Most operators don’t realize aluminum needs higher arc voltage than steel at the same thickness to hold a stable kerf. You’ll tune amperage to thickness, match nozzle size to flow, and set a tight standoff to control bevel and dross. Gas choice shifts edge oxide and wash—air, nitrogen, or mixed systems change finish and speed. With the right cut chart, you’ll push faster without warping. Here’s how to set it up step by step.

Can You Plasma Cut Aluminum?

Absolutely—plasma cutting can slice aluminum effectively when you control variables precisely. You’ll get clean edges on aluminum alloys by matching amperage, cutting speed, plasma gas, and torch height to the job.

With proper setup, you can achieve minimal dross and a narrow heat-affected zone, especially on gauges up to roughly 1/4 inch. Monitor amperage and arc stability continuously; insufficient current leaves uncut webs, while excess heat enlarges the kerf and increases warpage risk.

Achieve minimal dross and narrow HAZ on ≤1/4-inch aluminum by balancing amperage and stabilizing the arc.

Use data-driven gas choices: an argon-hydrogen mix or nitrogen improves edge quality and reduces oxidation on thicker materials; avoid oxygen because it degrades surface finish on aluminum.

Target cutting speeds of 10–15 ipm for manual passes to maintain penetration and edge fidelity, and leverage automated systems for higher speeds to boost productivity while holding tolerance.

Maintain consistent torch height to stabilize arc voltage and heat input, ensuring uniform edge geometry across different aluminum alloys and part geometries.

Thickness Ranges and Recommended Power

For most aluminum jobs, match thickness to amperage, speed, and standoff to control kerf and dross. Use these ranges as your baseline and make settings adjustments from cut feedback.

For sheets up to 1/4 inch, run 20–30 amps; keep travel fast and standoff tight to minimize heat input and improve edge finishing. Watch for a narrow, even kerf and minimal backside spatter.

For 1/4 to 1/2 inch, step to 40–50 amps and increase cutting speed to reduce heat soak and warping. Maintain consistent arc height; if dross forms, either raise speed slightly or increase amperage within the band. Verify full penetration by a uniform, bright cut face.

Over 1/2 inch, target 50–80 amps with slower travel to secure complete penetration and stable arc behavior. Preheat thick sections to lower energy demand and stabilize the kerf.

Keep standoff precise; adjust speed until slag releases easily and edges require minimal post-cut edge finishing.

Gas Selection for Clean Edges

You’ll choose plasma and shield gases as a matched system: nitrogen plasma with water shield for <5 mm, argon‑hydrogen plasma for >12 mm, and compressed air only when cost outweighs edge quality.

Data shows nitrogen in high‑definition systems yields cleaner edges than air, while oxygen is unsuitable due to oxidation and dross.

Set flow rates to spec; correct mixes and calibrated flow stabilize the arc column and minimize oxide film on cut faces.

Plasma vs. Shield Gas

Although any plasma cutter can pierce aluminum, clean edges depend on the right gas strategy: plasma gas selection plus shield gas control.

Treat plasma gas as the arc’s chemistry and shield gas as the thermal/atmospheric manager. For plasma efficiency and gas purity, choose nitrogen over air; it limits oxidation and dross, improving consistency.

Air remains economical but compromises finish on aluminum due to oxide tint and rougher kerfs.

When thickness and finish demands rise, shift to argon–hydrogen as the plasma gas above 12 mm for tighter arc energy and superior edge quality.

Pair it with a shield—water mist or CO2—to cool the kerf, sweep oxygen, and stabilize the jet.

Calibrate flows: insufficient flow destabilizes the arc; ideal flow sharpens edges and reduces rework.

Best Mixes by Thickness

When edge quality matters, match plasma and shield gases to aluminum thickness to control arc chemistry, heat input, and oxidation.

For sub-5 mm sheet, run nitrogen plasma with a water shield. You’ll get high cut quality, minimal dross, and strong gas efficiency because nitrogen stabilizes the arc while water quenches oxides.

From 5–12 mm, switch to an argon–hydrogen plasma (typically 65–35 or 70–30). The hydrogen improves heat transfer and oxide disruption, producing smoother edges and lower bevel.

