use

- Portable design suited to garages and small shops

Rating: 4.7 (total: 16+)

If you want a compact cutter that still handles serious DIY work, this SILATU is a solid pick. You’ll appreciate the non‑touch pilot arc for cutting painted or rusty metal and the dual‑voltage flexibility when you move between locations. The large display and simple controls make setup quick, and the included torch and clamps get you cutting right away. It’s especially useful for weekend fabrications, small structural repairs, and artistic projects where portability and decent power matter.

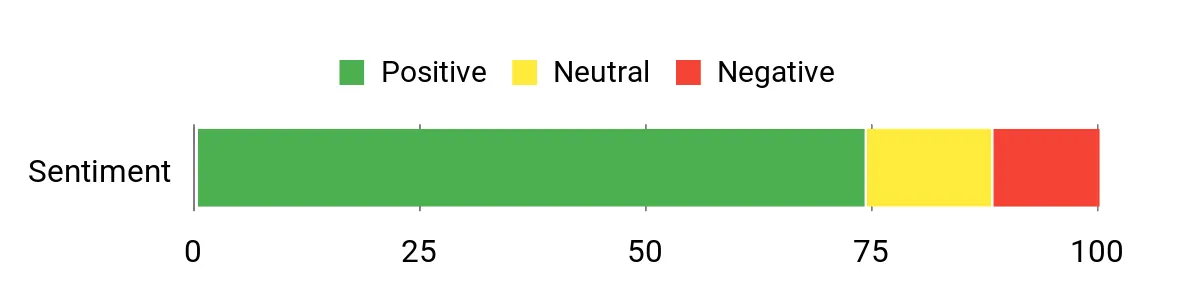

What People Say

Most users like how reliably it cuts on 220V and praise the non‑contact start for avoiding tedious prep. People frequently call out the compact size, decent torch reach, and straightforward controls, while a recurring caveat is the need for a solid, dry air supply and occasional QC or shipping hiccups that buyers should check on arrival.

Overall Sentiment: Positive

Long-Term Cost Benefits

You save time on prep and finish work because the pilot arc reduces grinding and cleaning. Consumables wear with use, so keeping extras on hand helps avoid downtime, but the faster cuts and reduced labor generally lower your project costs over time.

Return On Investment

If you do frequent repairs, small builds, or art pieces, this cutter pays back through faster cut times and less finishing work compared with basic hobby tools.

Situational Benefits

| Situation | How It Helps |

|---|---|

| Garage Fabrication | Delivers enough amperage to cut plates and bracketry quickly, letting you finish retrofit and repair tasks without a lot of grinding. |

| Painted or Rusty Metal | HF non‑touch start gets the arc going without scraping paint away first, so you can cut coated pieces faster. |

| Portable Jobsites | Lightweight build and included torch make it easy to move between locations and start cutting with minimal setup. |

Versatility

Works well for hobbyists, home fabricators, and small commercial tasks; dual voltage helps you adapt, though peak performance is on 220V with a good air source.

Durability

Build quality is generally solid and users report long runs when the unit is maintained and run with dry air; occasional reports of shipping or assembly issues mean you should inspect it on arrival.

Problem Solving

Solves common cutting problems like coating and rust with pilot arc and provides clean edges on a range of thicknesses, but very heavy continuous work will still stress consumables and air systems.

Speed

Cuts smoothly and quickly on 220V, and the display lets you dial settings fast; on 110V performance is reduced and may trip smaller breakers during heavy cuts.

Key Benefits

- HF non‑touch pilot arc handles coated or rusty surfaces

- Dual 110/220V for flexible workshop setups

- Large LED display and air sensor simplify tuning

- Compact, lightweight design for easy portability

- Good cutting performance up to about 3/4″ with proper air

Rating: 4.3 (total: 197+)

You get a compact, hardworking cutter that’s easy to move between the garage and jobsite. The dual‑voltage auto‑sense and non‑touch pilot arc make it forgiving on painted or slightly rusty metal, and the digital display helps you dial settings without guessing. It’s a handy tool for quick repairs, trailer work, and small fabrication runs, and it fits well in a mobile rig or a compact shop where portability and reliable performance matter.

