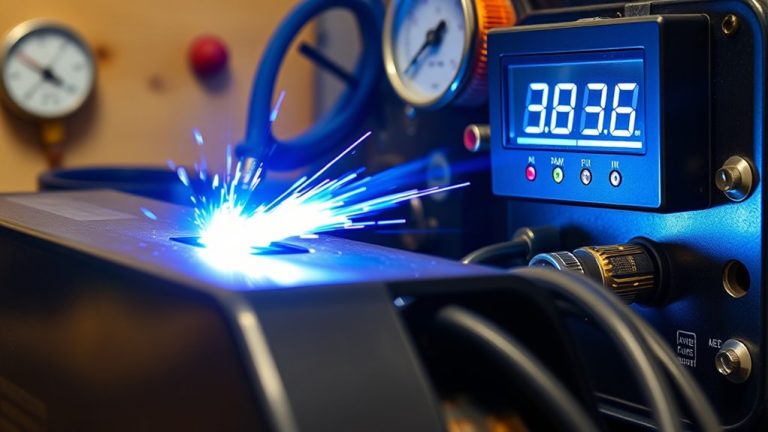

When deciding between a 110V and 220V plasma cutter, it’s essential to assess your cutting requirements and environment. While a 110V unit handles lighter materials with ease, a 220V cutter offers robust performance for thicker metals and demanding tasks. Consider efficiency, duty cycles, and power output. Understanding how these factors impact your projects will guide you in selecting the most suitable equipment for precision and versatility. Let’s explore the nuances further.

Understanding Voltage Options for Plasma Cutters

When you’re selecting a plasma cutter, understanding the voltage options is essential for maximizing its performance. Plasma technology benefits considerably from the voltage specifications you choose.

Dual-voltage plasma cutters, offering 110V and 220V, cater to varying needs. At 110V, you’re capped at a 20-amp output, restricting power and limiting material thickness capabilities. In contrast, a 220V setup also supports 20 amps but provides greater power capacity, enhancing cutting precision by minimizing voltage drop in the wiring.

Utilizing 220V not only improves cutting efficiency but also boosts the cutter’s duty cycle, allowing longer operation without overheating—critical for intensive tasks. Higher voltage guarantees cleaner cuts and reduces strain on the system.

Consider your electrical supply; while 110V circuits are more common in household environments, they mightn’t suffice for robust plasma cutting applications found in professional settings. Align your choice with power requirements and available infrastructure to maximize performance.

Evaluating Cutting Power and Efficiency

Choosing the right voltage for your plasma cutter directly influences its cutting power and efficiency. A 220V plasma cutter offers superior efficiency, handling thicker materials with ease due to its 6600-watt power capacity compared to 3600 watts on 110V. This higher capability enhances cutting speed, making it a preferred choice for demanding tasks. The consistent 50-amp output is standard for both voltages, but 220V reduces voltage drop risks, ensuring stable, high-quality cuts.

Here’s a quick efficiency comparison:

| Voltage | Cutting Capability | Duty Cycle |

|---|---|---|

| 110V | Limited (≤1/4 inch) | Shorter |

| 220V | Superior (>1/4 inch) | Longer |

A 220V system extends the duty cycle, allowing longer operation without cooling down, essential for intensive tasks. It also minimizes finishing work by delivering cleaner cuts. Although a 110V cutter may suffice for light-duty applications, investing in 220V maximizes efficiency, cutting speed, and overall performance.

Considerations for Home Users and Hobbyists

For home users and hobbyists, selecting the right plasma cutter involves several vital considerations to guarantee both performance and practicality.

Start by evaluating plasma cutter features like dual voltage capability—110V for convenience and 220V for efficiency. Having this flexibility lets you adapt to available power supplies, essential for diverse hobbyist projects. Operating on 220V not only delivers more power (6600 watts versus 3600 watts at 110V) but also facilitates cutting thicker materials cleanly.

Dual voltage capability in plasma cutters offers flexibility and efficiency, crucial for diverse hobbyist projects and thicker material cutting.

Consider the duty cycle; a 60% duty cycle at higher amperage supports longer cutting sessions, reducing downtime. If your projects often involve materials thicker than 1/4 inch, opting for a 220V unit prevents tripping breakers and guarantees consistent performance.

Finally, prioritize a lightweight, portable plasma cutter under 25 pounds. This enhances usability and allows easy transport, making it perfect for home use and varied hobbyist applications, ultimately optimizing your cutting tasks.

Industrial Applications and Contractor Needs

Given the demanding nature of industrial applications, plasma cutters operating at 220V stand out as the superior choice for efficiently handling tougher, thicker materials up to 5/8 inch steel. The increased amperage output guarantees cleaner cuts and faster operation, vital for maintaining industrial efficiency.

In industries like HVAC and plumbing, the consistent performance and reduced voltage drop of 220V units bolster productivity by streamlining operational workflows.

For contractors, mobility remains essential. Inverter plasma cutters, capable of running on both 110V and 220V, provide unmatched flexibility. Their compact design enhances contractor mobility, allowing you to easily navigate diverse job sites.

When dealing with extensive cutting tasks, a plasma cutter boasting a 60% duty cycle at 50 amps minimizes downtime, guaranteeing you maintain high productivity levels. In professional settings, where precision and time are of the essence, opting for a 220V plasma cutter aligns with both industrial demands and contractor versatility.

Duty Cycle and Performance Implications

High-performance plasma cutters are indispensable for contractors and industrial professionals tackling demanding tasks. When deciding between 110V and 220V plasma cutters, understanding the duty cycle and performance comparison is critical. The duty cycle, expressed as a percentage over a 10-minute interval, tells you how long a cutter can run continuously at a given amperage before requiring a cool-down.

