If you work with metal, you need to know a plasma cutter’s key parts so you can choose, operate, and maintain one properly. You’ll look at the power supply, torch assembly (electrode, nozzle, swirl ring), gas and air systems, arc-start circuitry, and safety devices—each affects cut quality and consumable life. I’ll outline how they function and what to check next so you can match a cutter to your tasks.

What Is Plasma and Why It Matters for Cutting

Plasma, the fourth state of matter, forms when a gas is ionized by extreme heat so it can conduct electricity and transfer intense thermal energy for cutting.

You’ll recognize plasma properties as high temperature, electrical conductivity, and sustained arc stability; these permit a concentrated plasma jet that reaches temperatures up to 40,000°F.

In cutting applications you use ionized oxygen, nitrogen, or argon to create a focused, high-energy stream that melts and expels material efficiently.

You should note the ionization yields a stable, energetic arc that produces clean edges by rapidly melting and removing molten metal.

Compared with oxy-fuel methods, plasma’s electrical conduction and extreme heat improve performance on non-ferrous and thin conductive metals, expanding material compatibility.

To optimize results you’ll adjust gas type, flow, and power to match material and thickness, since plasma properties directly determine kerf width, dross formation, and cut speed.

Adjust gas type, flow, and power to material and thickness—plasma settings dictate kerf, dross, and cut speed.

Understanding these relations reduces trial-and-error and guarantees consistent, high-quality cuts.

How a Plasma Cutter Works: Step-by-Step

When you start a cut, you first clamp the ground to the workpiece to complete the electrical circuit, then press the torch trigger to release gas and strike the arc; that ionized, high-temperature jet melts the metal while the high-velocity gas stream blows the molten material away, producing a kerf whose quality depends on correct amperage, torch-to-work distance, and travel speed. You then maintain a steady travel speed and consistent torch height to control kerf width and dross. The operator modulates amperage and gas flow to match material thickness and desired cutting techniques. Monitor arc stability; instability indicates improper settings or torch wear. Follow safety precautions: eye and skin protection, ventilation, and secure ground. After cutting, inspect the edge for oxidation, dross, and perpendicularity; adjust parameters if needed. Routine consumable checks and proper torch maintenance preserve cut quality and process repeatability.

| Step | Action |

|---|---|

| 1 | Ground clamp attached |

| 2 | Trigger — gas flow |

| 3 | Arc — plasma jet |

| 4 | Melt + blowaway |

| 5 | Inspect & adjust |

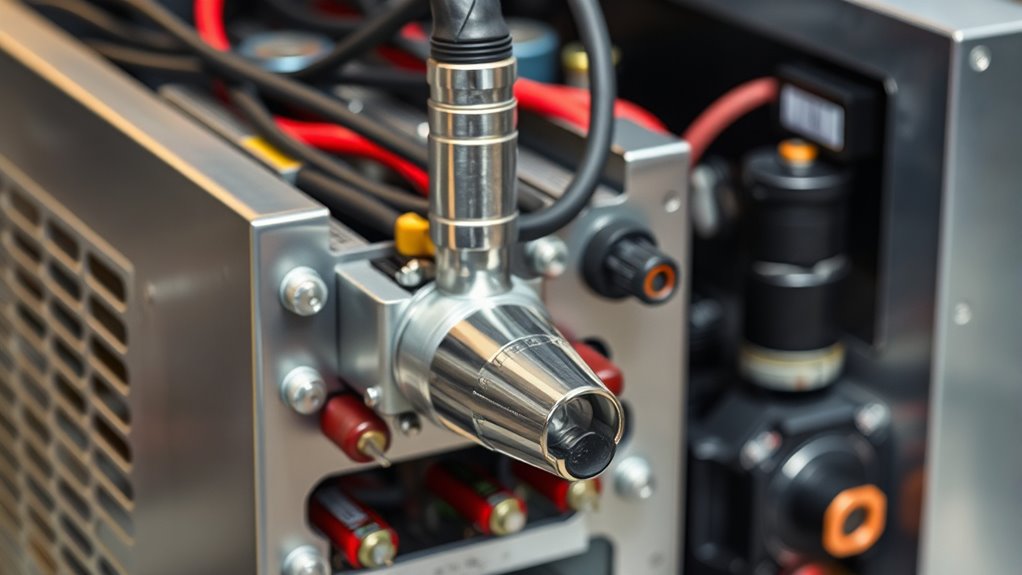

Power Supply and Electrical Components

After you’ve set torch height, amperage, and travel speed for a cut, the power supply and associated electrical components take over to create and sustain the arc that does the work.

The power supply converts your AC line voltage (typically 120V or 240V) into the high DC voltage (200–400 VDC) required to form the arc. A transformer and rectifier pair regulate voltage and current, delivering steady output under varying load to keep the plasma jet temperature consistent — often reaching ~40,000°F at the arc core.

An arc-starting console supplies an initial high-frequency AC pulse (≈5,000 VAC at ~2 MHz) to ionize the gas and initiate conduction.

