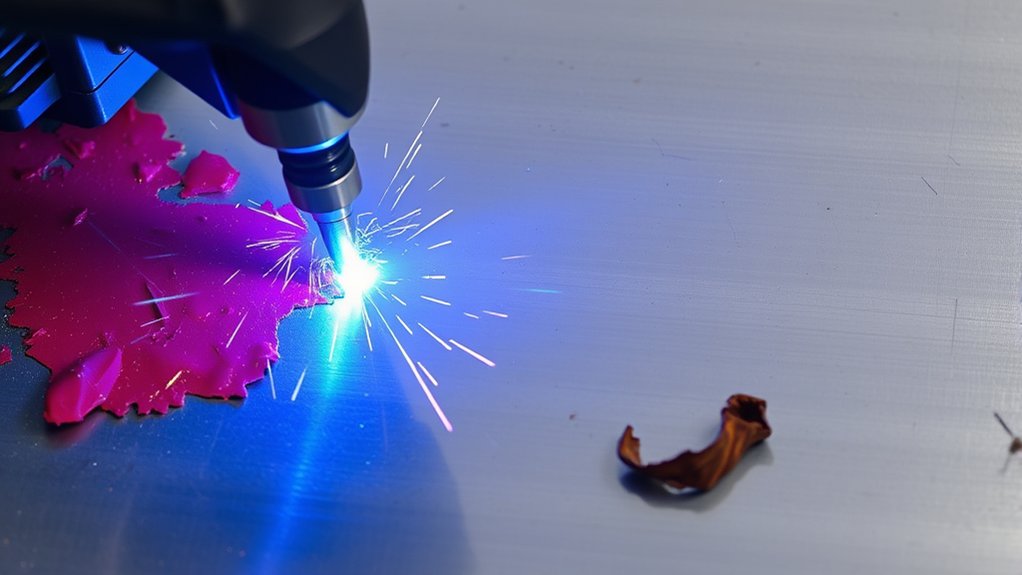

When using a plasma cutter to tackle painted surfaces, you’ll find it can cut through, but with varying success. The plasma arc’s interaction with paint presents challenges that can affect cut quality. Thick paint layers may disrupt the arc, leading to uneven cuts and extra dross. For ideal outcomes, understanding how to manage these issues and adjust your settings is essential. Ready to uncover the techniques to enhance your cutting precision?

Understanding Plasma Cutters and Their Capabilities

When mastering the art of plasma cutting, understanding the capabilities of plasma cutters is vital. You need to grasp the plasma cutter basics to fully exploit this cutting technology.

Plasma cutters, like the AHP Alpha Cut 60, excel at slicing through painted surfaces, proving their prowess through various user demonstrations. However, the paint can introduce challenges such as uneven cuts and excessive dross if not managed properly.

Plasma cutters like the AHP Alpha Cut 60 shine on painted surfaces but require careful handling to avoid uneven cuts.

It’s important to recognize that cutting technology advancements have refined these tools for thin to mid-thickness materials, which are ideal for painted surfaces.

Ensure you’re equipped with proper ventilation and safety gear, especially when dealing with galvanized steel, to mitigate toxic fume risks. By acknowledging these essentials, you liberate yourself from the limitations traditionally associated with cutting painted metals.

For best results, consider removing coatings before cutting, empowering you to achieve precise and clean cuts while minimizing harmful emissions.

Challenges of Cutting Coated or Painted Metals

Cutting through coated or painted metals presents distinct challenges that require careful planning and execution. You’ll encounter several obstacles due to paint thickness, which can interfere with the plasma arc and lead to uneven cuts.

