MIG welding aluminum without gas is one of those jobs that really tested my patience when I first tried it in the shop. Most of us are used to running MIG with shielding gas on mild steel or even TIG on stainless, where arc control and joint prep give predictable results. But with aluminum, especially thin metal thicknesses, trying to weld without gas quickly exposes every weakness in your setup.

The filler wire doesn’t flow the same, porosity becomes a constant battle, and the welds often end up brittle or weak if the process isn’t dialed in. A lot of welders and DIY enthusiasts get confused here, asking whether flux core aluminum wire is a real solution or just a shortcut that leads to poor weld quality.

This matters because in real-world fabrication — whether it’s auto body repair, trailer work, or shop projects — a bad aluminum weld can fail under load, costing time and money. In this guide, I’ll share the practical truth about MIG welding aluminum without gas and the shop-tested tricks to make it work when you don’t have access to shielding gas.

Image by energianowa

Can You Really MIG Weld Aluminum Without Gas?

Straight up, yes—but with caveats that could fill a toolbox. Traditional MIG on aluminum screams for 100% argon to shield that oxide layer and keep porosity at bay. Without it, you’re inviting contamination like an uninvited guest at a barbecue.

Enter flux-cored aluminum wire: it’s self-shielded, meaning the flux inside the wire does the heavy lifting, releasing gases as it melts to protect the puddle. Think of it like the wire’s got its own mini-atmosphere.

I first tried this on a buddy’s aluminum toolbox repair back in Ohio winters—cold shop, no gas on hand, just a basic flux core spool and some ER4043 knockoff. It held up through a season of hauling tools, but the bead was rougher than a fresh grind. When to use it? Light-duty fab, like joining 1/8-inch sheets for garden gates or trailer ramps.

Why? Cost efficiency—ditch the $50 tank refills—and simplicity for mobile work, like farm repairs or off-grid builds. But if your project’s load-bearing, like a chassis mod, bite the bullet for argon; codes like AWS D1.2 demand it for structural integrity.

Practical know-how: Polarity matters big time. Flip your machine to DC electrode negative (DCEN) for flux core—it’s the opposite of steel’s DCEP, helping penetrate that stubborn oxide without gas. And preheat? Always. Aluminum sucks heat like a sponge, so a rosebud torch at 200-300°F evens the field, cutting distortion risks.

Common pitfall: Rushing the wire choice. Not all flux core plays nice with aluminum—grab something like Hobart or Lincoln’s aluminum-specific .035-inch diameter. I once ran generic steel flux core on ally by mistake; the arc spat like a cornered cat, and the joint cracked under a light tap. Fix? Double-check the spool label—look for “gasless aluminum MIG” or “self-shielding ER4043 flux core.”

What Makes Aluminum Such a Pain for Gasless MIG Welding?

Aluminum’s got personality—shiny, strong, but it fights back. That thin oxide skin forms instantly in air, tougher than steel’s, and it melts at twice the temp of the base metal (around 1,200°F vs. 660°F). In a gasless setup, your flux has to blast through it solo, which it does okay for thin stuff but struggles on thicker plates.

From my days troubleshooting at a Midwest trailer plant, I’d see stacks of rejected parts because heat built unevenly—edges warp, center stays cold. High thermal conductivity means the puddle cools fast, leading to incomplete fusion if your travel speed’s off. Why care? Poor prep equals weak welds that fail inspections or, worse, mid-job. For students hitting the books or pros chasing AWS certs, understanding this builds better habits across processes.

Semantic tie-in: It’s all about material compatibility. Aluminum alloys like 6061 (common in extrusions) pair best with silicon-rich fillers for fluidity, while 5052 sheets need magnesium-heavy wire to match strength. In gasless, the flux compensates for no external shield, but it leaves slag—plan to chip and grind post-weld.

Early on, I gaslessly welded a 1/4-inch 6061 frame for a go-kart. No preheat, straight arc—beautiful start, then the whole thing bowed like a banana. Lesson? Clamp fixtured joints and tack every inch. Pro tip: Use a soapstone to mark heat zones; it helps visualize where you’re dumping energy.

Essential Equipment for Gasless MIG Aluminum Welding

You don’t need a fortune in gear, but skimping shows in the bead. Start with a versatile MIG box—something like a 140-200 amp flux core model from Lincoln or Miller, capable of DCEN output. I’ve run a Harbor Freight 140 on scraps forever; it’s no beast, but for 16-gauge to 1/8-inch ally, it punches above weight.

