You might think plasma cutter shield drag is just another technique. However, it is essential for achieving precise cuts on thin metals. Understanding when and how to use this method improves your cutting control and efficiency. The details of shield drag make a big difference in your projects. This is especially true for minimizing spatter and extending consumable life. Let us look at the specifics to improve your metalworking skills.

Quick Answer

- Shield drag involves resting the plasma torch directly on the metal surface using a specialized copper tip.

- It works best on thin metals at lower amperages, typically 40 amps or less.

- This technique eliminates the need to maintain a manual standoff distance.

- Using a drag tip improves control, reduces double arcing, and extends consumable life.

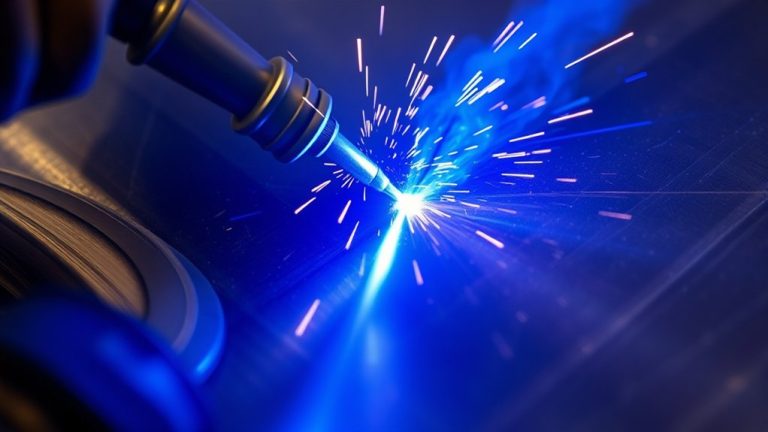

What Is a Plasma Cutter?

A plasma cutter is a powerful tool that uses compressed gas to create high-temperature plasma. This enables precise cuts through various metals.

You will find different plasma cutter types. These include air, nitrogen, and argon-based systems. Each type is tailored for specific applications.

The advantages of using a plasma cutter are numerous. You can achieve clean, accurate cuts on materials like copper, brass, aluminum, and steel. This makes it an incredibly versatile option for metalworking.

Modern plasma cutters feature a pilot arc mechanism. This streamlines the cutting process by generating plasma before it contacts the workpiece.

This efficiency enhances precision and reduces wear on consumables like tips and electrodes.

Understanding these elements empowers you to choose the right plasma cutter for your needs. This maximizes both performance and productivity in your projects.

How Do Plasma Cutters Work?

Understanding how plasma cutters operate is essential for achieving the best performance in metalworking. Plasma cutters utilize compressed gas that is ionized to create plasma. This plasma reaches temperatures up to 20,000°C (40,000°F) for effective metal cutting.

When you pull the trigger, gas flows through the machine and torch. It undergoes gas ionization and is forced through a high-speed vortex device. This generates a pilot arc that precedes contact with the metal, establishing a smooth shift to the cutting arc.

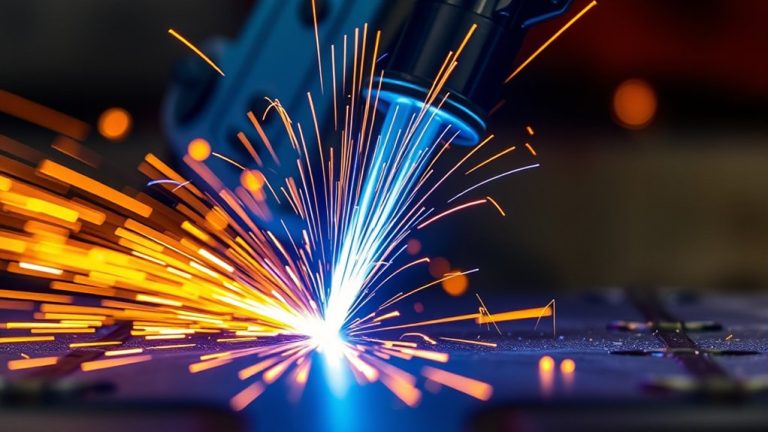

Employing proper cutting techniques is crucial. Dragging the torch directly on the surface enhances efficiency and minimizes the risk of double arcing. However, moving the torch too quickly can compromise cut quality. This often leads to undesirable lag lines angled back at 15 to 30 degrees.

