I build tools the way most people build furniture: by breaking down a problem, gathering simple parts, and welding them together into something that lasts. One of my favorite projects to make at home is a heavy-duty vise clamp made from a sprocket and a motorcycle chain. It is inexpensive, rugged, and surprisingly simple to fabricate with basic metalworking tools.

In this guide, I will walk you through everything I do when I make one of these clamps: the materials and tools I use, how I prepare and cut the sprocket and chain, the welding and assembly steps, and the finishing touches that make the tool both reliable and safe. I will share tips I’ve learned the hard way so you can avoid common mistakes, and I will cover testing and maintenance so your homemade vise lasts for years.

🛠️ Why build a sprocket-and-chain vise clamp?

There are plenty of commercial clamps and vises available, but building a vise using a sprocket and motorcycle chain offers several advantages. First, it is extremely strong for its size. The chain distributes load over multiple links, giving you high clamping force without the need for expensive threads or proprietary parts. Second, the parts are often cheap or scavenged: a worn motorcycle chain and a sprocket can be found at scrap yards or sourced online for a low price. Third, the design scales and adapts to many situations — you can make a compact bench clamp or a large pipe vise with the same basic idea.

I often say to myself, “I’m going to make a little bit of something solid,” and that spirit is exactly what this build captures. The finished clamp will hold work steady for cutting, grinding, bending, and welding, and it can be customized for your shop needs.

🔩 Materials and tools I use

Before you start, gather the right materials. You will save time and frustration if everything is ready when you need it.

- Sprocket — choose a medium-sized sprocket from a motorcycle, scooter, or chain-driven machine. The sprocket forms the heart of the clamping mechanism and provides the teeth that engage the chain.

- Motorcycle chain — a regular roller chain that matches the sprocket pitch. I prefer a chain with some heft (thicker links) for heavy clamping jobs.

- Steel plate and flat bar — for the clamp jaws and mounting plates. Typical thicknesses range from 6 mm to 12 mm depending on how heavy-duty you want the clamp.

- Square tube or angle iron — for the body or frame of the clamp.

- Welding machine — MIG or stick welding works. I use MIG for cleaner welds and easier control on thinner material.

- Angle grinder — for cutting sprocket, chain, and shaping jaws. Include cut-off wheels and grinding discs.

- Drill and bits — for mounting holes and locating pins.

- Cutting torch or plasma cutter — optional but helpful if you have heavy parts.

- Clamps and fixturing — to hold parts aligned while welding.

- Protective gear — helmet, gloves, respirator, and hearing protection.