What People Say

Most buyers say it punches above its size, cutting cleanly on 240V and being straightforward to set up. Common praise goes to the display, portability, and ability to handle a range of metal thicknesses, while several users note the importance of a good air supply and occasionally report QC or shipping hiccups to inspect on arrival.

Overall Sentiment: Positive

Long-Term Cost Benefits

By cutting faster and reducing grinding, you spend less time finishing parts and more time building. Consumables are a recurring cost, but the efficiency gains and reduced need for gas cutting or outsourcing often make this a cost‑effective shop tool over time.

Return On Investment

If you do frequent repairs, mockups, or small production runs, the cutter pays back through saved labor and fewer outsourced cuts, especially when paired with a reliable air setup and spare consumables.

Situational Benefits

| Situation | How It Helps |

|---|---|

| Jobsite Repairs | Portable size and dual voltage let you jump in and fix brackets, rails, or trailer parts with minimal setup. |

| Hobby Fabrication | Digital controls and stable arc give you consistent cuts for brackets, frames, and small art pieces without a steep learning curve. |

| Coated Or Rusty Metal | Non‑touch pilot arc starts reliably on painted or slightly corroded surfaces so you can cut without extensive prep. |

Versatility

Good for hobbyists, mobile trades, and light shop work; it adapts to different jobs thanks to dual voltage and a forgiving arc, though heavy continuous industrial cutting is beyond its intended use.

Durability

Users report solid performance under regular use when the unit is maintained and run with dry air; occasional early defects are reported, so inspect the unit when it arrives.

Problem Solving

It addresses common issues like cutting through painted or slightly rusty material and makes freehand or on‑site repairs simpler, but very heavy duty or nonstop industrial tasks will still strain consumables.

Speed

Cuts quickly on 240V with proper air pressure, and the clear display helps you adjust settings fast; on 110V performance is limited and may require patience on thicker cuts.

Key Benefits

- Non‑touch pilot arc handles coated and rough surfaces

- Dual 110/220V auto‑sense for flexible power setups

- Large digital display makes settings easy to read

- Lightweight and portable for trailers or small shops

- ETL approval and IGBT inverter for dependable performance

Rating: 4.3 (total: 903+)

If you want a compact cutter that’s flexible on the road and in the garage, this YESWELDER model does a lot for the size. You get non‑HF pilot arc starting that helps with painted or rough surfaces, dual voltage so you can plug in where you need to, and multiple cutting modes for plate, grid work or light gouging.

The unit isn’t marketed as industrial, but for repairs, small builds, and on‑site fixes it gives you steady performance when paired with a decent air supply. Expect to check consumables and fittings when it arrives so you avoid startup hiccups.

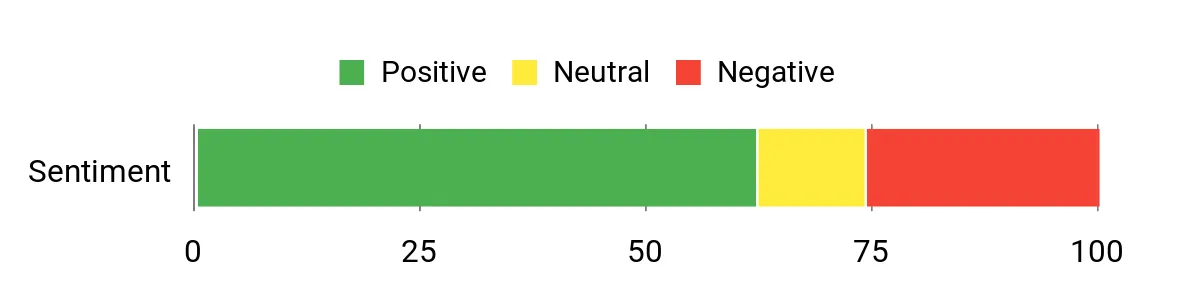

What People Say

You’ll see a lot of users impressed with how much this little machine can cut, especially on 240V, and many like the non‑contact start for coated or rough metal. People frequently mention the unit’s versatility and easy controls, while a number of reports point to air supply needs or occasional QC and shipping issues to watch for when the package arrives.

Overall Sentiment: Neutral

Cost Benefits

By reducing prep and finishing time on coated or rusted parts, this cutter cuts down labor hours. Consumables and occasional repairs are expected, so keeping spare tips and checking air quality helps avoid repetitive expenses and lost time.

