Much like a master sculptor, you can shape rusty metal with a plasma cutter, but preparation is key. Rust presents unique challenges, affecting cut quality and precision. Start by removing loose rust and debris with a wire brush or grinder. Adjust the cutter’s settings according to the metal’s thickness for ideal performance. With careful prep and proper technique, you’ll achieve cleaner, smoother edges. Ready to access the full potential of your plasma cutter?

Understanding Plasma Cutters and Their Capabilities

Plasma cutters are remarkable tools that harness ionized gas to slice through various metals, including those with rust. By employing plasma technology, these devices generate high temperatures that efficiently melt metal away, ensuring clean and precise cuts. This cutting process is ideal for maintaining the integrity of surrounding materials, liberating you to work without damaging adjacent structures.

The versatility of plasma cutters shines through as they adeptly handle metals in diverse conditions, from rusty to painted surfaces. For instance, the AHP Alpha Cut 60 plasma cutter has shown proficiency in cutting through quarter inch and half inch steel, as well as painted surfaces, without significant issues.

However, it’s important to highlight that while plasma technology excels with most metals, it struggles with non-metallic materials and coated metals like galvanized steel, which interfere with the ionization process. Understanding these capabilities empowers you to choose the right tool for your metalworking needs.

Challenges of Cutting Rusty Metal

When cutting rusty metal, you may encounter rust-induced cutting issues like jagged edges, which can compromise the quality of your work.

To maintain plasma cutter efficiency, adjust air pressure and settings to match the rust’s thickness and condition.

Although plasma cutting reduces the need for extensive surface preparation, applying basic techniques can enhance cutting precision and results.

Rust-Induced Cutting Issues

Cutting rusty metal poses several challenges that can impact the quality of your work. Rust creates uneven surfaces, leading to jagged edges, especially when you cut freehand.

To achieve edge smoothing, consider rust removal as a preliminary step. Though plasma cutters effectively slice through rust, they require careful handling to avoid interference with the plasma arc. Adjust settings such as air pressure to compensate for heavy rust, ensuring peak performance.

Watch out for coatings or paint beneath the rust, as these can complicate the cutting process. Removing loose rust can greatly enhance cut quality, but remember, proper preparation is essential.

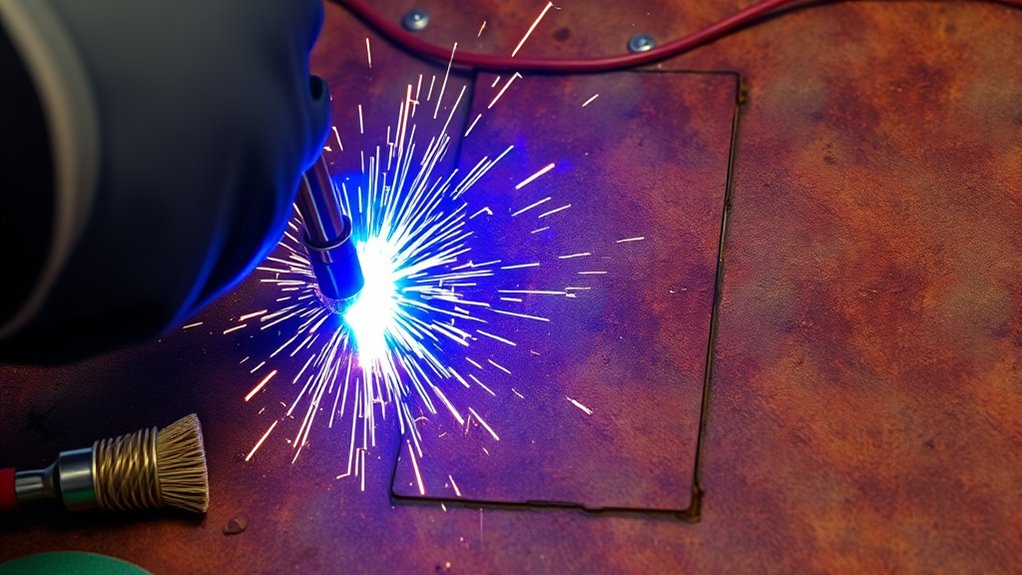

Surface Preparation Techniques

Addressing rust-induced issues isn’t enough if you don’t prepare the metal surface properly before cutting.

Begin by focusing on surface cleaning to guarantee peak plasma cutter performance. Use a wire brush or grinder for rust removal, targeting loose rust and contaminants. This step enhances the plasma cutter’s ability to ionize effectively, leading to cleaner, smoother cuts. The cleaner the surface, the more precise the arc, liberating you from jagged, rough edges.

