Did you know that the ideal tip height in plasma cutting can greatly impact your cut quality? Maintaining the right standoff distance, which varies by metal type, is essential for achieving precision and minimizing dross. For instance, mild steel and aluminum generally require a 1/16-inch to 1/8-inch standoff, while stainless steel may need adjustments to prevent excess heat. Understanding these nuances can transform your cutting efficiency and accuracy, but there’s more to take into account.

Understanding the Importance of Tip Height in Plasma Cutting

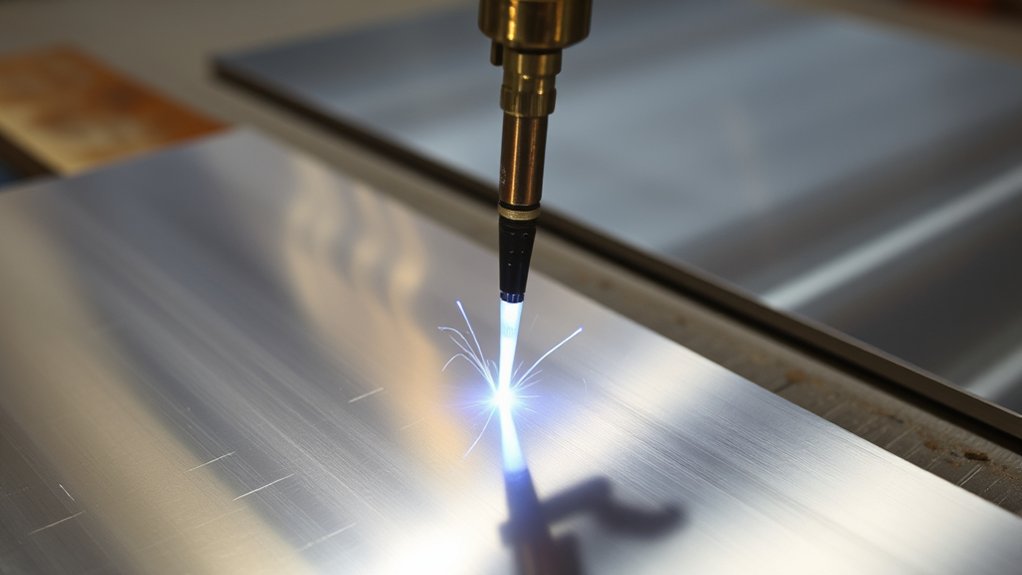

When it comes to plasma cutting, maintaining the correct tip height is vital for achieving high-quality results. Precise torch adjustment guarantees a stable arc, important for clean cuts. You need to calibrate the height diligently, keeping the standoff between 1/16-inch to 1/8-inch, which stabilizes arc voltage and minimizes angularity and dross.

Inconsistencies in tip height can lead to undesirable bevel angles and material warpage, compromising the integrity of your workpiece.

Achieving liberation in your cutting processes means embracing automatic height calibration systems. These systems use real-time sensor feedback to adjust the standoff distance dynamically, guaranteeing each cut maintains uniform quality.

Optimal Standoff Distance for Different Metal Types

Precision in torch adjustment sets the foundation for clean and efficient plasma cutting, making the understanding of ideal standoff distance for different metal types a priority. Your mastery of standoff distance calculations guarantees not only optimal voltage but also minimizes dross formation. For mild steel and aluminum, aim for a standoff between 1/16-inch to 1/8-inch, facilitating stable arcs. Stainless steel demands more finesse, often requiring adjustments towards the lower end of this range to prevent excessive heat input.

Material | Ideal Standoff Distance

———|————————-

Mild Steel | 1/16-inch to 1/8-inch

Aluminum | 1/16-inch to 1/8-inch

Stainless Steel | Closer to 1/16-inch

Thicker Materials | Higher standoff required

Consistent Standoff | Reduces angular cuts

It’s essential to integrate metal thickness considerations, adjusting torch height accordingly for thicker materials to maintain arc dynamics. By consistently maintaining precise standoff distances, you prevent angular cuts, minimize consumable wear, and boost cutting efficiency. This approach liberates your cutting potential and enhances your craftsmanship.

How Tip Height Affects Cut Quality and Precision

You must understand that maintaining the correct tip height directly influences arc stability, which is essential for achieving precise cuts.

Variations in height can alter the kerf width, affecting the dimensional accuracy of the workpiece.

Additionally, improper height can lead to increased dross formation, which compromises the cleanliness and quality of the cut edges.

Impact on Arc Stability

Although often overlooked, maintaining the correct tip height in plasma cutting is essential for guaranteeing arc stability, which greatly impacts cut quality and precision.

By adhering to an ideal standoff distance of 1/16-inch to 1/8-inch, you optimize arc dynamics, allowing for precise voltage regulation. This balance is critical to prevent excessive dross and achieve sharp edge quality.

Variations in torch height can disrupt arc voltage, leading to instability and irregular cuts. A consistently adjusted tip height guarantees a steady arc, fundamental for precision in complex designs and small apertures.

Embrace automatic systems with torch height sensors, which liberate you by continuously monitoring and adjusting the distance, assuring unwavering arc stability and superior cut integrity throughout the process.