ROI

If you do regular trailer repairs, mockups, or small production pieces, the time saved on cutting and cleaning up edges can quickly offset the effort of maintaining consumables and air treatment.

Situations

| Situation | How It Helps |

|---|---|

| Mobile Jobsite | Dual voltage and portability let you handle on‑site repairs without hauling heavy gear; it’s easy to move and set up where you need it. |

| Coated Or Rusty Parts | Non‑HF pilot arc gets the arc started without scraping paint or rust away first, so you save prep time and get to cutting faster. |

| Small Fabrication Runs | Multiple modes give you flexibility for plate cutting, grid work or light gouging, keeping small projects moving without swapping machines. |

Versatility

Good for hobbyists, mobile trades, and small shop tasks; the multi‑mode design and dual voltage make it adaptable, though peak cutting is on 220V with solid air.

Durability

Many users report reliable performance when the unit is maintained and run with dry, stable air; some buyers note early defects, so inspect fittings and sensors on arrival.

Problem Solving

It handles common annoyances like cutting through painted or slightly corroded metal and gives more consistent edges than basic hobby models, but heavy continuous industrial use will stress consumables.

Speed

Cuts cleanly and quickly on 240V with proper air pressure, and the digital readout helps you dial settings fast; expect reduced power and slower cuts on 110V.

Key Benefits

- Non‑HF pilot arc for painted or rusty surfaces

- Dual 110/220V compatibility for different sites

- 4‑in‑1 modes add versatility for plate, grid, gouging and marking

- Portable and fairly lightweight for jobsite use

- Clear digital display and straightforward controls

Rating: 4.2 (total: 81+)

You get a compact cutter that feels bigger than its size. It auto‑senses voltage, offers a clear digital display for quick dialing, and delivers steady cutting power on 240V for common garage and shop tasks.

The unit is light enough to move around yet capable of slicing through plate and pipe with less prep than oxy‑fuel. It’s handy for trailer repairs, mockups, and small production work, just pair it with a reliable air source and keep a few spare consumables on hand.

What People Say

Users often highlight how much cutting power this small unit delivers on 240V, noting clean cuts and reliable arc starting. People appreciate the portability, easy setup, and readable display, while common caveats mention the need for good, dry air and ordering extra consumables. A few reports of initial QC or connector issues pop up, so checking the unit on arrival is a frequent recommendation.

Overall Sentiment: Positive

Long-Term Cost Benefits

You spend less time grinding and prepping when cuts are cleaner, which lowers labor hours and finish materials. Consumables are recurring but easy to replace, and the time savings on repeated jobs tends to offset those running costs.

Return On Investment

If you do regular repairs, small fabrications, or site work, the cutter often pays back through faster completion and reduced outsourcing, especially when paired with a good air setup.

Situations

| Situation | How It Helps |

|---|---|

| Trailer And Farm Repairs | Portable size and reliable arc let you fix brackets, rails, and mounts quickly without hauling heavy equipment. |

| Hobby Fabrication | Digital controls and steady output help you get consistent cuts for frames, gates, and art projects with less cleanup. |

| On‑Site Emergency Fixes | Dual voltage and light weight make it easy to move between locations and get a repair done with minimal setup. |

Versatility

Well suited to hobbyists, mobile trades, and light shop work; it adapts between hand cutting and modest table setups, though industrial nonstop duty is beyond its design.

Durability

Owners report solid performance when the unit is maintained and run with dry air; consumables wear as expected and replacing them regularly keeps the cutter running reliably.

Problem Solving

It removes the need for extensive prep on painted or slightly corroded metal and produces cleaner edges than many basic cutters, cutting down finish work and rework.

Speed

Cuts quickly on 240V and the digital readout lets you adjust settings fast, though on 110V expect reduced power and slower progress on thicker stock.

Key Benefits

- Stable non‑touch pilot arc for coated or rough surfaces

- Dual 110/220V auto‑sense for flexible power options

- Digital display makes settings and monitoring simple

- Portable, lightweight design for jobsite mobility

- Strong cutting performance on common shop materials

Rating: 4.3 (total: 660+)

You get a compact, portable cutter that handles a wide range of garage and light‑shop tasks without fuss. The non‑touch pilot arc makes it easier to start on painted or rough metal, and the clear digital display helps you dial in settings quickly so you spend less time guessing.

