If you run a 40‑amp plasma cutter, you’ll face a trade‑off between clean cuts and severance. Expect clean, low-dross cuts to around 1/4 in (6 mm), with recommended speeds and standoff per manufacturer specs. You can sever close to 1 in (25 mm), but with heavy dross, bevel, and slow travel. Duty cycle, arc start type, and consumables further shape results—so you’ll want to match technique and machine to your thickest routine material next.

Clean Cut Vs Severance Cut: Key Definitions

Although both are plasma cuts, “clean cut” and “severance cut” denote distinct performance levels at a given amperage and material thickness.

You define a clean cut by a smooth edge finish and minimal dross, achieved when your cutting techniques match the machine’s ideal window—commonly around a recommended thickness, e.g., 3/8 inch on certain 40 A units. You’ll run higher travel speeds, maintain arc stability, and minimize secondary processing. This aligns with quality metrics for dimensional accuracy and cosmetic requirements.

By contrast, a severance cut occurs as you approach maximum machine capacity—often about 1/2 inch on thicker stock. Expect a rougher edge finish, heavier dross, slower travel speeds, and increased post-cut cleanup. Severance prioritizes part separation over precision.

You should classify jobs by required tolerance and finish: use clean cuts for precision and aesthetic surfaces; reserve severance for rough sizing.

Properly differentiating modes informs process parameters, consumable life, and downstream fabrication time.

Recommended Thickness for 40 Amp Plasma Cutters

You should target a clean cut capacity of about 1/4 in at 40 A, typically sustaining 20–40 ipm with minimal dross when standoff is controlled.

For severance, plan a practical limit near 1 in, understanding the edge will be rough and require post-processing.

Use these thresholds as your process window to set parameters, qualify procedures, and manage consumable life.

Clean Cut Capacity

When dialing in a 40 amp plasma cutter for quality, prioritize its clean cut capacity: up to 1/4 inch mild steel with smooth edges and minimal dross at roughly 20–40 inches per minute.

You’ll see clean cut advantages in dimensional accuracy, consistent kerf, and parts that drop free with minimal pry force—accelerating throughput and reducing post-cut abrasives before welding.

Maintain travel speed within the 20–40 ipm window, set amperage at 40 A with correct standoff, and use dry, high-flow air to control dross and bevel. These parameters deliver repeatable, production-grade results on moderate thicknesses.

By contrast, severance disadvantages include slower travel, rough edges, and significant cleanup, undermining precision workflows.

Selecting a machine rated for true 1/4-inch clean cuts maximizes efficiency and reliability.

Severance Thickness Limit

Despite a 40 A plasma cutter’s 1/4-inch clean cut rating, its severance thickness typically extends to about 1 inch—at the cost of speed and quality.

At severance cutting, expect slow travel rates to maintain full penetration, increased dross, wider kerf, and a rough edge profile that demands post-cut grinding. You’ll also see more taper and warping risk due to higher heat input.

Plan for plasma limitations: use fresh consumables, maintain correct standoff, and aim the arc slightly forward to clear molten metal.

Reduce speed methodically until you achieve continuous pierce-through without arc-out. For production-grade results on 3/8–1 inch plate, step up in amperage; a 40 A unit is a contingency tool at that thickness.

Match machine capacity to intended duty cycle and finish requirements.

Cut Quality, Dross, and Post-Cut Cleanup

Cut quality hinges on amperage, thickness, and travel speed, with a 40 A plasma cutter delivering clean cuts up to 1/4 in and severance-quality cuts around 1/2 in. To consistently meet that standard, apply disciplined cutting techniques and maintenance practices.

Maintain a correct standoff with a drag shield or height control to keep arc constriction stable, reduce bevel, and minimize dross.

On materials ≤1/4 in, you’ll see smooth kerf walls and light, friable dross that snaps off with a chipping hammer or wire brush. Near severance (~1/2 in), expect irregular kerf geometry, more top spatter, and heavy, adhered dross that requires grinding or aggressive brushing.

Verify torch alignment, electrode/nozzle condition, and gas flow; worn consumables or poor airflow increase dross accumulation. Keep consumables within manufacturer wear limits and inspect after each cut series.

For post-cut cleanup, sequence: slag knock-off, wire brush, then flap disc as needed, preserving dimensional tolerance.

Cutting Speed and Its Impact on Results

You’ll see a direct IPM-to-quality relationship: at 40 A, expect 20–40 IPM to produce clean kerfs, while slower travel increases dross and taper.

You must respect thickness-driven speed limits—reduce speed as material approaches clean cut and severance thresholds to maintain full penetration.

Don’t exceed recommended IPM, or you’ll degrade finish and accelerate consumable wear; go too slow, and you’ll stack dross and heat-affected distortion.

