Imagine a tool so efficient that it seems to slice through metal like a hot knife through butter—welcome to the world of pilot arc plasma cutters. With its ability to generate an initial arc without contacting the workpiece, this technology excels in cutting through tough, painted, or rusty surfaces. It’s the go-to choice for jobs requiring precision and durability. Curious about how it can transform your metalworking projects? There’s more to uncover.

Understanding Pilot Arc Technology

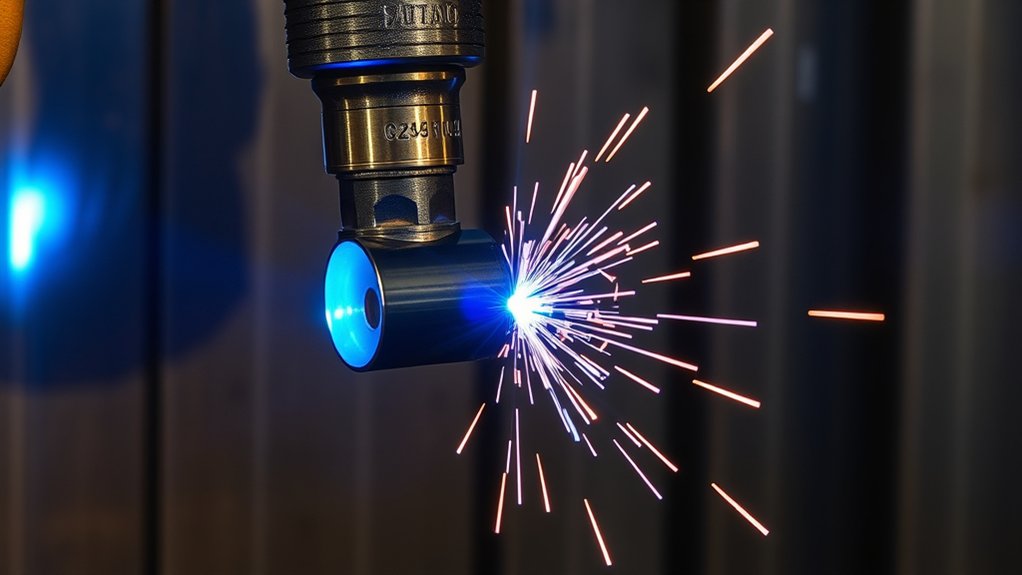

Pilot arc technology revolutionizes plasma cutting by generating a low-energy electrical arc between the electrode and nozzle before contacting the workpiece. This arc initiation method allows you to cut through materials without needing pre-drilled holes, considerably enhancing cutting efficiency.

By utilizing a pilot arc, you’ll experience seamless piercing through tough surfaces, like painted or rusty ones, without compromising performance.

Effortlessly pierce tough surfaces, including painted and rusty, without compromising cutting performance.

Non-contact initiation provided by pilot arc technology isn’t only practical but also economical. It minimizes torch wear, thereby extending the lifespan of consumables compared to traditional systems. This translates to less downtime and reduced maintenance costs, essential for maintaining productivity in industrial settings.

Moreover, pilot arc technology guarantees cleaner cuts with reduced dross formation, which is particularly beneficial when working on intricate designs. The stable arc performance leads to improved cutting quality, making it an ideal choice for detailed work across various applications.

Key Features of Pilot Arc Plasma Cutters

You’ll find that pilot arc plasma cutters excel in maintaining arc stability on surfaces with imperfections like rust or paint.

This capability guarantees consistent cutting performance without needing pre-drilled holes, making these cutters highly versatile across different cutting conditions.

