Coincidentally, your choice between 40A and 60A often aligns with plate thickness and the cut spec you’re chasing. At 40A, you’ll get tighter geometry on ≤3/8 in material with 10–130 ipm, minimal distortion, and manageable kerf. Step up to 60A for thicker stock, faster feeds up to ~200 ipm, cleaner edges, and less dross—if you tune standoff, gas flow, and consumables to maintain arc stability. But there’s a catch you’ll want to account for next.

Material Thickness and Recommended Amperage

Although plasma cutters can pierce thicker stock, you should match amperage to material thickness for clean, efficient cuts: about 20 A for up to 1/8″, add roughly 10 A for each additional 1/8″, and target 45 A for 1/4″ plates to balance speed and kerf quality.

Use these amperage recommendations across common material types—mild steel, stainless, and aluminum—while adjusting for thermal conductivity and melting point. For 3/16″, plan ~30 A; for 1/4″, hold 45 A; for 3/8″, 40 A performs effectively with controlled kerf width and minimal bevel.

Plan ~30 A for 3/16″, 45 A for 1/4″, and 40 A for 3/8″ cuts.

At 1/2″, 50 A maintains cut continuity and acceptable edge quality.

Monitor arc stability, slag formation, and heat-affected zone to verify parameter fit. If you see dross on the bottom edge, increase amperage incrementally or reduce travel speed; if top-edge rounding or warpage appears, back off current.

Confirm consumable ratings and duty cycle at the chosen setting, and verify nozzle size aligns with current to maintain columnar arc integrity.

Cutting Speed Tradeoffs at 40A Vs 60A

When you weigh 40A against 60A, treat cutting speed and edge quality as a controlled trade. You’ll see higher throughput at 60A, especially on thicker mild steel, but you must account for added heat load and post-cut cleanup. At 40A, cutting speed typically spans 10–130 ipm, and you’ll hold tighter geometry with less distortion. Jumping to higher amperage settings increases penetration and speed, yet it can widen kerf and build dross if you outrun the jet’s energy balance.

| Material (mild steel) | 40A typical speed | 60A typical speed |

|---|---|---|

| 1/8 in (3 mm) | 90–130 ipm | 140–200 ipm |

| 1/4 in (6 mm) | 35–70 ipm | 80–120 ipm |

| 3/8 in (10 mm) | 10–30 ipm | 40–70 ipm |

Set your target cutting speed, then back-calc amperage settings to meet duty cycle and thermal input limits. If the arc outruns the puddle (streaking, top spatter), slow feed or drop to 40A. If lag lines trail heavily, increase speed or step up to 60A.

Cut Quality, Kerf, and Bevel Considerations

Even as duty cycle and speed shape your process window, cut quality, kerf, and bevel largely hinge on amperage-to-thickness matching and travel speed control.

At identical thickness, 60 amps typically improves cut quality factors: cleaner edges, reduced dross, and more consistent face angularity versus 40 amps.

At the same thickness, 60 amps yields cleaner edges, less dross, and steadier face angularity than 40.

On 1/4 inch steel, 60 amps sustains energy density, producing a narrower kerf width and lower slag accumulation; 40 amps often widens kerf and increases post-cut cleanup.

Expect bevel angles in the 3–8° range at both settings, but you’ll see tighter tolerances at 60 amps due to deeper energy penetration and better jet momentum.

Maintain higher traverse rates at 60 amps to limit heat input and warping; slower 40-amp passes drive heat deeper, exaggerating bevel and hardness-affected zones.

For dimensional accuracy and fit-up, choose amperage that aligns with section thickness, then validate by inspecting top-edge rounding, dross type (top vs bottom), kerf symmetry, and measured bevel.