Other electrical components include control circuits, wiring, and safety devices: circuit breakers and thermal overload protection interrupt power on faults or overheating.

You’ll rely on coordinated operation of these components to maintain stable arc behavior, protect the cutter, and guarantee repeatable, safe cutting performance.

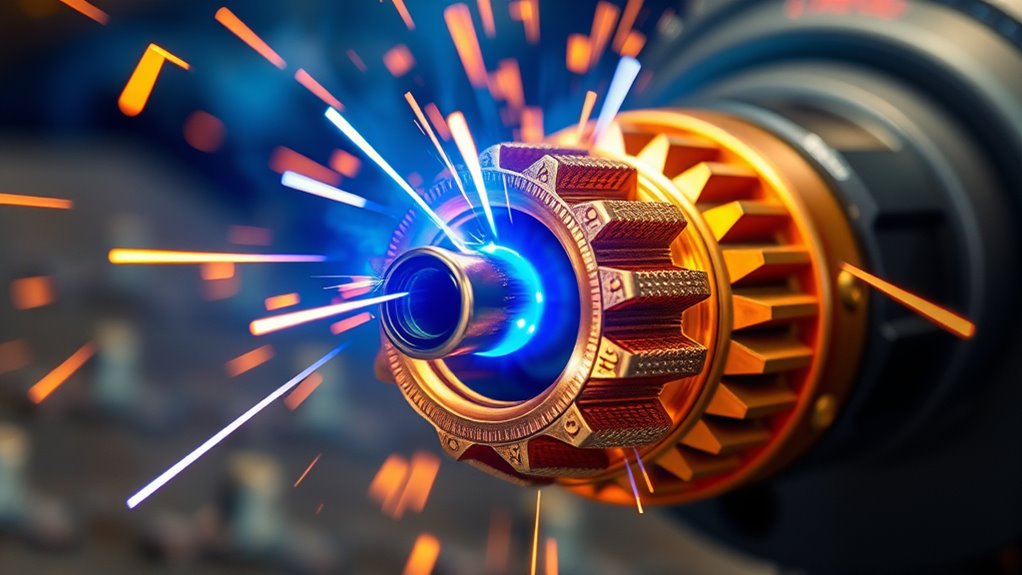

Plasma Torch: Electrode, Nozzle, and Swirl Ring

Although compact, the torch houses three consumable components—the electrode, nozzle, and swirl ring—that directly determine arc stability, cut quality, and consumable life. You rely on the electrode to generate a stable arc; electrode types vary by alloy and tip geometry to resist erosion and maintain consistent current transfer. Nozzle sizes determine plasma constriction; match nozzle sizes to cutting materials and material thickness for focused energy and minimal dross. Swirl ring designs impart controlled gas rotation, stabilizing the arc and improving kerf precision. Replace consumables on wear to preserve cut quality and efficiency. Inspect electrode erosion, nozzle lip shape, and swirl ring grooves during routine maintenance. Proper selection and timely replacement reduce wasted time, remakes, and consumable cost.

| Component | Emotional Cue |

|---|---|

| Electrode types | Confidence |

| Nozzle sizes | Precision |

| Swirl ring designs | Stability |

| Cutting materials | Control |

| Maintenance | Assurance |

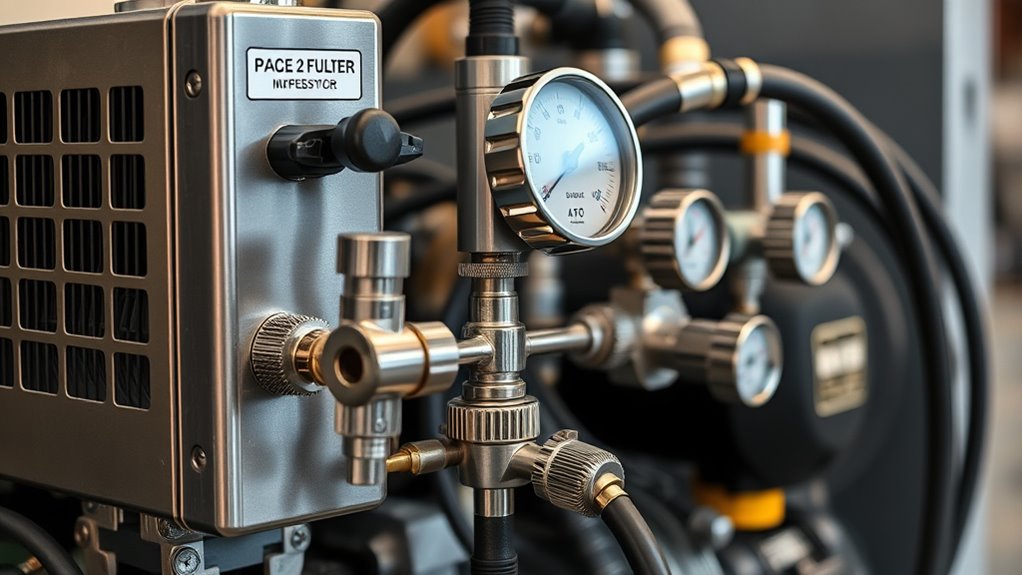

Gas and Air Systems: Compressors, Filters, and Regulators

Because the plasma arc depends on consistent, dry airflow, you need a properly sized compressor, filtration, and regulation to get repeatable cuts; compressors typically supply 70–120 psi, filters or air dryers remove moisture and particulates, and the regulator on the machine lets you fine-tune output pressure for stable plasma performance.