- Higher Duty Cycles: A 220V plasma cutter generally offers superior duty cycles, allowing for extended cutting without overheating. For instance, a 60% duty cycle at 50 amps lets you cut for 6 minutes, then cool for 4 minutes.

- Voltage Efficiency: Operating on 220V reduces voltage drop in wiring, enhancing performance consistency and potentially extending the duty cycle.

- 110V Limitations: Using a 110V setup might lead to reduced output and risk of tripping breakers, adversely affecting the duty cycle, especially when cutting thicker materials.

Impact on Cutting Thickness and Material Capability

When choosing a plasma cutter voltage, you should consider how the input voltage impacts cutting thickness and material capability.

Using a 220V plasma cutter enables you to tackle thicker materials efficiently, offering clean cuts up to 5/8 inch, whereas a 110V unit limits you to a maximum of 3/8 inch.

This increased capacity also means a broader range of material compatibility, allowing you to work with heavier and more robust metals without sacrificing cut quality.

Voltage Effect on Thickness

While evaluating the impact of voltage on cutting thickness, you’ll find that a plasma cutter’s input voltage plays a critical role in determining its material capability. The voltage impact directly influences cutting precision and maximum thickness.

Operating at 220V provides several advantages:

- Enhanced Thickness Capacity: A 220V plasma cutter can sever materials up to 3/4 inch, surpassing the 1/2 inch limit of 110V models.

- Improved Efficiency: Higher voltage increases cutting efficiency on materials over 1/4 inch thick, ensuring cleaner and faster cuts.

- Stable Performance: With a 60% duty cycle at 50 amps on a 220V circuit, the cutter maintains stable operation, reducing voltage drop and ensuring precision isn’t compromised during extended tasks.

Choosing 220V optimizes your cutting operations.

Material Compatibility Considerations

Understanding the impact of voltage on cutting thickness lays the groundwork for exploring material compatibility in plasma cutting.

When considering material types like stainless steel and aluminum, 220V offers distinct advantages. It facilitates cutting techniques that demand higher energy, delivering cleaner, more precise cuts.

With a 220V system, you can handle materials up to 5/8 inch thick, whereas a 110V system limits you to about 1/4 inch. The 50 amp output remains constant, but the 220V’s efficiency guarantees less voltage drop and smoother operation.

This is vital for professional or heavy-duty applications, where consistent performance is paramount. The improved duty cycle at higher voltages allows for prolonged operation without overheating, making 220V ideal for demanding cutting tasks.

Making an Informed Decision Based on Your Needs

Why should you carefully consider your needs when choosing a plasma cutter voltage? Your decision impacts user experience and project scope considerably.

By understanding your projects, you enhance performance and efficiency. Here’s how to decide:

Understand your projects to boost performance and efficiency effectively.

- Project Scope: For industrial or heavy-duty tasks, a 220V plasma cutter is ideal. It delivers up to 6600 watts, facilitating cuts on thicker materials with consistent power, essential for extensive projects.

- User Experience: A 220V cutter typically offers a 60% duty cycle at 50 amps, allowing for prolonged operation without overheating. This feature boosts user satisfaction, especially during intensive tasks.

- Versatility: If you work in varied environments, consider a dual voltage option. It allows flexibility, adapting to both 110V and 220V supplies, making sure you’re prepared for any situation.

Assessing your typical scenarios guarantees you choose a cutter that aligns with your specific requirements, maximizing both functionality and efficiency.

Frequently Asked Questions

How Does Voltage Affect the Lifespan of a Plasma Cutter?

Voltage impacts a plasma cutter’s lifespan by influencing heat generation and efficiency. Higher voltage often reduces stress, enhancing longevity. Consider longevity factors like consistent voltage supply and maintenance to maximize the cutter’s lifespan effectively.

Are There Safety Concerns Specific to 110V or 220V Plasma Cutters?

Coincidentally, when using plasma cutters, 110V poses electrical hazards like circuit overloads, while 220V risks higher shock potential. You’re advised to wear personal protective equipment, ensuring safety against arc flash and electrical exposure, regardless of the voltage.

Can You Switch Between 110V and 220V on a Single Plasma Cutter?

Yes, you can switch between 110V and 220V on a single plasma cutter if it offers dual voltage compatibility. This equipment flexibility enhances operational adaptability, allowing you to work efficiently across different power sources and project requirements.

What Are the Typical Maintenance Requirements for Each Voltage Type?

Did you know 75% of plasma cutter issues stem from neglecting maintenance? Regular plasma maintenance includes checking the torch, ensuring proper airflow, and inspecting consumables. Voltage differences don’t greatly alter these requirements, but always follow manufacturer guidelines for ideal performance.

How Does the Cost Compare Between 110V and 220V Plasma Cutters?

You’ll find 110V plasma cutters often lower in initial cost, making them attractive for budget considerations. However, 220V models provide better cost efficiency due to enhanced performance, potentially reducing long-term operational costs through increased efficiency.

Conclusion

Choosing between a 110V and 220V plasma cutter is like deciding between a gentle breeze and a hurricane of power. If you’re a home user or hobbyist, the 110V offers enough cutting prowess for lighter tasks. However, for industrial applications and tackling thicker materials, the 220V is your unstoppable force, offering superior efficiency and duty cycles. Assess your project requirements meticulously—your choice will dictate your cutting universe’s boundaries and capabilities.