Beyond 12 mm, pair higher amperage with the same argon–hydrogen blend to secure full penetration and clean kerfs.

Air plasma is economical for thin stock, but expect oxidation and rougher edges.

Verify flows and pressures; correct gas selection reduces rework and boosts throughput.

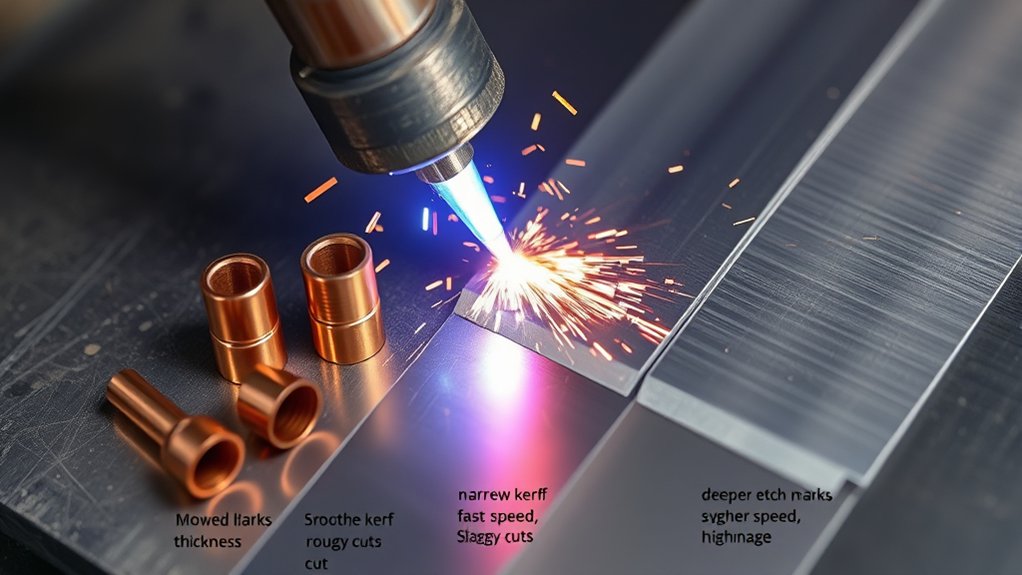

Nozzle Size, Amperage, and Line Speed

Even small changes to nozzle size, amperage, and line speed shift cut quality and productivity, so treat them as a linked set of controls.

Use targeted nozzle adjustments and quantify amperage impacts to maintain a stable kerf and smooth edge. For 1/4-inch aluminum, a 1.0 mm nozzle at 45 A is a proven baseline; step down in nozzle size and amps for thin sheet, and step up in amps (40 A or more) as thickness increases to hold speed and minimize dross.

Maintain 35–40 ipm to keep the arc energetic without washing the edge.

1) Fit-for-purpose nozzle selection:

– 1.0 mm for 1/4-inch at 45 A; smaller orifices tighten the jet on thin stock, larger supports higher flow on thick parts.

2) Amperage-speed coupling:

– Increase amps to preserve 35–40 ipm on thicker aluminum; reduce amps on thin to avoid overburn and taper.

3) Control via monitoring:

– Log nozzle wear, verify amperage output, and track ipm to sustain edge quality over long runs.

Torch Height, Voltage, and Bevel Control

Set torch height and voltage as primary controls for bevel and edge quality, then lock speed and angle to stabilize the kerf.

Begin with torch calibration: set cutting height to the manufacturer’s spec and keep pierce height at 1.5–2× that value to protect consumables. Use an automatic torch height control if available to hold a constant standoff; height drift produces inconsistent bevel and rough edges.

Apply voltage adjustments to tune bevel: increasing voltage widens the arc and steepens bevel angle; decreasing voltage tightens the arc for a squarer edge. Pair voltage with amperage by thickness—higher amperage for thicker aluminum guarantees full penetration without over-drossing.

Increase voltage to widen the arc and steepen bevel; lower it for squarer edges. Match amperage to aluminum thickness.

Maintain a perpendicular torch for square edges unless intentional bevel is required; small angle changes can bias taper.

Once height and voltage are correct, fix travel speed to prevent kerf wander and dross. Validate with cut tests: measure top-to-bottom taper, adjust height ±0.1 mm and voltage in small increments to converge on target bevel.