Wire feeder: Standard U-groove drive rolls crush soft aluminum, so swap to knurled or polymer ones—$10 fix at any supply house. Gun liner? Nylon or Teflon, .035-inch ID to glide that flux core without bird-nesting. I learned the hard way on a steel liner job; wire jammed mid-bead, spraying flux everywhere like fireworks gone wrong.

No gas means no regulator hassle—pure bliss for trailer setups. But add-ons shine: A foot pedal for amperage control if your machine allows, and insulated gloves rated for MIG splatter. Safety first—aluminum fumes from flux can irritate lungs, so ventilate like you’re grinding brake rotors.

For US shops, stick to UL-listed machines meeting OSHA vibes. Comparison table below breaks it down:

| Equipment Piece | Budget Pick | Pro Pick | Why It Matters for Gasless |

|---|---|---|---|

| MIG Welder | HF 140 Flux Core ($300) | Miller Multimatic 215 ($1,500) | Handles DCEN polarity; higher amps for thicker ally without gas lag. |

| Drive Rolls | V-groove steel ($5) | Knurled aluminum ($15) | Prevents wire shave; flux core needs grip without mashing soft filler. |

| Gun Liner | Steel .035″ ($8) | Teflon .040″ ($20) | Reduces friction—key for consistent feed in self-shielded runs. |

| Wire Spool | 2 lb ER4043 flux core ($25) | 10 lb ER5356 flux ($80) | Silicon for flow vs. magnesium for strength; match to your alloy. |

| Cleaning Tools | Wire brush ($5) | SS dedicated ally brush ($12) | Removes oxide—gasless relies on clean base 100%. |

Budget total? Under $350 to get rolling. I’ve kitbashed worse in a pinch—remember, it’s about function over flash for hobbyists.

Choosing the Right Flux Core Wire for Gasless Aluminum MIG

Wire’s your weld’s soul—pick wrong, and it’s heartbreak. For gasless, flux core aluminum wire (like 4043 or 5356 variants) is the star. ER4043’s my go-to: silicon additive lowers melt point, boosts fluidity for forgiving beads on dirty-ish surfaces. Great for 3000-6000 series alloys in trailers or enclosures.

ER5356? Packs magnesium for higher tensile strength—ideal for marine or outdoor fab where corrosion fights back. But it’s stiffer, trickier to feed gasless. Diameter: .030″ for thin sheets (less heat input, less warp), .035″ for versatility up to 3/16-inch.

Practical scoop: Check compatibility charts from AWS—6061 loves 4043, but 5052 demands 5356 to avoid cracking. I once mismatched on a bike rack; the joint hot-cracked after a week of trail abuse. Fix? Test welds on scraps—bend ’em 90 degrees; if they snap, recast.

Tips: Store spools in dry bags—flux hates moisture, turning your arc into popcorn. And spool size: 4 lb for portability, 12 lb for shop hauls. Cost? $2-4 per pound, way cheaper than argon setups long-term.

Pros of flux core gasless: No tanks to lug, works in wind, quick setup. Cons: Slag cleanup’s a chore, welds uglier (more grinding), and strength caps at 70-80% of gassed. For students, it’s a cheap entry to learn arc control without gas flow drama.

Step-by-Step Guide to MIG Welding Aluminum Without Gas

Alright, gloves on—let’s run some beads. This guide’s honed from shop floors to garage benches, assuming 1/8-inch 6061 sheets butt-jointed. Scale amps/thickness as needed.

Prep the Joint: Scrub like it’s surgery. Acetone wipe, then a dedicated stainless brush—dedicated means no steel cross-contam. Grind edges to 60-degree bevel for penetration. Clamp square; tack three points to hold shape.

Machine Setup: DCEN polarity, no gas port needed. Wire speed: 150-200 IPM for .035″ on 140 amp. Voltage: 18-22V—start low, dial up if arc stutters. Preheat to 250°F with a torch; use temp sticks for precision.

Wire and Gun Check: Load flux core, trim 3/4-inch stickout. Test feed on scrap—smooth? Good. Angle gun 10-15 degrees push for better shielding from flux gases.

Strike the Arc: Ear on, trigger squeeze—arc should hum steady, not hiss. Travel 8-12 IPM, weaving slight for width. Watch puddle: Shiny flow means gold; dull or bubbly? Clean more or up voltage.

Run the Bead: Short bursts for thin stuff—overheat warps fast. Overlap tacks by 1/4-inch. If slag balls up, chip between passes.

