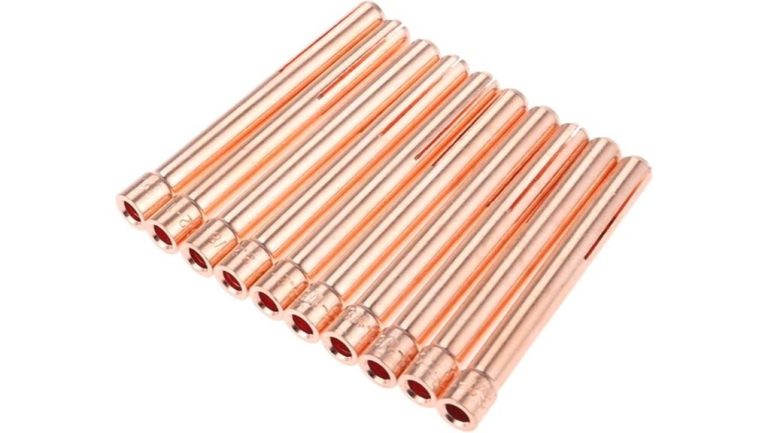

The STARTECHWELD 6011 Welding Rod is a versatile option, rated at 4.8 out of 5 stars by 48 users. This rod supports all-position welding and works seamlessly with small AC and DC machines. Notable features include excellent arc stability and high deposition efficiency, resulting in strong, non-porous welds with minimal spatter, even on challenging surfaces. Adhering to ANSI/AWS and ASME standards, it promises reliability for various applications. What makes this rod stand out in practical use?

Key Takeaways

- The STARTECHWELD 6011 Welding Rod features excellent arc stability, ensuring high-quality welds with minimal spatter.

- It is versatile for all-position welding and can be used on mild steel, including rusty or oily surfaces.

- Customers rate it 4.8 out of 5 stars, with high satisfaction noted for its performance and low spatter.

- It meets ANSI/AWS A5.1 and ASME SFA 5.1 standards, ensuring reliability for both professional and DIY applications.

- The rod is compatible with small AC and DC welding machines, making it suitable for various welding projects.

Features and Specifications

The STARTECHWELD 6011 Welding Rod stands out with its robust features and precise specifications, making it a reliable choice for various welding applications.

Weighing 5 pounds, this 1/8″ x 14″ electrode type is designed for all-position welding, ensuring versatility across different techniques.

Constructed from carbon steel, it boasts excellent arc stability and high deposition efficiency, producing non-porous welds with minimal spatter.

The rod is compatible with both small AC and DC welding machines, enabling effective use on rusty or oily surfaces.

Meeting ANSI/AWS A5.1 and ASME SFA 5.1 standards, it is an ideal option for diverse welding projects.

Performance and Applications

While exploring the performance and applications of the STARTECHWELD 6011 Welding Rod, it becomes evident that its design caters to a wide range of welding needs.

This electrode excels in various welding techniques, demonstrating strong material compatibility with mild steel, including rusty or oily surfaces. Its all-position capability guarantees versatility, making it suitable for projects such as car frames and farm implements.

The rod’s excellent arc stability results in high-quality welds with low spatter and quick solidification. With a size of 1/8″ x 14″, it is well-suited for both small AC and DC welding machines, enhancing user experience considerably.

Customer Feedback and Ratings

Customer feedback for the STARTECHWELD 6011 Welding Rod indicates a high level of satisfaction among users, as evidenced by its impressive average rating of 4.8 out of 5 stars based on 48 reviews.

Customers frequently highlight the rod’s excellent arc stability and low spatter, contributing to their overall satisfaction. User experiences reflect a strong appreciation for its versatility in various applications, from car frames to farm implements.

The welding rod’s performance on rusty or oily surfaces further enhances its appeal. Overall, customer reviews underscore the product’s reliability and effectiveness, reinforcing its status as a preferred choice for welders seeking quality results.

Frequently Asked Questions

What Is the Shelf Life of STARTECHWELD 6011 Welding Rods?

The shelf life of welding rods generally depends on storage conditions, but typically, E6011 rods exhibit good shelf longevity. Their durability remains intact when kept dry and away from extreme temperatures, ensuring reliable performance during use.

Are These Rods Suitable for Beginners in Welding?

These rods, like a gentle breeze guiding a novice sailor, are well-suited for beginners. Embracing basic welding techniques and following essential beginner tips, they facilitate a smooth journey into the world of welding mastery.

Can I Use These Rods for Aluminum Welding?

These rods are not suitable for aluminum welding, as their design focuses on carbon steel applications. Effective aluminum welding requires specific electrodes and techniques tailored to the material’s unique properties and challenges.

What Is the Recommended Storage Condition for These Welding Rods?

To guarantee the welding rods thrive, they should bask in a sanctuary of controlled temperature and proper humidity, shielded from moisture and extremes. This nurturing environment preserves their integrity, allowing them to perform at their finest.

Do These Rods Emit Harmful Fumes While Welding?

These rods may emit harmful fumes during welding, necessitating proper fume exposure management. Adhering to welding safety protocols, including ventilation and protective gear, empowers welders to work safely and effectively, ensuring a liberated and healthy environment.

Conclusion

To conclude, the STARTECHWELD 6011 Welding Rod stands out as a dependable option for welders seeking versatility and quality. With its remarkable arc stability and efficiency, it excels in various applications, including both professional and DIY projects. The adherence to ANSI/AWS and ASME standards further assures users of its reliability. With an impressive average rating of 4.8 from 48 reviews, this welding rod is a commendable choice for those looking to achieve strong, non-porous welds.