When I first tried MIG welding after years of TIG, I was surprised at how different it felt — almost like trading a fine-tuned guitar for a drum kit. MIG vs TIG isn’t just a debate for metalworkers; it’s about knowing which tool fits the job. From stainless welding to thicker steel plates, the choice affects spatter, arc control, joint prep, and which filler rods you’ll need.

I’ve been there, wondering why my beads weren’t as clean as I expected, only to realize that understanding these differences can save time, improve weld quality, and prevent costly mistakes. Stick with me, and I’ll share the tips and tricks that make both processes feel second nature.

Photo by minoo-cn

What Is MIG Welding?

You’re knee-deep in a fabrication shop, and the foreman needs a dozen brackets welded up before lunch. That’s MIG’s sweet spot—Metal Inert Gas welding, or GMAW if you’re feeling technical. It’s like the workhorse of arc welding, using a continuous wire electrode that feeds automatically through your gun.

As the wire touches the base metal, it creates an electric arc that melts everything into a puddle, and the wire itself acts as your filler. Shielding gas—usually a mix of argon and CO2—flows out to protect that puddle from the air, keeping out oxygen and contaminants that could weaken your joint.

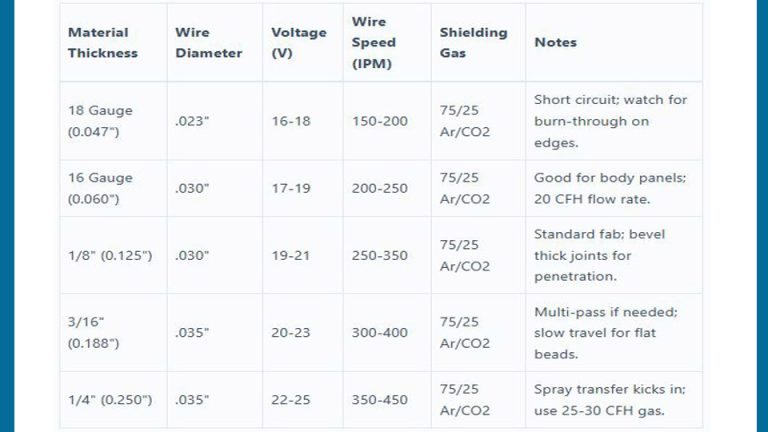

How does it work in practice? You set your voltage and wire feed speed on the machine—say, 18-22 volts and 150-250 inches per minute for 1/4-inch mild steel—and pull the trigger. The arc starts, and you just guide the gun along the joint, pulling or pushing depending on the angle.

It’s semi-automatic, so once you’re dialed in, it’s steady work. I remember my early days running MIG on a Lincoln Power MIG 210 in a rusty old auto body shop. That machine hummed like a dream, spitting out solid beads on exhaust pipes without breaking a sweat.

When do you reach for MIG? Anytime speed and volume matter—like automotive repairs, heavy fabrication, or even DIY furniture frames from scrap steel. It’s forgiving on thicker materials, from 24-gauge sheet up to half-inch plates, and handles positions like flat, horizontal, or even overhead if you’ve got good ventilation.

But here’s the real-world why: It boosts productivity without sacrificing too much strength, especially when you’re prepping joints with a bevel or V-groove for deeper penetration. Just watch for spatter—those little metal balls that fly off if your settings are off. A quick tip? Clean your workpiece with a grinder or acetone first; nothing kills a MIG run faster than mill scale or oil.

Common mistake I see with new folks? Cranking the wire speed too high, which floods the puddle and causes burn-through on thin stuff. Fix it by dialing back 20-30 inches per minute and practicing on scrap. And for safety, always hook up that fume extractor—MIG’s gas mix can kick up nasty vapors in a confined space.

What Is TIG Welding?

Now, shift gears to TIG—Tungsten Inert Gas, or GTAW for the pros. This one’s more like a finesse game, where you’re holding a non-consumable tungsten electrode in one hand to strike the arc, and dipping a separate filler rod with the other.

The tungsten doesn’t melt; it just focuses the heat super precisely, like a laser pointer on your weld pool. Pure argon (or sometimes a helium blend) shields it all, and you control the amperage with a foot pedal—think of it as your volume knob for heat input.

In the shop, it looks like this: Clamp your aluminum tubing, set the machine to AC for oxide cleaning on non-ferrous metals or DC for steel, and start with a light tap to ignite the arc. Glide the torch along, add filler as needed, and feather the pedal to keep things from overheating.

I cut my TIG teeth on a Miller Syncrowave back in ’05, restoring vintage Harleys. That first perfect stacked-dime bead on a tank seam? Pure magic. It took hours of practice, but man, the control you get is unmatched.

Why TIG in the real world? It’s your pick for thin materials—down to 0.005-inch foil—or when aesthetics count, like bike frames or food-grade stainless piping. It’s versatile across metals: steel, aluminum, titanium, even magnesium.

Use it when weld integrity is non-negotiable, like in aerospace parts or pressure vessels under ASME codes. The arc’s so tight, you get minimal distortion and cleaner edges, which saves grinding time later.

