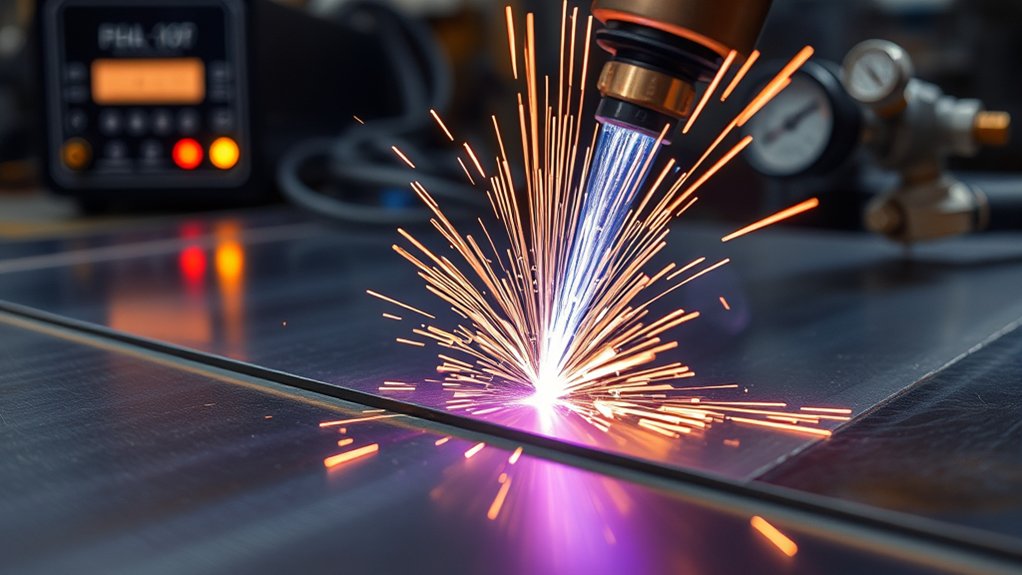

Cutting 26‑gauge stainless signage, you switch to Fine Cut consumables to stabilize the arc at low amperage, tighten kerf, and minimize HAZ. You’ll tune standoff with THC, lock pierce height, and trim cut speed to keep arc lag in check. Conical tip geometry boosts arc density for cleaner edge morphology and less dross. You’ll also decide between SYNC cartridges and traditional stacks—and spot wear patterns—before dialing gas and motion control for repeatability.

How FineCut Consumables Improve Edge Quality on Thin Sheet

Although thin sheet can be unforgiving, FineCut consumables tighten your process window by stabilizing the arc at low current and holding a consistent kerf on mild and stainless up to 45 A.

You leverage conical tip geometry to constrict the plasma column, which boosts arc density and directional control. That precision translates into minimal dross, cleaner edges on 26 gauge, and reduced heat input that limits warpage and bevel. The consumable benefits show up immediately: flatter edge morphology, smaller heat‑affected zone, and less micro-burr formation.

Apply disciplined cutting techniques: verify orifice integrity, align gas flow, and confirm amperage matches plate thickness.

Maintain a constant arc length to keep edge straightness and surface smoothness during 2‑D paths. Monitor electrode wear; once pit depth grows, arc wander increases and edge quality degrades.

Swap tips at defined intervals to preserve kerf consistency and cut fidelity. With fewer defects, you’ll skip secondary grind passes, compress cycle time, and cut total cost.

Matching Torch Height and Speed for Thin-Metal Precision

Two variables dominate thin‑metal precision: torch‑to‑work height and travel speed.

To hold a constant arc length on sheet thinner than 10 gauge, you’ll match torch height to a verified cutting speed from the cut chart, then lock both in. Start with the charted stand‑off for FineCut consumables and a cutting speed near 195 IPM on very thin stock, then fine‑tune in small increments.

Match torch height to verified speed; lock both. Begin near 195 IPM with FineCut, then fine‑tune.

Watch kerf behavior: dross on the bottom edge suggests slow speed or excessive torch height; beveled edges indicate height too high or speed too fast.

If you see ripples trailing the cut, stabilize motion and restore programmed feed rate. Adjust one variable at a time—prefer speed correction first, then trim height by 0.005–0.010 in to regain arc stability.

