When I first had to MIG weld an exhaust pipe, it was a real test of patience—thin tubing, awkward angles, and the constant risk of burning through the metal. Exhaust work isn’t just striking an arc and running a bead; it demands attention to metal thickness, joint prep, filler wire choice, and arc control to avoid leaks and weak spots.

Many welders get stuck wondering whether MIG or TIG is the better route, or how to handle stainless compared to mild steel, and that confusion often leads to messy welds or costly rework.

Dialing it in the right way makes all the difference, not just for weld quality and structural strength, but also for safety and long-term durability. Stick with me, and I’ll walk you through practical, shop-tested tips that will help you weld exhaust systems cleaner, stronger, and with less frustration.

Image by best10

Why MIG Welding for Exhaust Pipes?

MIG welding, or Metal Inert Gas welding, is my go-to for exhaust work because it’s fast, versatile, and forgiving—especially for beginners. It uses a continuous wire electrode fed through a gun, paired with a shielding gas to protect the weld from contaminants. The result? Clean, strong welds that can handle the thin metals (usually 1.6mm to 2mm) found in exhaust systems without burning through.

For exhaust pipes, typically made of mild steel or stainless, MIG’s adjustable heat settings let you dial in just the right amount of power. It’s perfect for DIYers in a garage or pros in a busy shop. Compared to TIG, which demands more skill, or stick welding, which can be too hot for thin pipes, MIG strikes a balance of control and ease. But it’s not foolproof—thin metals warp easily, and wrong settings can lead to weak welds or blow-through.

Choosing the Right MIG Welder for Exhaust Work

Picking the right MIG welder is half the battle. You don’t need a top-dollar machine, but it’s got to handle thin materials. I’ve welded exhausts with a basic 110V welder in my driveway and gotten solid results, so don’t stress about breaking the bank.

Look for a welder with an amperage range of 30–140 amps, adjustable voltage, and wire feed speed controls. This lets you fine-tune for thin pipes. Machines with synergic settings, which auto-adjust voltage and wire speed, are a godsend for beginners.

For example, I’ve used a Lincoln Electric 140C for years—it’s reliable, portable, and great for exhaust repairs. If you’re on a budget, a gasless flux-core welder works, but it’s messier and hotter, so I’d stick with gas-shielded MIG for cleaner welds.

If you’re welding under a car, portability matters. A lightweight welder with a shoulder strap makes awkward angles less of a pain.

Essential Tools and Safety Gear

Before you strike an arc, let’s talk gear. Here’s what I keep in my shop for exhaust welding:

- MIG Welder: 30–140 amps, with adjustable settings.

- Welding Wire: ER70S-6 (0.023” or 0.030”) for mild steel; 308L or 309L for stainless.

- Shielding Gas: 75% argon/25% CO2 (C25) for mild steel; tri-mix (argon/CO2/helium) for stainless.

- Wire Brush and Grinder: For cleaning rust and grime.

- Clamps and Hangers: To hold pipes steady.

- Degreaser or Acetone: To wipe off grease.

- Safety Gear: Auto-darkening welding helmet, gloves, long sleeves, closed-toe boots, and a welding blanket to protect your car’s paint.

Safety isn’t optional. I learned this the hard way when a stray spark burned a hole in my favorite jacket. Sparks fly, fumes are toxic, and UV rays from the arc can fry your eyes without a helmet. Always weld in a well-ventilated area, and if you’re working under a car, disconnect the negative battery terminal to avoid frying electronics.

Preparing the Exhaust Pipe

Prep work is where good welds start. Exhaust pipes are often rusty, greasy, or coated with aluminized layers, which mess with your weld quality. Here’s how I prep:

Clean the Pipe: Use a wire brush or grinder to remove rust, dirt, and coatings. For greasy spots, hit them with degreaser or acetone. A clean surface ensures a strong bond.

Cut Precisely: If you’re replacing a section, mark the pipe and use a hacksaw or chain pipe cutter for a straight cut. Crooked cuts make fit-up harder.

Fit and Clamp: Align the pipe sections tightly. A small gap (1.6mm or the pipe’s thickness) is okay, but too wide and you’ll struggle to fill it without burning through. Use clamps or tack welds to hold everything in place.

Check the Inside: Old pipes can have carbon buildup or rust inside, which contaminates the weld. If possible, wire-brush the inner surface.

Mistake to Avoid: I once skipped cleaning a rusty pipe, thinking it was “good enough.” The weld looked like pigeon droppings and failed a leak test. Always clean thoroughly.

