If you’re wondering, “Can you stick weld brass?”—the short answer is yes, but it’s not as straightforward as welding steel. I’ve been in the shop, torch in hand, tackling all sorts of metals, and brass can be a tricky one. Whether you’re a DIYer fixing a brass fitting, a hobbyist crafting a custom piece, a pro on a repair job, or a student learning the trade, stick welding brass requires some know-how to avoid cracked welds or a messy finish.

Why does this matter? Brass is common in plumbing, decorative work, and industrial applications, and getting it right ensures strong, safe welds without wasting material or time. Let’s dive into the details, as if we’re troubleshooting together in the shop.

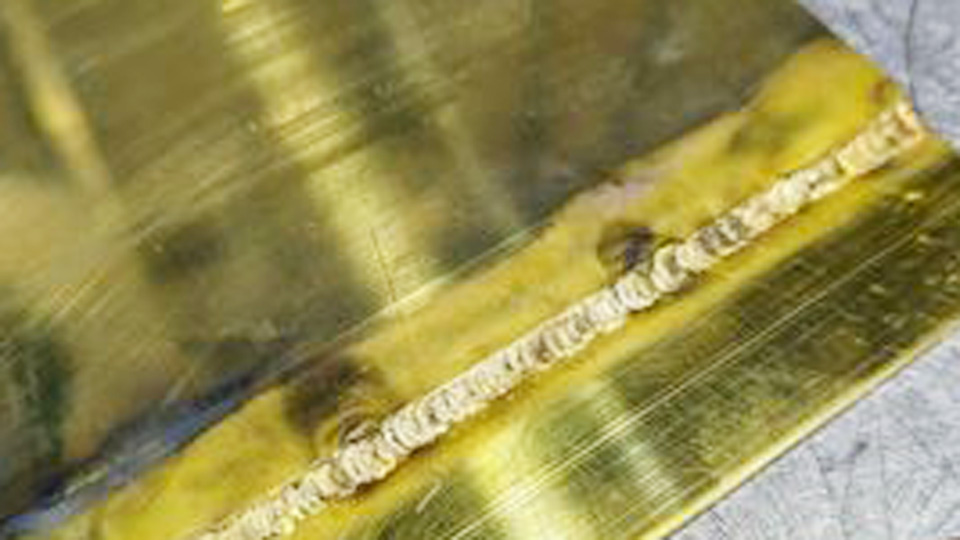

Photo by reddit

Why Stick Welding Brass Is Different

Brass, an alloy of copper and zinc, isn’t your typical weldable metal. Its zinc content (often 20-40%) creates challenges because zinc vaporizes at a lower temperature than copper, leading to porosity and weak welds if you’re not careful. I’ve seen welders burn through brass fittings because they treated it like steel—big mistake.

Stick welding, or shielded metal arc welding (SMAW), uses an electrode to create an arc, depositing filler metal into the joint. For brass, you need the right electrode, settings, and technique to manage its quirks, ensuring weld integrity and avoiding safety hazards like toxic zinc fumes.

Can You Stick Weld Brass? The Basics

Yes, you can stick weld brass, but it’s not the ideal process compared to TIG or brazing. Stick welding is rugged, portable, and great for outdoor jobs, which is why it’s popular among DIYers and pros alike. However, brass demands precise heat control to prevent zinc burn-off, which can weaken the weld or create porosity.

I’ve used stick welding on brass for quick repairs on heavy fittings when TIG wasn’t an option, but it takes practice. The key is choosing the right electrode, prepping the joint, and dialing in your welder to avoid overheating.

When to Stick Weld Brass

Stick welding brass makes sense for:

- Repairs: Fixing heavy brass parts, like marine fittings or industrial components, where TIG isn’t available.

- Thick Sections: Brass over 1/8-inch thick handles stick welding better than thin sheets.

- Field Work: Stick welders are portable, making them ideal for on-site jobs where brass components need quick fixes.

- Budget Constraints: Stick welding is cheaper than investing in TIG equipment for occasional brass work.

Why It’s Tricky

Brass’s low melting point (around 1,650-1,900°F, depending on the alloy) and zinc content make it prone to:

- Porosity: Zinc vaporizes, leaving tiny gas pockets in the weld.

- Cracking: Uneven cooling can cause thermal stress cracks.

- Fumes: Zinc fumes are toxic, so ventilation is critical. I learned this the hard way early on—always weld brass in a well-ventilated area or wear a respirator.

Choosing the Right Electrode for Stick Welding Brass

Your electrode choice is make-or-break for brass. Unlike steel, where E6010 or E7018 are go-to rods, brass needs electrodes designed for copper alloys to match its properties.

Best Electrodes for Brass

ECuSn-C (Phosphor Bronze): These rods (like AWS A5.6 ECuSn-C) are ideal for brass because they deposit a bronze filler that bonds well with copper and zinc. They’re forgiving and reduce porosity.