Use a height control to maintain constant arc voltage and probe each pierce to reset zero.

Continuously monitor cut speed through the toolpath and adapt torch height to contour changes to preserve edge finish.

Choosing the Right Power Level and Gas for Fine Features

When fine features drive the tolerance stack, set output current low and stable—typically 30–45 A with FineCut—to tighten kerf width and minimize heat input. You’ll get sharper radii, cleaner pierces, and less recast.

Prioritize power optimization: verify actual arc amperage matches the setpoint, then lock it in to avoid micro-taper.

For gas selection, run dry, oil-free shop air. Air delivers excellent edge fidelity at minimal cost, eliminating the complexity of mixed gases on thin stock.

Pair that with a consistent 0.06 in standoff to stabilize the arc column and suppress bevel and dross. Maintain a traverse speed near 195 IPM on intricate paths; adjust ±10% based on edge color and spatter signature.

Audit consumable condition frequently. A rounded electrode pit or widened nozzle orifice degrades feature definition and increases dross.

Swap components at the first sign of arc wander. Validate cut quality with coupon tests before releasing programs to production.

Consumable Selection: SYNC Cartridges vs. Traditional Sets

Locking in amperage, gas, and standoff only pays off if your wear stack holds tolerance, so the next lever is consumable architecture: SYNC cartridges vs. traditional sets.

If you’re chasing FineCut edge fidelity on ≤10 gauge, the SYNC advantages are clear: a patented single‑piece cartridge eliminates stack-up errors between nozzle, electrode, and shield, stabilizing arc geometry and reducing kerf wander.

With Powermax45 SYNC, you’ll see up to 5x consumable life and higher arc density, translating to faster cut speeds and cleaner edges on thin stock.

Powermax45 SYNC delivers up to 5x consumable life, higher arc density, faster cuts, and cleaner thin‑stock edges.

Traditional limitations show up as frequent swaps, part mismatches, and downtime for torch teardown. Multi-piece sets demand inspection discipline and torque consistency; any deviation shifts arc alignment and degrades cut quality.

SYNC’s built-in intelligence autoloads parameters, so you don’t burn time fine-tuning—pierce height, amperage, and gas flow hit spec automatically.

Net result: tighter bevel control, reduced dross, and predictable per-part cost on high-volume thin-metal programs.

Monitoring Wear: Signs, Checks, and Replacement Intervals

Although SYNC cartridges simplify setup, you still need disciplined wear monitoring to keep cut geometry in spec. Treat consumables as critical path components: verify condition, track life, and swap on schedule. Use objective wear indicators, not guesswork, to control replacement frequency and avoid rejected parts.

1) Visual inspection: After each nest or heat, check nozzle and electrode under magnification. Look for orifice ovality, edge pitting, and tip erosion. Any asymmetry telegraphs bevel and kerf growth—pull the set.

2) Electrical signature: Log arc voltage. Rising or erratic voltage under stable parameters flags internal erosion. Correlate voltage drift to cut quality; set a hard limit to trigger changeout.

3) Count-based intervals: Baseline replacement frequency at 600–1,200 pierces, adjusted for material, thickness, and duty cycle. Record pierce counts to prevent overrun.

4) Process discipline: Validate piercing technique—correct standoff, preflow timing, and pierce off-part when prescribed. Poor piercing torches the nozzle orifice, collapsing life and skewing cut geometry.

Table Motion and Height Control Requirements for Best Results

Tight consumable control only pays off if the torch rides at the right height and the table moves with repeatable kinematics. You’ll lock in cut quality on thin gauge when torch height and table motion are tuned to spec and verified on a schedule.

Set the torch-to-work distance per the Powermax cut charts for FineCut; that standoff preserves arc focus, minimizes bevel, and controls dross. Use a responsive torch height control that samples arc voltage accurately and filters noise, so surface waviness doesn’t translate into height error.

Validate table motion with periodic performance checks: confirm commanded versus actual velocity, acceleration, and jerk, and recalibrate if deviation exceeds tolerance.

Implement sinusoidal cornering profiles to maintain continuous velocity through direction changes; avoid hard decel/accel that distorts kerf and dumps molten material. Document feedrate windows for each thickness, then audit cuts to verify kerf symmetry.

When height control and motion are stable, you’ll produce flat, uniform edges consistently.