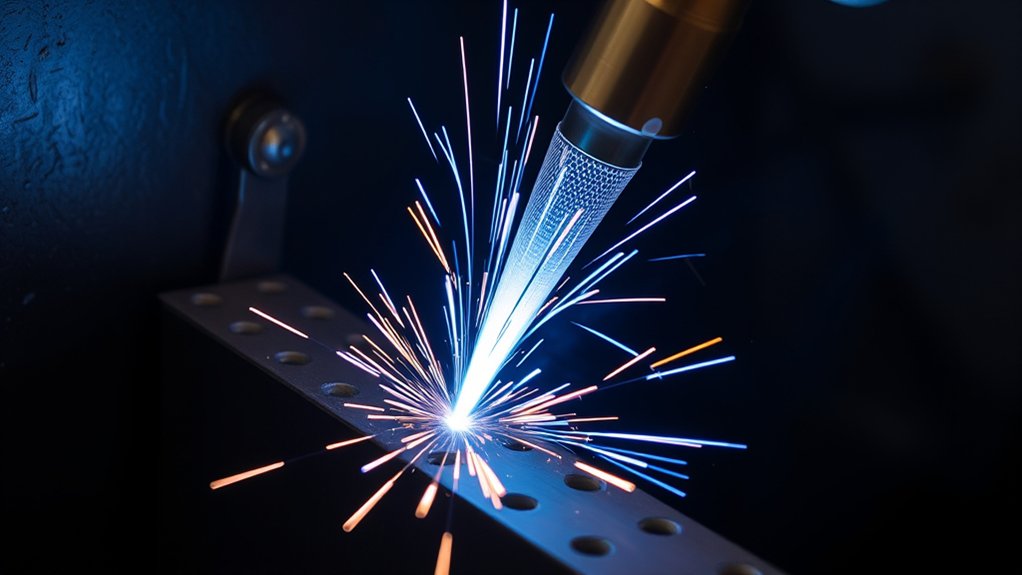

Arc Stability on Imperfections

Even when you’re dealing with painted or rusty surfaces, pilot arc plasma cutters excel at maintaining arc stability, ensuring consistent performance in tough conditions.

This is essential for enhancing arc performance and cutting precision, allowing you to tackle challenging materials effectively.

With a pilot arc, you enjoy several advantages:

- Non-Contact Cutting: The low-energy pilot arc cuts without touching the workpiece, reducing torch wear and damage.

- Enhanced Efficiency: You can pierce metal directly without pre-drilled holes, saving time and effort on flawed surfaces.

- Cleaner Cuts: Expect less dross and smoother edges, even on imperfect materials, compared to non-pilot arc options.

Utilize the pilot arc for intricate designs and maintain control across various materials.

Versatility in Cutting Conditions

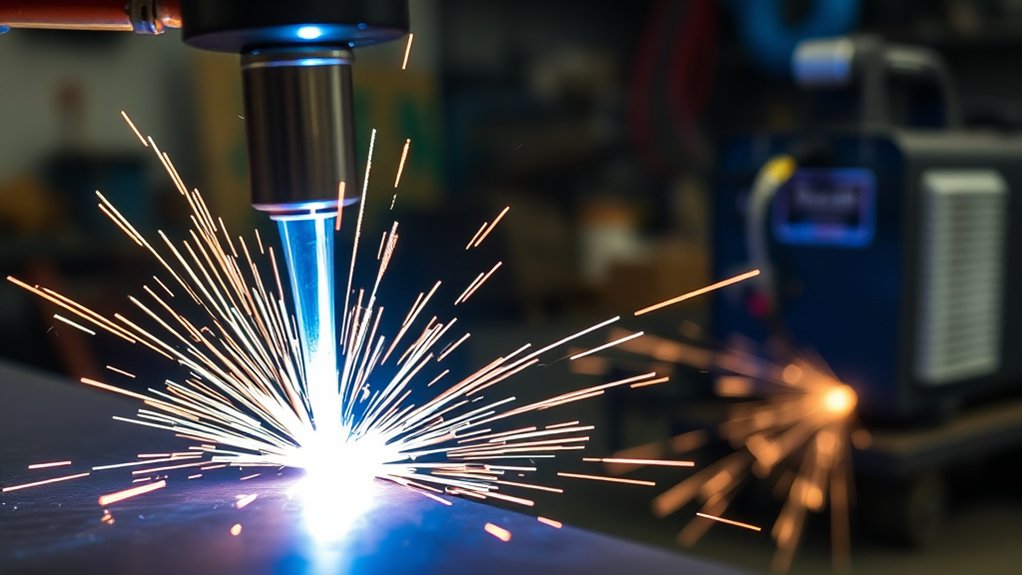

When tackling varied and challenging cutting conditions, a key feature of pilot arc plasma cutters is their remarkable versatility.

These tools excel in cutting efficiency and material compatibility, allowing you to work on a wide range of surfaces with ease. The technology enables you to begin cutting without direct contact, ensuring stable performance even on painted or rusty surfaces. This feature is essential for maintaining high cutting efficiency under challenging conditions.

Pilot arc cutters also eliminate the need for pre-drilled holes, letting you pierce thick metals directly, streamlining operations.

You’ll achieve cleaner cuts with minimal dross, producing superior finishes on intricate designs. In industrial settings, where surface imperfections are common, pilot arc technology delivers consistent, reliable results, catering to diverse applications and material types.

Comparing Pilot Arc and Non-Pilot Arc Cutters

Although both pilot arc and non-pilot arc plasma cutters serve the primary function of cutting through metals, they differ significantly in their operational mechanisms and suitability for specific conditions.

