The E6010 Welding Rod 3/32″ is a highly favored choice in the welding community, known for its strong arc and deep penetration capabilities. With a fast freeze characteristic, it minimizes sagging, making it ideal for overhead and vertical applications. This rod meets rigorous industry standards, ensuring x-ray quality welds. Its versatility is notable, as it can be utilized in various structural projects. Understanding its features can greatly impact welding efficiency and quality, prompting further exploration into its specific applications.

Key Takeaways

- The E6010 welding rod features exceptional welding characteristics, making it a preferred choice for professionals across various applications.

- Its strong arc stability and deep penetration ensure high-quality welds, suitable for critical applications like pipes and pressure vessels.

- With a 3/32 inch diameter and 5 lbs weight, this rod is versatile for multiple pass applications and various welding positions.

- The fast freeze characteristic minimizes sagging, allowing effective welding in tight spots and overhead positions.

- Slag removal is easy with thin, friable residues, contributing to efficient and clean welds that meet rigorous industry standards.

Welding Characteristics of E6010 Rod

The E6010 welding rod is renowned for its exceptional welding characteristics, making it a preferred choice among professionals.

Renowned for its exceptional welding characteristics, the E6010 is a top choice for professionals.

Its strong, forceful arc provides remarkable arc stability, allowing for consistent performance across various positions, including vertical-up and overhead.

This rod excels in creating deeply penetrating welds, achieving impressive penetration depth even in challenging applications.

Additionally, its fast freeze characteristic enhances usability by minimizing sagging, ensuring that welders can work effectively in tight spots.

Ideal for projects requiring sound welds, the E6010 is versatile enough to handle a range of materials, making it indispensable for critical welding tasks in diverse environments.

Weld Quality and Performance

Weld quality with the E6010 welding rod is particularly high, characterized by x-ray quality weld deposits that meet rigorous industry standards. This rod offers impressive weld strength and performance durability, making it suitable for a wide range of applications. The following table summarizes key features:

| Feature | Specification |

|---|---|

| Diameter | 3/32 inch |

| Weight | 5 lbs |

| Arc Characteristics | Strong, forceful, deeply penetrating |

| Slag Removal | Thin, friable, easily removable |

Applications and Use Cases

Applications for the E6010 welding rod are diverse and encompass a wide range of industrial and structural projects.

This welding rod excels in joining techniques, making it suitable for critical applications such as pipes, pressure vessels, and ship hulls. Its strong arc and fast freeze characteristics enable welds in various positions, ensuring adherence to industry standards.

The E6010 rod is particularly effective in multiple pass applications, where weld quality is paramount. Additionally, its compatibility with carbon and galvanized steel broadens its use in construction, storage tanks, and oil marine platforms, affirming its reputation as a versatile choice for welders.

Frequently Asked Questions

What Is the Recommended Amperage Range for E6010 Welding Rods?

The recommended amperage range for E6010 welding rods is typically between 70 to 100 amps. Mastering these welding techniques is essential for effective rod selection, empowering welders to achieve superior results in various applications.

Can E6010 Rods Be Used With AC and DC Welding Machines?

E6010 rods demonstrate excellent compatibility with both AC and DC welding machine types, allowing versatility in various welding applications. Their adaptability empowers welders to achieve high-quality results across diverse projects, promoting freedom in their craft.

How Should E6010 Rods Be Stored for Optimal Performance?

To guarantee the E6010 rods flourish, they should nestle in dry, controlled storage conditions, shielded from moisture. This careful embrace extends their rod lifespan, allowing welders to release their creative sparks without hindrance.

Is Preheating Required When Using E6010 Welding Rods?

Preheating is not generally required when using E6010 welding rods, but employing preheating techniques may enhance performance in specific welding applications, particularly where thicker materials or challenging conditions dictate a need for improved fusion and penetration.

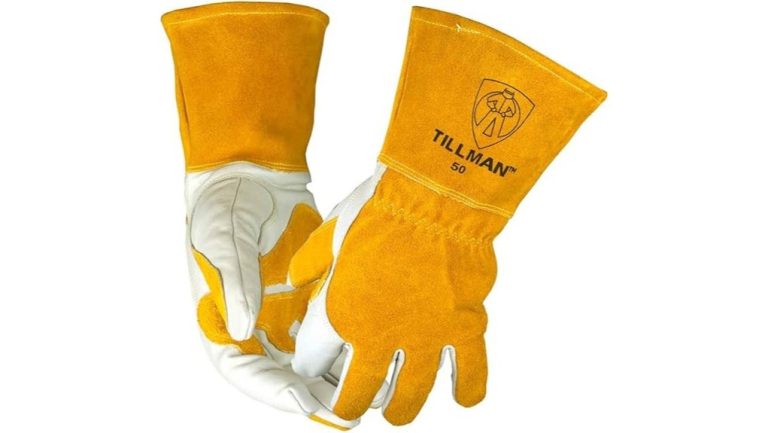

What Safety Gear Is Recommended When Using E6010 Welding Rods?

In the domain of welding safety, a knight must don protective equipment: helmets, gloves, and aprons. These shields guard against fiery sparks and toxic fumes, empowering the welder’s quest for mastery in metal’s embrace.

Conclusion

To sum up, the E6010 welding rod 3/32″ stands out as a top choice for professionals seeking reliability and quality in their welding projects. Its strong arc and fast freeze capabilities make it ideal for various positions and tight spots, ensuring deep penetration and x-ray quality welds. Whether working on structural projects or critical tasks, this rod proves its worth time and again. Investing in the E6010 is, indeed, putting your best foot forward in welding excellence.