Proper cutting techniques enhance efficiency and reduce double arcing, but excessive speed can compromise quality and lead to lag lines.

Mastering these operational principles will empower you to harness the plasma cutter’s full potential. This ensures precision and control in your metalworking endeavors.

What Is a Plasma Cutter Drag Tip?

A plasma cutter drag tip is a copper shield that you attach to the torch. It allows you to drag the torch directly on the metal surface.

This design enhances control and efficiency. It is particularly helpful when cutting thin materials because it eliminates double arcing and reduces spatter.

Drag Tip Functionality

When cutting thin metals with precision, you will likely rely on a drag tip. This copper shield is explicitly designed to attach to the end of the torch.

This design provides advantages by electrically isolating the nozzle from the workpiece. It allows you to drag the torch directly on metal surfaces. It effectively eliminates double arcing, enhancing operational ease and extending consumable lifespan by minimizing spatter.

However, drag tip limitations include the necessity for a steady hand. Moving too quickly can result in poor cut quality and angular lag lines.

Regular maintenance is essential. Materials like aluminum can wear tips down faster, requiring frequent cleaning.

Benefits of Drag Tips

Plasma cutter drag tips offer significant advantages for those working with thin metals. They enhance both precision and efficiency. By electrically isolating the nozzle from the workpiece, drag tips eliminate double arcing to improve cutting efficiency.

Here are the key benefits you will experience:

- Increased control and accuracy for detailed cuts

- Enhanced consumable lifespan due to reduced spatter and blowback

- Simplified operation for cutting straight lines and complex patterns

- Ideal performance at low amp rates for thin materials

- Reduced risk of damage to the workpiece for a clean finish

Recommended Amperage for Drag Cutting

Drag tips perform best at lower amperage settings. You will typically use them at 40 amps or below. Pushing a drag tip at higher amperages can cause the copper shield to melt or wear out prematurely. Always check your specific plasma cutter manual for the ideal amp settings for your drag shield.

Applications of Plasma Cutter Drag Tips

When cutting thin metals, you will find that plasma cutter drag tips offer a unique blend of precision and ease of use. They shine especially at low amperage rates.

These tips are tailored for tasks like sheet metal cutting. They allow you to achieve clean, accurate cuts with minimal effort. By dragging the torch directly on the metal surface, you enhance your control. This makes it easier to follow intricate designs without compromising quality.

The design of drag tips considerably reduces spatter and blowback. This helps extend the life of consumables and guarantees a smoother cutting experience.

To maximize effectiveness, maintain a steady speed during your cuts. Moving too quickly can lead to incomplete cuts or rough edges.

Utilizing drag tips for your projects empowers you to tackle complex patterns with confidence.

Differences Between Drag Tips and Nozzles

Understanding the differences between drag tips and nozzles is essential for optimizing your plasma cutting process.

Drag tips feature a unique design that allows direct contact with the workpiece. This enhances performance for thin materials. Standard nozzles require a standoff distance for effective cutting of thicker materials.

Functionality and Purpose

Both drag tips and standard nozzles guide the plasma arc during cutting. However, they differ markedly in functionality and application.

Drag tips offer specific advantages that enhance cutting precision, particularly on thinner materials. Here are some key advantages:

- Allows direct contact with the workpiece for ease of operation

- Features a copper shield to minimize double arcing

- Ideal for low amp rates, enabling straight line cuts

- Reduces spatter and blowback, prolonging consumable life

- Requires a steady hand and controlled speed for clean cuts

Design and Construction

The design and construction of drag tips and standard nozzles greatly influence their performance.

Drag tip design incorporates a copper shield that allows direct metal contact. This enhances user control while preventing double arcing. This construction material guarantees a more stable arc. It reduces spatter and blowback, which extends consumable life. Drag tips excel at low amp rates, making them ideal for intricate cuts on thin materials.