Cool and Clean: Air cool—no quench. Wire brush hot metal, then grind smooth. Inspect: No cracks? Bend test passes? You’re set.

My first gasless run? On a toolbox lid—too fast travel, incomplete fusion. Fixed by slowing to match melt pool. For hobbyists, practice on angle iron first; builds muscle memory.

Joint prep tip: For fillets, V-groove the toe—gasless flux struggles with flat butts. Filler compatibility: Always overmatch strength, like 5356 on 5052.

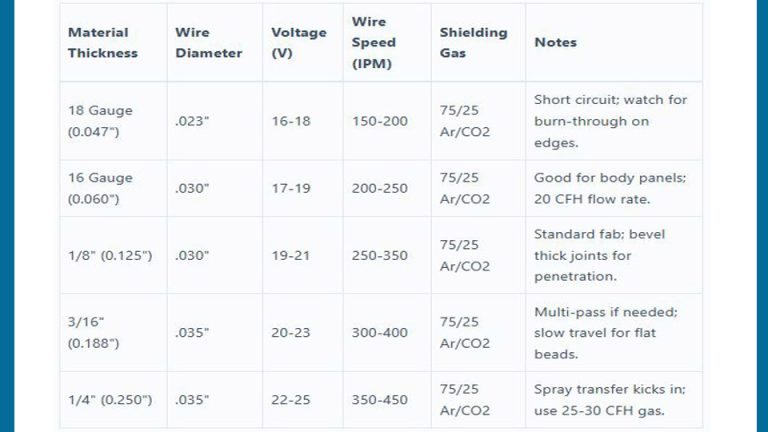

Best Machine Settings for Gasless MIG on Different Aluminum Thicknesses

Settings ain’t one-size-fits-all—aluminum laughs at steel charts. Base on your machine’s sweet spot; I’ve dialed these on Millers and Lincolns alike.

For 16-gauge (.060″): 90-110 amps, 16-18V, 120 IPM wire. Short stickout, quick travel—think surgical strikes to dodge burn-through.

1/8-inch (.125″): Bump to 140-160 amps, 20-22V, 180 IPM. Preheat mandatory; weave for heat spread.

3/16-inch: 180-200 amps, 23-25V, 220 IPM. Multi-pass, inter-run clean—slag builds fast gasless.

Common mistake: Ignoring base metal series. 2000-series (aircraft) needs hotter, slower for penetration; 7000-series hates heat, so pulse if your box allows.

Fabbed a 1/4-inch trailer hitch gasless—over-volted to 26V, blew holes like popcorn. Dial back 2V, perfect stack. Pro know-how: Use a chart sticker on your machine; update per wire batch.

Common Mistakes and Fixes in Gasless Aluminum MIG Welding

We all eat dirt learning—here’s mine, served up to save you grief. Mistake one: Skipping oxide removal. That gray film? It traps air, pores galore. Fix: SS brush + acetone, every time. I lost a weekend batch to it on boat panels—looked solid, failed flex test.

Bird-nesting wire: Flux core kinks easy. Fix: Lube liner lightly (silicone spray), straight spool path. Happened mid-job on a gate frame; quick liner swap saved the day.

Warp city: Heat soaks uneven. Fix: Sequential tacking, back-step technique—weld, skip, fill. For a custom rack, I fixtured with C-clamps; zero bow.

Slag inclusions: Flux doesn’t self-clean like gas does. Fix: Chip aggressive between layers, grind if needed. Ugly but strong—I’ve pressure-washed tested ’em.

Porosity pops: Moisture or dirt. Fix: Bake wire at 250°F if suspect, dry shop. Windy day outdoors? Shield with cardboard—flux gases blow away.

For pros: Code check—gasless often disqualifies for ASME, so document for audits. Students: Log settings; repeatability builds cred.

Pros and Cons of Gasless MIG vs. Traditional Gassed Aluminum Welding

Weighed ’em in real gigs—here’s the scorecard.

Pros of Gasless:

- Portability king—no tanks mean backpack welder vibes for field repairs.

- Cost cutter: $0.50/ft wire vs. $2+ with gas.

- Wind-proof: Flux shields hold in breezes that kill argon flow.

- Quick strikes: Less setup for hobby bursts.

Cons:

- Weaker joints: 20-30% less tensile; fine for brackets, not booms.

- Cleanup hell: Slag grinding eats time—post-weld file for smooth.

