When considering plasma cutting, you’ll find it can handle a wide range of metals with precision. It efficiently cuts both ferrous metals like mild and stainless steel and non-ferrous metals such as aluminum and copper. Each metal requires specific settings and considerations to achieve ideal results. With the right plasma cutter, you can tackle your project effectively. Want to learn about the nuances of cutting different metals?

How Plasma Cutting Works

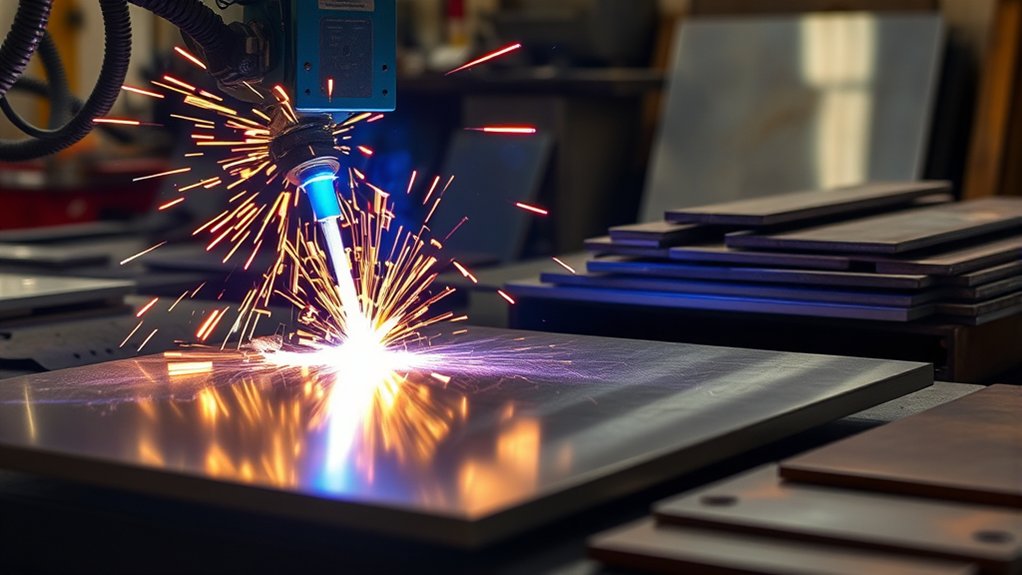

When exploring the intricacies of plasma cutting, it’s essential to understand that this process generates a high-temperature plasma arc through ionized gas, capable of reaching up to 30,000 degrees Fahrenheit.

By passing electricity through compressed air, you create ionized gas, which forms a focused flame powerful enough to slice through electrically conductive materials.

Your plasma cutter’s precision, achieving an accuracy of ±0.006 inches per 3 feet (0.15 mm per meter), guarantees that even demanding applications are met with ease.

As the plasma arc moves, it melts the metal, providing a smooth edge and polished finish.

This method liberates you from limitations, allowing precise cuts across a variety of metals.

Ferrous Metals Suitable for Plasma Cutting

When selecting ferrous metals for plasma cutting, you’ll find mild steel offers versatility and cost-effectiveness, making it a popular choice.

Stainless steel benefits from plasma technology’s precision, yielding minimal dross and maintaining its corrosion resistance and structural integrity.

High-strength low-alloy steels, like A572 or A514, are efficiently processed, ensuring robust edge integrity even with thicker materials.

Mild Steel Versatility

Thanks to its availability and cost-effectiveness, mild steel stands as the most commonly used ferrous metal for plasma cutting, offering remarkable versatility across various applications.

Mild steel applications in plasma cutting are vast, ranging from fabricating light-gauge sheets to crafting heavy structural plates up to 50 mm thick.

When you configure your plasma cutter correctly, you’ll achieve fast, clean cuts with minimal dross. This efficiency amplifies the value of plasma cutting benefits, making your fabrication processes more streamlined.

Utilizing oxygen as the cutting gas, you can achieve high-speed cuts and pristine edges, surpassing other methods.

Mild steel’s excellent conductivity further enhances its suitability for plasma cutting, allowing you to create intricate, precise designs that liberate your metalworking projects from limitations.

Stainless Steel Advantages

Stainless steel offers significant advantages in plasma cutting, particularly due to its outstanding corrosion resistance, which suits it perfectly for demanding environments like food processing and marine applications.

Its durability means you can rely on it for long-term use without compromising performance. Plasma cutting allows precision cutting of stainless steel up to 38 mm thick, minimizing dross and ensuring clean edges.

Consider these benefits:

- High-Temperature Stability: Stainless steel retains structural integrity at high temperatures, making it ideal for precision fabrication.

- Versatile Applications: Different grades allow plasma cutters to handle a range of projects, from architectural elements to medical equipment.

- Reduced Oxidation: Using nitrogen or argon-hydrogen as cutting gas reduces oxidation, enhancing the quality of your cuts.

With stainless steel, you’re equipped for precision and versatility.