You’ll select a compressor rated for continuous duty and adequate flow (CFM) at the working air pressure to prevent drop-off under load.

Install a staged filtration train: coalescing and particulate filters, then a desiccant or refrigerated dryer for effective moisture control.

Locate the regulator at the machine’s rear to adjust air pressure precisely for material thickness and torch specifications.

Use pressure gauges upstream and downstream of filters to monitor drop across elements and schedule replacements before differential rises.

For portable units with built-in compressors, verify integrated filtration and regulator capacity match the cutter’s required psi and CFM to maintain consistent arc stability and prevent contamination-related failures.

Consumables, Wear Parts, and Maintenance Tips

Clean, regulated air and correct pressure give you repeatable arcs, but the cut quality ultimately depends on consumables—nozzle, electrode, and gas baffle—which wear with use and must be inspected and replaced frequently.

Consumables typically require replacement every 1–2 hours of heavy cutting; tracking consumable lifespan prevents degraded performance. You’ll select nozzle size and type to match material thickness and composition; mismatched parts increase kerf width, inconsistent cuts, and dross.

Replace consumables every 1–2 heavy cutting hours; match nozzle size to material to avoid wide kerfs and dross.

For maintenance, keep the air supply clean and dry with quality filters and routine drain cycles to avoid moisture damage.

Verify torch and consumable alignment at each change; improper alignment shortens parts and alters arc stability. Use exploded-view diagrams for efficient disassembly, part identification, and reassembly when troubleshooting wear.

Establish a maintenance frequency schedule based on duty cycle and cutting conditions, logging hours and part changes. This disciplined approach maximizes cut quality, reduces downtime, and optimizes consumable lifespan.

Sizing, Capabilities, and Matching a Cutter to Your Work

When you size a plasma cutter, use the amperage rating as your primary guideline—machines from about 20 to 120 A determine practical cutting thickness and cycle speed—because higher amps penetrate thicker or denser metals and maintain faster travel rates.

You perform amperage selection by matching rated current to material thickness and composition: low‑amp units handle thin sheet (≈18 gauge) and light aluminum, midrange units cut up to 1/2″ mild steel, and high‑amp systems manage 1″ or more and dense stainless.

Adjust standoff distance and air pressure to optimize cut quality and speed for each material thickness; incorrect settings produce dross, taper, or reduced pierce capacity.

Confirm consumables (electrode, nozzle) match torch and amperage to avoid premature wear that degrades edge quality.

For production work, consider duty cycle and pierce rating at your chosen amperage so the cutter sustains required cycle speed without overheating.

Match cutter capabilities to part geometry, material, and planned throughput for efficient, repeatable results.

Frequently Asked Questions

Can a Plasma Cutter Be Used Underwater or in Wet Conditions?

No — you can’t safely use a plasma cutter underwater or in wet conditions. Plasma cutters require dry, controlled environments; underwater welding uses specialized hyperbaric or wet-arc systems, insulating gear, and strict protocols to prevent shock and equipment failure.

What Safety Equipment Is Legally Required for Plasma Cutting in Workshops?

Think of a fortress: you’ll need safety goggles, leather gloves, welding apron, respirator, ear protection, and steel-toe boots; you’ll keep a fire extinguisher nearby, grounded equipment, proper ventilation, and documented training and permits.

How Do Plasma Cutters Affect Nearby Electronics or Sensitive Equipment?

Plasma cutters generate EMI that can disrupt nearby electronics; you should mitigate interference using shielding, filtering, and grounding techniques, maintain distance, use ferrites and isolated circuits, and monitor sensitive equipment during cutting operations.

Can Hobbyists Build a DIY Plasma Cutter Safely and Legally?

You can, but you’ll need deep skills, proper PPE, and adherence to DIY plasma safety regulations; you’ll follow electrical codes, ventilation, fire prevention, and EMI controls, document testing, and often obtain permits or inspections before operating.

What Are Typical Warranty Terms and Service Options for Plasma Cutters?

You’ll typically get 1–3 year warranty coverage for defects, parts, and limited labor; extended service plans offering onsite repairs, preventive maintenance, and consumable discounts are optional; read exclusions, transferability, and response times before buying.

Conclusion

You now know the core plasma cutter parts and how they interact, so you’ll choose, maintain, and match systems with confidence. Keep the power supply, torch consumables, gas/air delivery, arc-starting circuitry, and safety devices in spec to preserve cut quality and lifespan. Treat consumables like clockwork: inspect, replace, and filter regularly. Like an analog pocket watch in a digital shop, attention to these mechanical details keeps precision cutting reliable and repeatable.