- Rough aesthetics: Beads ripple more; polish if visible.

- Limited thickness: Struggles over 1/4-inch without multi-pass marathon.

Gassed wins on beauty and strength—spool gun + argon for marine-grade. But gasless? My pick for 80% of shop side-jobs. Table for quick scan:

| Aspect | Gasless Flux Core | Gassed MIG |

|---|---|---|

| Strength | Good for light duty | Excellent |

| Setup Time | 2 min | 5-10 min |

| Cost per Foot | Low | Medium-High |

| Cleanliness | Slaggy | Clean puddle |

| Best For | DIY/Field | Structural |

Bottom line: Gasless shines where convenience trumps perfection.

Safety Considerations for Gasless MIG Aluminum Welding

Safety’s non-negotiable—I’ve seen flux fumes choke a shop newbie. Flux core spits more spatter; leather jacket, FR pants, no shortcuts. Fumes? Aluminum + flux = hexavalent chromium traces—ventilate or respirator up. Eye pro: Auto-darkening hood, shade 10-12.

Ground clamp solid—stray arcs shock. Fire watch: Aluminum drips hot; extinguisher handy. For students, OSHA 1910.252 basics: No loose clothes, insulated floors.

Personal story: Slipped a glove once, splatter burned thumb—lesson in fit. Pro tip: Post-shift lung check; if cough lingers, see doc.

Real-World Applications for Gasless MIG Aluminum Welding in the US

From Rust Belt fabs to California custom shops, gasless fits niches. Trailer builders tack hitches roadside—no gas truck needed. Hobbyists? Bike frames, RC chassis—light, quick.

US practices: Follow AWS D1.2 for non-crit, but DOT trailers demand gassed for hauls. I’ve gaslessly repaired FEMA trailers post-storm; held through relocates.

Examples: Welding ally storm shutters in Florida—flux core ate the salt air prep. Or Midwest ag gates: 5052 panels, ER5356 wire, zero rust after seasons.

Suggestions: Joint prep with 80-grit flap disc; filler match per alloy chart. Machine settings tweak for humidity—dry Midwest vs. humid South.

Advanced Tips for Cleaner Beads in Gasless Aluminum MIG

Level up: Pulse mode if available—reduces heat, minimizes warp. I retro’d a pulse kit on an old Miller; beads went from wavy to pro.

Prep hack: Vinegar soak for oxide—cheap, effective. Travel angle: 5-10 degree push, gun perpendicular to joint.

Mistake fix: Arc wander? Shorten stickout to 1/2-inch. For vertical ups, weave tighter—gravity pulls flux down.

Anecdote: Competed in a fab challenge gasless—preheated with heat blanket, aced it. Tip: Audio cue—steady sizzle means balanced.

Conclusion

Clean ruthless, match wire to alloy, and respect the heat—it’s your ticket to solid, if not showroom, joints. You’re now geared to tackle that trailer patch or shop prototype without gas woes, blending cost smarts with real-world grit.

Whether DIY sparking in the garage or pro hustling deadlines, this setup empowers confident runs. Go fire it up—your next bead’s waiting. Always bend-test scraps; it’s the ultimate truth serum for weld quality.

FAQs

Can I MIG Weld Aluminum Without Gas on Thick Material?

For anything over 1/4-inch, gasless gets dicey—multi-passes build slag fast, weakening layers. Stick to gassed or TIG for structural thickies; flux core shines on thin-to-medium for hobby or temp fixes.

What’s the Best Flux Core Wire for Gasless Aluminum MIG?

ER4043 for general fab—flows like butter on 6061 extrusions. ER5356 if strength’s key, like marine panels. .035-inch diameter balances feed and penetration; test on your alloy series.

Why Do My Gasless Aluminum Welds Look Porous?

Oxide ghosts or dirty flux—brush harder, dry wire overnight. Up voltage 1-2 points if arc’s lazy. Wind kills flux shield too; weld indoors or block gusts.

Is Gasless MIG Strong Enough for Trailer Repairs?

For non-load panels or brackets, yes—I’ve seen ’em haul 2,000 lbs fine. But hitches or frames? Add argon for code compliance and peace. Rivet hybrids for extra insurance.

How Do I Clean Up Slag After Gasless MIG on Aluminum?

Chip hot with a weld chisel, then 80-grit flap disc. For smooth, 120-grit belt—avoids gouging soft ally. Quick pass prevents re-contam; always wear a mask for dust.