When considering the ideal thickness for plasma cutting, it’s important to assess the capabilities of your machine and the specific material you’re working with. For thin sheets, a range between 0.5 mm and 6 mm is typically best, especially with FineCut consumables. Mid-range thicknesses from 1/4-inch to 1-inch require 65A to 85A. Heavy-duty cutting can tackle materials over 1 inch, with high-end machines reaching up to 2-2.4 inches. But what other factors could influence these capabilities?

Understanding Plasma Cutting and Metal Thickness

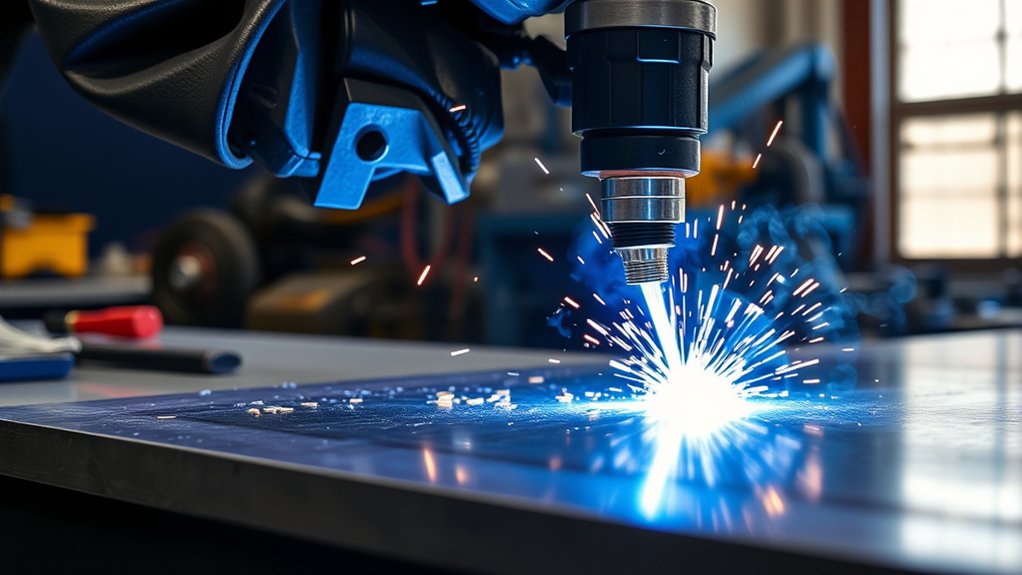

When you’re delving into plasma cutting, understanding the correlation between machine capabilities and metal thickness is vital. Plasma technology allows you to cut through metals with precision and efficiency, but choosing the right machine is important for achieving ideal results.

Entry-level machines efficiently handle steel up to 12mm (0.5 inches), catering to simpler tasks. For more demanding requirements, mid-range machines offer cutting efficiency up to 32mm (1.25 inches), aligning well with typical workshop needs.

Entry-level plasma cutters handle up to 12mm steel, while mid-range units cut efficiently up to 32mm.

High-end industrial systems push the boundaries further, cutting through thick steel plates up to 50-60mm (2-2.4 inches), liberating you to tackle heavy-duty applications. The key lies in selecting a machine with the appropriate power class. Higher amperage levels boost the capacity to cut thicker materials effectively.

Always align the machine’s rated thickness with your daily materials to maximize performance and efficiency. This synergy empowers you to harness plasma technology’s full potential.

Optimal Thickness for Thin Metal Sheets

When you’re plasma cutting thin metal sheets, precision challenges arise due to potential heat distortion and movement of the material.

Selecting the proper equipment, such as FineCut consumables, is essential to achieve a narrow kerf and a stiff arc, enhancing cut accuracy.

Make sure you maintain cutting speeds between 50 and 100 IPM and secure the sheet to minimize warping and optimize cut quality.

Precision Cutting Challenges

Despite the inherent challenges in precision cutting, achieving ideal results with thin metal sheets in plasma cutting hinges on several vital factors. Embrace precision control to combat thermal distortion, ensuring the metal remains intact and true. Here’s how you can master the process:

- Thickness Mastery: Stick to sheets ranging from 0.5 mm to 6 mm to minimize warping and excessive melting. This sweet spot enhances precision.

- Consumable Savvy: Employ FineCut consumables for a narrow kerf and stable arc, essential for fine precision.