ECu (Copper): Pure copper electrodes work for some brass alloys but can be trickier due to higher heat needs.

ECuNi (Copper-Nickel): Good for brass with high copper content or when corrosion resistance is key, like marine applications.

I’ve had great results with ECuSn-C on brass fittings. It flows smoothly and minimizes zinc burn-off. Check your local welding supply for brands like Lincoln Electric or ESAB—most carry phosphor bronze rods.

Electrode Size and Amperage

- 1/8-inch Rods: Common for brass up to 1/4-inch thick. Set your welder to 80-120 amps (DCEN for most bronze rods).

- 3/32-inch Rods: Better for thinner brass (1/16 to 1/8-inch). Use 50-90 amps to avoid burn-through.

- Tip: Always check the electrode manufacturer’s amp range. I’ve burned rods by guessing—stick to the specs.

Step-by-Step Guide to Stick Welding Brass

Let’s walk through how to stick weld brass, like I’m showing you in my shop. This guide assumes you’ve got a basic stick welder (like a Lincoln AC/DC 225/125) and some experience laying beads.

Step 1: Prep the Workpiece

Clean the Brass: Brass oxidizes fast, so scrub it with a wire brush or sandpaper to remove tarnish, oil, or dirt. I once skipped this and got a porous weld—cleanliness is non-negotiable.

Bevel the Edges: For thicker brass (over 1/8-inch), use a 30-45° bevel on butt joints to ensure good penetration.

Fit-Up: Ensure tight joint fit-up. Gaps lead to burn-through or weak welds. Use clamps to hold pieces snug.

Step 2: Set Up Your Welder

Polarity: Use DC electrode negative (DCEN) for phosphor bronze rods. It keeps heat on the electrode, reducing burn-through.

Amperage: Start low (e.g., 80 amps for 1/8-inch ECuSn-C) and adjust up if the arc is weak. Too high, and you’ll vaporize zinc.

Test Run: Practice on scrap brass to dial in settings. I always keep a test piece handy to avoid ruining the real job.

Step 3: Safety Gear and Ventilation

Fumes: Zinc fumes are no joke. Weld outdoors or use a fume extractor. A good respirator with a P100 filter is a lifesaver.

PPE: Wear a welding helmet (shade 10-12), leather gloves, and a flame-resistant jacket. Brass spits hot metal, and I’ve got the scars to prove it.

Fire Safety: Keep a fire extinguisher nearby. Brass welds can ignite nearby debris.

Step 4: Weld the Joint

Arc Strike: Start the arc on a scrap piece to avoid marking the brass. Hold a short arc (1/16-inch) to control heat.

Technique: Use a slight weave or drag motion to deposit filler evenly. Don’t linger too long in one spot—keep moving to avoid overheating.

Puddle Control: Watch the weld puddle. If it’s too fluid, lower the amps. If it’s sluggish, bump up slightly.

Multi-Pass: For thick brass, use multiple passes to build up the weld. Clean slag between passes with a chipping hammer and wire brush.

Step 5: Inspect and Clean

Visual Check: Look for cracks, porosity, or uneven beads. Brass welds should be smooth and bronze-colored.

Clean-Up: Brush off slag and polish with a wire wheel for a clean finish, especially for decorative work.

NDT: For critical jobs, use dye penetrant or ultrasonic testing to check for hidden flaws. I’ve caught tiny cracks this way on high-pressure fittings.

Common Mistakes and How to Fix Them

Stick welding brass isn’t forgiving, but here’s how to avoid the pitfalls I’ve hit over the years.

Mistake: Overheating the brass. Too much heat burns off zinc, leaving porous welds.

- Fix: Lower your amperage and move faster. Short, controlled welds beat long, hot ones.

Mistake: Poor cleaning. Oxides or grease cause inclusions.

- Fix: Scrub the brass until it shines. Use acetone for stubborn grease.

Mistake: Wrong electrode. Steel rods (like E7018) won’t bond properly with brass.

- Fix: Stick to ECuSn-C or similar bronze rods designed for copper alloys.

Mistake: Ignoring fumes. Zinc fumes can make you sick (metal fume fever).

- Fix: Weld in a ventilated area or use a respirator. I got dizzy once from poor ventilation—never again.

Pros and Cons of Stick Welding Brass

| Pros | Cons |

|---|---|

| Portable for field repairs | Tricky heat control |

| Cheaper than TIG setups | Toxic zinc fumes |

| Works on thick brass | Prone to porosity and cracks |

| Widely available equipment | Not ideal for thin brass |

Comparing Stick Welding to Other Methods for Brass

Stick welding isn’t the only way to join brass. Here’s how it stacks up against TIG and brazing, based on my experience.