Practical know-how: Prep is king—grind away oxides and degrease thoroughly, or you’ll get porosity like Swiss cheese. For machine settings, start at 80-120 amps for 1/8-inch aluminum, and keep gas flow at 15-20 CFH to avoid turbulence.

Mistake alert: Forgetting to sharpen your tungsten to a point (2-3% thoriated works great for DC). It arcs all over the place. Sharpen on a belt grinder at 45 degrees, and grind lengthways to avoid flat spots. Safety-wise, that foot pedal keeps your hands free, but wear a full face shield—TIG’s UV is brutal.

Key Differences Between MIG and TIG Welding

Let’s break down how MIG welding differs from TIG welding head-to-head. I’ve burned through both on everything from truck frames to jewelry repairs, and these contrasts show up every time you pick up the torch.

Electrode and Filler Material

At the heart of it, MIG’s electrode is consumable—it’s the wire that feeds in and becomes part of the weld, no extra filler needed. TIG flips that: Tungsten electrode stays put, non-melting, and you hand-feed a matching rod.

This makes MIG one-handed and automatic, while TIG demands coordination. In my fab shop days, switching to TIG for a thin brass fitting felt like going from automatic to stick shift—slower, but way more precise for tight joints.

Shielding Gas and Protection

Both use inert gas, but MIG leans on blends like 75/25 argon-CO2 for deeper penetration and less cost—flows higher at 35-50 CFH. TIG sticks to pure argon (15-25 CFH) to keep the tungsten pure; CO2 would erode it fast.

Why it matters: MIG’s mix handles windy shops better, but TIG’s cleaner shield means fewer inclusions in sensitive alloys. Pro tip: Test your flow with a soap bubble gauge; leaks kill both processes.

Speed and Productivity

MIG wins the race—it’s 2-3 times faster thanks to constant wire feed, ideal for production lines or batch work. TIG? Slower, deliberate, perfect for prototypes or repairs where rushing warps thin stock.

I once timed a 10-foot seam: MIG in 15 minutes, TIG in 45. But that TIG joint held up under a torque test where the MIG needed cleanup first.

Weld Quality and Aesthetics

TIG delivers that mirror-finish look—minimal spatter, tight beads, no grind marks. MIG’s rougher, with potential porosity if not tuned, but it’s plenty strong for structural stuff. For visible work like sculptures, TIG’s your artist; MIG’s the builder. Common fix for MIG aesthetics: Use short-circuit transfer mode on thinner metals to cut spatter by 50%.

Skill Level Required

MIG’s beginner-friendly—learn basics in a weekend, crank out decent welds. TIG? Months to master the dance of torch, rod, and pedal. Students in my old welding classes always nailed MIG first, then graduated to TIG for certs. If you’re a hobbyist, start MIG to build confidence; pros, TIG for versatility.

Cost Considerations

Upfront, MIG machines run $500-2,000; TIG’s $1,000-5,000 with water coolers. Ongoing, MIG’s cheaper wire vs. TIG’s rods and tungsten swaps. But TIG saves on rework for high-stakes jobs. In a small shop, MIG pays off quick; for custom work, TIG’s precision justifies the hit.

MIG vs TIG: Pros and Cons

No process is perfect, so here’s a straight-up comparison table to visualize how MIG welding differs from TIG in the field. I’ve pulled this from countless shop runs—helps when you’re debating with your crew.

| Aspect | MIG Welding Pros | MIG Welding Cons | TIG Welding Pros | TIG Welding Cons |

|---|---|---|---|---|

| Speed | Lightning-fast for production | Can overheat thin metals quickly | Precise control avoids distortion | Slower, labor-intensive |

| Ease of Use | One-handed, auto-feed | More spatter cleanup | Versatile on exotic metals | Steep learning curve, two-handed |

| Weld Strength | Deep penetration on thick stock | Potential for porosity if prep skimped | Superior ductility, fewer defects | Weaker on very thick without multi-pass |

| Aesthetics | Functional, easy to coat over | Rough beads need grinding | Clean, polished look out of the gate | Time-consuming for long runs |

| Cost | Affordable setup and consumables | Higher gas use in blends | Long-term durability | Pricier equipment and fillers |

| Versatility | Great for steel, aluminum in volume | Struggles with ultra-thin or reactive | Handles thin to medium, all alloys | Not ideal for heavy fab without backups |

Pros for MIG: That speed keeps projects moving, and it’s forgiving for DIYers fixing gates or trailers. Cons? Spatter’s a pain—hit it with anti-spatter spray pre-run. TIG pros shine in quality: No flux means cleaner fumes, better for indoor artistry. Downside: Fatigue sets in on long sessions without practice.

When to Choose MIG Welding

Grab MIG when you’re battling deadlines or thick materials—like welding 3/8-inch I-beams for a garage addition. It’s king for automotive panels, structural frames, or hobbyist trailers where strength trumps looks. In US shops following AWS D1.1 codes, MIG’s spray transfer mode nails high-deposition joints on carbon steel.