Influence on Kerf Width

When setting the torch height for plasma cutting, maintaining an ideal standoff distance is critical for controlling the kerf width and, consequently, cut quality and precision.

The perfect range, typically between 1/16-inch to 1/8-inch, guarantees consistent arc voltage. This precision directly influences kerf width, allowing you to achieve the sharpest, most accurate cuts.

If the torch height is too high, you’ll face a wider kerf, leading to unnecessary material waste and dimensional inaccuracies. Too low, and you risk excessive molten metal splatter and distortion, both detrimental to cut precision.

Adjusting the torch height relative to the material’s surface can enhance edge angularity, essential for maintaining tight tolerances.

Mastering this balance liberates your cutting process, guaranteeing superior results.

Effect on Dross Formation

Understanding the effect of tip height on dross formation is vital for achieving high-quality plasma cuts. Maintaining an ideal standoff distance of 1/16-inch to 1/8-inch enhances cutting efficiency by guaranteeing proper arc stability. Consistent torch height prevents angular cuts and minimizes dross by avoiding inconsistent arc voltage. Proper pierce height, 1.5 to 2 times the cutting height, aids in dross reduction by preventing molten pits. Adjusting torch height for material warpage ensures uniform cuts and reduces high-speed dross, which results from arc lagging. Regular adjustments are important for precision.

| Factor | Impact on Dross Formation |

|---|---|

| Ideal Standoff | Enhances cutting efficiency |

| Inadequate Torch Height | Increases dross formation |

| Proper Pierce Height | Reduces molten pits |

| Material Warpage | Requires height adjustments |

| High-Speed Dross | Caused by incorrect torch height |

Adjusting Tip Height for Intricate Designs and Small Holes

To achieve precision in plasma cutting intricate designs and small holes, it’s essential to maintain an ideal tip height between 1/16-inch and 1/8-inch. This fine-tuning guarantees consistent arc voltage, vital for preventing angularity and delivering clean, detailed edges.

Start by making precise torch adjustments to accommodate design intricacies, confirming that each cut remains sharp and true to the blueprint.

When cutting small holes, set the initial pierce height between 1.5 to 2 times the cutting height. This method reduces wear on consumables and stabilizes the arc, allowing for a seamless shift into the cut.

An automatic torch height control system can be your ally, adjusting the standoff distance in real-time. This technology maintains peak performance, confirming that the machine adapts to the demands of each intricate operation.

Regularly checking and fine-tuning the tip height will liberate you from the pitfalls of poor cut quality and excessive dross.

Common Mistakes With Torch Height and How to Avoid Them

Fine-tuning the tip height for intricate designs lays the groundwork for superior plasma cutting, yet common mistakes in torch height can undermine even the most meticulous setups.

One prevalent issue is neglecting the ideal torch-to-work distance of 1/16-inch to 1/8-inch. Deviating from this range leads to angularity in cuts and compromises precision. Setting the pierce height too low invites molten metal splatter, risking damage to both the workpiece and the cutter. Conversely, a height set too high disrupts arc voltage transfer, impairing the cut.

Neglecting the ideal torch height can lead to angular cuts and compromise precision.

To avoid these pitfalls, regularly check and adjust your torch height, accounting for material inconsistencies. Failing to do so results in excessive dross formation, degrading cut quality and accuracy.

Automatic systems with torch height sensors offer a solution by maintaining consistent standoff distances, adapting to varying material thicknesses. Embrace these practices to elevate your cutting performance and guarantee flawless results.

Tools and Techniques for Maintaining Consistent Standoff

When achieving ideal plasma cutting performance, maintaining a consistent standoff is essential. A precise torch-to-work distance of 1/16-inch to 1/8-inch enhances arc stability and cutting quality. To achieve this, consider integrating advanced tools and techniques.

- Torch Height Sensor Devices: These continuously monitor and adjust arc voltage, ensuring the torch height remains consistent, thereby preventing cut quality variations. Regular sensor calibration is vital for accuracy.

- Automatic Torch Height Controllers: These systems adjust the torch position in real-time based on feedback from height sensors, maintaining a uniform distance across the workpiece and optimizing cutting performance.

- Regular Checks and Adjustments: Consistently verify torch height settings and make necessary adjustments based on material inconsistencies to reduce dross formation and enhance overall performance.

Factors Influencing Ideal Tip Height Settings

Maintaining a consistent standoff, as emphasized in the previous discussion, hinges on understanding the factors that influence ideal tip height settings. Key elements include material properties and equipment calibration.

For optimal voltage and cut quality, the torch-to-work distance should generally be between 1/16-inch and 1/8-inch. However, material inconsistencies like warps or bumps can disrupt this precision, leading to angular cuts and arc instability. These irregularities necessitate a nuanced understanding of the material properties to anticipate potential disruptions.

Maintaining a precise torch-to-work distance is crucial, but material inconsistencies can lead to angular cuts and arc instability.

Equipment calibration is equally essential. The proper pierce height, typically 1.5 to 2 times the cutting height, must be meticulously set to prevent excessive wear on consumables and guarantee effective arc initiation.