Stick Welding vs. TIG Welding

TIG (GTAW): TIG is the gold standard for brass because it offers precise heat control and cleaner welds. You can use a pure tungsten electrode (2% thoriated) with ER70S-2 filler for brass. However, TIG rigs (like a Miller Syncrowave) are expensive and less portable. I’ve used TIG for thin brass sheets where stick would’ve burned through.

When to Choose TIG: For thin brass, decorative work, or high-precision jobs. Stick is better for quick, heavy repairs.

Stick Welding vs. Brazing

Brazing: Brazing uses a lower-temperature filler (like silver solder) to join brass without melting the base metal. It’s easier and safer (no zinc fumes) but weaker than welding. I’ve brazed brass fittings for plumbing jobs when strength wasn’t critical.

When to Choose Brazing: For thin brass, low-stress joints, or when you lack welding gear. Stick welding is better for structural repairs.

Real-World Applications for Stick Welding Brass

Stick welding brass shines in specific scenarios. Here are some I’ve tackled:

Marine Repairs: Welding brass propellers or fittings on boats. ECuSn-C rods handle saltwater corrosion well.

Plumbing Fixes: Repairing heavy brass valves or fittings in industrial systems. Stick is faster than setting up TIG on-site.

Decorative Work: Joining thick brass pieces for sculptures or custom hardware. Polish the weld for a seamless look.

Industrial Components: Fixing brass bushings or housings in machinery. Stick welding’s portability is a lifesaver in the field.

Machine Settings and Joint Prep Tips

Amperage: For 1/8-inch brass with a 1/8-inch ECuSn-C rod, start at 80-100 amps (DCEN). Increase by 10-15 amps for thicker material.

Joint Prep: Bevel edges at 30° for butt welds on brass over 1/8-inch. For thinner brass, a square edge works but needs tight fit-up.

Preheating: Preheat thick brass (over 1/4-inch) to 200-300°F to reduce thermal shock. Use a propane torch and a temp stick to avoid overcooking.

Post-Weld Cooling: Let the weld cool naturally. Quenching can cause cracks due to brass’s sensitivity to thermal stress.

Safety Considerations for Stick Welding Brass

Safety is non-negotiable. Brass welding throws unique hazards:

- Fumes: Zinc fumes cause metal fume fever (flu-like symptoms). Use a fume extractor or weld outside. A P100 respirator is a must indoors.

- Burn-Through: Thin brass can melt fast. Practice on scrap to get your heat right.

- Eye Protection: Use a welding helmet with a shade 10-12 lens. Brass arcs are bright and can cause arc flash.

- Fire Risk: Brass welds spit hot slag. Clear flammable materials and keep a fire extinguisher handy.

Meeting US Welding Codes

For pro welders, brass welding might need to meet standards like ASME Section IX or AWS D1.1 (for structural components). These codes often require:

Qualified Procedures: Document your electrode, amperage, and technique. I’ve had to submit weld procedure specifications (WPS) for brass repairs.

Inspection: Use dye penetrant or ultrasonic testing for critical welds. Visual inspection alone isn’t enough for code work.

Filler Matching: Ensure your electrode (e.g., ECuSn-C) matches the brass alloy per the code.

Conclusion

You’re now ready to tackle stick welding brass with confidence. Can you stick weld brass? Absolutely, with the right electrode (like ECuSn-C), proper prep, and controlled heat. It’s not the easiest metal to weld, but for field repairs, thick sections, or budget-conscious projects, stick welding gets the job done.

Avoid common mistakes like overheating or poor cleaning, prioritize safety with ventilation, and practice on scrap to nail your technique. My pro tip? Keep a steady, short arc and move fast to minimize zinc burn-off—your welds will be stronger and cleaner.

FAQ

Can you stick weld brass to steel?

Yes, but it’s tricky. Use a phosphor bronze electrode (ECuSn-C) and clean both metals thoroughly. Set your welder to DCEN, 80-100 amps for 1/8-inch rods. The brass’s zinc can cause porosity, so keep heat low and test on scrap first.

What’s the best welding process for brass?

TIG welding is best for brass due to precise heat control and cleaner welds. Stick welding works for repairs or thick brass but is prone to porosity. Brazing is great for thin brass or low-stress joints.

How do I avoid zinc fumes when welding brass?

Weld in a well-ventilated area or use a fume extractor. Wear a P100 respirator indoors. Keep your arc short and avoid overheating to minimize zinc vaporization.

What electrode should I use for stick welding brass?

Use ECuSn-C (phosphor bronze) electrodes for most brass alloys. They bond well, reduce porosity, and handle zinc content. Set your welder to DCEN and 80-120 amps for 1/8-inch rods.

Can I stick weld thin brass sheets?

It’s possible but risky. Thin brass (under 1/16-inch) burns through easily. Use a 3/32-inch ECuSn-C rod at 50-70 amps, keep a tight arc, and move quickly. TIG or brazing is better for thin brass.