Getting the stick welder settings just right can make or break your weld. Too cold, and the bead just sits on top; too hot, and you’re burning through your metal before you even get started. That’s where a good stick welder settings chart comes in handy.

It helps you match your amperage, rod size, and metal thickness so you can run smooth, consistent beads every time. Different filler rods like 6010, 6013, or 7018 each have their own preferred settings for arc control, penetration, and joint prep, and getting those details right makes all the difference in weld quality and structural strength.

It’s not just about following numbers — it’s about understanding how those settings affect your real-world welds. Stick around, because I’ll walk you through how to read, tweak, and master a stick welder settings chart like a seasoned pro.

Stick Welding Basics

Stick welding is straightforward but demands precision. The process starts with an electric arc between the electrode and workpiece, generating heat up to 6,500°F to fuse metals. The rod’s core provides filler material, while the flux creates slag to protect the cooling weld.

For beginners, start with mild steel—it’s forgiving and common in shops. Prep is key: clean the joint with a grinder or wire brush to remove rust, paint, or oil, as contaminants cause porosity or lack of fusion. I remember my first big job; skipped grinding once, and the weld popped under load. Lesson learned—always bevel thick edges for better penetration.

Safety first: wear a helmet with shade 10-12, leather gloves, flame-resistant jacket, and boots. Ground the workpiece properly to avoid shocks, and ventilate for fumes. In windy US outdoors, stick shines because no gas shield is needed, unlike MIG.

Types of Stick Welding Rods and When to Use Them

Choosing the right rod is like picking the right tool—mismatch it, and your weld suffers. Rods are classified by AWS, like E6010 or E7018, where “E” means electrode, the first two digits indicate tensile strength (60,000 psi for 6010), the third is position (1 for all positions), and the last two describe flux and current.

E6010 rods dig deep with a fast-freeze puddle, ideal for root passes on pipes or dirty steel. Use DC electrode positive (DCEP) polarity for better penetration. They’re great for vertical-up welding but can be snappy for newbies.

E6011 works on AC or DC, forgiving on rusty surfaces like old farm equipment. I use them for quick repairs where AC machines are handy.

E6013 offers smooth arcs and shallow penetration, perfect for thin sheet metal or poor fit-ups. All-position, low spatter—start here if you’re learning.

E7018 low-hydrogen rods excel in structural work, like bridges or buildings, with high strength and crack resistance. Store them dry to avoid hydrogen cracks; rebake if needed. Use for multi-pass welds on clean, thick steel.

For other materials, like cast iron, try nickel rods; stainless needs E308. Match rod to base metal for compatibility—mild steel with mild steel rods avoids brittleness.

Pros of each: 6010 for penetration, 7018 for strength. Cons: 6010 sputters more, 7018 needs dry storage.

How to Read and Use a Stick Welder Settings Chart

A stick welder settings chart matches rod diameter, metal thickness, and amperage for optimal results. For example, a 1/8-inch E6010 rod on 1/4-inch steel might call for 90-120 amps DCEP. Start mid-range, like 100 amps, and adjust based on the bead: too hot? Lower amps to avoid burn-through; too cold? Increase for fusion.

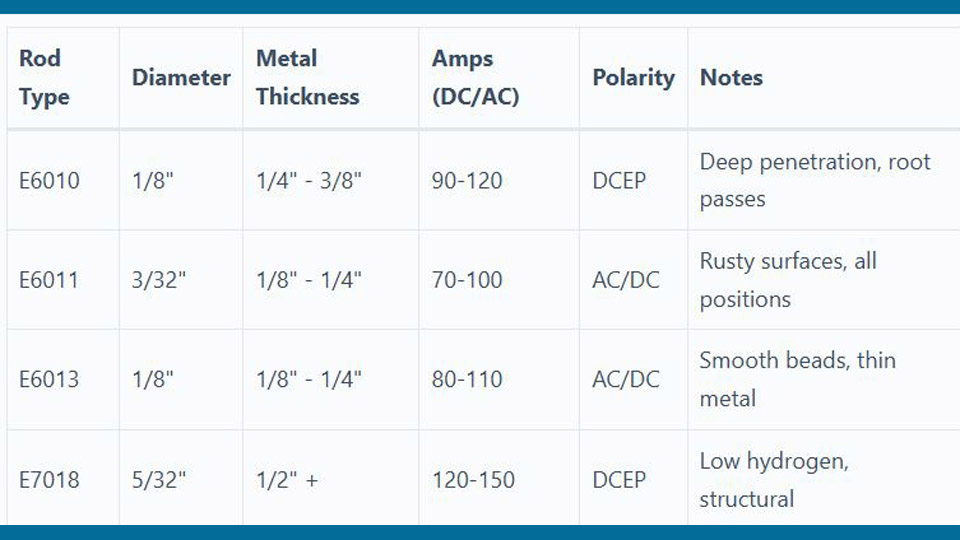

Here’s a basic comparison table for common setups on mild steel:

| Rod Type | Diameter | Metal Thickness | Amps (DC/AC) | Polarity | Notes |

|---|---|---|---|---|---|

| E6010 | 1/8″ | 1/4″ – 3/8″ | 90-120 | DCEP | Deep penetration, root passes |

| E6011 | 3/32″ | 1/8″ – 1/4″ | 70-100 | AC/DC | Rusty surfaces, all positions |

| E6013 | 1/8″ | 1/8″ – 1/4″ | 80-110 | AC/DC | Smooth beads, thin metal |

| E7018 | 5/32″ | 1/2″ + | 120-150 | DCEP | Low hydrogen, structural |

This chart assumes flat position; reduce amps 10-20% for overhead. Test on scrap—your machine’s output varies. Common mistake: ignoring polarity. E6010 sticks on wrong polarity; flip to DCEP for stability.