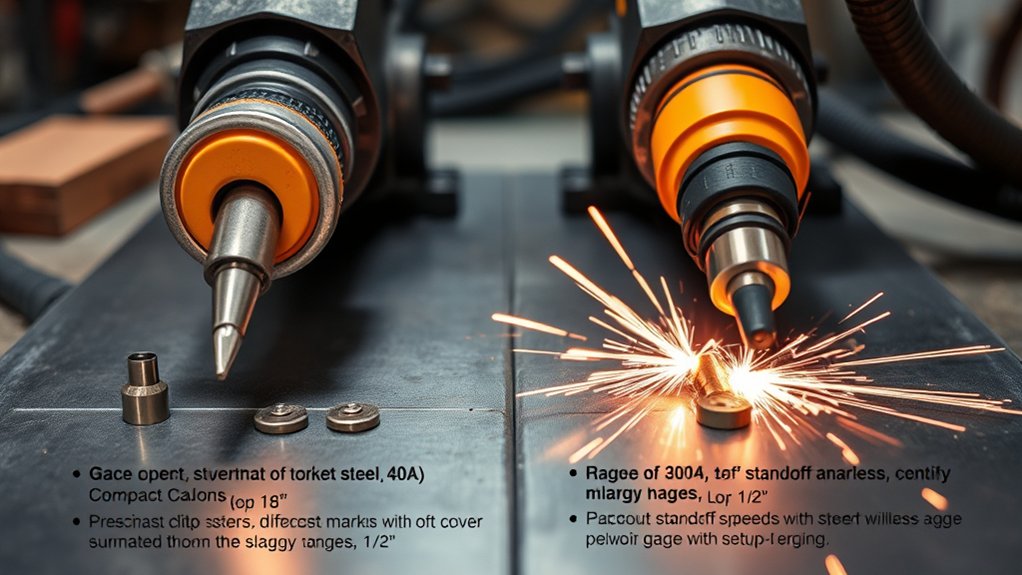

Setup, Tip Selection, and Standoff for Best Results

Foundation matters: start by clamping your work lead to bright, bare metal to minimize circuit resistance and stabilize arc voltage, then match consumables to the job.

Verify the ground clamp is secure and free of paint, rust, or mill scale; poor contact increases arc instability and dross. Select tip orifice size per material thickness and amperage: use 40‑amp tips for ≤3/8 in, shift to 60‑amp tips for thicker stock to maintain kerf control and straight edges. Wrong tips enlarge kerf and degrade angularity.

Hold a consistent standoff of 1/16–1/8 in using a drag shield or height control; too close overheats the tip, too high widens the arc and bevels the cut.

Calibrate torch height routinely to keep arc voltage and standoff within spec. Set current to load: 40 A for ≤3/8 in, 60 A above that for speed and quality.

Perform tip maintenance—inspect orifice wear, replace electrodes/nozzles on schedule.

Safety, Duty Cycle, and Power/Air Requirements

With setup dialed, cutting safely at 40 vs 60 amps hinges on respecting duty cycle, power capacity, and clean, dry air. You’ll cut 3/8″ at 40 A and up to 1/2″ at 60 A, but the 60 A duty cycle runs shorter, so schedule cool-downs to avoid thermal trips. Hold your air at 75–85 psi with filtration/drying to prevent dross and arc instability. At 60 A, expect more heat input; increase travel speed and maintain standoff to limit distortion. Wear full safety gear and meet ventilation requirements to control ozone, fumes, and hot slag risks.

| Parameter | 40 Amps | 60 Amps |

|---|---|---|

| Typical thickness | ≤ 3/8″ | ≤ 1/2″ |

| Duty cycle (relative) | Longer | Shorter |

| Air pressure (psi) | 75–85 (dry) | 75–85 (dry) |

| Quality adjustments | Moderate speed | Higher speed, tighter standoff |

Power notes: verify circuit capacity and breaker sizing per manufacturer specs; higher amperage increases line load. Always test-cut and log settings for repeatability.

Frequently Asked Questions

How Do 40A Vs 60A Affect Consumable Life and Operating Cost?

You’ll see longer consumable life at 40A due to reduced thermal load; 60A accelerates consumable wear. However, higher amperage improves operating efficiency per inch cut. Net operating cost depends on duty cycle, pierce count, gas quality, and arc-on time.

Can CNC Table Settings Differ From Hand-Cutting at the Same Amperage?

Yes, they can—shocking, right? You’ll set higher travel speed, tighter kerf compensation, arc-voltage height control, and lead-ins/outs on CNC precision. Hand cut variability forces slower speed, wider kerf allowances, looser torch standoff, and conservative pierce delays per standards.

What Edge Preparation Is Needed for Welding After 40A Vs 60A Cuts?

You’ll need stricter edge preparation after 60 A cuts: remove thicker oxide, dross, and nitrides, re-establish bevel/land per WPS, and verify welding readiness per AWS D1.1. At 40 A, lighter grinding, minimal bevel correction, and cleanliness suffice.

How Do Ambient Temperature and Humidity Impact Cut Consistency?

Ambient temperature and humidity affect cut consistency by altering arc stability, gas density, and moisture content. You’ll maintain cut quality by conditioning environmental factors: keep 10–35°C, <60% RH, dry air supply, preheat cold plate, and follow ISO 9013 monitoring.

Are There Noise and Fume Differences Between 40A and 60A Cuts?

Yes. You’ll encounter higher noise levels and fume emissions at 60A due to greater arc energy and gas flow. Use local exhaust per ISO 21904, maintain <85 dBA per OSHA/EN limits, and apply fume extraction-rated consumables.

Conclusion

You’ll pick amperage by thickness, speed, and quality targets. At 3/8 in, 40A hits 30–60 ipm with tight geometry and minimal distortion; at 1/2 in, 60A runs 80–150 ipm with cleaner kerf and less dross. Example: a fab shop cutting ASTM A36 brackets cut cycle time 32% by moving 3/8–1/2 in stock to 60A, using 1.0 mm tips, 0.06 in standoff, 90–110 psi dry air, and verifying arc voltage. Match duty cycle and air delivery to spec.