Next, test a small section of the metal to evaluate the effectiveness of your preparation. This guarantees your technique produces the desired results before committing to the entire piece.

After cutting, apply a rust-inhibiting primer or paint to protect the exposed metal, preventing future corrosion and maintaining your hard work.

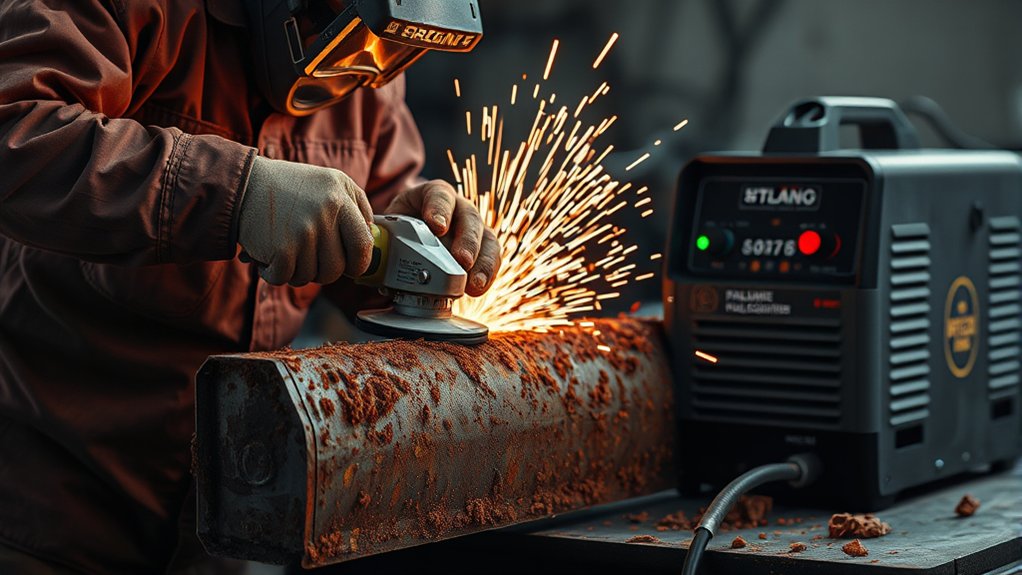

Maintaining Plasma Cutter Efficiency

To maintain your plasma cutter’s efficiency when tackling rusty metal, confirm that all components are in top condition.

Start with regular plasma maintenance by checking the nozzle and consumables for wear. This guarantees your cutter operates smoothly, minimizing disruptions.

Maintain air pressure at 70 psi to deliver a stable cut on corroded surfaces. It’s vital to address any jagged edges that may arise due to the rust; confirming your equipment is well-maintained can help mitigate this issue.

Despite the plasma cutter’s ability to cut rusty metal swiftly, removing excess rust beforehand enhances the quality of the cut.

Adopt these efficiency tips to liberate your workflow from the constraints of rusty metal, leading to cleaner and more precise results.

Preparing Rusty Surfaces for Plasma Cutting

Before you start plasma cutting rusty metal, it’s crucial to prepare the surface adequately to guarantee clean and precise cuts. Removing surface contaminants enhances the quality of your cutting techniques.

To do this effectively, focus on these preparatory steps:

- Use a wire brush or grinder to eliminate loose rust and debris, promoting better ionization of the plasma.

- Keep a consistent air pressure, ideally around 70 psi, to maintain peak plasma performance over rusted surfaces.

- Check that the nozzle is free from obstructions and wear, making sure it delivers precision and clean edges.

These steps liberate you from the confines of poor-quality cuts, allowing your project to shine.

Taking these actions not only improves performance but also extends your plasma cutter’s lifespan.

Consider performing test cuts on similar materials to refine your approach, making certain you’re ready for the main task.

Optimizing Plasma Cutter Settings for Best Results

When optimizing plasma cutter settings, precise adjustments guarantee the best results on rusty metal. Begin by adjusting amperage to suit the metal thickness. For half-inch steel, confirm your power supply is set to 220 volts. This delivers the necessary energy for clean, effective cuts. Air pressure should be set around 70 psi to maintain a steady ionized gas flow, essential for cutting through rust.

Consistency is key—keep a consistent distance between the torch and the metal to avoid uneven cuts. Adjust the cutting speed based on thickness; thicker metal may require slower speeds for smoother edges. Selecting consumables, like the appropriate nozzle size, is critical for cut precision.

Here’s a quick reference table:

| Setting | Recommendation |

|---|---|

| Amperage | Adjust for metal thickness |

| Power Supply | Configure to 220 volts |

| Air Pressure | Set to 70 psi |

| Nozzle Size | Select based on metal thickness |

These steps guarantee clean edges and excellent cutting performance.