A pilot arc cutter enhances cutting efficiency by generating an initial high-frequency arc independent of the workpiece, allowing you to cut through challenging surfaces without extensive surface preparation. This capability guarantees stable performance even on rusted or painted metals.

Conversely, non-pilot arc cutters require direct contact with the metal to initiate cutting, which might limit their functionality on coated or dirty surfaces. While they’re generally more cost-effective and portable due to fewer components, they often struggle with cutting quality on imperfect surfaces.

Consider these factors:

- Cutting Conditions: Pilot arc excels on uneven surfaces, whereas non-pilot arc suits clean metals.

- Cost: Non-pilot arc models are typically more affordable.

- Cut Quality: Pilot arc offers cleaner cuts with less dross.

Advantages of Using Pilot Arc Technology

Leveraging pilot arc technology in plasma cutters offers significant advantages, particularly in challenging environments where surface preparation isn’t feasible. You can easily cut through painted, rusty, or uneven surfaces without the hassle of pre-cleaning. This boosts cutting efficiency by maintaining stable arcs, leading to cleaner cuts and less dross. Additionally, because you don’t need direct contact to initiate the arc, consumables wear less quickly, reducing costs and extending their lifespan.

Consider the following:

| Benefit | Description | Impact |

|---|---|---|

| Surface Preparation | Cuts through paint, rust, or uneven surfaces | Saves time and effort |

| Arc Stability and Control | Cleaner cuts with reduced dross | Increases cutting efficiency |

| Consumable Longevity | Minimizes direct contact with workpiece | Reduces operational costs |

In industrial settings, especially in automotive and fabrication sectors, the versatility of pilot arc plasma cutters allows for handling various materials and thicknesses, supporting intricate designs with precision.

Ideal Applications for Pilot Arc Plasma Cutters

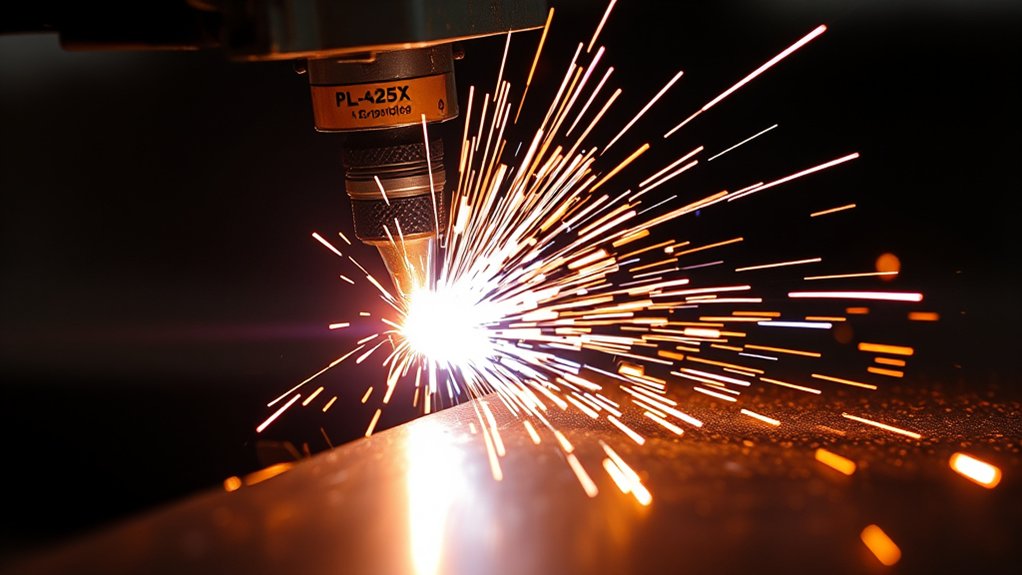

Pilot arc technology sets a new standard in plasma cutting, particularly in environments where surface preparation is challenging.

Pilot arc technology revolutionizes plasma cutting in tough conditions, redefining precision and reliability without extensive surface preparation.

You’ll find it invaluable in industrial applications where precision and reliability are non-negotiable. Whether you’re dealing with rusted, painted, or contaminated metal surfaces, pilot arc plasma cutters eliminate the need for pre-cleaning, streamlining your workflow.

Here’s where you should consider using them:

- Metal Fabrication: These cutters are perfect for intricate designs and detailed work, allowing you to pierce metal without pre-drilled holes, ideal for complex welding projects.

- Automotive Repair: In this sector, precision is key. Pilot arc plasma cutters provide consistent performance on uneven surfaces, ensuring clean cuts and reducing the need for post-processing.

- Heavy-Duty Industrial Use: Their ability to maintain a stable arc in challenging conditions makes them suitable for rough environments, enhancing cutting quality and efficiency.

