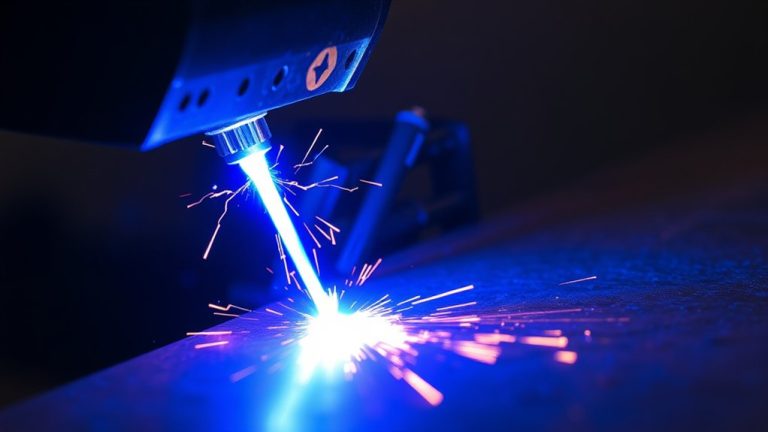

Starting plasma cutting with clean edges requires precision and preparation. You’ll need to equip yourself with essential safety gear like shade five glasses and a respirator. Set up your plasma cutter, adjusting its amperage to match the material’s thickness. Clean your workpiece meticulously to remove contaminants. With a pilot arc, ignite smoothly, ensuring consistent travel speed and steady air pressure. Ready to refine your technique for flawless cuts on scrap metal?

Essential Safety Gear and Precautions

When you’re about to start plasma cutting, confirming that you’re equipped with the right safety gear is essential.

Begin with wearing shade five glasses if you’re operating a 30 amp machine. For higher amperage, refer to the manufacturer’s guidelines for appropriate eye protection as the intensity of the light and sparks increases.

Always use a fume extractor to minimize inhalation of hazardous smoke and airborne particles. A respirator offers additional safety, protecting your respiratory system from potential harm.

Be conscious of the high temperatures generated by the plasma arc. Avoid direct contact with hot materials to prevent burns.

Maintain hazard awareness by confirming your cutting area is clean and organized. This reduces the risk of accidents and promotes a safer working environment.

Regularly inspect and maintain all tools and equipment to confirm they’re in prime condition, minimizing the chance of malfunctions that could lead to injuries.

Selecting the Right Plasma Cutting Machine

Selecting the right plasma cutting machine involves evaluating several key factors to match your specific cutting needs.

Start by considering the amperage selection; a machine like the Hypertherm Power Max 30, rated at lower amperage, is ideal for cutting thinner materials. Conversely, if you require thicker cuts, the Power Max 45 XP, with higher amperage, is more suitable.

For thinner materials, opt for the Hypertherm Power Max 30; for thicker cuts, choose the Power Max 45 XP.

Next, address compressor requirements. The Power Max 30 can operate efficiently with a smaller air compressor, but the Power Max 45 XP demands a larger compressor to maintain peak performance.

Machines with adjustable amperage settings are crucial, allowing you to fine-tune cutting speeds and quality according to material thickness.

Additionally, prioritize models featuring a pilot Arc for smoother changes during cutting operations. This feature greatly enhances cutting precision and ease.

Understanding Arc Starting Methods

To effectively initiate plasma cutting, you need to understand the advantages of pilot arc systems, which allow for seamless shifts and minimal electrode wear.

High frequency methods offer contactless ignition, minimizing physical wear but requiring careful handling to avoid electromagnetic interference.

Alternatively, blowback systems guarantee reliable starts by maintaining electrode contact until airflow initiates, protecting consumables and enhancing cut quality.

Pilot Arc Advantages

A pilot arc offers significant advantages in plasma cutting by establishing an initial arc without the need for direct contact with the workpiece.

This method provides several pilot arc benefits, including a cleaner start that prevents material damage and extends consumable life by minimizing nozzle contamination.

You’ll appreciate the cost efficiency from reduced operational expenses.

Pilot arc applications are extensive, allowing you to cut through painted or rusty surfaces without pre-cleaning, making it ideal for diverse materials and situations.

Machines like the Hypertherm Power Max series utilize this technology, enhancing cutting precision and quality.

The quick ignition of a pilot arc means faster operation and less downtime, ensuring that your plasma cutting process is efficient and effective, unlike traditional methods.

High Frequency Method

When you’re exploring arc starting methods for plasma cutting, the high frequency method stands out for its ability to initiate the arc without direct contact.

It leverages a high frequency spark to ionize the air gap between the electrode and workpiece, effectively starting the arc. This is particularly advantageous for cutting thin materials, as it reduces wear on the electrode and nozzle.

