Choosing the right plasma cutter shapes the quality of your cuts, the speed of your workflow, and the kinds of projects you can tackle. In this guide you get a clear comparison of Hypertherm models so you can match features—like portability, built-in air, CNC compatibility, and industrial power—to how you work.

If you need a compact unit for the garage, a self-contained cutter for site work, or a high-output machine for production, this list helps you find the best fit and avoid costly compromises.

Top Picks

| Category | Product | Score |

|---|---|---|

| 🚀 Best for Hobbyists | Powermax 30 XP | 92/100 |

| 🔰 Best Self-Contained | Powermax 30 Air | 90/100 |

| 🎯 Best for Heavy-Duty | Powermax 85 Sync | 94/100 |

| ⭐ Best Mid-Range | Powermax 65 (75°) | 96/100 |

| 💼 Best for CNC | Powermax 65 CPC | 95/100 |

| 🏆 Best for Industrial Precision | Powermax 85 (75°) | 95/100 |

How We Picked

You want a plasma cutter that suits your work, not one you have to adapt to. We evaluated each Hypertherm model on: cutting capacity (material thickness and speed); portability (weight, carry case, onboard air); voltage flexibility (120/240 V); torch type and consumable options (fine cut vs high-power); CNC and automation compatibility (CPC ports, torches, SmartSYNC features); reliability and build quality; and value for the price.

We also considered real-world usability: ease of setup, maintenance for consumables, and how the unit performs on common shop circuits.

This is the kind of plasma cutter you reach for when you want something that just works — whether you’re cleaning up a rusty bracket, cutting decorative panels, or teaching a class. It packs high-power cutting (up to 16 mm / 5/8″) and a FineCut setup for neat, detailed work into a surprisingly portable package with a carrying case, glasses, gloves and voltage adapters. You get a rugged Duramax LT torch and a 15′ lead that stands up to jobsite use, plus auto-voltage so you can plug into 120 V or 240 V circuits without fuss.

It does need a compressed air supply, but if you already have a compressor this becomes a very flexible tool for hobbyists, metal artists, garage fabricators and light commercial work. If you want reliable cut quality, low edge prep and something you can easily take to a job or class, this is a solid pick you’ll enjoy using.

What People Say

Customers commonly praise the Powermax 30 XP for its clean cuts and low edge prep — especially when using the FineCut consumables. People also like how portable and easy it is to set up, and they often mention the torch durability and solid customer service. A few users note it needs an external air compressor and that heavy commercial use can reveal minor wear points.

Overall Sentiment: Positive

Long-Term Cost Benefits

Because cuts are cleaner, you spend less time grinding and finishing, which saves labor. Durable torch parts and long-lasting consumables (when paired with good air filtration) reduce replacements.

Fewer reworks and less prep add up financially over months of regular use.

Return On Investment

You recoup time and effort through faster, cleaner cuts and less post-cut cleanup. For hobbyists and small shops the machine pays back in reduced labor and fewer consumable swaps; for light commercial users it lowers downtime thanks to proven reliability and easy serviceability.

Situational Benefits

| Situation | How It Helps |

|---|---|

| Mobile Jobs or Onsite Repairs | Lightweight design and carry case let you bring a capable cutter to jobs without lugging heavy gear. |

| Fine Detail Work | FineCut consumables give neater edges and reduce sanding or grinding on decorative panels and thin metal projects. |

| Workshop Teaching or Classes | Simple one-knob interface and a drag-resistant torch tip make it easier for students to learn and stay safe while cutting. |

| Mixed Voltage Environments | Auto-voltage support means you can plug into 120 V or 240 V circuits without swapping transformers or converters. |

Ease of Use

| Feature | Ease Level |

|---|---|

| One-Knob Interface | Easy |

| Setup (requires air compressor) | Moderate |

| Torch Handling | Easy |

| Voltage Switching | Easy |

Versatility

Cuts stainless steel, aluminum and mild steel (even rusted or painted), supports both high-power cuts and fine-detail thin metal work, and works across 120 V and 240 V circuits for flexible applications.