🔧 Planning the clamp: design basics

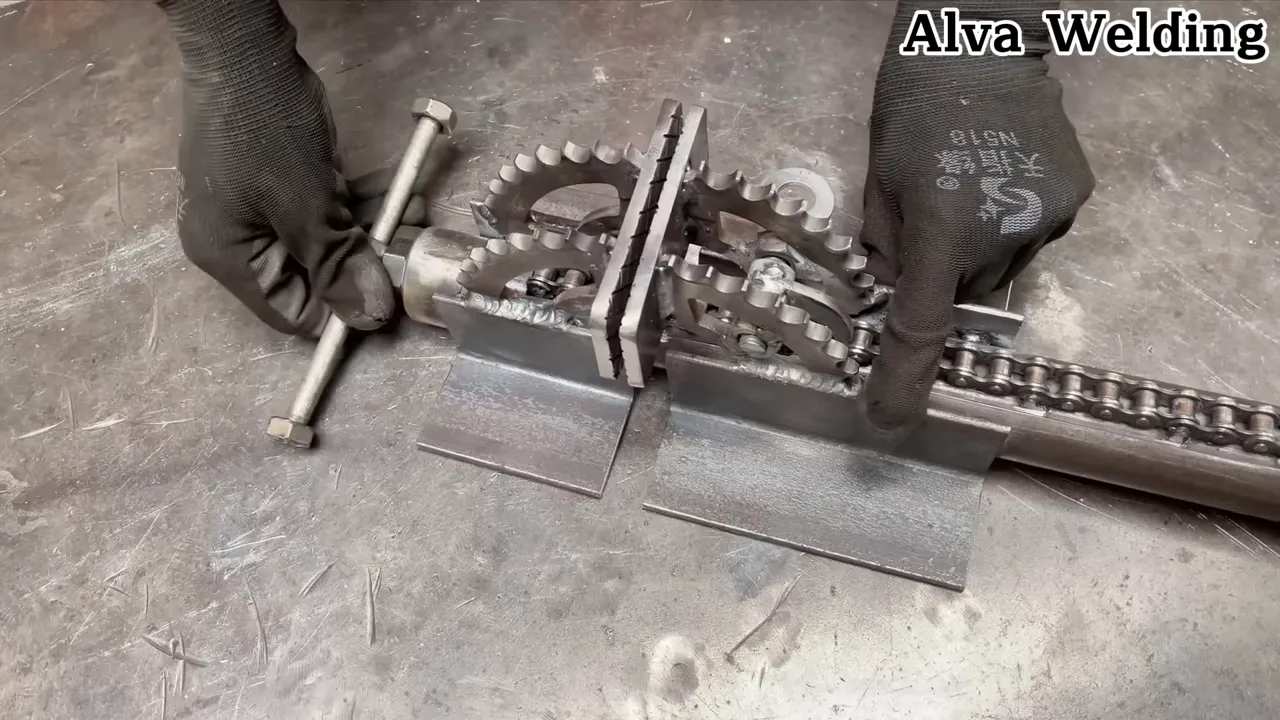

Start with a simple plan. My clamp design uses a sprocket mounted on one jaw, a fixed opposing jaw, and a chain that wraps around the workpiece and engages the sprocket teeth. Turning the sprocket tightens the chain and applies compressive force to the workpiece.

Key design decisions:

- Jaw spacing and capacity — decide the maximum diameter or width of work you want to clamp. This affects chain length and jaw geometry.

- Sprocket diameter — a larger sprocket gives more mechanical advantage and smoother engagement; a smaller sprocket can be more compact.

- Mounting method — will the clamp be bolted to a bench, or have its own base? I often design a boltable plate so the clamp can be removed when not needed.

- Rotation mechanism — I use a welded handle or socket for a removable bar; sometimes I add a ratchet if I need quick tightening.

I sketch the layout on paper or a tablet and measure the sprocket and chain in advance. A quick mock assembly on the bench helps validate jaw spacing before cutting and welding steel.

⚙️ Preparing the sprocket and chain

Cleaning and preparing the sprocket and chain is the step most people rush, but it matters. Remove grease, dirt, and any silicone or rubber that might have been used as a dampener. If the sprocket has a hub or old bearings attached, cut them off or grind them down until you have a clean wheel with teeth you can weld to or bolt through.

Inspect the chain for stretched pins, damaged rollers, or tight links. Replace any links that are compromised. If the chain is in good condition but too long, you will remove links to match your clamp’s intended range.

Sometimes I modify the sprocket by adding a central boss — a small plate welded to the center — to give a flat face to weld a handle or shaft. Other times I bore a hole through the sprocket and press-fit or weld a short keyed shaft so I can rotate it cleanly. The method depends on the parts you have and your welding confidence.

🔩 Cutting and shortening the chain

Chain length needs to be matched to the capacity of the clamp. To remove links:

- Mark the links you want to remove. Plan to remove an even number of links so the chain re-joins cleanly.

- Use an angle grinder or a pin punch to remove the retaining plate or to cut a link. Be careful not to damage the adjacent pins.

- Rejoin with a rivet-style or clip master link; do not weld chain links. I often use a master link because it allows adjustments later.

After rejoining, lubricate the chain lightly and test its fit over the sprocket. It should seat in the teeth without too much side play. If the chain rides too high or low, replace the chain or choose a different sprocket so their pitches match.

🛠️ Fabricating the jaws and body

The jaws determine how the clamp contacts the workpiece. For a general-purpose clamp I make two rectangular jaw plates from 8 to 12 mm steel and weld them to a backing plate or tube. One jaw holds the sprocket assembly, the other is a fixed plate with a smooth contact face.

Tips for jaw construction:

- Chamfer the jaw edges slightly to avoid sharp corners that could gouge the workpiece.

- If you plan to clamp pipes, cut V-notches into the jaws for better grip.

- Consider bonding a short piece of rubber or leather to the jaw faces for delicate work.

- Keep the distance between the sprocket axis and the jaw face consistent on both ends so the chain path remains predictable.

🔥 Welding and assembly tips

Welding is the stage where alignment matters most. If jaws are misaligned the chain will bind and the clamp will not work smoothly.

My sequence is:

- Tack-weld the jaw plates to the frame in multiple spots. Check alignment after each tack.

