When you consider the capabilities of a plasma cutter, focus on its ability to handle material thickness through clean cuts versus severance cuts. A clean cut guarantees precision and minimal dross, while a severance cut allows for thicker materials but often at the cost of a rougher edge. The choice depends on the material and desired finish. Understanding these nuances can greatly impact your project’s outcome, revealing more about plasma cutting’s potential.

Understanding Plasma Cutter Thickness Capabilities

When you’re considering the thickness capabilities of plasma cutters, it’s essential to understand the machine’s limits and ideal performance range. Embracing plasma technology advancements empowers you to maximize efficiency across various cutting material types.

Understanding plasma cutter limits enhances efficiency across diverse materials, unlocking the full potential of cutting technology advancements.

For instance, plasma cutters like the Lincoln Electric Tomahawk 30 excel in achieving clean cuts on materials up to 1/2” thick, offering high-speed precision. If you’re dealing with thicker materials, machines such as the Tomahawk 45 can manage up to 3/4″. However, as you approach the upper limits, expect a decline in cut quality.

Handheld plasma torches can cut steel plates up to 38 mm, while automated systems extend this capability to 150 mm. The power source and amperage greatly impact cutting rates, with higher amperage delivering more force for thicker materials.

Recognize that pushing a machine to its severance limit increases cutting time and can compromise precision, generating more dross. Understanding these dynamics liberates your cutting process.

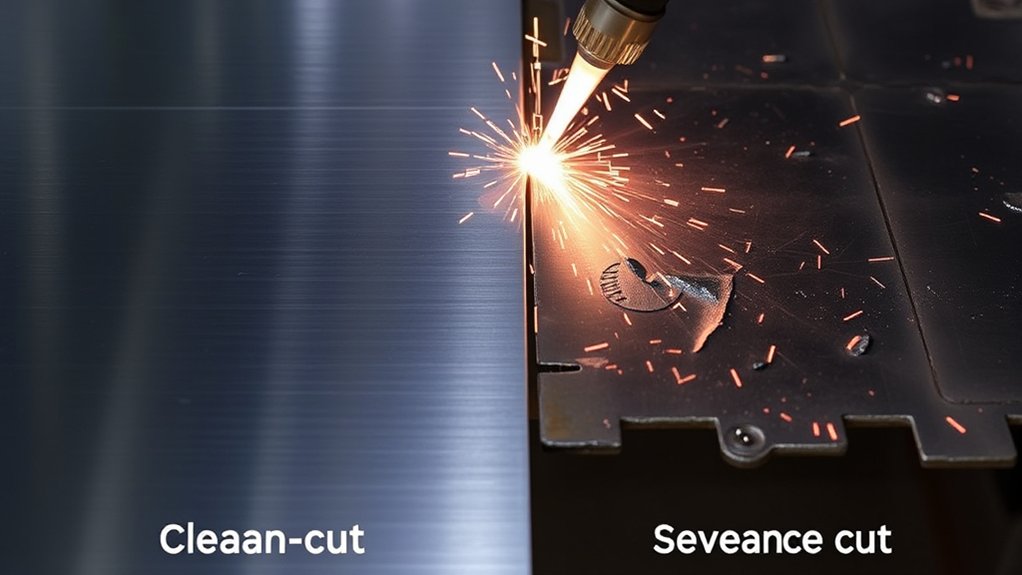

Differences Between Clean-Cut and Severance Cut

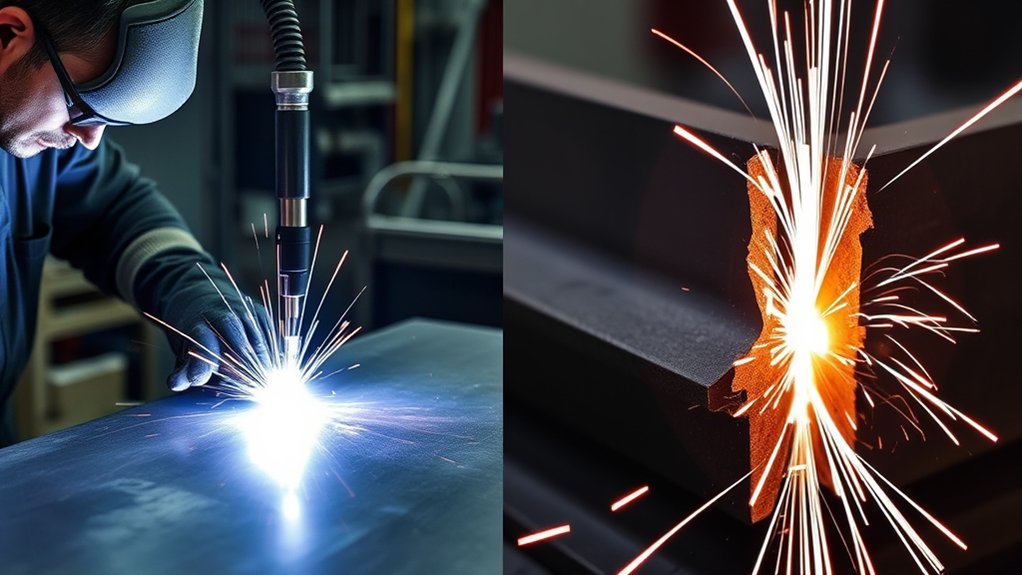

In the domain of plasma cutting, distinguishing between a clean cut and a severance cut is essential for achieving the desired finish and efficiency. A clean cut provides superior cut quality and edge finish, leaving minimal dross and requiring no post-processing. You’ll perform these cuts at ideal speeds within the machine’s recommended thickness, ensuring parts fall away effortlessly.

