In the domain of metal fabrication, like the legendary blacksmiths of old, you must navigate the intricacies of plasma cutting, where understanding limitations in thickness, precision, and edge quality becomes your forge’s fire. As you wield this tool, consider how operator technique, equipment setup, and consumable selection impact your work. Yet, there’s more beneath the surface—a deeper insight awaits as you explore the balance between speed and quality in achieving your desired outcomes.

Understanding Plasma Cutter Thickness Limits

When evaluating plasma cutter thickness limits, it’s vital to understand that these devices excel at cutting materials up to 50 mm (2 inches) thick, providing superior quality on thinner substrates.

Plasma cutters excel at cutting materials up to 50 mm thick, offering superior quality on thinner substrates.

Plasma cutter specifications, such as amperage and duty cycle, directly influence performance. For thicker cutting material types, like steel or aluminum, a higher amperage is necessary to maintain edge quality. For example, the Hypertherm MAX200 can handle 2-inch thickness at a 200A output.

It’s important to match these specifications with the material being processed to avoid quality issues like dross formation and edge irregularities.

Entry-level systems typically offer a tolerance of ±0.77 mm (±0.030 inches), while heavy industrial units can achieve tighter tolerances down to 0.25 mm (0.010 inches).

Factors Influencing Precision in Plasma Cutting

Although precision in plasma cutting is influenced by multiple factors, the operator’s skill is paramount, especially in hand plasma cutting where tolerances of about 1.6mm (1/16-inch) are achievable.

To enhance precision, consider these significant factors:

- Operator Technique: Mastery of torch motion, cut speed, and standoff distance is essential. An adept operator maintains consistent motion and ideal distance, directly affecting cut accuracy.

- Equipment Setup: Proper setup, including automatic torch height control in CNC systems, guarantees uniform cut quality. This feature adapts to material thickness variations, stabilizing precision.

- Consumable Selection: The choice of consumables, such as nozzle types and sizes, determines kerf width and edge quality. FineCut consumables are engineered to produce narrower kerfs, enhancing precision.

In automated systems, entry-level setups achieve ±0.77 mm tolerances, but high-end systems can reach 0.25 to 0.51 mm.

Precision demands a blend of skilled operator technique, meticulous setup, and ideal consumable selection.

The Role of Edge Quality in Metal Fabrication

Precision in plasma cutting doesn’t just depend on the factors influencing the cut itself; it manifests profoundly in the quality of the edge produced. Edge quality directly impacts the fit, function, and appearance of your final product. Clean, sharp edges minimize secondary finishing processes, aligning with stringent surface finish requirements. To achieve this, implementing effective edge preparation techniques is essential.

Managing cut speed and amperage settings minimizes dross formation, the undesirable solidified molten metal on cut edges. High angularity of cut, achieved through precise torch motion, guarantees parts align correctly, important for applications demanding tight tolerances.

Additionally, enhancing the kerf width—narrower kerfs improve material utilization—reduces waste and boosts efficiency.

When dealing with thin metal sheets, maintaining ideal cutting parameters is imperative. Excessive heat can cause warping, degrading edge quality and increasing rework. Therefore, understanding and controlling these variables are critical for superior fabrication outcomes.

Challenges in Cutting Thick Metal Plates

Cutting thick metal plates with plasma technology often presents a unique set of challenges that demand meticulous attention to detail. The increased heat input can lead to warping and distortion, making heat management imperative.

Here’s what you need to focus on:

- Cutting Techniques: The Hypertherm MAX200, for instance, can handle up to 2 inches of steel at 6 IPM, but you’ll need to finely tune speed and amperage for clean cuts.

- Tolerance Control: Maintaining a typical tolerance of 0.25 to 0.51 mm requires precise setup and skilled operators to guarantee quality and prevent deviations.

- Gas Mixtures: For peak edge quality and to avoid oxidation, using the right gas mixtures—like argon-hydrogen for stainless steel—is essential.

Moreover, handling these heavy plates safely is crucial. Their weight increases the risk of injury, so adhering to handling protocols is non-negotiable.

Each step plays a role in overcoming these challenges effectively.

Comparing Plasma, Laser, and Waterjet Cutting

When comparing cutting methods, you’ll find that plasma cutting offers superior speed for thicker metals, but this comes at the cost of edge quality, often requiring post-process cleaning to remove dross.

In contrast, laser cutting provides exceptional precision and edge quality, ideal for intricate patterns, but it’s typically slower for thicker materials and has limitations in maximum thickness.

Waterjet cutting stands out with its ability to cut a wide range of material thicknesses without thermal distortion, providing a smooth edge finish, making it versatile for various industrial applications.

Edge Quality Variations

Although each cutting method has its merits, edge quality variations are significant when comparing plasma, laser, and waterjet cutting techniques.

When you consider the edge finish, plasma cutting typically results in a wider kerf width and a rougher edge due to a more pronounced heat-affected zone, especially on thicker materials.

In contrast, laser cutting excels with a superior edge finish, characterized by a narrower kerf width and minimal dross, ideal for high-precision tasks.

