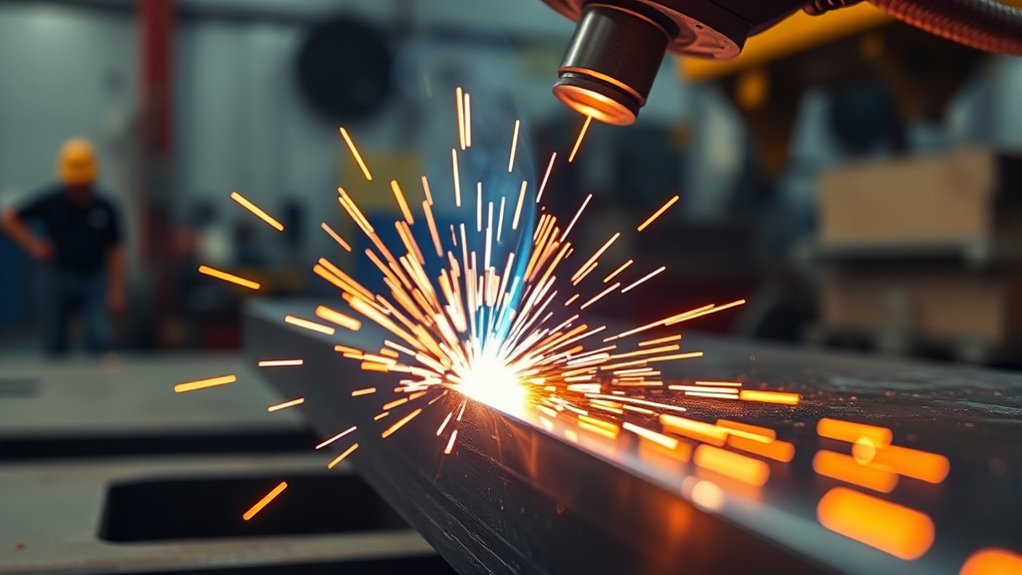

Plasma cutting offers you a host of advantages, making it a highly efficient choice for metal fabrication. Its versatility allows you to work with a variety of metals, including stainless steel and aluminum, with remarkable precision. You benefit from minimal heat distortion and reduced waste, enhancing both quality and cost-effectiveness. The process is fast, energy-efficient, and user-friendly, suitable for various material thicknesses. But what exactly makes plasma cutting so indispensable?

Versatility Across Various Metals

When you explore the versatility of plasma cutting across various metals, you’ll find it’s unmatched in efficiency and adaptability. This process excels in metal compatibility, effortlessly slicing through stainless steel, aluminum, brass, copper, and iron. Such compatibility guarantees that plasma cutting is suitable for diverse projects, whether you’re working on structural components or artistic endeavors.

The ability to stack and cut multiple materials at once further enhances project adaptability, streamlining fabrication tasks by boosting productivity.

Plasma cutting stands out with its rapid cutting speeds, especially for materials thicker than 15 mm, where it surpasses methods like oxy-fuel. This speed is vital for time-sensitive projects, allowing for quicker completion without sacrificing quality.

Furthermore, the technology’s capacity to craft intricate designs extends its utility beyond traditional applications, accommodating a wide array of creative and industrial needs. Ultimately, plasma cutting’s versatility makes it an indispensable tool in modern metal fabrication.

Enhanced Precision and Quality of Cuts

When you utilize plasma cutting, you achieve clean, sharp edges with minimal irregularities, essential for intricate patterns and detailed designs.

This method minimizes the heat-affected zone, preserving material integrity and preventing distortion.

Consequently, it guarantees high-quality cuts that meet stringent standards, even in complex fabrication tasks.

Intricate Pattern Capabilities

Plasma cutting stands out for its ability to produce clean, precise cuts, making it ideal for crafting intricate patterns and detailed designs in a variety of metals.

The high temperature of plasma, reaching up to 20,000°F, guarantees sharp edges and minimal jaggedness, fostering design creativity and artistic freedom. This technology easily handles conductive materials such as stainless steel and aluminum, maintaining precision across different thicknesses.

Its rapid cutting speed considerably reduces the time required for complex shapes, enhancing efficiency without sacrificing quality.

Whether you’re dealing with straight lines, curves, or elaborate artistic designs, plasma cutting‘s versatility supports a wide range of fabrication needs, allowing you to achieve precision and detail that are essential for intricate pattern capabilities.

Minimized Edge Irregularities

You’ll find that plasma cutting excels in producing clean and sharp cuts, greatly reducing jagged edges and irregularities compared to traditional methods.

The high temperatures, reaching up to 20,000°F, enable precise melting, resulting in superior edge refinement techniques. By minimizing the heat-affected zone (HAZ), plasma cutting preserves material integrity and reduces warping.

This process supports a thorough cutting quality assessment, ensuring high precision even in intricate designs.