It’s light enough to move between jobsite and trailer yet powerful enough for trailer repairs, brackets, and small fabrication runs. If you want a reliable, easy‑to‑use everyday cutter that doesn’t require industrial space, this one is a solid pick.

What People Say

Users commonly praise how capable this unit is for its size, especially when run on 240V, and note the clean cuts and reliable arc starting. People appreciate the readable controls and portability for mobile jobs, while recurring caveats point to the need for a solid, dry air supply and keeping spare consumables on hand.

Overall Sentiment: Positive

Cost Benefits

Cleaner cuts and reduced grinding lower finish time and labor, which saves you time across projects. Consumables are the main ongoing cost, but stocking spares and maintaining air quality prevents downtime and keeps long‑term operating costs predictable.

ROI

If you do regular repairs, mockups, or light fabrication, the time saved on cutting and finishing typically offsets maintenance and consumable expenses within a handful of projects.

Situations

| Situation | How It Helps |

|---|---|

| Trailer And Field Repairs | Dual voltage and portability let you set up quickly and fix mounts, brackets, or rails without hauling heavy gear. |

| Hobby Fabrication | Digital controls and steady output give you consistent cuts for frames, gates, and art pieces with less cleanup. |

| Coated Or Rusty Metal | Non‑touch pilot arc starts reliably on painted or slightly corroded surfaces so you can cut without extensive prep. |

Versatility

Well suited to hobbyists, mobile trades, and light shop work; dual voltage and a forgiving arc make it adaptable across many project types, though continuous industrial production is beyond its intended use.

Durability

Owners report consistent performance when the unit is maintained and run with dry air; consumables wear as expected and replacing them regularly keeps the cutter dependable over time.

Problem Solving

It addresses common hassles like cutting through painted or slightly rusted metal and reduces prep time, while the readable controls help you tune cuts quickly for better edge quality.

Speed

Cuts efficiently on 240V and the digital readout lets you fine‑tune settings fast; on 110V expect reduced power and slower progress with thicker stock.

Key Benefits

- Non‑touch pilot arc for cutting painted or slightly corroded surfaces

- Dual 110/220V auto‑sense for flexible power options

- Large digital display for quick, readable adjustments

- Portable, lightweight design for jobsite mobility

- IGBT inverter technology for consistent arc performance

Rating: 4.3 (total: 903+)

This little spring guide is one of those cheap upgrades that can make hand cutting easier. You slip it over the torch cup to keep a steady gap, which helps you get more consistent cuts and saves the ceramic cap from unnecessary wear. Fit can vary by torch model, so you may need to trim or reshape them for a snug match, but once they seat properly they do the job and are simple to replace when worn.

What People Say

Many users like that these guides help keep a steady standoff and protect the nozzle, calling them a worthwhile little accessory when they fit correctly. A recurring theme is compatibility: they work well on true AG60 style cups but can be too short or require trimming on other torch types, so buyers often mention checking fit before committing to a large batch.

Overall Sentiment: Neutral

Long-Term Cost Benefits

By preserving the ceramic cup and reducing tip contact, these standoffs can stretch the life of more expensive consumables and lower the frequency of replacements. Keeping a few spares on hand prevents downtime when a guide wears out.

ROI

If you do a fair bit of hand cutting, the small upfront effort to fit these guides usually pays off quickly through reduced tip wear and fewer interrupted cuts.

Situations

| Situation | How It Helps |

|---|---|

| Freehand Cutting | Keeps your torch at a consistent distance so your freehand lines stay steadier and require less cleanup. |

| Protecting Consumables | Acts as a sacrificial spacer to shield the ceramic cap from direct contact and accidental knocks. |

| On‑Site Repairs | Small and light, they’re easy to carry in a kit so you can replace a worn guide quickly and keep working. |

Versatility

Useful across hand‑cutting tasks where a consistent standoff matters, though compatibility varies by torch design so they’re most versatile with AG60‑style cups.

Durability

Made of sturdy metal, they hold up well unless exposed to extreme heat or melted during misuse; proper fit reduces movement and extends life.