Piercing Technique and Consumable Life

Dial in a disciplined pierce routine to protect the torch and stretch consumable life. Set pierce height at 1.5–2.0× cutting height to achieve piercing precision and keep the molten pit from climbing into the nozzle.

Hold a consistent torch-to-material distance until the jet stabilizes, then shift to cut height. Use argon–hydrogen on thicker aluminum to lower viscosity of the melt and evacuate slag faster, improving consumable longevity and edge consistency.

Inspect nozzles and electrodes routinely; swap at first signs of orifice ovality, double-arc marks, or voltage drift to prevent cascading wear and poor kerf geometry.

- Calculate heights: if cut height is 0.060 in (1.5 mm), pierce at 0.090–0.120 in (2.3–3.0 mm); delay motion until full pierce confirmation.

- Control sequence: pierce → clear spatter dwell → descend to cut height → advance; keep THC disabled during pierce.

- Track life: log pierces per nozzle, record arc voltage and cut face quality, replace on threshold, not failure.

Managing Dross and Surface Oxidation

Although aluminum sheds heat quickly, you’ll control dross and oxidation by tuning process variables and gas chemistry with tight tolerances.

Target dross reduction by setting speed, amperage, and torch height to keep the arc energy focused at the kerf. For manual cutting, verify travel speed near 10–15 ipm; too slow increases bottom dross and bevel, while too fast leaves uncut ligaments. Set amperage to match thickness, then refine height to maintain consistent arc voltage and minimal top spatter.

For oxidation prevention, select nitrogen as the plasma gas rather than shop air; nitrogen limits surface oxides and yields cleaner edges with less secondary cleanup.

Track consumable condition—nozzles and electrodes with orifice erosion destabilize the jet, increasing dross and roughness. Replace on schedule, not only on failure.

After cutting, remove residuals using scrapers or wire brushes to achieve a uniform finish and verify that parameter adjustments are delivering measurable improvements.

Water Tables, Water Shields, and Safety

You’ll assess underwater cutting risks by avoiding H-35/H-2 mixes and controlling water height to prevent hydrogen accumulation and explosive conditions.

You’ll leverage water shields and water tables to cut noise, dust, and UV exposure while stabilizing arc behavior and edge quality.

You’ll manage hydrogen with verified gas selections, measured water-to-plate spacing, and vendor-proven table solutions to sustain safe, repeatable performance.

Underwater Cutting Risks

While water tables and water shields cut noise, dust, and UV exposure during aluminum plasma cutting, they introduce hydrogen-related explosion hazards that demand strict control.

You must quantify hydrogen risks and implement rigorous explosion prevention. Avoid H-35 and H-2 underwater; they elevate dissolved hydrogen that can outgas and ignite.

Keep water depth stable to quench plume without submerging arc zones that trap bubbles. Remove cut parts immediately to prevent hydrogen pockets under plates and in kerfs. Use compatible gases and continuously vent or skim the table to avoid accumulation.

1) Gas selection: Replace H-35/H-2 with low-hydrogen blends; verify supplier specs and dew point.

2) Water management: Maintain level ±6 mm; circulate and aerate; monitor dissolved gas.

3) Workflow controls: Prompt part retrieval; enforce hot-work permits; log checks.

Water Shield Benefits

Even with rigorous ventilation, a properly managed water table or water shield measurably cuts noise (often 6–12 dB), airborne particulates, and UV exposure at the source, improving operator safety and compliance.

You’ll see immediate water table advantages: the fluid absorbs arc glare, traps fines, and quenches slag, elevating cutting safety while protecting adjacent equipment.

Set water height to just touch or submerge the plate per your process window; this maximizes convective cooling, limits heat-affected zones, and stabilizes kerf geometry for cleaner edges.

Use water shields to strip heat from the jet, minimizing distortion on thin aluminum and maintaining squareness.

Maintain flow to sweep dross into trays for faster cleanup. Control water chemistry and cleanliness to prevent foaming and residue.

Verify ventilation over the table to evacuate captured aerosols.