In contrast, standard nozzles necessitate a standoff distance from the workpiece. This limits precision and control if done manually. Their design lacks the direct engagement that drag tips offer, which can affect overall cut quality if your hand is unsteady.

Performance and Applications

When it comes to performance and applications, drag tips outperform standard nozzles in precision cutting tasks on thin metal. Their design enhances control and maneuverability.

Here are key advantages of using drag tips:

- Direct contact with the workpiece improves cutting precision.

- Copper shields prevent double arcing to extend consumable life.

- Reduced spatter and blowback lead to cleaner cuts.

- Lower amperage rates allow for intricate designs on sheet metal.

- Optimized for straight lines and patterns, ensuring high-quality results.

Techniques for Using Plasma Cutter Drag Tips

To achieve superior results with plasma cutter drag tips, you must maintain a steady movement speed. Keep the torch angled back ideally between 15 to 30 degrees. This position enhances control and accuracy when cutting thin metals at low amp rates.

Remember that safety precautions are essential. Always wear appropriate protective gear and ensure your workspace is clear.

Material selection plays a vital role. Drag tips excel on materials like aluminum, but they require regular cleaning to prevent excess wear.

Patience is paramount. Rushing can lead to poor cuts and damage your consumables.

Experimenting with varying cutting speeds and techniques will help you optimize performance.

Common Mistakes When Using Drag Tips

While many users find success with drag tips, several common mistakes can hinder performance. Recognizing these pitfalls is vital for maintaining efficiency and avoiding equipment damage.

- Moving the torch too quickly can result in incomplete cuts and rough edges.

- Applying excessive pressure may cause tip wear and disrupt arc transfer.

- Inconsistent dragging speed often leads to double arcing and increased spatter.

- Neglecting to keep the tip clean reduces arc stability and shortens consumable lifespan.

- Using a drag tip on metals thicker than recommended results in poor penetration and uneven cuts.

Maintenance Tips for Plasma Cutter Drag Tips

Understanding the significance of proper maintenance for plasma cutter drag tips can considerably enhance their performance and longevity.

Proper maintenance of plasma cutter drag tips is crucial for optimizing performance and extending their lifespan.

Regularly inspect and clean your drag tip to prevent the buildup of spatter and debris. Use a soft brush or compressed air to clear accumulated material from the copper shield and nozzle area. This ensures ideal function.

Replace the drag tip when you notice wear signs, like increased spatter or uneven cuts. Avoid using excessive force when installing or removing the drag tip to protect the copper shield and nozzle.

Maintaining proper torch settings and cutting techniques is essential. This minimizes unnecessary wear while maximizing the drag tip’s efficiency.

Frequently Asked Questions

What Types of Metals Can I Cut Using a Drag Shield?

You can cut various metals using a drag shield, including mild steel, stainless steel, and aluminum. Metal selection impacts your results. Employing proper drag techniques guarantees clean, precise cuts without excessive heat or distortion.

How Do I Know When to Replace My Drag Tip?

You will know to replace your drag tip when you notice inconsistent cuts, excessive wear, or damage to the hole. Regular maintenance guarantees maximum performance. Inspect your shield frequently and change it as needed to maintain efficiency.

Can I Use Drag Tips for Thin Materials?

Yes, drag tips are specifically designed for thin materials. By setting the correct low amperage and maintaining a steady drag technique, you can easily create clean, precise cuts without warping the metal.

What Safety Gear Should I Wear While Plasma Cutting?

You should wear personal protective equipment like a shade-appropriate welding helmet or glasses, heavy gloves, and flame-resistant clothing. Safety equipment ensures you are protected from sparks, heat, and harmful UV radiation.

How Can I Improve My Plasma Cutting Technique?

To sharpen your skills, focus on steady hand movements. Maintain a consistent speed and a proper distance from the material if you are not using a drag tip. Experiment with scrap metal to discover your own rhythm before starting a final project.

Conclusion

Incorporating plasma cutter shield drag techniques into your workflow can substantially enhance your cutting precision. By mastering these methods, you will minimize issues like double arcing and spatter while extending the life of your consumables. Remember that practice makes perfect. The more you refine your technique, the better your results will be. Embrace the drag method to help transform your metalwork into clean, accurate cuts with ease.