Updated on December 4, 2025

What is the BestArc BTC500XP? It is a 50-amp plasma cutter featuring IGBT technology and “Blowback” start (non-HF), specifically designed for CNC compatibility. It stands out for its high value-for-money, clean cutting capacity up to 1/2 inch, and integrated voltage output for Torch Height Controllers (THC).

📦 Unboxing and First Impressions

The BestArc BTC500XP arrives in careful packaging with custom-cut foam inserts and good padding around the unit. This type of packaging usually indicates the manufacturer considers transport and storage, which is appreciated in a budget-friendly machine.

Inside the box, you will find the basic accessories: air hose, ground clamp and cable, extra consumables, a 120-volt adapter, and the torch. It also includes specific adapters for CNC table mounting and labeled cables, facilitating initial integration with a cutting table.

⚙️ Design and Important Features

This unit stands out by offering CNC compatibility at a very accessible price point (around $325 at the time of testing). Several design details are worth noting:

- Blowback Pilot Arc Start: Uses a moving electrode that allows starting without a High Frequency (HF) signal. This feature is key for use on CNC tables to avoid interference with sensitive electronics.

- Integrated CNC Connectivity: Ports on the back for control signals and arc voltage reading, making it easy to connect a Torch Height Controller (THC).

- Front-mounted Air Regulator: The regulator and pressure adjustment knob are on the front of the unit, which is very convenient for “hot” adjustments while the machine is working.

- Graphic Panel: Bright and easy-to-read screen with settings for amperage, pilot arc time, post-flow time, and 2T/4T modes.

- IP60 Style Torch: The cable sleeve is thin compared to high-end machine torches. It works well but might be less durable in the long term.

A major technical point: the voltage output is at a 1:1 ratio, meaning the voltage reading sent to the THC is the raw torch voltage. This contrasts with professional machines that use a 50:1 voltage divider to send a safer, scaled signal to the controller. The 1:1 works, but it requires caution regarding the electronics you connect.

🔌 Initial Connections and Setup

Physical connection is simple: standard connector for the torch, air line, and ground clamp connection. The screen allows you to adjust:

- Amperage

- Pilot arc time

- Post-flow time

- 2T/4T Mode

- A mode called “mesh” whose behavior is unclear due to a lack of documentation

To adjust air pressure in real-time, simply open the flow and turn the front knob. This simplicity helps refine cuts without having to unlock or move the machine.

🛡️ Safety and Consumables

Eye protection: For the amperages used during testing, a Shade 5 was used, and a welding helmet with appropriate shade adjustment is recommended when necessary. Maintaining distance and using proper Personal Protective Equipment (PPE) remains essential.

View Shade 5 Safety Glasses on Amazon

Regarding consumables, the torch allows the use of drag-style consumables with the option to install a drag shield over the nozzle for template or stencil work. This is useful for repetitive cuts or fine details on a CNC table.

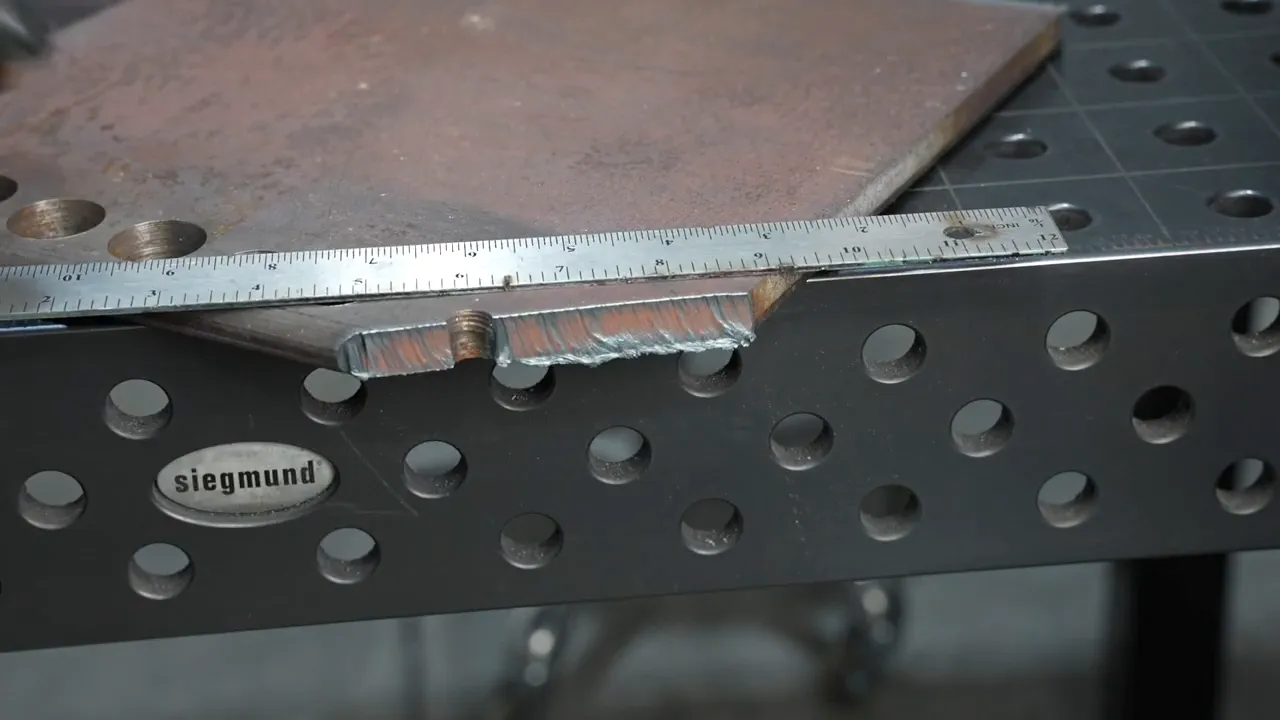

🔧 Performance in Manual Cuts

The unit was tested on 1/2″ and 1/4″ plates. With the output maxed at 50 amps, the machine pierces 1/2″ with decent results, although dross appears—especially on thicker materials, where it is somewhat expected. On fine cuts, dross is usually due to travel speed being too low; on thick cuts, it appears because the cutting capacity limit is being reached.