Hydrogen Management Tips

Because plasma-cutting aluminum can generate hydrogen—especially underwater—treat water tables and water shields as controlled systems with defined gas, water, and handling protocols.

Avoid H-35 and H-2; select non-hydrogen-producing gases to retain sound/dust suppression without elevating explosion risk. Control water level to just contact the plate underside or slightly submerge the arc zone, then ventilate the plenum to purge trapped gases.

Use hydrogen detection and continuous gas monitoring near the table and exhaust outlets. Remove cut parts immediately to prevent hydrogen accumulation in cavities.

- Specify process limits: gas type, water height (±3 mm), dwell times, and mandatory part removal within 60 seconds.

- Engineer airflow: minimum 200–300 cfm across the table, interlocked fans, and spark-proof ducting.

- Verify: pre-shift leak checks, detector bump-tests, and logged purge intervals.

Design, Fixturing, and Heat Management

Although aluminum cuts fast, your design, fixturing, and heat management choices determine whether the part stays accurate or warps.

Start with design optimization: favor smooth, continuous curves over tight jagged features to stabilize arc behavior and reduce dross, which shortens deburr time. Maintain minimum web widths and adequate spacing between adjacent cuts; increasing ligament distance spreads heat input and limits plate distortion.

For fixture integration, add locating holes, tabs, or breakaway bridges that register parts and keep them flat during pierces and long contours.

Match process variables to thickness: as material gets thicker, plan for higher current, larger nozzles, and slower torch speeds to sustain kerf energy without over-beveling edges.

Clean the plate and clamp a low-resistance ground directly to bare aluminum; a stable circuit lowers arc wander and improves edge fidelity.

Use heat sequencing—skip cutting neighboring features consecutively, rotate sides, and pierce away from finished edges—to control cumulative heat and preserve dimensional accuracy.

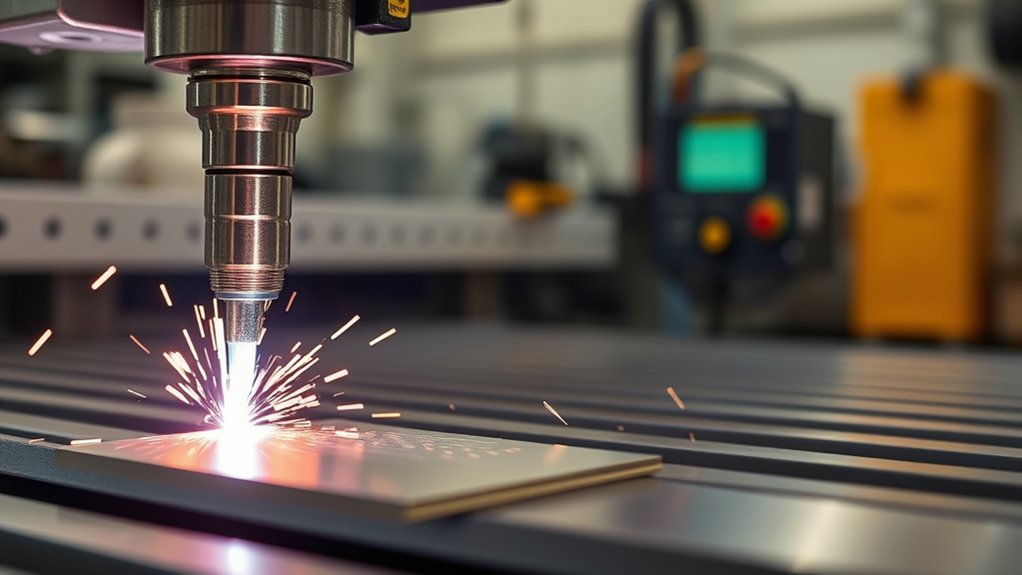

Cut Charts for Common Aluminum Gauges and Plates

You’ll use gauge-to-amp settings to match edge quality with heat input—e.g., 30–40 A for ≤1/4 in, 45–60 A for 1/4–1/2 in, and 60–80 A for >1/2 in plates.

Next, apply a thickness-speed lookup to set feed rate—target about 10–15 IPM in the 1/4–1/2 in range, then slow further as thickness increases.

