The E7018 Premium Arc Welding Rods offer a range of features that appeal to both professionals and hobbyists alike. With a length of 14 inches and available in various diameters, these carbon steel electrodes provide excellent arc stability and reduced spatter. Their performance shines particularly in thick steel sections, minimizing the risk of cracking. Users have noted high satisfaction ratings, leading to a growing interest in their applications. What sets these rods apart in the welding market?

Key Takeaways

- E7018 arc welding rods feature durable carbon steel construction, ensuring long-lasting performance in various welding applications.

- Available in three diameters (3/32″, 1/8″, 5/32″), these rods offer flexibility for different welding tasks.

- Users report smooth arc stability and minimal spatter, enhancing overall welding quality and efficiency.

- The rods excel in all-position welding, making them suitable for challenging joints and thick sections with reduced cracking.

- With an average rating of 4.3 out of 5 stars, customer feedback highlights versatility and high satisfaction across various steel types.

Product Features and Specifications

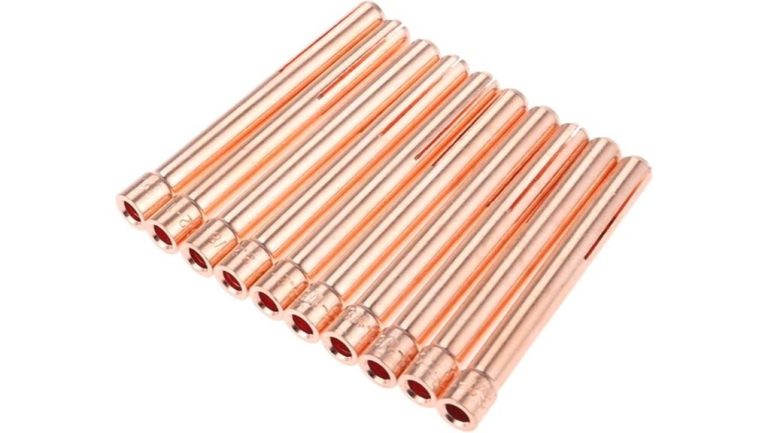

The E7018 Premium Arc Welding Rods stand out as a reliable choice for various welding applications, particularly due to their robust specifications and versatile features.

Designed as carbon steel electrodes, these rods come in three diameter options: 3/32″, 1/8″, and 5/32″. Each 14-inch rod facilitates diverse welding techniques, empowering welders to tackle both mild and low alloy steels.

With a total weight of 60 lbs, packed in six 10 lb boxes, they provide ample supply. Classified under AWS E7018, this electrode type is suitable for all-position welding, enhancing adaptability for projects requiring precision and strength in joint integrity.

Application and Performance

When considering the application and performance of E7018 Premium Arc Welding Rods, it becomes clear that these electrodes are specifically engineered for a range of welding tasks that require durability and precision. Their versatility allows for effective use in various welding techniques, especially when working with hardenable and low alloy steels. The electrodes excel in all-position welding, providing reliable performance in thick sections and restrained joints.

| Feature | Specification | Benefit |

|---|---|---|

| Diameter Options | 3/32″, 1/8″, 5/32″ | Flexibility for different tasks |

| Electrode Length | 14 inches | Adequate reach for various joints |

| AWS Classification | E7018 | Quality assurance in welding |

| Application | All-position welding | Mitigates cracking in difficult joints |

Customer Feedback and Rankings

Customer feedback on the E7018 Premium Arc Welding Rods indicates a generally positive reception, with an average rating of 4.3 out of 5 stars based on 66 reviews.

Customers express satisfaction regarding their user experiences, highlighting specific aspects:

- Versatility: Effective for various steel types and all-position welding.

- Quality: Strong performance on thick sections, reducing cracking.

- Ease of Use: Smooth arc stability and minimal spatter.

Frequently Asked Questions

What Is the Shelf Life of E7018 Welding Rods?

The shelf life of E7018 welding rods typically ranges from six months to one year, depending on storage conditions. Properly maintained rods guarantee ideal welding performance and minimize issues related to moisture absorption and contamination.

Can These Rods Be Used for Vertical Welding Positions?

Vertical welding positions are well within the capabilities of these rods, showcasing their versatility. With a customer rating of 4.3 stars, users appreciate effective welding techniques for challenging angles, empowering welders to conquer diverse projects confidently.

Are These Rods Suitable for Outdoor Welding?

These rods are suitable for outdoor welding conditions, maintaining reliable welding performance despite environmental challenges. Their design allows effective use in various positions, ensuring adaptability and efficiency for welders seeking freedom in diverse working environments.

How Should E7018 Rods Be Stored Before Use?

Proper storage of E7018 rods resembles safeguarding a treasure; maintaining humidity control is essential. Storing them in a dry, temperature-regulated environment guarantees peak performance, liberating welders from potential defects caused by moisture exposure and environmental factors.

What Safety Gear Is Recommended When Using E7018 Rods?

When using E7018 rods, personal protection is essential. Recommended safety gear includes welding helmets, gloves, and protective clothing to mitigate welding hazards, ensuring a safer and more liberated welding experience for the operator.

Conclusion

To sum up, the E7018 Premium Arc Welding Rods stand out for their reliability and versatility, making them suitable for a range of welding tasks. For instance, a local metal fabrication shop reported significant improvements in joint quality when using these rods for thick steel assemblies, leading to fewer rework instances. With their commendable ratings and positive customer feedback, these welding rods are an excellent choice for both seasoned professionals and enthusiastic DIYers seeking dependable performance in their projects.