To utilize this method, guarantee your plasma cutter is equipped with a high frequency unit capable of generating the necessary voltage.

Despite the high frequency benefits, be mindful of potential electromagnetic interference with nearby electronics.

Troubleshooting interference involves maintaining a safe distance from sensitive devices and ensuring proper grounding in your workshop to mitigate electromagnetic disruptions.

Blowback System Mechanics

Although the high frequency method offers its own advantages, the blowback system provides a more reliable and interference-free approach to arc starting in plasma cutting.

In this system, the electrode maintains contact with the nozzle until air flow initiates, ensuring arc stability advantages from the get-go. As air begins to flow, the pilot arc shifts seamlessly into the main arc when it touches the workpiece, enhancing cutting consistency.

The blowback system benefits include reducing electrical interference issues, which are common with high-frequency methods, thereby prolonging consumable lifespan and ensuring clean cuts.

Understanding this system allows you to optimize your cutting performance, reducing arc instability risks and maintaining consistent edge quality across various materials, ensuring precision in your plasma cutting projects.

Techniques for Optimal Travel Speed and Quality Cuts

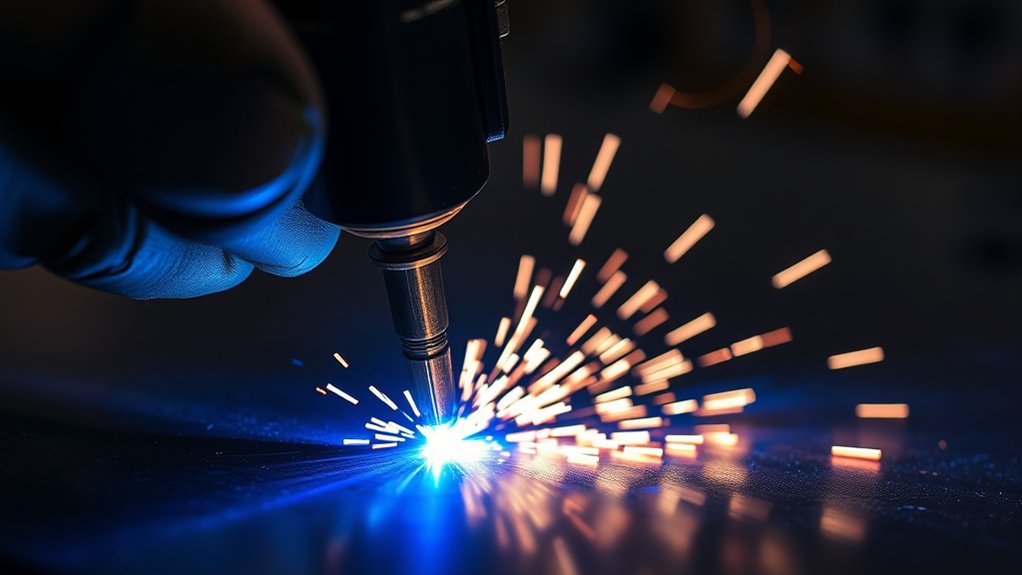

To achieve ideal travel speed and quality cuts, verify that sparks trail slightly behind the cutting path by maintaining a consistent speed—this prevents consumable clogs and minimizes dross formation.

Adjust amperage settings according to material thickness and monitor air pressure closely to maintain a stable arc.

Practice on scrap metal to refine your technique, allowing for adjustments that enhance precision in your final projects.

Adjusting Travel Speed

Achieving ideal travel speed in plasma cutting is vital for producing high-quality cuts and minimizing dross formation. Start by focusing on travel speed adjustment; it’s essential for maintaining clean edges.

Watch the sparks—they should trail slightly behind the cut line. If they lead, you’re cutting too fast, risking poor quality and consumable clogs. When sparks fall behind excessively, you’re too slow, resulting in excessive dross.

Adjust for material thickness considerations: thicker materials typically need slower speeds for precision. Maintain air pressure stability—fluctuations affect arc stability, altering travel speed needs.

Practice on scrap material to dial in the perfect speed before cutting your final workpiece. This method enhances precision and quality, guaranteeing ideal results.

Preventing Consumable Clogs

When it comes to preventing consumable clogs in plasma cutting, maintaining ideal travel speed is crucial. Cutting too fast risks poor quality and clogs, while too slow can cause excess dross. Aim for a speed where sparks trail slightly behind the cut, indicating efficient material removal.

Use clog prevention techniques like regularly monitoring and adjusting air pressure to guarantee consistent performance. These consumable maintenance tips are essential for avoiding clogs during cutting. Test cuts on scrap materials help determine the best speed and settings for various materials and thicknesses.