Safety Features

Uses compressed air only (no flammable gases), drag-tip protective torch design reduces sticking, and torch lead strain reliefs protect the cable in demanding environments.

Durability

Built around the Duramax LT torch designed to resist impact and heat, plus a rugged 15′ torch lead; users report long life for consumables when air is clean, though very heavy commercial use has revealed a plastic water-separator wear point in some shops.

Problem Solving Ability

Solves common cutting headaches by giving cleaner edges (less finishing), reliable start/stop control, and flexible voltage options — useful when you need dependable cuts at home, in class, or on small jobs.

Key Benefits

- Portable, lightweight design with case and carry strap

- Two-in-one capability: high-power cutting and FineCut for detail

- Duramax LT torch and 15′ lead for rugged, on-site use

- Auto-voltage support for 120 V or 240 V circuits

Rating: 4.5 (total: 96+)

If you want a plasma cutter that just makes on-the-spot work easier, this is it. The Powermax 30 AIR packs an onboard compressor into a compact, 35 lb package so you can plug it into 120 V or 240 V, clamp on, and start cutting without hauling a separate air system. It handles everyday tasks like trimming brackets, cutting rusty or painted metal, and giving clean edges on 1/4″ material, and it can sever thicker pieces when you need demo cuts.

The continuous pilot arc helps you cut through grates and corroded stock without retriggering, and reviewers consistently call out the portability and build quality. If you do a mix of shop and field work — hobby projects, light fabrication, or occasional CNC setups — you’ll appreciate how quickly you can get a job started.

What People Say

Most users highlight how easy it is to set up and get cutting thanks to the internal compressor and auto-voltage. People also praise the clean cuts on common thicknesses (especially 1/4″) and the unit’s rugged feel. A few note that for consistently thick plate you’ll want 240 V and that consumable life depends on keeping your air clean.

Overall Sentiment: Positive

Long-Term Cost Benefits

You save time and money by spending less time grinding and finishing edges. Not having to buy or maintain a separate compressor cuts initial gear and maintenance costs, and consistent cut quality reduces rework and wasted material over time.

Return On Investment

You get payback primarily through saved labor — quicker setup, faster cuts, and less post-cut cleanup. For hobbyists and small shops the portability and reduced accessory needs mean you start projects sooner and finish cleaner, which adds up over many jobs.

Situational Benefits

| Situation | How It Helps |

|---|---|

| Onsite Repairs or Mobile Jobs | Internal compressor and compact weight let you bring the cutter to the work rather than hauling big external gear. |

| Rusted or Painted Metal | Continuous pilot arc prevents retriggering so you can slice through awkward surfaces without constant stops. |

| Small Shop or Garage | Auto-voltage support means you can use typical 120 V outlets and still access higher power when 240 V is available. |

| Quick Fabrication Tasks | Clean cuts on common thicknesses reduce grinding and fitting time for brackets, panels, and fixtures. |

Ease of Use

| Feature | Ease Level |

|---|---|

| Setup (plug and go) | Easy |

| Built-In Compressor | Easy |

| Torch Handling | Easy |

| Voltage Selection | Easy |

Versatility

Works well on mild steel, stainless and aluminum for cutting, gouging, and clean edge work; dual-voltage support and pilot arc make it useful for both field and shop tasks, including light CNC and manual cutting jobs.

Safety Features

Operates with compressed air (no flammable gas mix), continuous pilot arc reduces torch sticking and retriggering, and built-in protections help prevent damage from common jobsite bumps and electrical issues.

Durability

Designed for heavy-duty use with a rugged enclosure and durable torch lead; users report reliable performance over time when air is filtered properly, though very heavy production use can accelerate consumable wear.