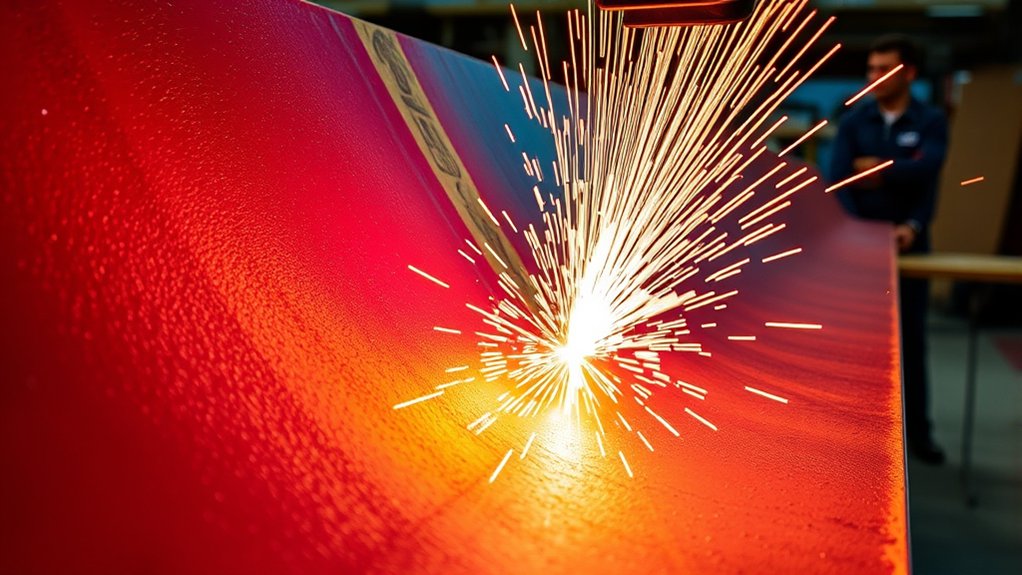

This interference often results in excessive dross formation, leaving behind unwanted slag that undermines cut quality. Additionally, coatings like epoxy paint can emit harmful fumes when subjected to heat, necessitating the use of proper ventilation and safety gear for protection.

To achieve precise cuts, it’s advisable to clean or remove paint before starting the plasma cutting process. This reduces the risk of damaging your equipment and guarantees better quality by minimizing dross formation.

While tools like the AHP Alpha Cut 60 have demonstrated effective cutting through painted surfaces, remember that any coating’s presence can still impact cutting precision and speed. Proper preparation liberates you from these challenges, enabling smoother, cleaner, and safer cutting operations.

How Paint Affects Plasma Cutting Performance

As you engage in plasma cutting on painted surfaces, the paint’s characteristics can greatly influence the overall performance of the cut.

Paint thickness plays a vital role, affecting how smoothly and cleanly the plasma cutter operates. Here’s how paint affects the cutting process:

Paint thickness significantly impacts plasma cutting, influencing smoothness and cleanliness in the operation process.

- Cut Quality Variations: Thicker paint layers can disrupt the plasma arc, leading to inconsistent cut quality and uneven edges.

- Excessive Dross Formation: Paint interferes with the cutting process, often resulting in excessive dross that requires additional cleanup, hindering efficiency.

- Harmful Fumes: The interaction of the plasma arc with paint produces harmful fumes. Proper ventilation and safety gear are essential to mitigate health risks.

- Surface Preparation: Removing or thoroughly cleaning paint from the surface before cutting can improve cut quality considerably, ensuring more precise and cleaner results.

Understanding these factors empowers you to optimize your plasma cutting performance on painted metals.

Effective Techniques for Cutting Through Paint

Understanding how paint affects plasma cutting performance lays the groundwork for employing effective techniques when working with painted surfaces.

To guarantee precision and minimize dross, consider using paint removal techniques before initiating the cut. Removing coatings, especially those containing harmful chemicals, can greatly enhance cut quality and reduce fume production. Different coating types, like epoxy or powder coatings, might require specific removal methods to maintain a clean surface for cutting.

When proceeding with the cut, adjust your plasma cutter’s voltage and speed settings. Fine-tuning these parameters allows you to achieve cleaner edges and mitigate the challenges presented by the paint layer.

Ventilation is another critical factor; make sure the workspace is well-ventilated to protect yourself from toxic fumes that may arise from the paint.

Safety Considerations When Cutting Painted Surfaces

When using a plasma cutter on painted surfaces, guarantee adequate ventilation to mitigate toxic fume exposure, particularly from epoxy coatings.

You should wear proper personal protective equipment, including a respirator, to protect against inhaling hazardous fumes.

Additionally, carefully assess the paint type and potential ignition risks due to heat to maintain a safe working environment.

Ventilation and Fume Hazards

Even though plasma cutting offers precision and efficiency, it poses significant ventilation and fume hazards, especially when dealing with painted surfaces.

Meeting ventilation requirements is essential. The heat from the plasma arc can release toxic fumes if the paint contains harmful chemicals. Make certain the cutting area is well-ventilated to help dissipate these fumes.