On 1/4″ and in piercing tests, the cut quality was quite clean. There was one instance where a spot needed a second pass, but overall the cut line remained well-defined with little dross on straight sections.

🔩 Power Consumption and 120V Considerations ⚡

When the machine is powered via the 120-volt adapter and set to maximum, input consumption can be high. In our measurement, it exceeded 40 amps of input draw. This is a critical aspect to consider if using it in a home shop with standard circuits, as it can stress the electrical installation.

Practical recommendation: Check circuit capacity and avoid using the unit on outlets or cords not rated for high current peaks. If your setup is limited, consider powering the machine at 240V or upgrading wiring before subjecting it to long jobs at full power.

🕸️ “Mesh” Mode and Expanded Metal

The machine includes a mode called mesh intended for cutting expanded metal continuously. In practice, during tests, it was observed that the pilot arc needed to re-ignite between sections, forcing pauses. We attempted to compare it with normal mode and noticed no significant difference.

🖥️ CNC Integration and Torch Height Control (THC) 🔭

The BestArc BTC500XP was integrated with a Langmuir Crossfire Pro table and a Langmuir THC box that accepts raw voltage for its reading. When connecting the voltage output at 1:1, the reading given by the THC was approximately 135V in the test, allowing the controller to function as intended.

To get good results with THC remember:

- Ensure the voltage signal reaches the controller correctly.

- Verify initial calibration: the reading must correspond to the actual arc distance.

- If the cut shows taper (narrowing towards the top), it usually indicates the cut height is too high. Reducing height or adjusting arc voltage usually corrects this.

🧭 CNC Cutting Results

Circular cuts and more complex shapes were tested on 1/8″, 3/16″, and 1/4″ using the CNC table. Key points:

- In curves and corners, slightly more dross appeared, which is typical when the machine reduces travel speed in those sections.

- In straight sections, an adequate travel speed offered clean cuts with little dross.

- Observed bevel and taper could be attributed to unoptimized parameters: mainly cut height and arc voltage.

By adjusting speed and voltage, we managed to improve consistency and cut definition. Overall, the final parts were not bad for a budget unit: acceptable edges, little dross on most points, and repeatable cuts when the table and setup were correct.

✅ Pros and ❌ Cons Summary

After several tests, here is a practical summary to decide if this machine fits your needs.

- Pros

- Very competitive price for a CNC-compatible unit.

- Clear interface and bright, easy-to-read screen.

- Very convenient front-mounted air regulator.

- Connectors and adapters for table mounting included.

- Cons

- 1:1 Voltage output (no divider), which is less ideal for some THC controllers and may require caution.

- High amperage draw on 120V, can overload home circuits.

- Torch build quality and sleeve could be inferior to professional models.

- Limited manual and documentation; modes like “mesh” are not well explained.

🛠️ Practical Tips for Better Cuts

- Use an air regulator and adjust it while the torch is flowing. Fine adjustment changes arc quality and dross formation.

- If there is taper, reduce cut height and check arc voltage; both settings affect the cut kerf shape.

- For CNC cuts, start with slightly slower speeds in curves and corners and accelerate in straight sections. Monitor dross to adjust ideal speed.

- If using 120V, ensure the circuit can handle peaks over 40A or consider 240V power for long jobs or maximum power.

- Keep spare consumables and consider drag shields if you are going to work with templates or repetitive thin parts.

Frequently Asked Questions (FAQ)

Is this plasma cutter compatible with CNC tables?

Yes, it incorporates ports for control signals and a voltage output for THC. The voltage output is 1:1, so it works with controllers that accept raw voltage.

Does it need high frequency to start the arc?

No. It uses a Blowback pilot arc start with a moving electrode, so it does not require a high-frequency signal. This reduces interference in nearby electronic equipment.

What are the thickness limitations?

It can cut 1/4″ and 1/2″ with reasonable results depending on settings and speed. In thicker gauges, more dross will appear, and the machine’s capacity limit may be reached.

Can I use it on a 120V home network?

Yes, but with caution. Consumption can exceed 40 A at maximum peaks. Check wiring capacity or consider 240 V for intensive work.

Does mesh mode improve cutting on expanded metal?

In tests performed, no clear difference was observed. Documentation is limited, so results may vary depending on exact configuration.

What maintenance does the torch require?

Regularly check consumables (electrodes and nozzles) and replace them if there is wear. Keep the torch sleeve clean to avoid unexpected arc cutouts.

🔚 Final Thoughts

The BestArc BTC500XP is an interesting proposition for those looking to get into plasma cutting with CNC capability without paying professional machine prices. It offers useful functions like blowback start, front air regulation, and THC connectivity.

For home projects and prototyping, it is a high-value option. For intensive production, it is worth evaluating machines with integrated voltage dividers. By adjusting parameters like speed and voltage, the BTC500XP can deliver repeatable and functional cuts.