IPM Vs Cut Quality

When you dial in cutting speed, measured in inches per minute (IPM), you directly set the trade-off between throughput and edge quality.

With disciplined cutting techniques and speed optimization, higher IPM typically produces cleaner edges and minimal dross on 40‑amp systems—e.g., around 20 IPM on 3/8-inch plate can yield a clean cut.

Slowing down increases penetration margin but shifts you toward severance: rougher kerf, more dross, and heat-affected taper.

Near the severance limit—such as 1 inch at 40 amps—you must drop speed substantially to maintain full penetration, accepting downgraded finish.

Control standoff precisely: too low at high speed blows molten metal onto the part; too high widens kerf.

Balance IPM, standoff, and amperage to meet target cut quality.

Thickness-Driven Speed Limits

Although amperage sets the ceiling, material thickness dictates your workable speed window on a 40‑amp plasma. As thickness increases, you must lower inches‑per‑minute to maintain full penetration and kerf straightness.

For clean cuts near the recommended thickness, target 20–40 IPM; this range maximizes speed efficiency while preserving edge fidelity and minimal bevel. As you approach severance capacity, reduce travel speed to sustain the arc column and avoid incomplete cut-through, accepting rougher edges and longer cycle time.

Exceeding the speed limit for a given thickness produces undercut, unpierced sections, and excessive dross. Undershooting speed can widen kerf and distort geometry.

Validate material compatibility by referencing the machine’s cut charts for each alloy and thickness, then verify with test coupons, observing arc lag, drag lines, and kerf angle to confirm efficient speed.

Dross at Slower Travel

As travel speed drops on a 40‑amp plasma, heat input rises and dross increases, especially near severance thickness. You’re pushing more thermal energy into the kerf, so molten metal solidifies on the edge instead of ejecting cleanly.

Below the ideal 20 ipm window, cut quality degrades: edges roughen, bevel increases, and post-cut cleanup grows. For dross reduction, hold a stable travel speed matched to thickness and amperage; don’t chase arc stability by slowing down.

- Verify cut speed: target ~20 ipm for clean cuts; slower speeds trend toward severance with heavy dross.

- Monitor arc lag angle; increasing lag indicates insufficient travel speed and excess heat input.

- Optimize standoff and gas flow to maintain coherent jet and dross ejection.

- Validate edges: measure bevel and recast layer; adjust speed before increasing amperage.

Selecting a Machine for Your Thickest Regular Material

Start by matching the machine’s clean-cut rating to the thickest material you regularly process, then add headroom.

Use material thickness and machine ratings as primary selectors. If you cut 1/4 in plate often, a unit with a 1/4 in clean-cut spec meets baseline quality, but you’ll want a step up to preserve edge integrity at production speeds and to accommodate occasional severance.

Differentiate clean cut vs severance. Clean cut defines repeatable edge quality, minimal dross, and perpendicularity; severance is an upper limit with acceptable but degraded results. A 1/4 in clean-cut machine can sever up to 1/2 in, but expect more dross and taper.

For general shops, a 3/8 in clean-cut class (e.g., Tomahawk 30) offers balanced capacity. For heavier duty, a 3/4 in clean-cut class (e.g., Tomahawk 45) provides robust throughput and future margin.

Select the smallest machine that exceeds your regular thickness to maintain quality, duty cycle, and process stability.