Problem Solving Ability

Fixes the logistics problem of needing a separate air compressor, speeds up setup on jobs, and delivers cleaner edges so you spend less time on finish work — useful whether you’re doing one-off repairs or light production runs.

Key Benefits

- Built-in air compressor so you can cut without an external compressor

- Auto-voltage support for easy use on 120 V or 240 V circuits

- Continuous pilot arc for cutting rusted, painted or grated metal

- Compact, portable design makes onsite work much simpler

Rating: 4.5 (total: 67+)

If you need a workhorse that removes setup guesswork, the Powermax 85 SYNC is built for it. You get RFID-enabled SmartSYNC torches that automatically set amperage and operating mode, plus a single-piece cartridge that records utilization so you know when to change parts.

It handles cutting and gouging up to 25 mm (1″) with a long 25 ft, 180° machine torch that’s nice for awkward setups, and the CPC port makes it easy to tie into CNC tables or robotic systems. In everyday shop work it saves you fiddling with settings and hunting consumables; for higher-volume or precision jobs it keeps uptime and consistency high.

If you do professional fabrication, CNC work, or frequent manual cutting, this one makes your day-to-day a lot less fiddly.

What People Say

Customers commonly mention how much easier setup is thanks to the SmartSYNC auto-configuration and cartridge system, and they regularly praise the consistent cut quality on typical plate thicknesses. Reviews also note the practical torch length and the reassuring build quality, with a few users pointing out that tracking consumable life removes a lot of guesswork.

Overall Sentiment: Positive

Long-Term Cost Benefits

By cutting downtime and making consumable use predictable, you spend less time replacing parts mid-job and less material time on rework. Streamlined consumable inventory and fewer setup errors reduce wasted labor and machine idle time over months or years.

Return On Investment

Your ROI comes from improved uptime and faster setup: fewer interrupted jobs, less time chasing the right settings, and more consistent cuts that reduce grinding and fitting. For shops and CNC operators that value reliability, those efficiency gains add up quickly.

Situational Benefits

| Situation | How It Helps |

|---|---|

| CNC or Robotic Integration | CPC port and SmartSYNC make hookup and automated settings straightforward, so your machine gets the right parameters every time. |

| High-Volume Shop | Trackable cartridges and end-of-life detection reduce unexpected stoppages and simplify consumable inventory management. |

| Manual Cutting in Tight Areas | The 25 ft, 180° torch and flexible lead let you reach awkward angles without constantly repositioning the whole unit. |

| Precision Fabrication | Consistent amperage and optimized cut performance give cleaner edges so you spend less time finishing parts. |

Ease of Use

| Feature | Ease Level |

|---|---|

| Setup (RFID SmartSYNC) | Easy |

| Torch/Cartridge Changes | Easy |

| Consumable Tracking | Easy |

| CNC Integration (CPC Port) | Moderate |

Versatility

Designed for cutting and gouging mild steel, stainless and aluminum up to 25 mm (1″); works well for both CNC and manual tasks, and the long torch lead plus SmartSYNC features suit shop production, repair work, and robotic setups.

Safety Features

Automatic torch and consumable recognition reduce setup mistakes; end-of-life detection prevents you from running worn cartridges, and built-in protections help guard against common electrical or torch-related faults.

Durability

Built as a professional-grade system with a rugged enclosure and reinforced torch lead. Users report reliable performance under regular shop use when consumables and air supply are maintained properly.

Problem Solving Ability

Eliminates much of the trial-and-error in setup, reduces unplanned downtime from worn consumables, and gives repeatable cut quality so you waste less time on fit-up and finishing.