- High temperatures improve edge quality

- Reduced heat-affected zone maintains material integrity

- Intricate pattern cutting with high accuracy

- Dross-free cutting simplifies material removal

- Enhanced edge refinement techniques for superior results

These qualities make plasma cutting an excellent choice for projects requiring precision and quality, ensuring minimal edge irregularities and a refined finish.

Cost-Effective Operation

Although traditional cutting methods like oxy-fuel have been widely used, plasma cutting stands out for its cost-effective operation. By reducing cutting times, plasma cutting notably enhances cost savings and operational efficiency. You’ll find that faster cutting reduces overall project expenses, making it a more economical choice compared to conventional methods.

Additionally, plasma cutting generates minimal waste, maximizing material use and lowering scrap costs, which additionally contributes to financial savings.

Moreover, plasma cutting is highly efficient at processing materials up to 50 mm thick, making it a practical option for large-scale operations requiring medium to heavy-duty cuts. This efficiency translates into reduced labor costs, as quicker project completion often demands fewer personnel.

Efficiently cuts materials up to 50 mm thick, reducing labor costs and expediting project completion.

In addition, the reduced risk of on-the-job injuries inherent in plasma cutting minimizes insurance and liability expenses, benefiting your business’s bottom line.

Minimal Heat-Affected Zone

When you use plasma cutting, the minimal heat-affected zone (HAZ) guarantees the integrity of your material by preventing excessive heat transfer that can lead to warping or distortion.

This precision is particularly beneficial for heat-sensitive materials, like aluminum, where maintaining structural stability is critical.

Preserved Material Integrity

Preserving material integrity during cutting processes is vital, and plasma cutting excels by generating a smaller heat-affected zone (HAZ) than many other methods.

This advantage plays a significant role in maintaining material performance and structural integrity. By minimizing heat exposure, plasma cutting guarantees that the surrounding material remains unaffected, leading to:

- Enhanced material performance: Preserves properties by reducing metallurgical changes.

- Superior structural integrity: Maintains strength in applications requiring precision.

- Tighter tolerances: Achieves higher quality in finished parts due to reduced HAZ.

- Consistency: Ensures consistent quality by minimizing heat-induced alterations.

- Suitability for sensitive materials: Ideal for materials like aluminum that are prone to heat damage.

With these benefits, plasma cutting stands out as a precise and reliable method for preserving material integrity.

Reduced Warping and Distortion

In plasma cutting, the reduced heat-affected zone (HAZ) plays a critical role in minimizing warping and distortion. By ensuring precise heat control, plasma cutting keeps thermal impact minimal, making it ideal for heat-sensitive materials like aluminum. The high-speed plasma jet reduces the heat exposure time, preserving the integrity of the surrounding material and maintaining overall quality.

| Aspect | Traditional Cutting | Plasma Cutting |

|---|---|---|

| Heat-Affected Zone | Larger | Smaller |

| Heat Exposure | Longer | Shorter |

| Material Selection | Limited | Versatile |

| Warping Risk | High | Low |

| Quality Control | Challenging | Enhanced |

Material selection becomes more flexible with plasma cutting, allowing you to work with thinner gauges without compromising on structural integrity. This precision leads to clean edges and fewer issues associated with warping and distortion.

Reduced Dross Production

By utilizing high-temperature, electrically charged gas, plasma cutting technology minimizes dross production, guaranteeing cleaner cuts with less residual material.

This innovation in cutting efficiency and dross management means you spend less time dealing with post-cut cleanups and more time focusing on production. Plasma cutting not only melts metal but also effectively blows molten metal away from the cut area, resulting in considerably reduced slag formation.

Consider these benefits:

- Cleaner Edge Quality: Achieve smoother, high-definition cuts with minimal dross.

- Reduced Post-Processing: Spend less time on cleanup and finishing, enhancing operational throughput.

- Enhanced Cutting Efficiency: Efficiently manage dross, allowing for quicker shifts between tasks.

- Versatility: Suitable for various thicknesses while maintaining dross-free results.

- Operational Cost Savings: Lower labor costs due to diminished need for manual dross removal.

The diminished dross production guarantees that plasma cutting remains a top choice for many fabrication applications, optimizing both workload and resources.

Fast Cutting Speeds

Plasma cutting delivers exceptional speed advantages, making it a standout choice for metal fabrication tasks. Its cutting speed benefits are undeniable, especially when handling thinner materials. Plasma cutting operates up to 12 times faster than oxyfuel, drastically enhancing productivity.

When dealing with materials up to 2 inches thick, its speed remains impressive, doubling that of traditional oxyfuel methods. This rapid pace means you can complete jobs quicker, maximizing operational efficiency.

One of the key factors contributing to these productivity enhancements is the elimination of preheating. Plasma cutting lets you start immediately, cutting down on preparation time.

