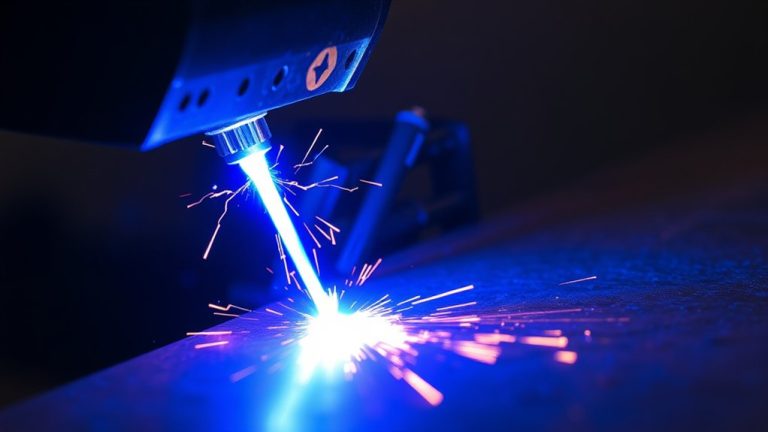

When you explore how a plasma torch operates, you uncover the critical interplay of electric arcs and gas dynamics. The torch generates a high-voltage arc that ionizes gas, transforming it into plasma at astonishing temperatures to slice through metal with precision.

A plasma torch operates by forcing a gas—such as nitrogen or compressed air—through a constricted nozzle while subjecting it to an electric arc. This process ionizes the gas, turning it into plasma that reaches temperatures up to 40,000°F. This high-velocity plasma jet melts the metal, while the gas flow blows the molten material away to create a clean cut.

Key Takeaways

- Plasma State: Ionized gas acts as an electrically conductive medium to transfer energy.

- Extreme Heat: The arc generates temperatures up to 40,000°F, instantly melting conductive metals.

- Gas Dynamics: Swirling gas flow constricts the arc for precision and cools the nozzle components.

- Pilot Arc: A high-voltage spark initiates the ionization process before the main cutting arc is established.

Understanding Plasma: The Fourth State of Matter

When exploring plasma, often called the fourth state of matter, you discover a domain where gases transform into an electrically conductive medium through ionization. Unlike solids, liquids, or standard gases, plasma consists of free-moving electrons and ions.

This transformation occurs when a gas is subjected to extremely high temperatures. At these levels, enough energy is imparted to the gas molecules to break them apart. This creates a conductive medium capable of carrying current.

The ionized particles grant plasma remarkable electrical conductivity. In industrial applications, this allows the torch to slice through metals with minimal resistance, making it an essential tool for precision cutting and welding.

The Role of Electric Arc in Plasma Formation

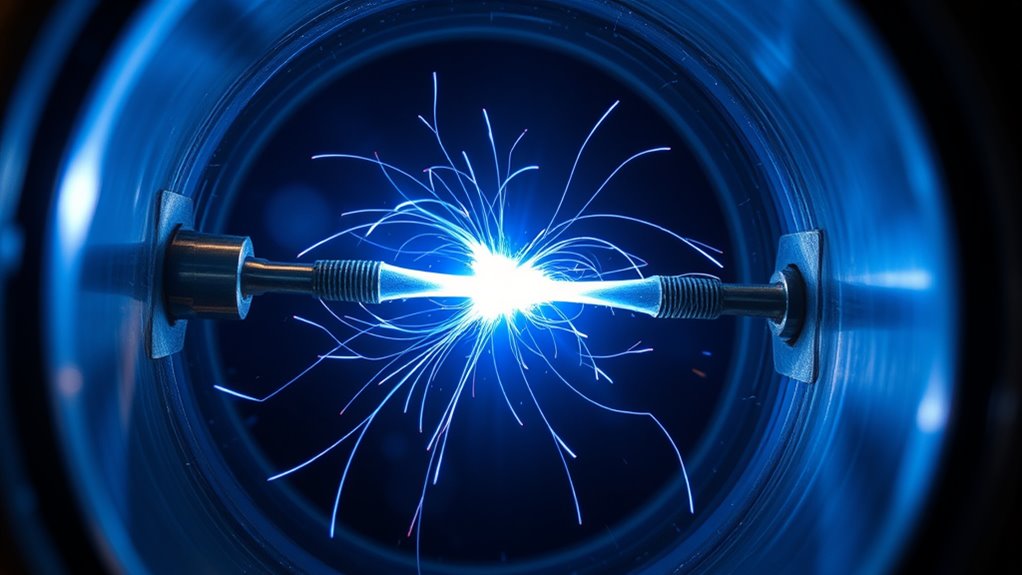

The electric arc is the engine of the plasma torch. It initiates the ionization process by generating a high-voltage spark between the electrode and the workpiece (or nozzle).

Arc and Ionization Process

The process begins when an electric arc establishes a path between a negatively charged electrode and the workpiece. This arc initiates the ionization of gas, heating it to extreme temperatures. Such intense heat causes gas molecules to break apart, forming plasma. As the gas ionizes, it produces charged particles that create a continuous electrical circuit.

This plasma jet effectively slices through conductive materials. The efficiency of this process is enhanced by preflow gas, which often forms a swirling vortex to stabilize the arc. This stabilization improves the precision of the cut.