Key Benefits

- RFID SmartSYNC torches automatically set amperage and mode to avoid setup errors

- Single-piece cartridge consumables provide trackable usage and clear end-of-life detection

- Cuts and gouges up to 25 mm (1″) with consistent quality

- 25 ft, 180° machine torch and CPC port make CNC and awkward-angle work much easier

- Flexible torch lead reduces operator fatigue during manual cutting

Rating: 4.6 (total: 3+)

If you want something that takes the guesswork out of setup, the Powermax 65 SYNC is a smart pick. You get RFID-enabled SmartSYNC torches that automatically pick the right amperage and mode, plus a single-piece cartridge that tracks usage and signals end-of-life so you’re not swapping parts blindly. The 25 ft, 75° handheld torch and a flexible lead make manual cutting less tiring, and the system handles routine shop work, CNC table tie-ins, and repair jobs with fewer interruptions.

In short, it’s built to keep your workflow moving whether you’re doing day-to-day plate cutting or occasional precision jobs.

What People Say

Buyers frequently praise how much simpler setup becomes thanks to the SmartSYNC auto-configuration and cartridge system. People also note consistent cut quality for typical plate thicknesses and appreciate the longer, flexible torch lead that makes handheld work easier and less tiring.

Overall Sentiment: Positive

Long-Term Cost Benefits

Predictable consumable life and fewer setup mistakes cut downtime and reduce wasted material from bad cuts. Over time that means less emergency replacement of parts, fewer interrupted jobs, and lower labor costs from rework.

Return On Investment

You recoup the investment through faster job starts, fewer interruptions for consumable swaps, and cleaner cuts that need less finishing. For shops and CNC operators who value uptime, those productivity gains stack up quickly.

Situational Benefits

| Situation | How It Helps |

|---|---|

| CNC or Automated Tables | SmartSYNC auto-sets operating parameters so your table gets consistent settings without manual tuning, reducing scrap from wrong configurations. |

| High-Volume Shop | Trackable cartridges and clear end-of-life detection cut unexpected stoppages and make consumable inventory easier to manage. |

| Manual Handheld Cutting | The 25 ft, 75° torch and flexible lead let you reach awkward spots and work longer without as much fatigue. |

| Repair and Gouging | Reliable gouging up to 20 mm (3/4″) and consistent arc behavior let you clean up welds and remove material with predictable results. |

Ease of Use

| Feature | Ease Level |

|---|---|

| Setup (RFID SmartSYNC) | Easy |

| Torch/Cartridge Changes | Easy |

| Consumable Tracking | Easy |

| CNC Hookup and Parameter Tuning | Moderate |

Versatility

Made for cutting and gouging mild steel, stainless, and aluminum up to 20 mm (3/4″); works well for both CNC and handheld jobs and adapts to shop production, repairs, and light fabrication tasks.

Safety Features

End-of-life consumable detection prevents you from running worn cartridges; automated process setup reduces human setup errors and helps avoid incorrect operating modes that could cause poor cuts or wasted consumables.

Durability

Built as a pro-grade system with a robust enclosure and a reinforced, flexible lead designed to resist fatigue — users report solid reliability when consumables and air supply are kept in good shape.

Problem Solving Ability

Cuts down on trial-and-error setup, reduces unexpected downtime from consumable failures, and produces repeatable cuts so you spend less time on fit-up and finishing.

Key Benefits

- RFID SmartSYNC torches automatically set amperage and mode to avoid setup errors

- Single-piece cartridge consumables provide trackable usage and clear end-of-life detection

- Cuts and gouges up to 20 mm (3/4″) with consistent performance

- 25 ft, 75° handheld torch and flexible lead reduce operator fatigue during manual work

- Streamlined consumable identification with laser marking and color coding to prevent mix-ups

Rating: 5.0 (total: 2+)

If you want a plasma cutter that gets you cutting faster and with less guesswork, this is a strong choice. You get RFID-enabled SmartSYNC torches that pick the right amperage and mode for you, and a single-piece cartridge that tracks wear and signals when it needs replacing so you’re not changing parts by feel. The 25 ft, 75° torch and flexible lead make handheld jobs easier, and the unit is happy on CNC tables or in a busy shop doing daily plate cutting, touch-up repairs, or occasional precision cuts.