- Test fit the sprocket and chain assembly to ensure engagement remains correct.

- Finish welds once alignment is verified. Use small, consistent welds to avoid warping.

- Grind welds smooth where the chain might rub or where a tight fit is required.

MIG welding works great because it allows quick tacks and minimal distortion on thinner steel. If you use stick welding on heavier material, stay mindful of heat concentration and reduce warping by alternating weld locations.

When you fabricate the shaft or handle that turns the sprocket, consider two approaches:

- Fixed shaft — weld a short stub shaft, then add a socket or handle. This gives a stout, rigid drive but is permanent.

- Removable handle — use a square tube handle that slides over a keyed shaft or uses a locking pin. This makes storage and transport easier.

🔧 Final assembly and testing

Assemble the sprocket on its shaft and lock it in place. If you used a keyed shaft, make sure the key seats well and that the sprocket cannot rotate relative to the shaft. If you chose a press-fit or welded hub, ensure the welds are solid and continuous.

Fit the chain and rotate the sprocket to verify smooth engagement. The chain should wrap consistently and not skip teeth. Tighten the clamp on a piece of scrap to confirm that the pressure is even across the jaw faces.

Test the clamp with different materials — steel plate, round bar, and pipe — to understand how the chain seating changes with shape. Make microadjustments to the chain length or jaw geometry if the clamp tends to pull the workpiece off-center.

🧰 Finishing touches and maintenance

A few finishing steps improve longevity and usability:

- Paint or coat the clamp to protect against rust. Use heat-resistant paint if the clamp will see grinding sparks.

- Lubricate the chain periodically; keep sprocket and jaw faces clean and dry. A light spray of chain oil prevents squeaking and reduces wear.

- Inspect pins and welds regularly, especially after heavy use. Replace any suspect chain links immediately.

- Pad the jaws when clamping delicate materials. Padded jaws prevent marring and concentrate force more gently.

Maintenance is simple: wipe off metal dust after grinding, re-lubricate after heavy use, and check fasteners and welds yearly. With regular care, this clamp will serve well for many years in a busy shop.

🔩 Uses and advantages of this clamp design

This sprocket-and-chain clamp is versatile. Here are common uses I rely on it for:

- Holding round stock for cutting, grinding, or weld buildup.

- Clamping awkward shapes where traditional bench vises struggle.

- Applying even compression for bending or straightening operations.

- Temporary fixturing for welding assemblies that need to be held fast during tacking.

Because the chain wraps the workpiece, pressure is distributed over multiple contact points, reducing the tendency for slippage and allowing you to clamp irregularly shaped parts securely.

⚠️ Safety and common mistakes to avoid

Safety is paramount. Follow these rules:

- Wear eye protection and a respirator when grinding and welding.

- Do not exceed the safe working load of the chain. Chains have rated strengths; overloading a weak or damaged chain can cause catastrophic failure.

- Ensure the handle is not left in a place where it can be caught by a moving tool or belt drive during operation.

- Keep fingers away from the sprocket and chain path when tightening.

- Do not use the clamp as a step or leverage point for other work.

Common mistakes I see:

- Using mismatched sprockets and chain pitch causes skipping and accelerated wear.

- Welding parts out of alignment leads to binding. Double-check with tacks before final welds.

- Leaving burrs or sharp weld spatter where the chain rides causes premature chain failure.

🛡️ Troubleshooting tips

If the chain binds or skips, check these items in order:

- Chain pitch and sprocket compatibility. Even small mismatches cause problems.

- Alignment of sprocket axis with jaw faces. Misalignment makes the chain want to ride off.

- Damaged or stiff chain links. Replace or free up tight links by working them with penetrating oil.

- Weld spatter or burrs on the sprocket teeth. Clean and dress teeth to restore smooth engagement.

If the clamp slips under load, verify that the jaw faces are not glazed or oily. Adding traction pads, serrated inserts, or V-notches for pipe will dramatically improve grip.

🔁 Variations and upgrades

This basic build is a great learning project, but there are plenty of ways to upgrade:

- Ratchet mechanism — add a ratchet and pawl so you can quickly tighten with incremental clicks.

- Torque indicator — weld or bolt a simple mechanical gauge that shows approximate tension on the chain.

- Swappable jaws — design jaws to be bolted on so you can swap between V-jaws, flat jaws, or rubber-padded jaws quickly.

- Quick-release master link — use a master link that lets you open and close the chain around large pieces without removing the whole assembly.

