At 20–30 A, a plasma tip can run 2–5 hours, but at 60 A it typically falls to about 1 hour—push max amps and wear accelerates sharply. You’ll balance amperage, duty cycle, and pierce count against consumable cost and cut quality. Standards-driven setup—correct standoff, clean dry air (per ISO 8573-1), and proper pierce height—can double life. But how do you judge tip health, schedule swaps, and avoid scrap without slowing production?

Understanding Plasma Tips and Amperage Ratings

Although consumables vary by torch design, plasma cutter tips are engineered with specific amperage ratings that dictate permissible current density, thermal load, and expected wear. You should match the tip to the machine’s output and material demands; misalignment drives rapid degradation.

Across plasma tip designs, amperage effects are measurable: higher current increases arc energy density, elevates nozzle wall temperature, and accelerates orifice erosion.

Plan for 1–3 hours of active arc time under standard shop conditions, recognizing that higher amperage shortens that window. Cutting thicker sections or pushing travel speed raises heat load and ionized gas velocity, compounding wear.

Maintain correct torch-to-work distance and verify gas type, purity, and flow rate per the manufacturer’s spec; these parameters stabilize the arc column and reduce mechanical pitting of the orifice.

Replace tips when you observe a widened orifice, kerf growth, bevel, dross increase, or arc instability. Early replacement maintains cut quality and limits collateral wear on electrodes and shields.

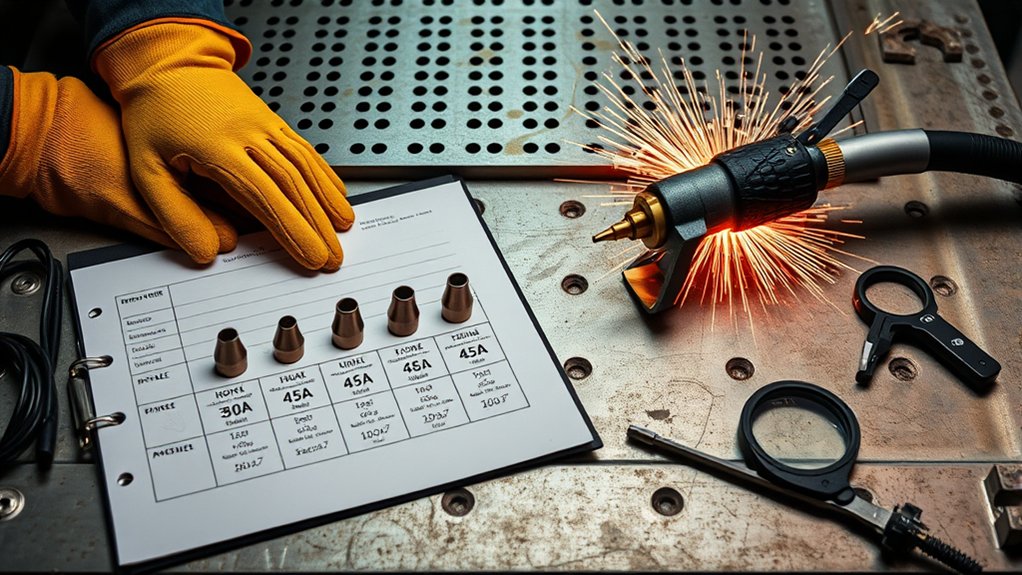

Typical Tip Lifespan by Common Amp Settings (20–100 A)

When you set amperage between 20 and 100 A, tip life tracks directly with current: expect roughly 1–3 hours of arc-on time overall, with longer life at lower settings and faster wear as amperage rises. You’ll see clear amperage impact on tip longevity: at 20 A, tips commonly reach the high end of the range; at 100 A, they approach the low end.

- 20–30 A: Plan for 2–3 hours, with some high-quality tips stretching to 4–5 hours.

- 40 A: Typical life lands near 1–2 hours.

- 60 A: Around 1 hour is common.

- 80–100 A: Operate closer to 1 hour, sometimes less, depending on duty cycle and cut quality targets.

| Amperage setting | Typical tip lifespan |

|---|---|

| 20–30 A | 2–3 h (best cases 4–5 h) |

| 40 A | 1–2 h |

| 60–100 A | ~1 h (decreasing as amps rise) |

Use these benchmarks to schedule consumable checks, align duty cycles, and maintain consistent kerf quality across common shop settings.

Factors That Accelerate or Extend Tip Wear

Two variables dominate tip wear: thermal load and contamination. You shorten life when you push amperage near the machine’s maximum; arc temperature and plasma velocity rise, eroding the orifice faster.

Empirically, tips average 1–3 hours of arc-on time, but at 90–100% load you can halve that. Running near 50% of the nameplate rating reduces thermal cycling and stabilizes the arc column, extending life.