Troubleshooting Dross, Bevel, and Edge Ripple on Light Gauge

When light-gauge cuts show dross, bevel, or edge ripple, start by verifying torch-to-work height at roughly 0.06 in per the FineCut chart and confirm the THC is sampling arc voltage cleanly with ohmic sensing on the Duramax shield.

Height errors drive dross formation and skew kerf, so validate pierce and cut heights, then run a short cut test to confirm stabilization.

- Set amperage within FineCut limits (≤45 A) and match it to thickness. Overshoot blows a wider kerf; undershoot starves the arc, hurting bevel reduction and edge fidelity.

- Lock in feed rate near 195 IPM for thin sheet and avoid velocity ripple in corners. Overtravel leaves low-speed dross; undertravel lifts the arc and causes bevel.

- Inspect consumables: nozzle orifice growth and electrode wear degrade arc column density. Replace at the first sign of double-arcing or taper.

- Verify consumable stack-up and shield: use FineCut nozzles with the ohmic shield. Confirm concentricity, gas flow, and THC response to maintain consistent stand-off and reduce edge ripple.

Safety and Material Considerations for Thin Stainless and Mild Steel

Before you strike an arc on thin stainless or mild steel, establish safe process controls and material-specific settings to protect operators and preserve cut quality.

Implement safety measures: verified PPE, grounded work surface, dry air supply, and fume extraction. Treat galvanized as a separate material type—use local exhaust and a respirator rated for metal fumes; zinc off-gassing is toxic.

Dial in the torch-to-work distance. Maintain correct standoff to keep the kerf narrow, edges flat, and dross minimal. Run FineCut consumables within spec—up to 45 amps—and match amperage, travel speed, and gas flow to sheet thickness and alloy.

Chemical composition varies across material types; higher alloy or coatings shift arc characteristics, so fine-tune height control, pierce delay, and cut speed.

Audit consumable wear. Inspect electrodes and nozzles at defined intervals; swap components before pit depth or orifice erosion degrades geometry.

Document parameters per heat lot, and lock out changes without QC sign-off.

Frequently Asked Questions

Do Fine Cut Consumables Work With Hand Torches or Only CNC Tables?

They work with both. You’ll run fine cut consumables on hand torches for precise, low-amp trims—strong hand torch compatibility. On CNC, you’ll leverage cnc table efficiency: tighter kerf, consistent standoff, optimized cut charts, superior edge quality, minimal dross.

What Minimum Thickness Benefits Most From Fine Cut Tips?

Around 22–16 gauge (0.8–1.6 mm) is the minimum thickness that benefits most from fine cut tips. Picture threading a needle; you tune amperage, standoff, and kerf to prevent warpage, dross, and tapered edges.

Are Fine Cut Parts Compatible With Water Tables and Downdraft Systems?

Yes. Fine cut parts work with both, but you’ll optimize water table compatibility by keeping plate just above water, controlling splash, and maintaining dry air. For downdraft system effectiveness, manage capture velocity, zoned suction, and fume extraction near torch.

How Do Fine Cut Consumables Affect Kerf Width and Part Nesting Efficiency?

Like dialing a rotary phone, you tighten kerf width with fine cut consumables, enabling denser layouts. You’ll boost nesting efficiency via narrower striations, reduced heat-affected zones, optimized amperage, smaller nozzles, precise arc constriction, and tighter pierce spacing for material yield gains.

Can Fine Cut Settings Be Stored as Cut Charts in CAM Software?

Yes. You can store fine cut settings as cut charts in CAM software, mapping amperage, arc voltage, kerf, pierce delay, feedrate, and height control. You’ll parameterize toolsets, link material libraries, and apply post-processors for consistent, repeatable profiles.

Conclusion

You’ll tighten cut quality by pairing FineCut consumables with correct standoff, amperage, and gas, then validating motion, arc voltage, and kerf compensation. Select SYNC or traditional sets to match workflow, log wear indicators, and replace on schedule. Calibrate THC, tune feedrates, and mitigate dross, bevel, and ripple with data-driven tweaks. Observe stainless/mild steel safety and metallurgy. When dialed in, your edges are crisp, HAZ minimized, and repeatability locked—like a CNC metronome keeping every note perfectly on time.