Benefits of Proper Surface Preparation

To enhance cutting precision with a plasma cutter, guarantee you properly prepare the metal surface by removing rust and contaminants.

This preparation allows the plasma arc to maintain a focused energy transfer, reducing edge imperfections and resulting in cleaner cuts.

Enhance Cutting Precision

Proper surface preparation is essential for enhancing the precision of plasma cutting. By ensuring the metal is free from rust and contaminants, you allow the plasma arc to ionize efficiently, leading to cleaner cuts.

To achieve precise cutting techniques, consider these precision factors:

- Rust Removal: Eliminates jagged edges and improves cut accuracy, particularly in thinner materials.

- Smooth Surface: Facilitates better heat transfer, enabling faster cutting speeds and minimizing nozzle wear.

- Impurity-Free Metal: Prevents arc instability, enhancing the overall effectiveness of your plasma cutter.

These steps not only improve precision but also maintain the integrity of the surrounding material, freeing you from the constraints of imprecise cuts.

With proper preparation, you reveal the full potential of your plasma cutter.

Reduce Edge Imperfections

Although many factors contribute to the quality of plasma cuts, meticulous surface preparation stands out as a crucial step in reducing edge imperfections.

By cleaning rust and debris, you greatly enhance edge quality and cutting precision. Use a wire brush or grinder to eliminate heavy rust, guaranteeing cleaner edges by minimizing jaggedness. This preparation allows the plasma cutter to make ideal contact, enhancing the ionization process for smoother results.

Removing potential contaminants and coatings guarantees efficient cutting, liberating you from interference. Flattening the metal surface aids precision, reducing post-cut finishing work.

Embrace these steps to release your potential, achieving superior cuts and freeing yourself from imperfections. Remember, a well-prepared surface is your key to mastery.

Tips for Achieving Cleaner Cuts on Rusty Metal

When you’re aiming for cleaner cuts on rusty metal, start by guaranteeing your plasma cutter is set up correctly with the right air pressure, ideally around 70 psi, to optimize performance.

Effective cutting techniques are essential for achieving superior edge quality. Avoid freehand cutting, which can lead to jagged results. Instead, use a guide or straight edge to maintain stability and precision.

Use guides or straight edges to ensure stability and precision, avoiding jagged cuts.

Cleaning the metal surface is another key step. Removing rust with a wire brush or grinder enhances the plasma cutter’s effectiveness and results in smoother edges.

- Adjust the cutting speed: A slower pace can improve control and produce cleaner cuts.

- Experiment with torch angles: Varying angles can optimize your approach and enhance edge quality.

- Surface preparation: Clean thoroughly to guarantee a smoother cutting process.

Frequently Asked Questions

Can Plasma Cutters Cut Through Paint-Covered Rusty Metal?

Yes, you can cut paint-covered rusty metal with a plasma cutter. For cleaner edges, focus on paint removal and surface preparation. Thoroughly clean the metal, removing loose paint and rust, ensuring an ideal cutting path for precision.

Is Protective Gear Necessary When Using a Plasma Cutter?

Absolutely, protective gear is your armor against potential hazards. Don’t cut corners; guarantee you follow safety protocols. Gear types like gloves, goggles, and aprons shield you, letting you focus on precision and creativity without constraint.

How Does Humidity Affect Plasma Cutting on Rusty Surfaces?

Humidity levels can impact cutting efficiency on rusty surfaces. You should guarantee low humidity to avoid moisture interference, which can lead to arc instability. This step enhances precision, liberating you from inconsistent cuts and improving overall results.

Are There Specific Plasma Cutter Models Better for Rusty Metal?

You’d think all plasma cutters are equal, but no. Look for models with advanced arc stability features and adjustable amperage for varying metal thickness. These guarantee you’re not just cutting, but liberating that rusty metal effortlessly.

Can Plasma Cutting Cause Sparks to Ignite Surrounding Materials?

Yes, plasma cutting can cause sparks ignition, creating potential fire hazards. Always clear flammable materials from your workspace and use fire-resistant barriers. Embrace safety protocols to guarantee your liberation from accidents while achieving precise, high-quality cuts.

Conclusion

Think of cutting rusty metal like gardening; you wouldn’t plant seeds in rocky soil and expect lush blooms. Just as a gardener preps the soil, you must prep the metal. A study shows that proper surface preparation can improve cut quality by up to 30%. By adjusting your plasma cutter’s settings and maintaining your tools, you guarantee that each cut is as precise as a well-tended garden, resulting in cleaner edges and peak performance.