Step-by-step for a basic MIG butt joint on mild steel:

- Prep: Bevel edges 30 degrees, clean to bright metal.

- Settings: 20V, 200 IPM wire speed for 1/4-inch plate.

- Tack: Three points, 1-inch apart.

- Run: Push the gun at 10-15 IPM travel, 10-15 degree angle.

- Cool: Natural air, no quench.

Anecdote time: Last summer, a buddy called mid-trailer haul—axle snapped. MIG’d it in 20 minutes roadside with my Hobart Handler. Saved the trip, no cracks since.

When to Choose TIG Welding

TIG’s your call for thin sheets, exotics, or show pieces—like aluminum boat hulls or stainless sinks. It’s essential for code-compliant work in pharma or aviation, where zero defects rule. Hobbyists love it for custom knives or bike racks that need that pro gleam.

Quick TIG lap joint guide for 16-gauge stainless:

- Prep: Grind to satin, acetone wipe.

- Settings: DCEN, 90 amps, 2% lanthanated tungsten.

- Start: Foot pedal to 50 amps, arc on edge.

- Fill: Dip rod every 1/2-inch, weave slight.

- Finish: Back off pedal slow, post-flow 10 seconds.

I botched my first TIG on a copper pipe—too much heat, warped it flat. Lesson: Pulse the pedal like breathing. Now, it’s my go-to for heirloom repairs.

Equipment and Setup Tips for MIG and TIG

Gear up right, and half the battle’s won. For MIG, a spool gun’s a game-changer for aluminum—prevents bird-nesting. Brands like Miller or Lincoln dominate US shops; pair with a 250-amp unit for versatility. Settings cheat sheet: For ER70S-6 wire on steel, match voltage to wire speed via the machine’s chart—too low, and it’s cold laps; too high, blow holes.

TIG setups scream precision: Water-cooled torch for long runs, CK Worldwide collets for grip. Filler match matters—ER308L for 304 stainless. Anecdote: Swapped to a CK torch mid-job on titanium exhaust; held shape where air-cooled fried. Tip: Balance your tungsten—too long, unstable arc; aim 1.5 times diameter.

Joint prep universal: 60-degree vee for MIG thickies, square butt for TIG thinnies. Filler compatibility: MIG’s solid wire for clean; flux-core if outdoors. Machine tweak: Clean drive rolls monthly, or MIG feeds like taffy.

Safety Considerations for MIG and TIG Welding

Safety isn’t a checkbox—it’s what keeps you welding tomorrow. Both arc processes throw UV, so full leather jacket, gloves, and auto-darkening hood (shade 10-13). MIG’s CO2 mix means more fumes—ventilate or use a respirator per OSHA 1910.252. Spatter? Boots and long sleeves; I’ve got scars from forgetting.

TIG’s argon is cleaner but displaces oxygen—never weld in tanks without fresh air. Tungsten dust? Thoriated types have low radiation, but grind outside. Foot pedals trip hazards? Secure ’em. Common oversight: Gas cylinder chains—tip one, and it’s ER time. Pro move: Post-weld inspect with dye penetrant for cracks, especially on load-bearing US code work.

Conclusion

MIG’s your efficient beast for thick, fast jobs where productivity rules, saving time and bucks on everyday fab. TIG elevates quality for thin, visible, or exotic work, delivering welds that stand up to scrutiny and make you beam with pride.

Whether you’re a DIYer patching a fence, a student chasing certs, or a pro chasing deadlines, knowing these differences arms you to pick right—boosting safety, cutting waste, and ensuring joints that last.

You’re more prepared now than ever to torch up confidently. Hybrid your skills—learn both, then blend ’em on multi-process machines like the Multimatic 215. It’ll open doors from hobby sheds to high-end shops.

FAQs

Is MIG Welding Easier to Learn Than TIG?

Absolutely— MIG feels like pointing a hot glue gun after a day of practice, while TIG’s like learning violin. Start with MIG for quick wins, then tackle TIG for mastery. Most trade schools sequence ’em that way.

Which Is Better for Welding Aluminum?

TIG edges out for thin aluminum thanks to AC cleaning and control, avoiding burn-through. For thicker stock, MIG with a spool gun and 100% argon works fast. Prep’s key either way—oxide free or bust.

Can You Use MIG Wire as Filler in TIG Welding?

No, MIG wire’s too soft and fluxed for TIG’s clean arc—it contaminates the tungsten. Stick to dedicated TIG rods like ER4043 for aluminum. Mismatch, and your puddle turns to mush.

How Do Gas Costs Compare Between MIG and TIG?

MIG burns more gas volume but cheaper blends—expect $20-30 per tank fill. TIG’s pure argon costs more per cubic foot but flows less, so tanks last longer. Factor in usage: MIG for volume, TIG for precision savings.

What’s the Strongest Weld: MIG or TIG?

TIG typically yields stronger, more ductile joints with better penetration and fewer defects, especially on thin or reactive metals. MIG holds its own on thick steel with proper prep, but TIG’s the champ for critical apps.