- Speed Regulation: Carefully monitor cutting speeds. Slower speeds reduce heat input, preserving edge quality.

- Amperage Adjustment: Use 45-65 A for cuts up to 12.7 mm to maintain peak efficiency and precision.

Liberate your craft by controlling these variables effectively.

Proper Equipment Selection

Selecting the right plasma cutting equipment for thin metal sheets requires precision and a keen understanding of machine capabilities. Focus on machine features and the duty cycle to guide your choice.

Handheld models like the Hypertherm Viper 30 XP are ideal for sporadic tasks, while the Viper 65 suits high-demand environments. When cutting materials between 1/16 inch (1.6 mm) and 1/4 inch (6.35 mm), consider FineCut consumables for a narrow kerf and stiff arc, essential for minimizing warping.

Secure the sheet properly to enhance cut quality and speed. Adjust the amperage meticulously, aligning it with the material’s thickness for maximum performance.

This strategic approach empowers precision, ensuring clean, accurate cuts on thin metals, liberating your creative potential.

Recommended Thickness for Medium-Thickness Metals

When cutting medium-thickness metals from 1/8 inch to 1 inch, you’ll need to adjust the power output to match the material’s thickness for ideal precision.

Consider cutting speeds, as a machine like the Hypertherm Powermax 85 SYNC offers 200 IPM at 1/4-inch and 21 IPM at 1-inch thickness, impacting overall productivity.

Material type plays an important role; different metals may require specific settings to minimize dross and guarantee clean cuts.

Optimal Power Output

To achieve clean cuts on medium-thickness metals, it’s vital to operate your plasma cutter within the recommended power output range of 65A to 85A. This range guarantees ideal power settings for materials spanning 1/4-inch to 1-inch thick. The precision of your cutting techniques is influenced by maintaining consistent amperage, significant for cut quality.

Consider these aspects:

- Duty Cycle: Select a plasma cutter with at least a 60% duty cycle, like the Hypertherm Powermax 85 SYNC, for sustained performance.

- Cutting Speed: While higher amperage boosts speed, balance it with quality on thicker metals.

- Consistency: Verify your machine delivers steady amperage to maintain cut precision.

- Continuous Operation: For high uptime, a machine with a 100% duty cycle, like the Hypertherm Powermax 105 SYNC, is ideal.

Cutting Speed Considerations

Although thickness plays an essential role, achieving ideal cutting speed for medium-thickness metals requires a nuanced understanding of your plasma cutter’s capabilities.

For instance, when cutting 1/4-inch mild steel, aim for 200 inches per minute (IPM) to minimize heat input and reduce warping. In contrast, a 1-inch thickness necessitates a slower cutting speed of around 21 IPM.

To maintain peak performance, adjust your amperage settings between 85 to 94A based on material specifics. The gas type used can considerably affect cutting speed; oxygen, for example, can enhance speed and edge quality.

Monitor arc stability vigilantly—too rapid a traverse results in poor edge quality, while sluggish movement leads to excessive dross. Balance is key for precise, liberating cuts.

Material Type Impact

Understanding the impact of material type on plasma cutting is essential for achieving ideal results, especially with medium-thickness metals.

Different metals require specific cutting techniques, tailored to their material properties:

- Mild Steel: For thicknesses of 1/2 inch (12 mm) to 3/4 inch (19 mm), utilize a power output of 65-85 A. For up to 1 inch (25 mm), increase to 85-105 A.

- Stainless Steel: Needs higher amperage. Use 45-65 A for 1/2 inch (12 mm) and 65-85 A for 3/4 inch (19 mm).

- Aluminum: Softer, allowing 45-65 A for 1/2 inch (12 mm) and 65-85 A for thicker cuts.

- Plasma Gas Choice: Opt for nitrogen with stainless steel, reducing oxidation and enhancing cut quality.

These precise settings guarantee efficient liberation from material constraints.

Best Thickness for Cutting Thick Metal Plates

When tackling the challenge of cutting thick metal plates, selecting the right plasma cutter is crucial for achieving precise and efficient results. In heavy-duty applications, you need a powerful machine that can handle substantial thicknesses.

Consider the Hypertherm MAX200, which delivers a 200A output, cutting up to 2 inches (50mm) at 6 IPM. This workhorse is ideal for industrial-grade plasma cutting techniques.