These improvements extend the clamp’s usefulness and make it faster to work with during repetitive tasks.

🧾 Parts sourcing and cost

You can source sprockets and chains from multiple places:

- Local salvage yards or motorcycle shops often have inexpensive used parts.

- Online marketplaces sell new sprockets and chains at reasonable prices if you prefer fresh components.

- Fabrication supply stores will stock steel plate, tube, and welding consumables.

Cost varies with size and material, but a basic clamp can be made for under the price of a mid-range commercial clamp if you use scavenged parts. You pay with your time and shop skills rather than cash.

📐 Measurements and example build (detailed)

Here is a concrete example from a clamp I built in my shop. Use it as a reference and scale to your needs.

- Sprocket: 30-tooth motorcycle sprocket with 520 pitch.

- Chain: 520 roller chain shortened to a 26–32-link loop with a rivet-style master link.

- Jaw plates: 100 mm by 60 mm by 8 mm flat steel.

- Frame: 40 mm square tube with 5 mm wall thickness, 200 mm long between jaw centers.

- Shaft: 12 mm round bar welded through the sprocket hub with a welded square for detachable handle.

- Mounting plate: 120 mm by 80 mm by 6 mm with four countersunk bolt holes for bench mounting.

With that layout I can clamp pipes up to 70 mm in diameter or flat stock up to 80 mm wide. The chain provides enough reach to wrap completely around medium sections and hold them without slippage.

❓ Frequently Asked Questions

What size sprocket and chain should I use for a general-purpose clamp?

For most bench-sized clamps a motorcycle sprocket in the 30-tooth range with a 520 or 525 chain pitch offers a good balance of strength and compactness. If you want a larger capacity, use a larger sprocket and a heavier chain rating. Make sure chain pitch and sprocket match exactly to avoid skipping. Note: 520/525/530 share 5/8″ pitch but differ in width/tooth thickness — match the chain width to the sprocket’s tooth thickness as well.

Can I use any motorcycle chain or do I need a specific grade?

Not all chains are created equal. Look for a roller chain in good condition with solid pins and rollers. For heavy-duty clamping use chains rated for high tensile loads. Avoid corroded or stretched chains. If in doubt, purchase a new chain and match it to your sprocket pitch.

Do I need special welding skills to build this clamp?

Basic welding skills are enough. Tack-welding and checking alignment before finishing welds helps prevent mistakes. MIG welding is beginner-friendly for this project. If you are new to welding practice on scrap before committing to the clamp parts.

How do I prevent the chain from slipping when clamping round objects?

For round objects add V-notches in the jaw faces or use a rubber or leather pad to increase friction. Proper jaw alignment and a clean, well-lubricated chain that seats fully in the sprocket also reduce slip. For repeated pipe work consider serrated jaw inserts specifically shaped to fit pipe diameters you use often.

Is it safe to weld directly on the sprocket teeth?

Welding on sprocket teeth is possible but introduces risks like hard spots and brittle welds if done improperly. I prefer to weld a hub or back plate to the sprocket center rather than altering the teeth. If you must weld near the teeth, use small tack welds and dress them carefully to maintain tooth profile.

How often should I lubricate the chain and sprocket?

Lubricate the chain after heavy use and at least once a month in typical shop conditions. If you grind or weld near the clamp frequently, wipe metal dust off and apply fresh chain oil more often. Proper lubrication reduces wear and keeps the mechanism smooth.

Can I scale this design up for industrial use?

Yes, the design scales well but requires stronger components and proper engineering for high loads. Use higher grade chains, larger sprockets, and thicker jaw plates. For very heavy or safety-critical applications consult load ratings and consider using a commercially rated chain drive or torque-limiting device.

🏁 Final thoughts

Making a sprocket-and-chain vise clamp is a rewarding project that teaches you a lot about fit, alignment, and practical welding. The finished tool is adaptable, strong, and a great addition to any home shop. Start with a simple bench model, learn from the first build, and then refine the design with upgrades like ratchets, removable jaws, or torque indicators.

I built my first clamp with parts salvaged from an old bike and a handful of steel offcuts. It held together through years of use and became a go-to fixture for odd jobs. With a little planning, basic tools, and the tips above you can make one that suits your work and saves you money while giving you a unique, custom tool tailored to your needs.

If you build one, remember to inspect it regularly and never exceed safe loads for the chain and welds. Enjoy the process of making something practical with your hands — that is the heart of good DIY metalworking.