Inside piercing applications are another area where plasma excels, as it can pierce ½ inch thick steel in just two seconds, a stark contrast to the over 30 seconds required with oxyfuel.

User-Friendly and Portable

Steering through the world of metal fabrication becomes considerably easier with the user-friendly and portable nature of modern plasma cutters.

These machines are engineered with intuitive interfaces, making them accessible even to less experienced operators. Thanks to portable designs, you can effortlessly transport them for both shop and fieldwork.

Intuitive interfaces make plasma cutters accessible, and portable designs allow easy transport for versatile use.

Their lightweight construction guarantees a single user can maneuver and control them without additional support. This adaptability meets diverse cutting needs while maintaining efficiency.

Consider these user-friendly features and portable benefits:

- Intuitive Interfaces: Simplifies operation for quick learning curves.

- Lightweight Construction: Enables easy handling and mobility by a single operator.

- Guided Settings: Reduces training time, boosting productivity.

- App-Based Operation: Enhances convenience and operational efficiency.

- Versatility Across Locations: Ideal for diverse environments, assuring reliable performance.

The combination of these features makes plasma cutters a robust choice for various metal cutting applications, providing unmatched ease and flexibility.

Suitable for Various Thicknesses

With plasma cutting, the ability to tackle diverse thicknesses transforms your metal fabrication projects. This process excels in thickness adaptability, effectively cutting metals up to 50 mm thick, making it perfect for heavy-duty applications.

It’s especially efficient in the 15 to 50 mm range, where it offers high-quality cuts for medium to thick materials. Plasma cutting isn’t just about thickness; it also boasts impressive material compatibility. You can confidently cut through steel and aluminum, though it’s best to limit aluminum thickness to 40 mm for best results.

When working with plates starting from 15 mm, plasma cutting provides a faster and more economical solution than many other methods. Its versatility allows seamless adaptation to varying thicknesses, making it a go-to choice for diverse fabrication projects.

This capability guarantees you can handle a wide range of tasks without compromising on quality or efficiency.

Energy Efficiency and Sustainability

When considering cutting methods for your fabrication projects, prioritizing energy efficiency and sustainability can greatly impact your operations.

Plasma cutting stands out by considerably reducing energy consumption compared to traditional methods. This efficiency not only cuts down utility costs but also supports your sustainable practices by minimizing environmental impact.

Plasma cutting offers energy efficiency and cost savings while enhancing sustainable practices.

Key benefits include:

- Lower Energy Consumption: Plasma cutting consumes less energy, reducing your operational costs.

- Minimal Waste Production: Its precise cutting capability generates minimal waste, enhancing sustainability in fabrication.

- No Preheating Required: Eliminating the need for material preheating saves additional energy and resources.

- Safer and Less Hazardous: Using non-flammable gases, plasma cutting is safer and environmentally friendlier than some alternatives.

- High Cutting Speed: Faster processing times allow for more efficient resource and energy use.

Frequently Asked Questions

What Safety Precautions Are Necessary When Using Plasma Cutting?

You should always wear personal protective equipment like gloves, goggles, and flame-resistant clothing. Guarantee equipment safety by regularly inspecting tools, maintaining clean workspaces, and using proper ventilation to prevent exposure to fumes and potential fire hazards.

How Does Plasma Cutting Compare to Laser Cutting in Terms of Precision?

Plasma cutting’s efficiency is notable, with cutting speeds up to 5 times faster than laser on thicker materials. However, laser cutting typically offers greater precision, achieving accuracy within ±0.1mm, which plasma can’t consistently match.

Can Plasma Cutting Be Used for Artistic Metalwork Projects?

Yes, you can use plasma cutting for artistic metalwork projects. It offers precision and versatility, enabling intricate plasma art and creative design. Its capability to cut diverse metals enhances your ability to execute detailed, imaginative pieces.

What Maintenance Is Required for Plasma Cutting Equipment?

You need to regularly replace plasma consumables, clean the equipment thoroughly, inspect connections for wear, guarantee airflow is unobstructed, and check cables for damage. Prioritize equipment cleaning procedures to maintain precision and prevent operational disruptions.

Are There Any Limitations to the Types of Materials That Can Be Cut?

Yes, you’ll encounter material compatibility and thickness limitations with plasma cutting. It’s best for conductive metals like steel or aluminum, but struggles with non-conductive materials. Cutting effectiveness decreases with materials exceeding certain thickness thresholds.

Conclusion

You’ve explored the compelling benefits of plasma cutting, from its versatility with metals to its precision and cost-effectiveness. Isn’t minimizing heat distortion and reducing waste essential in metal fabrication? With fast cutting speeds and minimal dross, plasma cutting guarantees efficient project completion. Plus, its user-friendly nature and portability make it accessible for various applications. By embracing energy efficiency and sustainability, plasma cutting not only lowers operational costs but also supports environmental responsibility.