High-Strength Alloys Efficiency

While stainless steel showcases impressive capabilities in plasma cutting, the domain of high-strength alloys opens up further possibilities for efficient metal fabrication. High-strength low-alloy (HSLA) steels, like A572 and A514, excel in high strength applications. Their superior alloy performance guarantees edge integrity and minimal thermal distortion even in thicker grades. Plasma cutting is particularly effective for HSLA steels, offering rapid heat input and high cutting speeds, ideal for structural engineering and pressure vessels.

| Feature | Benefit |

|---|---|

| Thermal Properties | Maintains edge integrity |

| Thickness Range | 1 mm to over 50 mm |

| Cost Efficiency | Faster, cost-effective cutting |

You’ll find plasma cutting’s efficiency liberating, especially in mass production, as it elevates alloy performance while conserving material integrity.

Non-Ferrous Metals Suitable for Plasma Cutting

When using a plasma cutter on non-ferrous metals, aluminum cutting requires careful gas selection to avoid oxidation, ensuring clean cuts up to 38 mm thick.

For copper and brass, controlling the cutting parameters is essential due to copper’s high conductivity, but precise handling can produce excellent results, particularly in telecommunications and decorative applications.

Additionally, titanium and nickel alloys are compatible with plasma cutting, offering precision and efficiency for industries that demand high strength and corrosion resistance.

Aluminum Cutting Techniques

Release the potential of aluminum with plasma cutting techniques that cater to its unique properties as a non-ferrous metal. To master aluminum cutting, focus on optimizing plasma cutter settings for precision and efficiency. Here’s how:

- Select the Right Cutting Gas: Use nitrogen or argon-hydrogen to minimize surface oxidation and achieve high-quality cuts. This choice enhances the cutting speed and reduces post-processing work.

- Adjust Amperage Settings: Proper amperage is essential to avoid excessive melting. This guarantees clean edges and maintains the integrity of the aluminum, especially with alloys up to 38 mm thick.

- Control the Process Carefully: Due to aluminum’s reflective surface, precise process control is necessary to achieve the desired precision and avoid complications.

These techniques free you from traditional, slower methods.

Copper and Brass Handling

Copper and brass, known for their high conductivity and reflective surfaces, present unique challenges and opportunities for plasma cutting. When cutting these metals, careful process control is vital. Plasma cutting handles copper oxidation efficiently, but slower speeds guarantee clean edges and minimize thermal distortion. Use nitrogen or specialized gas mixtures to optimize cuts and reduce oxidation.

| Metal | Considerations |

|---|---|

| Copper | Mitigate copper oxidation with gas |

| Brass | Adjust for brass thickness and speed |

High-frequency arc initiation is essential due to their reflective properties. This process excels where traditional laser struggles, making it ideal for telecommunication hardware and electrical connectors. Adjusting for brass thickness and using the right gas improves results. Embrace plasma cutting to master these metals with precision and innovation.

Titanium and Nickel Alloys

While plasma cutting titanium and nickel alloys presents unique challenges, mastering these metals is possible with the right approach. Both require precise control due to titanium’s high melting point and the diverse applications of nickel alloys.

To achieve ideal results, consider these critical factors:

- Power and Control: Titanium cutting demands higher power and careful control to manage its thermal conductivity and prevent warping.

- Cutting Speed: Operating at lower speeds minimizes heat input during titanium cutting, ensuring clean edges and reducing oxidation risks.

- Gas Mixtures: Use specific gases like argon-hydrogen to improve cut quality and decrease surface oxidation for both titanium and nickel alloy.

Cutting Mild Steel With Plasma

As you explore plasma cutting mild steel, you’ll find it’s the most prevalent material due to its availability and cost-effectiveness, catering to a wide range of thicknesses.

By employing ideal cutting techniques and focusing on equipment maintenance, you guarantee efficient, precise cuts. Configuring your plasma cutter with oxygen as the cutting gas enhances speed and produces cleaner edges, minimizing dross. This setup allows you to cut mild steel up to 50 mm thick, suitable for diverse construction and manufacturing applications.

To maintain superior cut quality, regularly replace nozzles and electrodes. This practice not only extends the life of your plasma cutter but also secures consistent performance.

As you master plasma cutting, you’ll experience the freedom of completing projects swiftly and with precision. Embrace the power of plasma technology to transform mild steel into remarkable creations, releasing potential and achieving innovations previously thought unattainable.

Stainless Steel Plasma Cutting

Having mastered plasma cutting mild steel, you can now apply your skills to stainless steel, a material that demands precision and care. Plasma cutting stainless steel is highly effective, handling thicknesses up to 38 mm with minimal dross. This method guarantees an exceptional edge finish, making it ideal for industries like food processing and medical equipment manufacturing, where superior cut quality is vital.

To achieve the best results, consider the following:

- Gas Selection: Use nitrogen or an argon-hydrogen mix to minimize oxidation, preserving the pristine appearance of the cut edges.