For more portable needs, the Hypertherm Python 125 offers cutting up to 1 and 3/4-inch steel at 10 IPM with a 125A output, though it demands a 480/600 3-phase input.

To enhance performance on stainless steel and aluminum, utilize an argon-hydrogen gas mixture (35% hydrogen, 65% argon).

Your machine’s pierce capacity and cutting speed are critical; they guarantee efficient, clean cuts without excessive dross. Typical thickness ranges span 1 inch to over 2 inches.

Factors Affecting Cut Quality and Thickness

For ideal plasma cutting, several key factors directly influence cut quality and thickness. First, the machine’s power class is essential. An entry-level system handles up to 1/2 inch, while high-end machines tackle 2 inches or more. Here’s what you need to evaluate:

The machine’s power class dictates the maximum material thickness achievable during plasma cutting.

- Amperage: Higher amperage levels, like a 45 A machine, enable cutting thicker materials, such as 1/2 inch steel, enhancing cut quality.

- Process Gas: The choice of process gas is fundamental. Oxygen yields cleaner edges on mild steel, whereas nitrogen optimizes results for stainless steel and aluminum, directly affecting cut quality.

- Torch Height Control (THC): Accurate THC maintains a consistent kerf. It adjusts for material warpage, ensuring precise cut thickness.

- Cut Speed: Monitor your cut speed meticulously. Excessive speed can degrade cut quality and cause dross, especially with thicker materials.

Liberate your skills by mastering these elements for superior plasma cutting results.

Safety Precautions and Equipment Selection for Plasma Cutting

Although plasma cutting is a powerful and efficient process, prioritizing safety precautions and equipment selection is imperative for best results. Equip yourself with the correct personal protective equipment (PPE): heavy-duty gloves, safety glasses, and reinforced boots. These essentials shield against sharp edges and burns from hot metal.

Choose a plasma cutter that’s fit for your task. Industrial-grade machines like the Hypertherm MAX200, with high amperage output and superior duty cycles, are ideal for thick metal plates.

Ensure equipment compatibility by aligning your plasma cutter with CNC electronics. High-frequency machines can harm incompatible control boxes, which could jeopardize your operation. Secure thin metal sheets to prevent warping, which maintains precision during cutting.

Always handle freshly cut parts with caution due to their retained high temperatures, reducing burn risk. Prioritizing safety and selecting appropriate equipment not only enhances efficiency but also liberates you from potential hazards.

Frequently Asked Questions

How Can I Improve Cut Quality on Stainless Steel?

Improve your cut quality on stainless steel by optimizing cutting speed and ensuring meticulous material preparation. Calibrate speed precisely; too fast causes dross, too slow increases heat-affected zones. Clean and deburr the steel surface for ideal conductivity.

What Role Does Gas Selection Play in Plasma Cutting?

Gas selection is essential; it can influence cut speed by up to 25%. Utilizing the right gas types and pressure settings guarantees precision in plasma cutting, liberating you from inefficiency and enhancing your craftsmanship with detailed precision.

Are Special Nozzles Required for Different Metal Thicknesses?

Yes, you’ll need special nozzle types to handle various metal thicknesses. Precise nozzle selection guarantees ideal plasma arc control, enhancing performance within specific thickness limits. This precision liberates you to achieve cleaner, more efficient cuts across diverse materials.

Can Plasma Cutting Be Used on Non-Metal Materials?

You can use plasma cutting on non-metal materials like carbon composites, but efficiency drops. Studies show only 10% of plasma cutters handle non-metals effectively. Precision demands understanding material properties, conductivity, and thermal resistance for successful cuts.

How Does Plasma Cutting Compare to Other Cutting Methods?

You’ll find plasma cutting excels in speed and cost-efficiency compared to laser cutting. However, when precision’s paramount, laser cutting’s superior. Waterjet cutting’s versatility handles diverse materials but lacks plasma’s speed, requiring you to prioritize needs.

Conclusion

In your plasma cutting journey, the metal’s thickness becomes the dance floor for precision and power. Thin sheets, like delicate lace, find their match at 0.5 mm to 6 mm, while 1/4-inch to 1-inch thicknesses invite mid-range prowess at 65A to 85A. For the heavyweights, over 1 inch, you wield the might of machines up to 2.4 inches. Remember, your settings are the maestro, orchestrating quality cuts with safety and precision.