In practice, for a 1/2-inch plate, use 5/32-inch E7018 at 140 amps, weaving for fill passes. Personal tip: mark your dial with tape for repeat jobs.

Step-by-Step Guide to Setting Up Your Stick Welder

Let’s walk through setup like I’m showing a buddy in the shop.

- Select rod based on material and job—E7018 for clean structural, E6011 for dirty repairs.

- Check machine: Ensure cables are intact, ground clamp clean. Set to DC or AC per rod.

- Insert rod into holder—secure but not crushing flux.

- Clamp ground close to weld area to minimize resistance.

- Dial amps: Use chart, start low. For 1/8-inch rod on 3/16-inch steel, 100 amps.

- Prep joint: Bevel thick metal 30-45 degrees, clean surfaces.

- Strike arc: Tap or scratch like lighting a match—quick pull back to avoid sticking.

- Weld: Maintain 1/8-inch arc length (rod diameter rule). Drag at 45-degree angle.

- Chip slag between passes, inspect for defects.

I once set amps too high on thin stock—hole city. Fix: Practice on scrap, listen to the arc—crackly means too long, hissy too short.

Common Mistakes with Stick Welder Settings and How to Fix Them

Newbies often crank amps too high, causing spatter and burn-through. Fix: Drop 10-20 amps, shorten arc. Low amps lead to sticking—bump up and clean rod end.

Arc blow on DC? Magnetic fields deflect arc; switch ground or use AC.

Porosity from moisture? Dry rods in oven at 250°F for 1-2 hours. Anecdote: Wet 7018 cracked a beam—now I store in airtight cans.

Undercut from fast travel? Slow down, weave properly. Overwelding adds weak filler—stick to joint size.

For thin metal, use 3/32-inch rods at low amps (40-70); thick needs multi-pass with larger rods.

Stick Welding Techniques for Different Positions

Flat welding is easiest—drag straight or slight weave. Angle rod 10-15 degrees back.

Vertical up: Whip or pause technique with E6010 for uphill build. Point rod up 30 degrees, short arc.

Overhead: Lower amps, drag to control drip. Use E7013 for less spatter.

Horizontal: Slight weave, watch for undercut.

Pro know-how: Stringer beads for speed, weave for gaps. Practice vertical on plate—builds control.

Stick Welding on Different Materials

Mild steel: Standard rods like 7018, clean prep.

Thick plate: High amps, multi-pass for heat management.

Thin sheet: Low amps, 6013 to avoid warping.

Stainless: E308 rods, DCEN polarity for less heat.

Aluminum: Rare with stick—use TIG; if must, special rods and preheat.

Cast iron: Nickel electrodes, preheat to 500°F.

Match filler to base for compatibility; test for distortion.

Safety Considerations in Stick Welding

Electric shock risk—insulated boots, dry gloves, no wet floors. Arc rays burn skin/eyes—full PPE.

Fumes: Ventilate, respirator for indoors. Fire watch—sparks fly far.

Slag expulsion: Chip carefully, wear long sleeves.

US OSHA mandates training; ground machines properly.

Advanced Tips for Professional Welders

Tune arc force on inverters for stability. For code work, certify procedures per AWS D1.1.

Multi-layer: Alternate passes, peen for stress relief.

Efficiency: Preheat thick steel to reduce cracking.

I’ve fabbed trailers with precise settings—saves rework.

Conclusion

Mastering a stick welder settings chart empowers you to tackle any job confidently, from hobby fixes to pro builds. Key takeaways: Match rod and amps to material/thickness, prep thoroughly, practice techniques, and prioritize safety.

You’re now equipped to avoid common pitfalls and produce welds that last. Keep a notebook of successful settings for your machine—personalizes the chart for real results. Fire up that welder and get building.

FAQs

What Amperage Should I Use for 1/8-Inch Rod on Mild Steel?

For 1/8-inch E6011 rod on 1/4-inch mild steel, start at 90-110 amps DCEP. Adjust based on bead: higher for penetration, lower to prevent burn-through.

How Do I Prevent Electrode Sticking in Stick Welding?

Strike with a quick tap or scratch, maintain short arc (rod diameter length). Clean rod end, use correct polarity—DC for digging rods. Dry storage helps too.

Can Beginners Use E7018 Rods?

Yes, but store dry and rebake if moist. They’re great for all-position structural welds but less forgiving than E6013 for practice.

What’s the Best Rod for Welding Rusty Metal?

E6011—works on AC/DC, cuts through rust and paint for field repairs without heavy prep.

How Thin Can I Weld with Stick?

Down to 1/8-inch with 3/32-inch rods at 40-70 amps, but TIG or MIG is better for thinner than that to avoid holes.