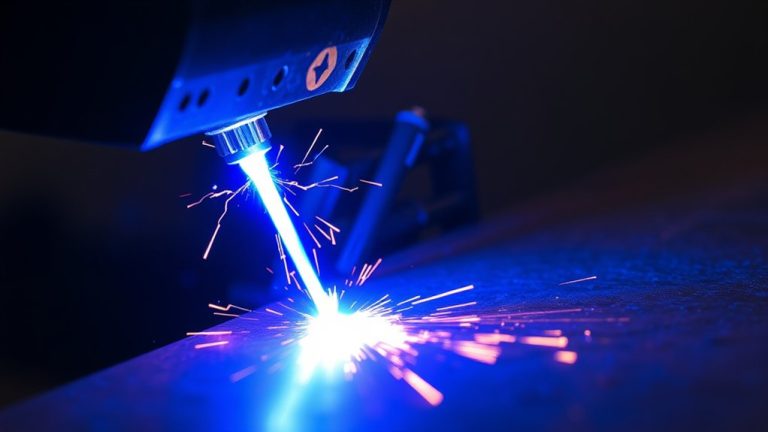

To arc start a plasma cutter effectively, you’ll first need to guarantee the torch settings are optimized. Begin by selecting the right consumables and verifying the gas pressure sits between 70-85 psi for a floating tip. Position the torch vertically, about 1/8 inch above the workpiece’s edge. Pull the trigger to ignite the pilot arc, creating a plasma jet. Once the arc is established, there’s more to master for clean and precise cuts.

Essential Tools and Equipment for Arc Starting

To successfully arc start a plasma cutter, you’ll need to gather the right tools and equipment. First, confirm you have the correct plasma cutter model and essential consumables, including the torch, electrode, and nozzle. These components are vital for an effective arc start.

Equipment maintenance is key, so regularly check that all parts are in good condition and correctly installed.

Next, verify that the power supply settings align with the torch’s amperage rating, adjusting it to suit the material thickness you plan to cut. Use a high-velocity gas like compressed air, maintaining the pressure between 70-85 psi for floating the tip or 75-95 psi for dragging it.

Position the torch at an ideal angle, usually vertical or slightly tilted above the workpiece. Engage the torch trigger to initiate the pilot arc, then lower the torch smoothly onto the workpiece. This approach guarantees a reliable and safe arc start.

Setting Up the Plasma Cutter for Optimal Performance

Although achieving ideal performance with your plasma cutter requires precise setup, it’s a straightforward process with the right guidance. Start by installing the appropriate consumables or a Hypertherm cartridge onto the torch. This guarantees peak performance during operation. Move the torch lock switch to the “on” position if applicable, and connect the torch and work lead to the power supply. This guarantees proper connectivity.

Next, securely attach the work lead clamp to the work surface, avoiding any potential falling metal. This maintains both safety and effectiveness. Connect the gas hose to the back of the plasma cutter system, ensuring a tight seal to prevent leaks.

Refer to your owner’s manual for recommended settings. Here’s a quick setup checklist:

| Step | Action |

|---|---|

| Consumables Installation | Install appropriate consumables |

| Torch Lock | Set to “on” position |

| Power Supply Connection | Plug torch and work lead |

| Work Lead Attachment | Secure clamp to work surface |

| Gas Hose Connection | Ensure tight seal to prevent gas leaks |

Following these steps guarantees a successful plasma cutter setup for peak performance.

Adjusting Amperage and Gas Pressure

With your plasma cutter now set up for ideal performance, focus on adjusting the amperage and gas pressure to achieve precise cuts.

Amperage adjustments are vital; align them with the material thickness. For thinner materials, lower settings suffice, whereas thicker materials demand higher amperage. Consult the manufacturer’s recommended amperage cut charts to guide you.

Gas pressure also plays a significant role in cutting efficiency. Set the pressure between 70-85 psi if you’re floating the tip, and adjust to 75-95 psi for dragging. The gas type, whether ordinary air or bottled nitrogen, must be suitable for your cutter to guarantee effective arc initiation.

Here’s how to proceed:

- Check Material Thickness: Make amperage adjustments accordingly.

- Set Gas Pressure: Align with tip technique—floating or dragging.

- Use Correct Gas Type: Confirm compatibility for consistent performance.