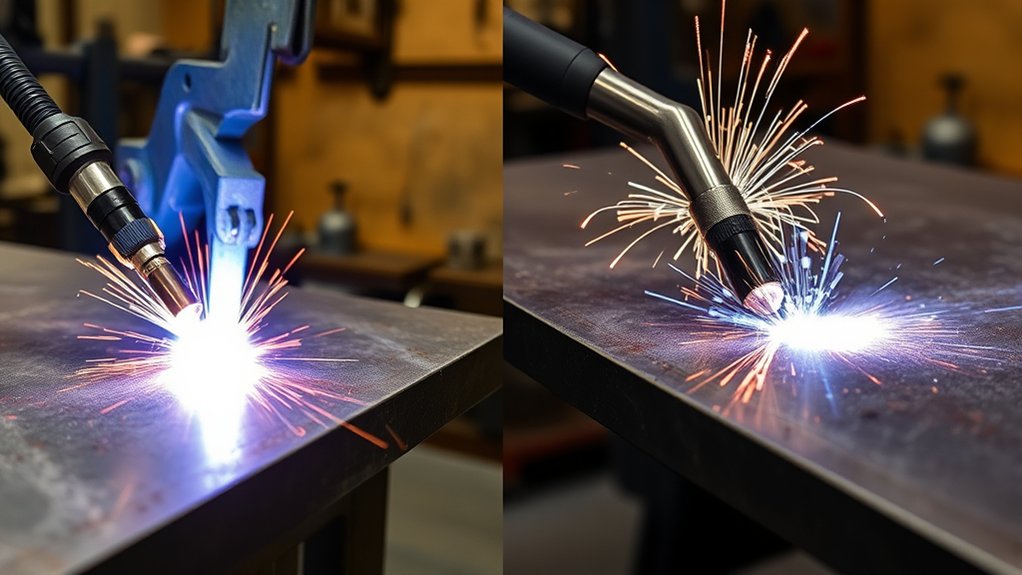

Techniques: Drag Cutting, Standoff, and Ignition Types

With machine capacity matched to your typical thickness, cut technique determines whether you hold clean-cut specs in practice. For sub‑40 A systems, drag cutting keeps the shield on the plate, stabilizes arc length, and often reduces bevel and dross on thin to mid‑gauge.

Matched machine capacity is just the start—technique locks in clean cuts on thin to mid‑gauge.

Above 40 A, adopt a controlled standoff to protect the nozzle, maintain kerf fidelity, and limit top-edge rounding. Your choice of ignition methods also affects reliability and CNC safety.

- Set mode by amperage: use drag cutting ≤40 A; use a calibrated standoff >40 A to limit nozzle wash and double-arcing.

- Control stand-off to ±0.5 mm with a height control; verify arc voltage correlates to cut charts to maintain straight, oxides-free edges.

- Prefer Short Circuit starting on CNC tables to reduce EMI risk; reserve HF ignition for isolated, shielded systems.

- Benchmark quality: track dross grams per meter and Ra on coupons; adjust travel speed, standoff, and ignition to meet clean-cut targets.

Plasma Vs Oxy-Fuel for Occasional Heavy Cuts

Though both processes can reach thick plate, you’ll complete occasional heavy cuts faster and cleaner with plasma, especially around 40 A systems that can sever to ~1 in while holding lower dross and tighter kerf than oxy‑fuel at comparable duty.

You gain plasma efficiency from higher travel speeds, minimal preheat, and consistent arc stability, which improves edge quality and reduces post‑process grinding. You’ll also avoid gas handling; no bottles lowers consumable cost, site clutter, and flammable‑gas risk.

Oxy‑fuel still has value on very thick stock and can deliver straighter edges on substantial sections, but oxy fuel limitations include slower cut rates, preheat delays, slag generation, and a messier, ventilated work zone.

When budget restricts premium plasma gear, oxy‑fuel can be a practical fallback. For occasional heavy cuts near the 1 in threshold, a competent 40 A inverter with proper standoff and dry air typically meets tolerance targets faster and safer than oxy‑fuel.

Frequently Asked Questions

What Gases Work Best With a 40A Cutter for Various Alloys?

Use air for carbon steel; oxygen offers faster speeds with proper oxygen compatibility. Choose nitrogen for stainless and aluminum; argon mixtures (argon-hydrogen or argon-nitrogen) improve edge quality. Verify torch ratings, consumables, and duty cycle; follow ISO plasma-cutting gas standards.

How Does Ambient Temperature Affect Cut Performance and Duty Cycle?

Ambient temperature dramatically swings performance: in heat, duty cycle plunges, arc stability degrades, and you slow cutting speed; in cold, duty cycle improves but starts stiffen. You’ll tune amperage, gas flow, and standoff by material type and manufacturer specs.

Which Consumables Extend Tip Life at Near-Severance Thickness?

Use silver‑alloy or hafnium‑inserted tip materials with matched swirl rings; they resist erosion near severance. You’ll extend tip life by reducing cutting speed 10–20%, maintaining 65–75 psi dry air, correct standoff, and adhering to OEM amperage charts.

Can CNC Tables Improve Edge Squareness at 40 Amps?

Yes. You’ll improve edge squareness with CNC precision by stabilizing speed, standoff, and torch perpendicularity. Use height control, fine-cut consumables, verified kerf compensation, and dry air. Expect measurable edge quality gains per ISO 9013; optimize feed around manufacturer’s cut charts.

How Do Power Supply Voltage Drops Impact Cut Quality?

Let’s avoid unpleasant surprises: voltage drops degrade cut quality by reducing voltage stability, altering arc length, and causing dross, taper, and micro-voids. You’ll see slower speeds, erratic kerf, and poor repeatability; maintain regulated supply, short leads, and monitor under-load voltage.

Conclusion

You’ve seen the line in the sand: a 40 A plasma gives clean, low‑dross cuts to 1/4 in, and severance up to ~1 in with heavy cleanup. Match thickness to duty cycle, standoff, and travel speed to hit spec. Choose the machine for your thickest routine job, not the rare outlier. For occasional heavy stock, consider oxy‑fuel. Treat process variables like dials on a safe—set them right, and your cut quality clicks into repeatable, standards‑grade results.