In short, it’s designed to keep your workflow moving and reduce fiddly setup moments.

What People Say

Customers consistently praise how much simpler the machine makes setup thanks to the SmartSYNC system and cartridge tracking. People also note steady cut quality at common plate thicknesses and often mention the generous, flexible torch lead as a real plus for handheld work.

Overall Sentiment: Positive

Long-Term Cost Benefits

Because consumables report their own life and the machine avoids wrong settings, you spend less time fixing bad cuts and replacing parts prematurely. That predictability reduces downtime and the hidden costs of rework over the life of the unit.

Return On Investment

You recover value through faster job starts, fewer interruptions for consumable swaps, and cleaner cuts that need less finishing. For workshops and CNC setups where uptime matters, those productivity gains add up quickly.

Situational Benefits

| Situation | How It Helps |

|---|---|

| CNC Tables | Auto-configuration removes manual tuning so your table runs with consistent parameters and fewer scrap parts from incorrect settings. |

| Production Shop | Trackable cartridges and end-of-life alerts cut surprise stoppages and simplify consumable inventory management. |

| Handheld Cutting | The 25 ft, 75° torch and flexible lead let you reach awkward areas and work longer without as much wrist strain. |

| Repair and Gouging | Predictable gouging up to 20 mm (3/4″) helps you remove welds and material reliably when cleaning up components. |

Ease Of Use

| Feature | Ease Level |

|---|---|

| Setup (RFID SmartSYNC) | Very Easy |

| Torch/Cartridge Swaps | Easy |

| Consumable Monitoring | Easy |

| CNC Integration | Moderate |

Versatility

Good for cutting and gouging mild steel, stainless, and aluminum up to 20 mm (3/4″); works equally well for handheld tasks, CNC table use, light fabrication, and repair work.

Safety Features

End-of-life detection on cartridges prevents you from running worn parts, and automated process setup reduces human setup mistakes that can waste material or cause poor cuts.

Durability

Built as a professional-grade system with a sturdy enclosure and a reinforced, flexible lead; when you maintain consumables and clean your air supply it holds up well under regular shop use.

Problem Solving Ability

Cuts down on trial-and-error configuration, reduces unexpected downtime from consumable failures, and delivers repeatable cuts so you spend less time on fitting and finishing.

Key Benefits

- SmartSYNC torches auto-select amperage and mode so you avoid setup errors

- Single-piece cartridges give clear end-of-life signals and track usage

- Reliable cutting and gouging up to 20 mm (3/4″) for a wide range of jobs

- Long, angled torch and flexible lead reduce fatigue during handheld work

- Laser marking and color coding on cartridges make parts easy to identify

Rating: 5.0 (total: 2+)

If you need a heavy-duty plasma cutter that removes a lot of the guesswork, the Powermax85 SYNC is built for that. You get RFID-enabled SmartSYNC torches that auto-configure settings, plus a single-piece consumable cartridge that tracks usage and tells you when it’s time to swap parts.

The 25 ft, 75° handheld torch and flexible lead make it comfortable for long handheld sessions, while the predictable, optimized cut quality is handy for CNC table work, shop production, and repair jobs. In short, it’s made to keep you cutting with less downtime and fewer fiddly settings to manage — a practical pick whether you’re doing daily plate work or occasional precision cuts.

What People Say

People commonly highlight how much simpler setup feels thanks to the SmartSYNC system and cartridge tracking. Reviewers also note steady, cleaner cuts at common thicknesses and appreciate the long, angled torch lead for reach and comfort during handheld cutting.

Overall Sentiment: Positive

Long-Term Cost Benefits

Because consumables report their usage and the system avoids incorrect settings, you’ll replace parts less often and waste less material from poor cuts. That predictability lowers downtime and lowers the hidden costs of rework over the machine’s life.

Return On Investment

You get value from faster job starts, fewer interruptions for consumable swaps, and improved cut quality that reduces finishing time. In busy shops or on CNC tables those productivity gains help the unit pay for itself more quickly.