Waterjet cutting stands out with the cleanest edge quality, devoid of any heat-affected zones, making it best for thermally sensitive materials.

- Plasma: Wider kerf, rougher edge.

- Laser: Narrower kerf, superior edge.

- Waterjet: No heat effects, cleanest edge.

Cutting Speed Comparison

In evaluating cutting speed across plasma, laser, and waterjet technologies, you’ll find distinct advantages and trade-offs.

Plasma cutting, as a cutting technique, offers remarkable speed, operating at 15-200 inches per minute (IPM) for thin ferrous metals. It’s best for material types up to 50 mm thick.

Laser cutting, although slower than plasma, excels in precision, with tolerances of ±0.002 inches, making it ideal for thinner materials. It also provides cleaner edge finishes with minimal heat-affected zones.

Waterjet cutting, although the slowest at 2-10 IPM, accommodates a broader range of material types, including non-metals, and allows for intricate designs without thermal distortion.

It’s the preferred method when versatility and material thickness aren’t compromised by speed.

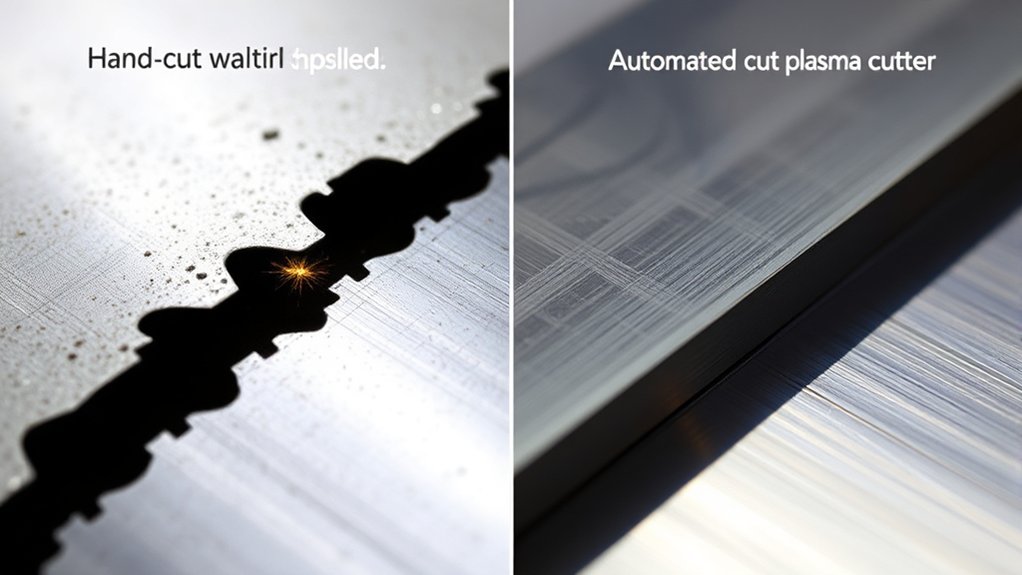

Hand vs. Automated Plasma Cutter Accuracy

Despite the operator’s skill playing a crucial role in hand plasma cutter accuracy, automated systems present a different set of advantages and challenges.

Hand cutting depends on your proficiency, enabling tolerances of around 1.6 mm (1/16-inch) when conditions are ideal. However, automated systems, especially entry-level CNC setups, offer normal tolerances of ±0.77 mm (±0.030-inch), which might appear less precise than skilled hand cutting.

Hand cutting offers tighter tolerances with skill, while entry-level CNC systems provide ±0.77 mm precision.

Yet, high-production plasma systems change the game by achieving tolerances from 0.25 to 0.51 mm (0.010 to 0.020 inches).

When comparing both methods, consider the following:

- Flexibility vs. Consistency: Hand cutting offers operational flexibility, while automated systems guarantee repeatability.

- Dependence on Components: Automated accuracy relies on plasma table quality, CNC controls, and torch height controls.

- Precision Levels: Advanced automated systems surpass hand cutting precision, enhancing production quality.

Ultimately, your choice depends on the specific demands of your cutting tasks.

Impact of Cutting Speed on Quality

When you adjust the cutting speed in plasma cutting operations, you directly influence the quality of the cut. Cutting speed is essential in determining edge consistency and the overall appearance of your workpiece. Higher speeds can narrow the kerf but often lead to dross formation, compromising edge quality.

Conversely, slower speeds can enhance the finish but risk excessive heat build-up, causing warping and distortion, especially in thin metal sheets.

For best results, you must consider material thickness; for example, a speed of 3500–4000 mm/min is ideal for 1mm stainless steel. Achieving a balance between cutting speed and amperage output is important. This balance minimizes the heat-affected zone and maintains high edge quality.

Adjusting these parameters guarantees that you achieve precise, clean cuts without compromising structural integrity. Ultimately, understanding the interplay between speed and quality will enhance your plasma cutting proficiency.