Monitor closely to maintain cutting speed and prevent dross buildup. Proper settings preserve consumables and guarantee clean cuts.

Techniques for Initiating the Arc

Initiate the arc in your plasma cutter by confirming all consumables are properly installed and the torch lock switch is turned on if your model includes one.

Position the torch vertically above the workpiece’s edge, maintaining a 1/8 inch gap to prevent accidental contact. This is essential for effective arc initiation techniques.

Pull the trigger to ignite the pilot arc; this creates an electrical arc that heats the gas, forming a plasma jet capable of cutting metal.

Ignite the pilot arc to generate a plasma jet, effortlessly slicing through metal with precision.

Once the pilot arc is established, carefully lower the torch onto the workpiece to start cutting. For best results, slightly tilt the torch at the end to confirm the cut is complete.

Remember, adjusting the amperage settings based on material thickness is critical, so consult the manufacturer’s cutting charts.

These pilot arc tips help you manage the process safely and efficiently, guaranteeing precise cuts and extending the life of your plasma cutter.

Maintaining Torch Contact and Angle

To guarantee precise cuts, position the torch tip about 1/8 inch above the workpiece, or drag it with a steady hand when necessary.

Keep the torch angle at roughly 10 degrees backward to direct sparks away and maintain visibility.

Consistently checking your torch angle and contact will help prevent dross buildup and extend the life of your consumables.

Torch Angle Consistency

A consistent torch angle is essential for achieving clean and efficient cuts with a plasma cutter. To guarantee torch stability, maintain an angle of about 10 degrees. This directs sparks away from the workpiece, enhancing cutting efficiency.

Make necessary angle adjustments to stay consistent throughout your cut, preventing irregularities and dross buildup.

Here’s how to maintain consistency:

- Steady Hand: Keep a steady hand to guarantee the torch angle remains constant.

- Distance Management: Maintain a 1/8 inch gap above the material when floating. This helps reduce consumable wear.

- Gas Pressure: Regularly check and adjust gas pressure (70-85 psi for floating, 75-95 psi for dragging) for peak performance.

Proper Torch Contact

Maintaining proper torch contact is essential for achieving precision in plasma cutting. Keep the torch height at about 1/8 inch above the workpiece with the floating technique to minimize consumable wear and enhance cut quality. If you drag the tip, guarantee direct contact with the material for better precision, but be aware of increased tip wear. Tilt the torch back at a 10-degree angle to guide sparks away and maintain clear visibility.

| Technique | Torch Height |

|---|---|

| Floating | 1/8 inch above |

| Dragging | Direct contact |

Consistently monitor the torch angle and height to prevent dross buildup. This guarantees a steady cutting speed. Adjust gas pressure accordingly—70-85 psi for floating, 75-95 psi for dragging—to maintain an efficient cutting arc. Safety and precision go hand in hand!

Maintaining Steady Hand

When operating a plasma cutter, ensuring a steady hand is critical for maintaining precise torch contact and angle.

Employing steady hand techniques will greatly impact the quality of your cut. Here are key tips:

- Angle Control: Maintain a consistent angle of about 10 degrees. This directs sparks away, resulting in a cleaner cut with less dross buildup.

- Height Management: Keep the torch tip approximately 1/8 inch above the material for floating cuts. This technique reduces amperage needs and prolongs consumable life.

- Speed Consistency: Use a uniform travel speed. Adjust speed according to material thickness, guided by charts in the owner’s manual.

Avoid pressing the torch tip too hard against the material to prevent premature wear.

Regularly check gas pressure for best performance.

Safety Measures and Protective Gear

Before you start arc cutting with a plasma cutter, guaranteeing your safety is paramount.

Welding hazards are numerous, and following PPE guidelines is vital to protect yourself. Always wear heavy-duty welding gloves, a fire-resistant jacket, safety glasses or a welding helmet, and closed-toed shoes. These items shield you from sparks and intense heat. Use a welding helmet or safety glasses with the appropriate shade rating to protect your eyes from the plasma cutter’s bright light.

High noise levels are common, so don’t forget ear plugs to safeguard your hearing.

Keep the area clear of flammable materials, maintaining at least a 20-foot safety zone to prevent fires. Proper ventilation is essential; verify your workspace is well-ventilated to avoid inhaling harmful fumes and smoke.