Cost Considerations for Pilot Arc Machines

Why consider investing in a pilot arc plasma cutter? Though the initial investment is 20-30% higher due to advanced technology, you’ll appreciate the long-term savings. These machines reduce wear on consumables and boast a longer lifespan, cutting your operating costs considerably over time. Additionally, their enhanced performance on challenging materials like painted or rusty surfaces saves you time and labor, improving efficiency.

| Feature | Non-Pilot Arc Model | Pilot Arc Model |

|---|---|---|

| Initial Cost | Lower | Higher |

| Consumable Lifespan | Shorter | Longer |

| Performance on Rust/paint | Lower | Higher |

| Long Term Savings | Lesser | Greater |

In industrial settings where precision and reliability are essential, pilot arc cutters justify their cost through increased productivity and reduced downtime. When evaluating your options, weigh the benefits of improved cutting quality against the higher upfront cost. Ultimately, investing in a pilot arc cutter can be a strategic financial decision, maximizing both performance and savings.

Choosing the Right Plasma Cutter for Your Needs

When selecting a plasma cutter, consider whether a pilot arc or non-pilot arc model suits your needs.

Pilot arc cutters are ideal for materials with imperfections, initiating the arc without direct contact and offering superior performance in challenging conditions.

Non-pilot arc models, being more affordable and portable, are perfect for simple, clean-cutting tasks and DIY projects.

Pilot vs. Non-Pilot Differences

Selecting the right plasma cutter hinges on understanding the fundamental differences between pilot and non-pilot arc models.

Pilot arc advantages are clear when dealing with challenging surfaces like rust or paint. These models initiate the cutting process with a high-frequency arc, providing consistent performance without direct contact. They excel at piercing metal without pre-drilling, making them ideal for intricate tasks.

In contrast, non-pilot limitations include the need for direct contact to start the arc, which can hinder effectiveness on coated or dirty surfaces.

Consider these factors when deciding:

- Surface Condition: Use a pilot arc for rusty or painted surfaces.

- Cutting Complexity: Choose a pilot arc for intricate cuts.

- Cost Concerns: Non-pilot is more budget-friendly.

Cost and Portability Factors

In evaluating plasma cutters, how do cost and portability influence your choice? Cost efficiency is essential.

Pilot arc plasma cutters are typically $20-$30 more expensive due to their advanced features, impacting your budget. However, if you’re working with painted or rusty materials, the investment may offer a better long-term return.

On the other hand, non-pilot arc cutters provide a cost-effective solution for simple, clean cuts, especially when budget constraints are pressing.

Weight comparison is another factor. Non-pilot arc models are generally lighter, enhancing portability for DIY enthusiasts who need to move their equipment frequently.

Frequently Asked Questions

How Does Pilot Arc Affect the Lifespan of Consumables?

Using a pilot arc enhances consumable lifespan by providing better arc stability. You’ll notice reduced wear on parts since the pilot arc initiates without direct contact, minimizing electrode and nozzle degradation, thereby extending your consumables’ effective use.

Can Pilot Arc Plasma Cutters Be Used Underwater?

Can you use pilot arc plasma cutters underwater? Absolutely, but you’ve got to guarantee the equipment is designed for underwater cutting. Specialized plasma technology helps maintain performance and safety, preventing electrical hazards while delivering precise, efficient cuts.

What Maintenance Does a Pilot Arc System Require?

Guarantee pilot arc maintenance by regularly inspecting and replacing consumables. Keep the nozzle, electrode, and torch clean to prevent performance issues. Check connections for wear and tear, and verify airflow is unobstructed for peak cutting efficiency.

Are There Specific Safety Precautions for Using Pilot Arc Technology?

Are you ready to tackle electrical hazards safely? Always wear proper safety gear like gloves and goggles. Make certain your workspace is dry and well-ventilated. Regularly inspect cables and connections to prevent any unexpected electrical surges or shocks.

How Does Pilot Arc Influence Cutting Speed and Quality?

Pilot arc enhances cutting efficiency and arc stability, allowing you to cut faster with smoother edges. You’ll experience less slag and reduced dross, resulting in superior precision and quality, especially on rusted or painted metal surfaces.

Conclusion

Think of a pilot arc plasma cutter as the key opening a door to efficiency and precision. Its technology lets you cut through barriers like rust and paint with ease, ensuring every slice is clean and precise. Opt for a pilot arc when you’re tackling intricate designs or challenging surfaces. While the initial cost might seem steep, the savings on consumables and improved productivity are the real treasures, making it a worthy investment for any metalworking journey.