Arc’s Role in Heating

The arc generated between the electrode and the workpiece drives temperatures up to 40,000°F. Such extreme heat is imperative for melting through conductive metals efficiently. The arc’s energy breaks gas molecules into fast-moving electrons and ions, sustaining the plasma jet.

| Function | Description |

|---|---|

| Arc Generation | Initiated between electrode and workpiece; ionizes gas to form plasma. |

| Heat Production | Temperatures reach 40,000°F, sufficient for instant melting. |

| Plasma Sustain | Energy maintains the plasma state for continuous cutting. |

This efficient heating pierces and blows away molten metal, ensuring clean edges.

Key Components of a Plasma Torch

The power supply plays a vital role by converting AC voltage to high DC voltage, enabling the creation of a pilot arc. The electrode and nozzle work in tandem: the electrode acts as the emitter, while the nozzle focuses the plasma jet’s velocity. Additionally, the swirl ring introduces a rotating gas flow to enhance arc stability.

Power Supply Functionality

The power supply converts standard AC line voltage into a high DC voltage (typically 200-400 VDC). This conversion allows the arc to efficiently ionize gas. The system often works with an Arc Starting Console, which uses high-frequency AC voltage (around 5,000 VAC at 2 MHz) to initiate the spark.

After establishing the pilot arc, the power supply ramps up the DC current to the desired cutting amperage. Maintaining stable voltage and current levels is fundamental to cut quality.

Electrode and Nozzle Interaction

When you activate the torch, the electrode and nozzle perform a synchronized operation. An electric arc forms, ionizing the gas flowing through the nozzle. The nozzle constricts this flow, directing the plasma with precision at high speeds.

Regular maintenance of consumables is vital. A worn nozzle or pitted electrode will distort the plasma jet, reducing accuracy and cutting speed.

Gas Flow Dynamics

The plasma torch relies on high-velocity gas—often compressed air, oxygen, nitrogen, or argon. This gas is forced through the nozzle orifice, where it undergoes ionization. The swirl ring aligns and cools the gas flow, creating a vortex that centers the arc within the nozzle. Precisely controlling the flow rate and pressure optimizes the jet’s density and cutting performance.

Handheld vs. Precision Plasma Operations

Handheld plasma systems initiate the flow of gas and DC current via a trigger, establishing an electrical arc manually. These are ideal for portability and simplicity, often used for DIY projects or salvage work.

Precision plasma systems, conversely, are integrated into CNC machines. They use a swirl ring to separate the electrode and nozzle, creating a swirling vortex that ionizes gas more efficiently. These systems achieve higher current densities (40-50K amps/in²), resulting in cleaner edges and minimal dross. Secondary shielding gases further constrict the arc, creating a cut quality that rivals laser cutting in some thicknesses.

Transferred and Non-Transferred DC Plasma Torches

Transferred DC torches establish an arc between the electrode (in the torch) and the workpiece itself. This method is highly efficient for cutting electrically conductive metals because the workpiece becomes part of the circuit.

Non-transferred DC torches house both the electrode and the nozzle (anode) internally. The arc forms inside the torch body rather than transferring to the material. While less efficient for cutting thick metal, this configuration allows the torch to cut non-conductive materials or be used for plasma spraying. However, it generates significant internal heat, often requiring larger electrodes and water cooling.

Applications and Advancements in Plasma Cutting Technology

CNC plasma cutters and robotic arms have revolutionized manufacturing sectors like automotive and aerospace by enhancing accuracy. High-frequency pilot arcs ensure reliable starts, while advanced shielding gas mixtures minimize heat-affected zones (HAZ).

| Feature | Benefit | Industry Impact |

|---|---|---|

| CNC Plasma Cutters | High Precision | Automotive, Aerospace |

| Robotic Arms | Automation | Increased Production Rates |

| Shielding Gas Mixtures | Cleaner Cuts | Enhanced Product Quality |

| Thermal Efficiency | Energy Optimization | Lower Operational Costs |

Frequently Asked Questions

How do plasma torches work?

Plasma torches work by ionizing a gas (like air) with an electric arc to create plasma. This superheated plasma jet melts the metal, while the high-velocity gas stream blows the molten metal away to form a cut.

What metals cannot be cut with a plasma cutter?

Standard transferred-arc plasma cutters cannot cut non-conductive materials like glass, ceramics, wood, or plastic. They rely on the workpiece being electrically conductive to complete the circuit.

Will a 20 gallon air compressor run a plasma cutter?

A 20-gallon compressor may run smaller plasma cutters for short bursts, but it often lacks the sustained CFM (cubic feet per minute) required for continuous cutting. Insufficient air volume leads to pressure drops and poor cut quality.

Does a plasma torch need gas?

Yes. Plasma torches require a gas supply to create the plasma jet and cool the torch. Compressed air is most common for shop use, while nitrogen, oxygen, or argon blends are used for high-precision industrial cutting.

Conclusion

You have now explored the intricate workings of a plasma torch, grasping how the electric arc transforms gas into a searing plasma jet. By mastering the controlled dynamics of gas flow, you optimize cutting precision and efficiency. Whether using a handheld unit or a CNC table, understanding these principles helps you harness plasma technology’s full potential for your metalworking projects.