Setting Up Your MIG Welder

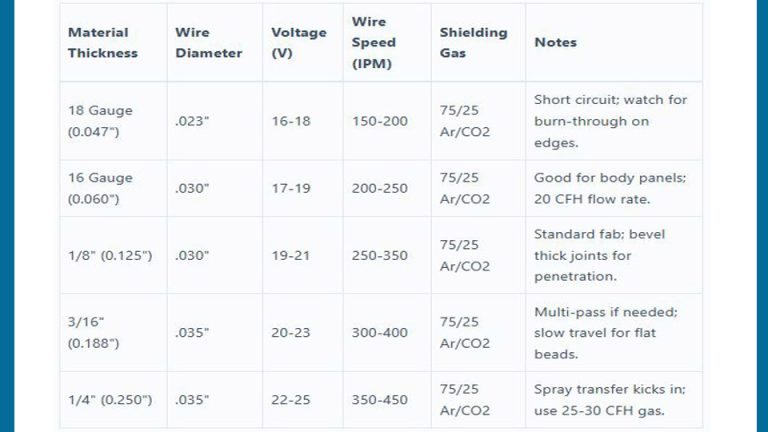

Getting your welder dialed in is critical for thin exhaust pipes. Too much heat, and you’ll burn holes; too little, and the weld won’t penetrate. Here’s how I set mine up for mild steel (1.6–2mm thick):

Polarity: Set to DCEP (Direct Current Electrode Positive) for solid wire with shielding gas.

Amperage: Start at 30–50 amps for 0.023” wire or 40–60 amps for 0.030” wire. Adjust based on your test welds.

Voltage: Around 15–18 volts for thin pipes. Lower for less heat, higher for better penetration.

Wire Feed Speed: Set to 150–200 inches per minute (IPM). Too fast causes spatter; too slow weakens the weld.

Gas Flow: 20–25 cubic feet per hour (CFH) for C25 gas. Check for leaks in the hose to avoid porosity.

Stick-Out: Keep the wire stick-out at 1/4” to 3/8” for stability.

For stainless steel, use 308L wire and a tri-mix gas, and drop the amperage slightly (25–40 amps) to avoid overheating. Always test your settings on scrap metal of the same thickness. I keep a pile of old exhaust scraps for this—saves me from ruining a good pipe.

Common Mistake: Don’t crank the heat thinking it’ll weld faster. I did this early on and blew holes in a customer’s muffler. Practice on scrap to find the sweet spot.

Step-by-Step MIG Welding Process

Now that you’re set up, let’s weld. Here’s my step-by-step process for a leak-free exhaust weld:

Tack Weld: Start with small tack welds (3–5 around the pipe) to hold the sections together. Keep them short to avoid warping. I use a quick trigger pull—about a second.

Weld in Short Bursts: Use stitch welding—short beads (1/2” to 3/4”) with pauses to let the metal cool. This prevents burn-through and warping. I move downhill on thin pipes for better control.

Maintain Torch Angle: Hold the gun at a 10–15-degree angle, pushing the weld pool slightly. Too much angle causes spatter; too little reduces penetration.

Weld the Entire Joint: Work around the pipe, connecting the tacks with short beads. Rotate the pipe if possible to avoid awkward angles. If you’re welding under a car, a small mirror helps check the top side.

Inspect and Clean: Let the weld cool naturally (no water—it weakens the bond). Brush off spatter with a wire brush. Check for cracks, holes, or porosity. If you spot issues, grind them out and re-weld.

If you’re struggling to see the weld pool, add more light to your workspace or use a cheater lens in your helmet. Clear vision makes all the difference.

Filler Wire and Material Compatibility

Choosing the right wire is crucial for exhaust welds. For mild steel pipes, ER70S-6 (0.023” or 0.030”) is my go-to. It’s versatile, flows smoothly, and handles minor rust or impurities. For stainless steel exhausts, common in high-performance cars, use 308L or 309L wire to match the pipe’s grade and resist corrosion.

Match the wire diameter to the pipe thickness:

- 0.023”: Best for thin pipes (1–1.6mm). Lower heat, less burn-through risk.

- 0.030”: Good for slightly thicker pipes (1.6–2mm) or when you need more filler.

Mistake to Avoid: Don’t use aluminum wire on steel pipes or vice versa. I saw a newbie try this, and the weld was a brittle mess. Always match the wire to the base metal.

MIG vs Other Welding Methods for Exhaust

MIG isn’t the only way to weld exhaust pipes. Here’s a quick comparison to help you decide:

| Method | Pros | Cons | Best For |

|---|---|---|---|

| MIG | Fast, beginner-friendly, good for thin metals, clean welds | Requires gas tank, can spatter if settings are off | Mild steel, stainless, DIY repairs |

| TIG | Precise, clean, ideal for stainless or thin pipes | Slow, requires more skill, expensive setup | High-performance exhausts, pro shops |

| Stick | No gas needed, good for rusty pipes, budget-friendly | Hotter arc, harder to control on thin metals | Outdoor repairs, thick pipes |

| Flux-Core | No gas tank, works in windy conditions | Messy, hotter arc, more spatter | Quick fixes, gasless setups |

I stick with MIG for most exhaust jobs because it’s fast and forgiving. TIG is great for show cars where looks matter, but it’s overkill for a daily driver. Stick and flux-core are fallback options if you’re in a pinch, but they’re trickier on thin pipes.