Additionally, keep the cutting area clean and free of debris, as this can interfere with the process and contribute to clogging issues. Attention to these details guarantees high-quality cuts.

Minimizing Dross Formation

While mastering the art of plasma cutting, minimizing dross formation is a key focus to guarantee high-quality results. Start with proper surface preparation by cleaning the material to promote smooth cuts.

Employ dross reduction techniques by maintaining an ideal travel speed; too fast results in poor quality, too slow increases dross. Observe the sparks—they should trail slightly behind the cutting arc, marking the perfect speed.

Monitor these critical factors:

- Air pressure settings: Confirm they’re consistent to avoid cut quality issues.

- Ruler and clamps: Use them for stable guidance, reducing dross by maintaining accurate movement.

- Test cuts on scrap material: Fine-tune your technique before final cuts.

- Surface preparation: Clean surfaces lead to cleaner cuts.

Focus on these strategies for effective dross management.

Utilizing Cutting Guides and Tools for Precision

To enhance your plasma cutting precision, consider how effectively you’re utilizing cutting guides and tools.

Begin by verifying cutting accuracy through proper tool maintenance. Secure a ruler with clamps to act as a straight edge guide—clamp it tightly to the workpiece for stability. Implement pony clamps, removing their rubber tips, to keep materials firmly set, reducing movement during the cut.

For circular cuts, attach a circle cutting guide with magnet-based hooks. This method guarantees consistent arc paths and precise outcomes.

Regularly calibrate your cutting tools and perform test cuts on scrap material to verify alignment and readiness before proceeding to your main project. Adjust your guides as required for varied cuts, confirming they align with your intended path.

Consistently monitor your air pressure settings; maintaining ideal conditions helps deliver clean and accurate cuts. Your diligence in these areas will greatly improve your cutting precision.

Mastering Air Dynamics for Enhanced Cutting Accuracy

Achieving precision in plasma cutting goes beyond using guides and tools; mastering air dynamics is equally important. Swirling airflow within the plasma torch plays a critical role in cut quality. By understanding that the arc’s right side usually offers straighter cuts, you can enhance your cutting accuracy.

Maintain consistent air pressure to preserve that swirling effect, ensuring the arc remains stable.

To improve your results, adjust the torch angle effectively. An ideal torch angle leverages the swirling airflow, directing the arc precisely where needed. Hypertherm machines excel in air dynamics, providing cleaner edges and more accurate cuts, but only if you harness their capabilities correctly.

Consider these steps:

- Maintain consistent air pressure to support swirling airflow.

- Position the torch at the ideal angle for effective arc direction.

- Utilize the right side of the arc for straighter cuts.

- Practice with various materials to observe air dynamics.

Refine these techniques to achieve enhanced accuracy.

Frequently Asked Questions

What Materials Can Be Cut Using a Plasma Cutter?

You can cut materials like mild steel, stainless steel, aluminum, brass, and copper using a plasma cutter. Confirm cutting thicknesses match your machine’s capability, as thicker materials require more power for smooth, precise cuts. Always verify specifications.

How Do I Maintain My Plasma Cutter for Longevity?

To maintain your plasma cutter for longevity, regularly inspect and clean the torch, replace worn consumables promptly, check and adjust air pressure, and guarantee proper grounding. Follow these plasma cutter maintenance tips to secure peak performance and lifespan.

Can Plasma Cutting Be Used Underwater?

Just like a dancer gliding effortlessly, plasma cutting can be used underwater with precise technique. Prioritize safety considerations by using specialized torches and PPE designed for underwater applications to guarantee effective and secure operations.

How Do I Troubleshoot Common Plasma Cutting Issues?

To troubleshoot plasma arc issues, first verify proper grounding. Check your cutting speed; if it’s too fast, you’ll face jagged edges. Inspect consumables for wear and verify correct air pressure to maintain ideal arc stability and precision.

What Is the Environmental Impact of Plasma Cutting?

Plasma cutting emits fumes and particulates, contributing to air pollution. You should implement proper waste management by using ventilation systems and filters to minimize plasma emissions, ensuring compliance with environmental regulations and protecting both workers and the environment.

Conclusion

With your plasma cutting gear ready, you’re like a modern-day Prometheus, wielding the power of fire to shape metal. Ensuring safety and precision, you’ve mastered the art of adjusting amperage and maintaining steady air pressure. You’ve practiced on scrap metal, refining your technique for clean edges. Use cutting guides for precision and remember, consistency in travel speed is key. With these skills, you’re equipped to turn raw materials into crafted art, much like a sculptor with stone.