- Cutting Speed: Plasma cutting’s rapid speeds boost productivity, essential for both industrial and fabrication settings.

- Maintenance: Regularly maintain your plasma torch to guarantee consistent cut quality and efficiency, especially when working with stainless steel.

Embrace the precision and speed of plasma cutting stainless steel, elevating your work to new heights of excellence.

Plasma Cutting of Aluminum

Plasma cutting aluminum offers a precise and efficient method for working with this versatile metal, especially in industries like automotive and aerospace. You’re able to cut aluminum alloys up to 38 mm thick effectively.

This process is a faster alternative to traditional methods like sawing or waterjet cutting, which liberates you from time-consuming production constraints. By using cutting gases such as nitrogen or argon-hydrogen, you achieve high-quality results while minimizing surface oxidation.

A faster alternative to traditional methods, minimizing oxidation with nitrogen or argon-hydrogen cutting gases.

To maximize efficiency, it’s essential to carefully control the amperage settings. This prevents excessive melting or warping, ensuring your aluminum parts remain intact.

Despite aluminum’s reflective and conductive nature, plasma cutting excels due to its ability to generate a high-temperature arc that precisely melts the material. This level of precision and control allows you to handle aluminum with confidence, freeing you to focus on innovation and creativity in your projects.

Copper and Brass Plasma Cutting

While copper and brass present challenges due to their reflective and conductive properties, mastering plasma cutting for these metals opens up various possibilities.

Harnessing copper’s conductivity and exploring brass applications requires precision and the right approach. High-frequency arc initiation is essential, as it effectively navigates the metals’ characteristics.

Here’s how you can optimize your plasma cutting process for these materials:

- Choose the Right Gas: Opt for nitrogen or specialized gas mixtures to enhance cut quality and minimize oxidation.

- Control the Process: Implement meticulous process control for clean, precise cuts, as these metals are trickier compared to ferrous counterparts.

- Post-Cut Refinement: Plan for post-cut cleaning, especially if a polished finish is desired. The process can leave rough edges needing refinement.

Considerations for Selecting Plasma Cutting Equipment

Mastering the art of plasma cutting for metals like copper and brass sets the stage for selecting the right equipment that meets your specific needs. When considering plasma cutting equipment, focus on machine specifications that align with the thickness of materials you plan to cut. Confirm your chosen cutter can handle the diversity of metals you frequently work with, both ferrous and non-ferrous. Evaluate cutting speed and precision, especially if intricate designs are your forte. CNC plasma machines offer accuracy of ±0.006 inches per 3 feet, making them ideal for detailed projects.

| Factors | Considerations |

|---|---|

| Material Thickness | Machine specifications |

| Metal Types | Ferrous & non-ferrous |

| Cutting Speed & Precision | CNC accuracy |

Selecting the right gases is vital; oxygen for mild steel, nitrogen or argon-hydrogen for stainless steel and aluminum. Finally, weigh operational costs. Plasma cutting offers a cost-effective solution, especially for thicker materials, compared to laser cutting.

Frequently Asked Questions

Can Plasma Cutters Cut Through Rusty or Painted Metal Surfaces?

Yes, you can cut through rusty surfaces and painted metal with a plasma cutter. The arc efficiently burns through contaminants, minimizing oxidation issues. Confirm proper grounding for safety, and adjust settings to optimize performance on compromised surfaces.

How Does Metal Thickness Affect Plasma Cutting Speed?

When metal thickness is beyond belief, it dramatically slows cutting speed. You’ll find thinner materials allow for faster, more efficient cuts, while thicker metals require slower processing. Understanding thickness impact liberates your plasma cutting capabilities.

Are There Specific Safety Precautions for Plasma Cutting Titanium?

When plasma cutting titanium, guarantee you wear appropriate safety gear, including fire-resistant clothing and a proper respirator. Titanium’s properties make it flammable at high temperatures, so maintain a clean work area to prevent accidental fires.

Can Plasma Cutters Be Used Underwater for Cutting?

Yes, you can use plasma cutters underwater, enhancing cutting efficiency and expanding application possibilities. Guarantee proper equipment and safety measures are in place to harness this liberating technique effectively for diverse underwater applications. Stay safe and empowered!

How Does Altitude Impact Plasma Cutting Performance?

At higher altitudes, plasma cutting performance decreases due to reduced atmospheric pressure. You’ll notice less efficient arc formation and weaker cutting power. Embrace this challenge; adjust your equipment settings for liberation from altitude effects and achieve precise cuts.

Conclusion

You’ve seen how plasma cutting conquers both ferrous and non-ferrous metals with precision and prowess. Whether slicing through sturdy steel or adeptly addressing aluminum and alloys, plasma cutting proves powerful and precise. Proper process parameters and perfect gas selections guarantee clean cuts and ideal outcomes. So, when selecting your plasma cutter, scrutinize specifications, study materials, and set yourself up for success. This technology will transform your tasks, tailoring to your technical needs with tenacity.