Common Mistakes and How to Fix Them

Even seasoned welders mess up sometimes. Here are mistakes I’ve made (or seen) and how to fix them:

Burn-Through: Too much heat or slow travel speed. Lower voltage, increase wire feed speed, and move faster. Practice on scrap to get the rhythm.

Poor Penetration: Weld looks good but isn’t strong. Increase amperage slightly or tighten the fit-up. Check the backside of the weld for fusion.

Spatter Everywhere: Wrong wire speed or gas flow. Dial back wire speed, ensure 20–25 CFH gas flow, and clean the nozzle.

Warping: Continuous welding without pauses. Use stitch welding and let the pipe cool between beads.

Leaks: Gaps or poor fusion. Test welds with soapy water and air pressure. Grind out bad spots and re-weld.

I once rushed a job and ended up with a leaky weld because I didn’t tack enough. Now, I always do extra tacks and test for leaks before calling it done.

Testing Your Weld for Leaks

A weld that looks good might still leak, letting exhaust fumes into your car. Here’s how I test mine:

- Visual Inspection: Check for cracks, holes, or uneven beads.

- Soapy Water Test: Mix dish soap and water, apply it to the weld, and blow compressed air through the pipe. Bubbles mean leaks.

- Smoke Test: If you have access, run the engine and use a smoke machine to detect leaks.

If you find a leak, grind out the bad section, clean it, and re-weld. Patience here saves headaches later.

Advanced Tips for Pro Welders

If you’re a pro or student aiming for next-level welds, try these:

Pulse MIG: Some modern welders offer pulse settings, which reduce heat input while maintaining penetration. Great for thin stainless pipes.

Downhill Welding: For thin pipes, weld downhill to minimize heat buildup. It’s faster and reduces burn-through risk.

Fit-Up Perfection: Use a pipe expander for slip joints instead of butt welds. They’re stronger and easier to weld.

Notebook Trick: Keep a log of your settings for different pipe thicknesses and materials. I jot mine down in a greasy notebook in my shop—it’s a lifesaver.

Maintaining Your Welded Exhaust

A good weld is only half the battle. To make it last:

- Coat the Weld: Apply high-temp paint or anti-corrosion spray to protect against rust.

- Check Hangers: Ensure the exhaust is securely hung to reduce vibration stress.

- Inspect Regularly: Look for cracks or rust every few months, especially in salty climates.

I welded an exhaust for a buddy’s truck, and it held up for years because we painted it and checked it regularly. Neglect can undo even the best welds.

Conclusion

There you have it—a complete guide to MIG welding an exhaust pipe. From prep to cleanup, you now know how to tackle cracks, build custom systems, or repair a rusty muffler with confidence. You’ve got the tools, settings, and techniques to create strong, leak-free welds that stand up to heat, vibration, and corrosion.

Whether you’re a DIYer saving cash, a hobbyist crafting a hot rod exhaust, or a pro in a busy shop, these steps will get you there. The key is preparation, proper settings, and patience—rush it, and you’ll pay later.

FAQ

What’s the best MIG wire for welding exhaust pipes?

For mild steel exhausts, use ER70S-6 wire (0.023” or 0.030”) for smooth, versatile welds. For stainless steel, go with 308L or 309L to match the pipe’s grade and prevent corrosion. Match the wire diameter to the pipe thickness to avoid burn-through.

Can I MIG weld an exhaust pipe without gas?

Yes, with flux-core wire, but it’s not ideal. Gasless welding produces more spatter and a hotter arc, increasing burn-through risk on thin pipes. Stick with gas-shielded MIG (C25 for mild steel) for cleaner, stronger welds.

How do I avoid burning through thin exhaust pipes?

Use low amperage (30–50 amps), a small wire (0.023”), and stitch weld in short bursts. Let the pipe cool between beads to prevent warping. Practice on scrap to dial in your settings and travel speed.

Is MIG or TIG better for exhaust welding?

MIG is faster, easier, and great for mild steel or DIY repairs. TIG is more precise and ideal for stainless or show-quality welds but requires more skill. For most exhaust jobs, MIG’s versatility wins out.

How do I know if my exhaust weld is leak-free?

After welding, inspect visually for cracks or holes. Apply soapy water to the weld and blow compressed air through the pipe—bubbles indicate leaks. Alternatively, use a smoke machine with the engine running to detect leaks.