Conversely, a severance cut is executed at the machine’s maximum thickness, sacrificing cut quality and precision. The edge finish is ragged, filled with dross, necessitating additional cleaning, especially for welding applications.

| Aspect | Clean-Cut | Severance Cut |

|---|---|---|

| Cut Speed | Faster, ideal speed | Noticeably slower |

| Edge Finish | Smooth, minimal dross | Ragged, dross-filled |

| Thickness | Within recommended range | At maximum thickness |

| Post-Processing | Not required | Required for welding |

Choosing between these approaches hinges on your material thickness and desired edge finish, offering you the freedom to balance quality and efficiency.

Factors Affecting Cutting Thickness

Understanding the differences between clean-cut and severance cut enables you to better navigate the factors affecting cutting thickness. The power source and amperage of your plasma cutter greatly influence the maximum thickness you can achieve.

Distinguishing clean-cut versus severance cut helps optimize your plasma cutter’s thickness potential.

Higher-amperage machines, like a 100 amp model, can cut materials up to 40 mm thick, offering you greater freedom in material selection.

Material type also plays an essential role. For instance, aluminum and stainless steel may require specific techniques to maximize cutting speed and performance.

Advanced machine design and cutting-edge technologies enhance precision and speed, empowering you to achieve desired results with ease.

Don’t overlook consumable conditions; the state of the nozzle and electrode can impact cutting performance dramatically.

Keeping these components in ideal condition guarantees you maintain maximum cutting capabilities. By mastering these factors, you can push the limits of your plasma cutter and release its full potential.

Recommended Plasma Cutters for Various Thicknesses

Selecting the right plasma cutter is essential for achieving ideal cutting thickness for your projects. With numerous plasma cutter types available, it’s vital to match your machine to your material’s demands.

For light to mid-range tasks, the Lincoln Electric Tomahawk 30 Air delivers clean cuts up to 1/2” and severance at 5/8”. If you’re tackling thicker materials, consider the Tomahawk 45, designed for clean cuts up to 3/4”, with severance beyond that.

For more robust requirements, handheld plasma torches efficiently handle steel plates up to 38 mm, while automated machines conquer up to 150 mm thickness. Higher-amperage models, like 100 amps, are perfect for materials up to 40 mm, emphasizing the relationship between amperage and cutting power.

The VEVOR Pilot Arc offers a clean cut of 12 mm and severance at 16 mm, showcasing how different plasma cutter types meet specific thickness recommendations, empowering you to break limits.

Tips for Achieving Optimal Cutting Quality

After selecting the right plasma cutter for your material’s thickness, it’s time to focus on achieving ideal cutting quality. Start by setting the machine to the appropriate amperage. High amperage supports deeper cuts but necessitates faster travel speeds to prevent warping.

Regular maintenance is essential; replace consumables like the electrode and cutting tip regularly, as worn parts degrade performance and increase dross.

Maintain proper air pressure settings, around 75 psi, to avoid poor-quality cuts and excessive dross buildup. Your travel speed should match material thickness; too fast leads to incomplete cuts, while too slow results in wider kerfs and more dross.

Choose the right cutting techniques: drag cutting for simplicity or standoff cutting for enhanced quality on thicker materials. Each technique influences the cut’s finish, so select wisely.

Frequently Asked Questions

Can Plasma Cutters Be Used Underwater for Cutting?

Yes, you can use plasma cutters underwater, but it requires specialized equipment. Underwater cutting with plasma technology demands robust insulation and proper gas flow management to maintain efficiency and safety, freeing you to work in diverse environments.

What Safety Precautions Are Needed for Plasma Cutting?

When plasma cutting, you must wear protective equipment like flame-resistant clothing, gloves, and a welding helmet. Guarantee proper ventilation to avoid inhaling fumes. Secure your workspace, and regularly check your equipment for leaks to enhance plasma cutting safety.

How Does Air Pressure Affect Plasma Cutting Performance?

You’ll find that ideal air pressure greatly affects cutting efficiency. Coincidentally, precise pressure settings guarantee a stable arc, enhancing cut quality and speed. Adjustments liberate you to tackle various materials with superior precision and minimal dross.

Can Plasma Cutters Work on Non-Metal Materials?

You can’t typically use a plasma cutter on non-metal materials. Plasma cutters rely on electrical conductivity, which non-metals lack. For non-metal cutting, consider alternative tools like laser cutters for precise and efficient results.

What Maintenance Is Required for Plasma Cutter Longevity?

Ensuring your plasma cutter’s longevity is a dance of preventive maintenance and cleaning tips. Regularly inspect and replace consumables, keep the torch clean, and check for air leaks. Don’t let neglect chain your tool’s potential.

Conclusion

When operating plasma cutters, you’ll find that models like the Lincoln Electric Tomahawk 30 achieve pristine clean cuts up to 1/2”, while the Tomahawk 45 handles up to 3/4”. Remember, opting for severance cuts on thicker materials often results in rough edges needing extra work. Notably, plasma cutters can reach severance capacities up to 1.5 times their clean cut capabilities, but at the cost of precision. Always consider material thickness and desired finish quality when choosing your cutting approach.