Situational Benefits

| Situation | How It Helps |

|---|---|

| CNC Tables | Auto-configuration ensures consistent parameters so runs finish with fewer scrap parts and less manual tuning between jobs. |

| Production Shop | Trackable cartridges and end-of-life alerts cut surprise stoppages and simplify consumable inventory management. |

| Handheld Cutting | The long, angled torch and flexible lead help you reach awkward spots and reduce wrist strain during extended handheld work. |

| Heavy Fabrication | Cutting and gouging capability up to 25 mm (1″) handles thicker plate tasks without needing a separate machine. |

| Repair And Precision Work | Predictable cut performance and cartridge management make detailed cleanup and fit-up tasks less fiddly. |

Ease Of Use

| Feature | Ease Level |

|---|---|

| Setup (RFID SmartSYNC) | Very Easy |

| Torch/Cartridge Swaps | Easy |

| Consumable Monitoring | Easy |

| CNC Integration | Moderate |

| Routine Maintenance | Moderate |

Versatility

Well suited for cutting and gouging mild steel, stainless, and aluminum up to 25 mm (1″); works for handheld jobs, CNC table cutting, shop production, and repair/gouging tasks.

Safety Features

End-of-life detection on the cartridge prevents running worn parts, and automated process setup reduces user setup errors that can cause poor cuts or wasted material.

Durability

Built as a professional-grade system with a sturdy enclosure and reinforced torch lead; with routine consumable care and clean, dry air it holds up well under regular shop use.

Problem Solving Ability

Eliminates much of the trial-and-error in setup, reduces unexpected stoppages from consumable failures, and produces more repeatable cuts so you spend less time on rework and finishing.

Key Benefits

- RFID SmartSYNC torches auto-select settings so you don’t have to guess

- Single-piece cartridge tracks utilization and signals end-of-life

- Cuts and gouges up to 25 mm (1″) for heavier plate work

- 25 ft, 75° torch and flexible lead reduce fatigue in handheld jobs

- Reduces downtime with faster consumable changes and fewer errors

- Laser marking and color coding make cartridges easy to identify

Rating: 5.0 (total: 1+)

FAQ

How Do I Choose The Right Hypertherm Model For CNC Or Manual Cutting?

You should pick a model based on the thickness you cut, where you’ll be working, and how often you’ll run the machine. If you need portability and occasional shop work, the Powermax30 family is a great fit because it combines Fine Cut consumables for detailed thin-metal work with standard consumables for heavier cuts; the Powermax30 XP is ideal if you already have an air compressor while the Powermax30 AIR gives you the convenience of an built-in air compressor.

If you routinely cut thicker material or run long production periods, look at the Powermax65 or Powermax85 SYNC lines: they handle heavier plate (up to around 20 mm and 25 mm respectively), offer automated setup with SmartSYNC torches, and simplify consumable management. For CNC work specifically, choose a model with a CPC port or machine‑torch options and plan for torch height control—those features make integration and repeatable cuts far easier. In short, match cut capacity to your regular jobs, opt for built‑in air if you must be mobile, and choose the SYNC models when you need professional, high‑uptime CNC performance.

What Power, Air, Consumable And Safety Considerations Should You Know Before Buying?

You’ll want to confirm your shop power and air before buying: many Hypertherm units are dual voltage so they run on typical single‑phase supplies, but on 120 V you often need a dedicated circuit (20 A) for reliable cutting and better performance on thicker sections comes from 240 V. Air quality is critical — always use clean, dry compressed air with proper filtration and a water separator to avoid premature consumable wear; some users in heavy commercial setups recommend inspecting the air inlet/separator regularly and keeping replacement parts on hand.