Note kerf and gas effects in your chart: around 0.06 in kerf at 1/8 in, and argon‑hydrogen for >12 mm to reduce oxidation and dross.

Gauge-To-Amp Settings

Cut charts anchor your setup by tying aluminum gauge or plate thickness to amperage, travel speed, and torch standoff. Read them as a map of gauge thickness and the amperage relationship needed to maintain arc stability, kerf control, and clean edges.

For thin gauges, step amperage down to avoid overburn; for plates, scale up to guarantee penetration. Example anchors: 10‑gauge often lands near 60 A; 1/4 in plate cuts clean around 45 A at 35–40 ipm; over 1/2 in may benefit from preheat. Maintain a 1/8 in standoff to reduce dross and tighten kerf.

1) Calibrate baseline: verify nozzle rating matches target amps; undersized nozzles distort kerf.

2) Increment amps by thickness, then fine-tune via edge bevel and dross cues.

3) Log kerf compensation beyond 1/4 in to protect part accuracy.

Thickness-Speed Lookup

While material thickness drives your amperage choice, the cut chart ties that thickness to a target speed and standoff so you hit clean edges without overburn. Use these ranges to align cutting techniques with stable arc behavior and consistent edge finish. Hold torch-to-material distance near 1/8 inch. Favor nitrogen above 1/4 inch to reduce dross and brighten edges.

| Thickness | Amperage (A) | Speed (IPM) |

|---|---|---|

| ≤ 1/8 in | 30–35 | 30–40 |

| 3/16–1/4 in | 35–45 | 15–30 |

| 5/16–3/8 in | 45–55 | 15–25 |

| 7/16–1/2 in | 55–60 | 12–20 |

| > 1/2 in | 60–100 | 10–20 |

Procedure:

- Set current at the low end, test a 2–3 in coupon, then tune speed for full penetration.

- Watch bevel and top kerf: increase speed if top widens; slow slightly if slag tails forward.

- Verify 1/8 in standoff; recheck after cornering or lead-ins.

Frequently Asked Questions

How Do Shop Humidity and Air Dryer Types Affect Aluminum Cut Quality?

They directly impact cut quality: higher humidity increases porosity, dross, and arc instability; effective humidity control and high air dryer efficiency deliver drier plasma gas, stabilizing arc voltage, reducing bevel, tightening kerf, improving edge smoothness, and minimizing post‑processing.

What Post-Cut Finishing Removes Micro-Burrs Without Rounding Sharp Edges?

You remove micro-burrs without rounding by glass bead blasting, fine Scotch-Brite brushing, or vibratory tumbling with non-abrasive media—controlled, low-pressure, short-cycle post cut polishing. You’ll achieve precise edge treatment, preserving sharpness while eliminating 10–50 µm burrs consistently.

How Does Paint or Anodizing Near the Cut Affect Arc Stability?

It destabilizes the arc. Coatings increase surface resistance, impede pilot transfer, and cause erratic kerf. You’ll grind to bare metal for stable starts. Anodizing effects: higher voltage demand, arc wander. Paint adhesion improves post-cut only after oxide removal and degreasing.

Can CNC Lead-In/Lead-Out Geometry Reduce Edge Waviness on Tight Contours?

Yes. You’ll reduce edge waviness on tight contours by optimizing lead in geometry and lead out geometry: use tangential arcs, 80–120% material thickness lengths, 1–1.5× kerf radius, exit outside features, synchronize feed ramp and pierce timing.

What Maintenance Schedule Prevents Nozzle Drift and Inconsistent Kerf Width?

Like winding a cassette, you prevent nozzle drift and inconsistent kerf width by scheduling weekly nozzle alignment checks, daily torch height verification, shift-based consumable inspections, monthly kerf calibration cuts with recorded deviations, and quarterly gantry squareness audits with backlash compensation.

Conclusion

You dial amperage to match thickness, you choose gas to tame oxide, you size nozzles to shape the arc. You set height to control bevel, you tune voltage to steady the plume, you pace travel to starve dross. For ≤1/4 in, run 20–30 A fast and tight; for 1/4–1/2 in, 40–50 A; for >1/2 in, 50–80 A. With charts in hand and fixtures locked, you cut cleaner, flatter, repeatable edges—by design, by data, by discipline.