Troubleshooting Common Arc Starting Issues

When troubleshooting common arc starting issues, first verify that all torch connections are secure and properly attached to guarantee a reliable arc.

Inspect the consumable components like the torch tip and electrode for wear or damage, as these can impede arc creation.

Always prioritize safety by disconnecting power before handling any parts.

Verify Torch Connections

Guaranteeing proper torch connections is essential for troubleshooting common arc starting issues with a plasma cutter.

Begin by confirming that the torch assembly is properly secured. Loose components can impede arc initiation, so make sure everything is tightly fitted.

Next, perform a connection verification to guarantee the system is ready for operation:

- Power Supply: Confirm that it’s on and configured with the correct voltage and amperage for your material thickness.

- Ground Clamp: Attach it firmly to a clean, unpainted workpiece surface for a complete electrical circuit.

- Gas Supply: Inspect connections to verify that the appropriate gas is flowing at the correct pressure.

Inspect Consumable Components

Inspecting consumable components is essential for troubleshooting common arc starting issues with your plasma cutter.

Begin with a tip inspection; check the torch tip for wear or damage. A compromised tip can prevent proper arc initiation, affecting your cutting performance.

Next, assess the electrode condition. Verify it’s correctly seated and not excessively worn, as a degraded electrode can lead to inconsistent arc starting.

Examine the shield cup for obstructions or damage that might disrupt gas flow and hinder plasma arc initiation.

Confirm the gas pressure is set correctly—aim for 70-85 psi when floating and 75-95 psi when dragging.

Finally, verify all electrical connections are secure and corrosion-free, as poor connections can impede the electrical flow necessary for arc initiation.

Tips for Clean and Efficient Cuts

Achieving a clean and efficient cut with a plasma cutter requires careful attention to several vital factors. First, maintaining a consistent cutting speed is essential. Follow the manufacturer’s cutting speed charts, aiming for around 15 inches per minute for rated cuts. This pace minimizes dross buildup and enhances cut quality.

Second, adjust the amperage according to the material’s thickness. Refer to your owner’s manual for ideal settings, ensuring smooth and efficient cutting.

Here are three essential tips for superior cuts:

- Torch Distance: Keep the torch approximately 1/8 inch from the workpiece. This distance reduces wear on consumables and improves cut quality.

- Visibility and Protection: Use drag shields or extended tips, especially at higher amperages, to protect the cutting tip and maintain visibility.

- Torch Angle: Angle the torch slightly (around 10 degrees) away from the cutting direction. This directs sparks away, minimizing dross buildup and producing cleaner edges.

Frequently Asked Questions

How Do I Choose the Right Gas for My Plasma Cutter?

Choose the right plasma gas by considering material type and thickness. For best performance and safety, guarantee gas flow matches your cutter’s specifications. Using the correct plasma gas selection enhances cut quality and prolongs cutter lifespan.

What Are the Signs of Worn-Out Consumables?

Think of worn-out consumables as a car running on empty. If you notice reduced arc stability or increased slag, it’s time. Monitor performance indicators regularly to maximize consumable lifespan and guarantee peak cutting performance and safety.

Can I Use a Plasma Cutter on Painted Surfaces?

Yes, you can use a plasma cutter on painted surfaces, but prioritize safety. Guarantee proper surface preparation by removing the paint first. This minimizes toxic fumes and improves cut quality, guaranteeing precise and safe operation.

How Does Humidity Affect Plasma Cutting?

Imagine a foggy morning. Humidity affects plasma cutting by reducing cutting quality. Moisture can cause arc instability, leading to rough edges. Always make certain your workspace is dry to maintain precision, prevent accidents, and guarantee peak performance.

What’s the Best Way to Store a Plasma Cutter?

Store your plasma cutter in a cool, dry place to prevent damage. Make certain plasma storage is secure and away from flammable materials. Follow safety precautions by disconnecting power and properly coiling cables to avoid hazards.

Conclusion

Congratulations, you’ve mastered the art of arc starting a plasma cutter—without any shorts, sparks, or unexpected fireworks! Remember, while the plasma cutter might seem like a sci-fi tool, it’s not meant for pyrotechnic displays. Keep your torch settings precise, your protective gear on, and your cutting speed consistent. Ironically, now that you’re an expert, the real challenge is resisting the urge to cut everything in sight. Stay safe, cut smart, and enjoy those perfectly clean edges!