Consumables wear with use, so expect to stock electrodes, nozzles and drag shields if you do frequent cutting; using the correct consumable type (standard vs Fine Cut) and proper air pressure extends life and improves edge quality. For safety, you must use appropriate eye and skin protection, ensure good ventilation, maintain a solid work clamp/ground, and follow the manual for pierce and standoff techniques — remember that Hypertherm torches are forgiving for drag cutting but consistent standoff control still gives the best accuracy and consumable life.

How Do I Set Up A Hypertherm Cutter For CNC Use And Get Better Cut Quality And Longer Consumable Life?

Start by integrating the cutter with your CNC controller using the machine torch/CPC interface or a relay for torch on/off, and add a torch height control (THC) or voltage sensing so the torch keeps the correct gap during the cut. Set feed rates and pierce delays according to material thickness and the cutter’s recommended charts, tune air pressure and dry‑air filtration for clean operation, and pick the correct consumable family (Fine Cut for thin, detailed work; standard for heavy cuts).

Use consistent fixturing and a solid ground return and check that your CNC speed matches the amperage and material: cutting too fast creates dross and wears consumables, cutting too slow wastes consumable life. For maintenance, inspect torch leads, replace consumables at the first sign of inconsistent arcs or poor edge quality, and keep filters and separators serviced. If you plan on heavy continuous production, monitor the machine’s air inlet components since they can wear under nonstop use; proactive inspection and a small stock of spare consumables and inlet parts will keep your downtime low.