Air quality is the next lever. Moisture and oil create micro-explosions at the orifice, pit the copper, and distort flow. Use dry, filtered air to keep the plasma jet coherent and conductive losses low.

Tip materials matter. Premium copper alloys and plated or silver-bearing inserts dissipate heat better and resist softening, preserving orifice geometry and cut precision longer than budget consumables.

Process choices also influence wear: excessive pierce height, long arcs, and slow travel increase heat input per unit length, while correct standoff maintains laminar flow and lowers erosion rates.

Maintenance Practices to Maximize Pierce Count and Torch Time

Building on how heat and contamination drive wear, you can extend tip life through disciplined maintenance and parameter control.

Apply cleaning techniques 2–3 times per shift to remove dross, spatter, and oxide from the tip, electrode, and shield; use non-abrasive brushes and alcohol-based wipes to avoid dimensional change. Control moisture with refrigerated air dryers and secondary filters to keep dew point low and prevent arc instability that erodes orifices.

Set and verify machine parameters before each run: a plunge rate of 60 and a pierce delay of 0.3–0.4 s minimize double-arcing and back-splash. Match high-quality consumables to material thickness and amperage; torque and seat them per the manufacturer’s spec to maintain concentricity and cooling flow.

Log pierce counts and correlate with cut quality and arc voltage. With consistent performance optimization, users routinely achieve 2,500–4,500 pierces per tip.

Adjust delay, height, and gas flow incrementally based on data to stabilize arc transfer and maximize torch time.

Signs Your Tip Is Spent and How to Replace Efficiently

How do you know a tip is past its service window and swap it without disrupting throughput? Start with disciplined tip inspection. If your cut edges turn jagged, spatter increases, or the orifice shows discoloration and pits, the tip’s geometry is no longer controlling the arc. Most tips last roughly 1–3 hours of arc-on time, varying by amperage, material, and setup. Replace before failure to lock in kerf accuracy and minimize rework.

- Verify condition: Pause, power down, and cool. Under magnification, check the orifice roundness and surface for deep pits or burnishing. Compare to a new tip to quantify wear.

- Apply replacement techniques: Follow the manufacturer’s torque and sequence to avoid damaging the electrode, swirl ring, and shield. Clean interfaces; never mix mismatched consumables.

- Reset for performance: Reinstall, then confirm gas flow, standoff, and amps per spec. Use high-quality tips and optimized settings to extend life and maintain repeatable cut quality.

Frequently Asked Questions

How Do Different Air Dryers Impact Tip Life in Humid Climates?

Refrigerated dryers moderately extend tip life by stabilizing humidity levels; desiccant dryers maximize it by delivering −40°C dew point air quality. Membrane dryers help mobile setups but vary with inlet conditions. Monitor dew point, ISO 8573-1 classes, and condensate management.

Are Aftermarket Tips as Durable as OEM Consumables?

As a rule, no—aftermarket durability often trails OEM consumables. You’ll see shorter life unless metallurgy, orifice concentricity, and plating match OEM specs. Verify ISO 9001, SPC data, tolerance ±0.01 mm, and amperage/torch compatibility for a fair OEM comparison.

What Cut Quality Changes Indicate Impending Tip Failure During Automated Runs?

You’ll notice widening kerf, increased bevel angle, dross accumulation, striations migrating upward, arc wander, and edge hardening. Monitor cut quality metrics: surface roughness, HAZ width, and dimensional drift. These trends quantify tip wear and forecast imminent consumable replacement.

How Does CNC Pierce Height Calibration Affect Tip Longevity?

Proper pierce height calibration effects are decisive: miscalibration doubles molten backsplash, while ±0.1 mm accuracy can extend tip life 30%. You prevent double-arcing, minimize crater diameter, reduce electrode erosion, and maintain consistent gas flow alignment, meeting ISO 9013 cut-quality tolerances.

Can Nitrogen or Oxygen Plasma Gases Extend Tip Life Over Compressed Air?

Yes. Depending on plasma gas types, nitrogen and oxygen can reduce tip wear versus compressed air. You’ll see cleaner arcs, lower oxidation, and steadier cooling. Follow OEM consumable specs, duty cycle limits, and ISO 9013 cut-quality parameters.

Conclusion

You’ve seen the data: at 20–30 A, expect 2–5 hours; around 60 A, about 1 hour; at max amps, even less. So, will you run blind—or benchmark consumables like a pro? Track pierces, inspect orifice wear, and adjust gas pressure, standoff, and travel speed to IPC/ANSI best practices. Replace tips at the first sign of double-arc, bevel, or dross. Do this, and you’ll convert consistent standards into consistent cuts—and predictable costs.