Consider these steps for effective fume extraction:

- Open Ventilation: Use fans or open windows to promote airflow, reducing fume concentration.

- Fume Extractors: Invest in local exhaust ventilation systems to capture hazardous fumes at the source.

- Surface Preparation: Remove or clean paint from metal surfaces before cutting to minimize fume hazards.

- Monitoring: Regularly check air quality to make certain fume levels remain safe.

Liberate yourself by prioritizing safety!

Protective Gear Essentials

While ensuring proper ventilation and fume extraction is key when using a plasma cutter on painted surfaces, wearing the right protective gear is equally important for your safety. Protect your eyes with a welding helmet equipped with suitable helmet shades to shield against intense light and sparks. For your hands, select heavy-duty glove materials to guard against heat, sharp edges, and molten metal. Opt for flame-resistant clothing to reduce burn risks from sparks.

| Gear | Purpose | Considerations |

|---|---|---|

| Welding Helmet | Eye protection from light and sparks | Choose appropriate helmet shades |

| Respiratory Mask | Protection from toxic fumes | Essential for epoxy paints |

| Heavy-Duty Gloves | Hand protection from heat and sharp edges | Durable glove materials |

| Flame-Resistant Suit | Minimize burn risks from sparks | Essential for coated materials |

| Ventilation Setup | Disperse harmful fumes | Prioritize safety |

Breathe easy, stay guarded, and embrace the freedom of safe cutting.

Maximizing Results With the AHP Alpha Cut 60

The AHP Alpha Cut 60 is a robust tool designed to maximize your cutting results, even on painted surfaces. Leveraging effective cutting techniques and precise surface preparation guarantees clean cuts. Here’s how to achieve superior outcomes:

Maximize cutting results on painted surfaces with the AHP Alpha Cut 60 through effective techniques and preparation.

- Cutting Techniques: Utilize guided cuts instead of freehand to minimize unevenness. This enhances precision on painted surfaces, especially those with complex coatings like epoxy.

- Surface Preparation: Before cutting, clean the metal to remove any loose paint or contaminants. Proper preparation reduces dross formation and elevates the quality of your cuts.

- Voltage and Air Pressure: For peak performance, operate at 220 volts with air pressure around 70 psi. This setting balances power and efficiency across various materials, including painted and rusty metals.

- Practical Application: The AHP Alpha Cut 60 excels in handling diverse conditions, making it a versatile choice for both painted and rusted surfaces, liberating you to tackle any project confidently.

Frequently Asked Questions

Can Plasma Cutters Be Used on Non-Metal Surfaces?

You can’t use plasma cutters on non-metal surfaces because they rely on electrical conductivity, which non-metals lack. For effective plasma cutter applications, focus on conductive materials, as non-metal cutting isn’t feasible with this technology.

Are There Any Alternative Tools to Plasma Cutters for Painted Metals?

By Jove, you’ve got options! Consider using oxy fuel cutting for thick painted metals, offering precision and freedom. Alternatively, abrasive blasting effectively cleans paint layers, liberating the surface before cutting. Each method suits different project needs.

How Do Different Paint Types Affect Cutting Speed?

Different paint types and thickness directly impact cutting efficiency. Thicker or heat-resistant paints slow cutting speed, requiring adjustments. You’ll achieve ideal results by understanding your material’s properties and making necessary adaptations for efficient plasma operation.

Do Plasma Cutters Require Additional Maintenance After Cutting Paint?

After slicing through painted metal, you’ll need to clean the torch to maintain plasma efficiency. Imagine cutting an artful sculpture; removing residue prevents clogs. Regular plasma maintenance guarantees peak performance and freedom from inefficiencies.

Can Plasma Cutters Remove Paint Without Damaging the Metal Underneath?

You can use a plasma cutter for paint removal techniques, but it risks damaging the metal underneath. To protect the metal, adjust the settings precisely and consider alternative methods for safer, effective metal protection during paint removal.

Conclusion

You’ve now coincidentally accessed the key to effectively cutting through painted surfaces with a plasma cutter. By removing paint beforehand, adjusting voltage and speed, and ensuring proper ventilation, you’ll achieve cleaner cuts with minimal dross. As if orchestrating a symphony, each adjustment plays its part, ensuring precision and safety. With the AHP Alpha Cut 60, you’ll navigate the challenges like a seasoned conductor, transforming painted metal into masterpieces with technical precision and exacting detail.