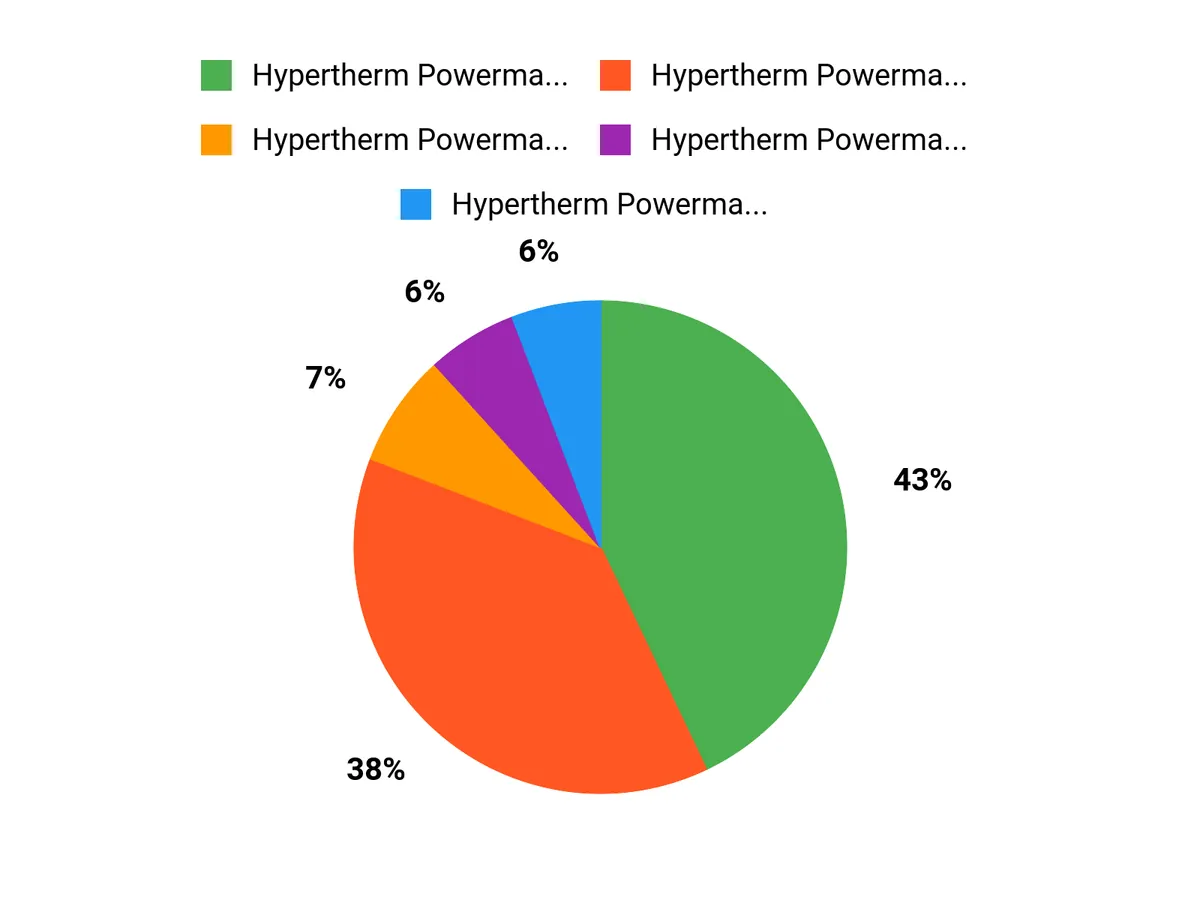

Buyers Top Picks

When choosing between the Powermax 30 XP, 30 AIR, and 85 SYNC you usually balance cutting power and thickness capacity against portability and convenience — the 85 SYNC is preferred for heavier-duty CNC and production work thanks to higher output and precision, the 30 XP wins fans as a solid, cost-effective all‑rounder, and the 30 AIR is picked when on-the-go use and an integrated air system matter most. You also weigh duty cycle, consumable costs, ease of setup, and CNC compatibility to match the cutter to your shop’s workflow.

Wrapping Up

You now have a quick way to match Hypertherm models to real needs: the Powermax 30 XP is a compact, two-in-one performer if you value portability and clean fine cuts; the Powermax 30 Air adds an internal compressor so you can plug in anywhere and go; the Powermax 65 line gives strong mid-range cutting with SmartSYNC convenience for faster setup and less downtime; and the Powermax 85 models are designed for higher-thickness cutting, production environments, and precision when you need industrial results. Pick the model that aligns with the thickness you cut most, whether you need on-board air, and whether CNC/machine integration matters.

That approach helps you avoid overspending while getting the reliable cut quality Hypertherm is known for.

| Product | Image | Rating | Cutting Capability | Weight | Special Highlights |

|---|---|---|---|---|---|

| Hypertherm Powermax 30 XP Plasma Cutter with Case 088079 |

|

4.5/5 (96 reviews) | Up to 16 mm (5/8″) with Fine Cut consumables for detailed cuts. | 2.2 pounds (1 kg) |

|

| Hypertherm Powermax 30 Air Plasma Cutter 088096 with Built-In Air Compressor |

|

4.5/5 (67 reviews) | Fast cutting speeds for up to 1/4″ plate; sever up to 3/4″. | 35 pounds (15.88 kg) |

|

| Hypertherm Powermax 85 SYNC Plasma Cutter w/CPC Port, 25 ft. 180 Degree Machine Torch 087189 |

|

4.6/5 (3 reviews) | Cutting and gouging capability up to 25 mm (1″). | N/A |

|

| Hypertherm Powermax 65 SYNC Plasma Cutter w/ 25 ft. 75 Degree Handheld Torch 083343 |

|

5.0/5 (2 reviews) | Cuts and gouges up to 20 mm (3/4″). | N/A |

|

| Hypertherm Powermax 65 SYNC Plasma Cutter w/CPC Port, 25 ft. 180 Degree Machine Torch 083349 |

|

5.0/5 (2 reviews) | Cuts and gouges up to 20 mm (3/4″). | N/A |

|

| Hypertherm Powermax 85 SYNC Plasma Cutter w/ 25 ft. 75 Degree Handheld Torch 087183 |

|

5.0/5 (1 review) | Capable of cutting and gouging up to 25 mm (1″). | N/A |

|

This Roundup is reader-supported. When you click through links we may earn a referral commission on qualifying purchases.