Selecting the Right Plasma Cutter for Your Needs

Achieving the perfect balance between cutting speed and quality underscores the importance of selecting the right plasma cutter for your projects.

Selecting the right plasma cutter is key to balancing cutting speed and quality for your projects.

When evaluating plasma cutter types, consider these critical factors:

1. Material Thickness: For thin metals (1-5mm), a handheld plasma cutter like the Hypertherm Viper 30 XP excels.

Medium-thickness metals (up to 25mm) require the Powermax 85 SYNC for its superior cutting speeds and duty cycle.

Thick plates (up to 50mm) demand an industrial-grade model like the MAX200.

2. Precision Needs: Entry-level CNC systems offer tolerances of ±0.77 mm, whereas high-production systems boast tolerances of 0.25 to 0.51 mm.

3. Gas Selection: For stainless steel and aluminum, an argon-hydrogen mixture provides maximum cutting capability.

Nitrogen is ideal for cleaner cuts and reduced oxidation.

Assess the duty cycle based on your application needs; a machine like the Viper 65 with a 100% duty cycle fits high-uptime tasks.

Safety Precautions for Plasma Cutting Operations

While operating a plasma cutter, ensuring safety is paramount due to the inherent risks involved. You must adhere to PPE requirements by donning safety glasses, heavy-duty gloves, and heat-resistant clothing to shield yourself from intense light and harmful fumes. Avoid bare-hand contact with freshly cut parts to prevent burns, and wear proper footwear against hot edges. Safety protocols for heavy lifting are essential, especially with thick metal plates, to mitigate injury risks from swaying loads.

Electrical safety is critical; plasma cutters like the Hypertherm Python 125, with its 175V output, necessitate strict precautions to minimize electrocution hazards. Review Safety Data Sheets (SDS) to understand the material-specific risks, including toxic fumes.

| Safety Aspect | Requirement | Risk Mitigated |

|---|---|---|

| PPE | Safety glasses, gloves, clothing | Burns, exposure |

| Handling | Proper footwear | Hot edges, falling items |

| Lifting | Follow lifting protocols | Injury from heavy loads |

| Electrical Safety | Adherence to guidelines | Electrocution |

| Material Hazards | Review SDS | Toxic fumes |

Tips for Improving Plasma Cutting Efficiency

To enhance plasma cutting efficiency, precise control of your equipment settings and work environment is essential. Start by fine-tuning the amperage to align with material thickness, ensuring ideal speed and cut quality. For instance, when cutting 1mm stainless steel, set the amperage between 15-25A.

Implement automatic torch height control to maintain a consistent torch-to-workpiece distance, which minimizes dross and enhances precision.

Consider these important steps:

- Secure Thin Metals: Prevent warping by fastening thin sheets securely to avoid distortion during cutting.

- Select Appropriate Consumables: Utilize FineCut consumables for a narrower kerf and stable arc, essential for achieving clean edges on thin materials.

- Engage in Real-world Testing: Conduct site visits and learn from existing users to gain insights into best practices and equipment capabilities, boosting operational efficiency.

Proper torch height, careful consumable selection, and strategic adjustments are critical for maximizing plasma cutting effectiveness.

Frequently Asked Questions

How Does Plasma Cutting Affect Metal Hardness?

Plasma cutting can increase metal hardness through rapid heating and cooling, leading to martensitic transformation. You might notice a hardened heat-affected zone (HAZ) near the cut edge, potentially affecting subsequent machining processes. Consider post-cutting treatments for uniformity.

Can Plasma Cutters Be Used Underwater?

Yes, you can use plasma cutters underwater, but guarantee safety considerations like proper insulation and grounding. Underwater applications require specialized equipment to prevent electrical hazards, maintain arc stability, and achieve efficient cutting in submerged conditions.

What Gases Are Used in Plasma Cutting?

You’ll use argon, oxygen, nitrogen, and hydrogen gases in plasma cutting. Argon enhances arc stability, oxygen increases cutting speed, nitrogen provides clean cuts, and hydrogen improves edge quality. Select gases based on material type and desired results.

How Do Temperature Changes Impact Plasma Cutting?

Temperature fluctuations symbolize the dance of heat and cold, impacting plasma cutting by causing thermal expansion. This can alter kerf width, affect dimensional accuracy, and lead to material warping, affecting cut quality and consistency. Stay vigilant.

Are There Environmental Concerns With Plasma Cutting?

Yes, you’ve got to take into account environmental concerns with plasma cutting. Guarantee efficient fume extraction to minimize airborne contaminants and implement proper waste disposal protocols for metal slags and residue to prevent environmental pollution and maintain workplace safety.

Conclusion

So, you’re diving into the world of plasma cutters with visions of precision and speed, but let’s face it, you’re really wrangling a fire-breathing dragon. It’s a beast that demands your attention—factors like setup, technique, and consumables are your knightly armor. Sure, you’ll battle wider kerfs and jagged edges, but who needs perfection when you’ve got post-processing? Just remember, this isn’t laser surgery; it’s more like wielding a medieval broadsword. Happy cutting!