Consistent calibration guarantees the machinery responds to material variations, maintaining reliable performance. By mastering these factors, you can achieve a stable and precise cutting process, freeing you from the constraints of unpredictable outcomes.

The Role of Technology in Managing Torch Height

In plasma cutting, automated height control systems are essential for achieving consistent cut quality by continuously monitoring and adjusting the torch height based on real-time data from sensor devices.

These systems maintain the ideal torch-to-work distance, typically between 1/16-inch to 1/8-inch, ensuring precise cuts while preventing damage to both the material and the equipment.

Automated Height Control

Although achieving ideal cutting results necessitates meticulous control of the torch height, automated height control systems revolutionize this process by leveraging advanced sensor technology.

These systems employ torch height calibration and sensor accuracy to maintain the best standoff distance, typically between 1/16-inch and 1/8-inch.

- Real-Time Adjustments: They continuously monitor arc voltage, adjusting the torch height on-the-fly to adapt to varying material thickness.

- Damage Prevention: By ensuring precise standoff, they prevent damage to the plasma cutter, essential for intricate designs and small holes.

- Enhanced Productivity: Automation reduces manual interventions, boosting productivity and freeing you from the constraints of constant oversight.

With automated control, you’re empowered to achieve high-quality cuts with minimal dross formation, enhancing both the efficacy and efficiency of your plasma cutting operations.

Consistent Cut Quality

To achieve consistent cut quality, leveraging technology to manage torch height is indispensable. Maintaining a precise torch-to-work distance—typically between 1/16-inch to 1/8-inch—ensures ideal arc stability.

Automatic torch height control systems utilize sensors to monitor arc voltage, providing real-time adjustments for precise standoff management. This technology is pivotal in torch maintenance, preventing angular cuts and dross formation, common pitfalls of inconsistent height.

Tools like the Beacon app exemplify advanced solutions for cut optimization, adjusting arc voltage and torch distance instantaneously. Such innovations liberate you from manual oversight, enhancing uniformity in cut bevels across varied materials.

Tips for Ensuring Effective Arc Voltage Transfer

When aiming for effective arc voltage transfer in plasma cutting, maintaining the correct torch-to-work distance is paramount. This standoff must ideally be set between 1/16-inch to 1/8-inch for most home applications to guarantee maximum cutting quality.

The relationship between arc voltage and standoff distance is inverse, making torch calibration essential. A precise setup allows for consistent voltage monitoring, guaranteeing a stable arc.

Arc voltage inversely relates to standoff distance; precise torch calibration ensures consistent monitoring for a stable arc.

Here are key tips to enhance your cutting performance:

- Use Automatic Torch Height Control: This system adjusts in real-time based on arc voltage measurements, maintaining precise standoff and preventing voltage fluctuations.

- Set Proper Pierce Height: Adjust to 150% to 200% of the cut height. This enhances initial arc stability, reducing misfires and guaranteeing effective voltage transfer during piercing.

- Guarantee Consistent Torch Height: Variations can lead to poor cut quality and excessive dross. Consistent height maintains stable arc voltage, delivering cleaner cuts.

Liberate your cutting process by mastering these techniques.

Frequently Asked Questions

What Safety Equipment Is Needed When Adjusting Plasma Cutter Tip Height?

When adjusting plasma cutter tip height, make certain you’re wearing safety goggles to protect your eyes from sparks and debris. Don protective gloves to shield your hands from heat and sharp metal edges, guaranteeing safe and precise operation.

Can Environmental Factors Affect the Ideal Tip Height for Plasma Cutting?

Yes, environmental factors like weather conditions and material properties can affect the best tip height. Variations in temperature or humidity may alter metal expansion or contraction, impacting cutting precision, potentially requiring adjustments for optimal performance and freedom in execution.

How Does the Thickness of the Metal Impact Standoff Settings?

Imagine metal thickness as a mountain’s height, dictating your journey’s path. As thickness increases, adjust standoff settings to maintain precision and efficiency, ensuring your cutting torch navigates smoothly, like a climber scaling the peak with finesse.

Is There a Recommended Tip Height for Cutting Non-Metal Materials?

For plasma cutting non-metal materials, you should maintain a standoff distance of about 1/8 to 1/4 inch. This guarantees ideal energy transfer and minimizes damage, providing precise cuts without compromising material integrity.

How Do You Troubleshoot Inconsistent Arc Voltage Due to Incorrect Tip Height?

To troubleshoot inconsistent arc voltage, check your tip height first. Adjust it gradually while measuring arc voltage. Use troubleshooting techniques like inspecting the consumables and ensuring proper ground connection to stabilize the performance throughout your cuts.

Conclusion

In plasma cutting, achieving the right tip height isn’t just a technical detail—it’s a game changer. Coincidentally, a mere adjustment of 1/16-inch can transform your cuts from mediocre to impeccable. By understanding the ideal standoff distances for various metals, you’ll enhance precision and reduce dross, ensuring your intricate designs come to life. So, take the time to fine-tune your torch height; it’s the key to revealing superior performance and efficiency in your cutting projects.