Problem Solving

Solves the annoying problem of inconsistent gap and protects fragile ceramic cups, but it won’t help if the guide doesn’t match your torch geometry without modification.

Speed

Quick to install and swap out, so you can get back to cutting with minimal interruption when a guide wears or a job needs a fresh spacer.

Key Benefits

- Maintains a consistent cutting gap for cleaner cuts

- Protects the ceramic cap from direct wear

- Simple to fit and replace when worn

- Lightweight, low‑cost spare that’s easy to carry

Rating: 4.2 (total: 438+)

FAQ

Do I Need A Special Outlet Or Compressor?

It depends on the model and how hard you plan to run it. Many cutters can run on 110V for light work, but you’ll get full cutting power and higher duty cycles on 220V, so check if you have a true 240V/50A or 240V/30A circuit available. For air, the machine needs clean, dry air; a small pancake compressor may work for occasional light cuts, but for sustained or thicker cutting you’ll want a larger compressor and moisture traps or dryers to avoid consumable fouling and arc instability.

How Often Do Consumables And Maintenance Come Up?

Consumables wear with use, especially when you’re piercing or cutting rough material, so expect to replace tips and electrodes regularly on big projects. Keep a small stock of spares and check the torch and fittings on arrival for tightness.

Regularly drain moisture from your air system and inspect hoses and connections; a little preventive maintenance keeps the cutter cutting and reduces the chance of early failures.

Which Cutter Features Matter Most For My Projects?

Match the cutter’s strengths to your work: if you cut painted or rusty metal often, pilot arc or HF non‑touch start and drag‑cut capability save prep time and give cleaner edges. If you handle thicker plate, prioritize higher amperage and a good duty cycle, and if you move between sites look for dual‑voltage and a comfortable torch with long leads.

Also consider ergonomics, included accessories, and whether the vendor supplies consumables that fit your torch so you avoid compatibility headaches.

What Buyers Prefer

When you’re choosing between the LOTOS LTP8500, LTP6300 and the SILATU STC750P, you tend to balance raw amperage and severance ability (the LTP8500) against solid mid‑range cutting and rugged shop use (the LTP6300) while the SILATU wins if portability, dual‑voltage flexibility and easy setup matter most. You also consider whether you have reliable 240V power and dry compressed air, plus torch comfort and consumable availability, because those practical details determine how smoothly your spring projects actually go.

Wrapping Up

Match the cutter to your priorities: pick a high‑amp model if you frequently cut thick plate, choose drag‑cut or pilot‑arc units for rusty or painted surfaces, and opt for dual‑voltage if you move between shops. Also plan for a reliable air source, moisture traps, and spare consumables so you avoid frustrating downtime.

If you want one machine to handle heavy spring fabrications, go with the LOTOS LTP8500; if your projects are occasional but demanding, the LOTOS LTP6300 gives strong performance for the price; for budget or portable needs consider the YESWELDER or SILATU models and add the PLAXCON standoff as a low‑cost helper. With the right cutter and air setup you’ll finish projects cleaner and faster and spend more time building and less time fixing cuts.

| Product Name | Image | Rating | Max Cutting Thickness | Power Source | Weight |

|---|---|---|---|---|---|

| LOTOS LTP6300D 63AMP Non-Touch Pilot Arc Plasma Cutter |

|

4.5/5 (N+ reviews) | 3/4″ (19 mm) clean cut, 1″ (25mm) severance | Dual Voltage 110V/220V | 21.4 pounds |

| LTP8500 | 85A HF Pilot Arc Plasma Cutter |

|

4.7/5 (16 reviews) | 1″ clean (1.5″ severance) | 220V Single-Phase | 37.5 pounds |

| SILATU Plasma Cutter, STC750P 75Amps HF Non-Touch Arc |

|

4.3/5 (197 reviews) | 1″ | Dual Voltage 110/220V | 16.98 pounds |

| YESWELDER CUT-55DS Plasma Cutter |

|

4.3/5 (903 reviews) | 1/2″ | 110/220V | 20.4 pounds |

| YESWELDER CUT-55DS NHF PLUS Plasma Cutter |

|

4.2/5 (81 reviews) | N/A | Hand-Powered | 18.96 pounds |

This Roundup is reader-supported. When you click through links we may earn a referral commission on qualifying purchases.