The HVAC Tools Welding Blanket is engineered from high-quality carbon fiber, providing exceptional heat resistance up to 600°F. Its 5mm thickness balances flexibility and durability, making it suitable for demanding tasks. The blanket features cut-out openings and snap buttons for adaptability, ensuring ease of use in various applications. With low thermal conductivity and flame-retardant properties, it protects against heat, sparks, and slag. Understanding its performance specifications is essential for maximizing its effectiveness.

Key Takeaways

- The welding blanket is made from high-quality carbon fiber, ensuring excellent heat resistance up to 600°F for safety during HVAC tasks.

- With a thickness of 5mm, it provides softness and flexibility, making it easy to wrap around equipment or areas needing protection.

- Its low thermal conductivity of 0.13 W/(m-K) makes it effective for insulation and flame retardant applications in HVAC environments.

- Designed with cut-out openings and snap buttons, the blanket enhances usability in tight spaces while offering robust protection against heat and sparks.

- The durable carbon felt construction ensures longevity, outperforming standard mats and reducing the need for frequent replacements in demanding work settings.

Material and Construction Quality

When considering the material and construction quality of HVAC tools welding blankets, it becomes evident that these products are engineered for exceptional performance and durability.

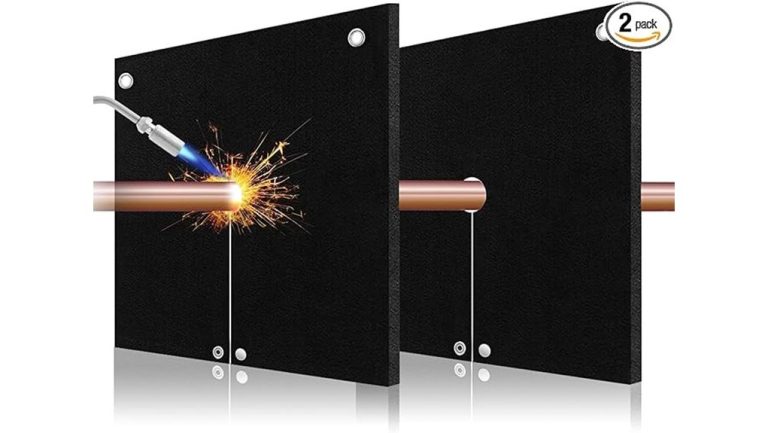

Crafted from high-quality carbon fiber, these blankets exhibit remarkable heat resistance, withstanding temperatures up to 600°F. Their 5mm thickness offers both softness and flexibility, enabling easy wrapping around various objects, including grills and smokers.

Additionally, the tear-resistant nature guarantees longevity, outperforming thinner mats with 2-3mm thickness. Enhanced usability features, such as cut-out openings with snap buttons, allow for adaptability in tight spaces, providing ideal protection for personnel and equipment during demanding tasks.

Performance Specifications and Applications

Performance specifications for HVAC tools welding blankets highlight their remarkable capabilities in various applications.

These blankets deliver exceptional thermal protection and guarantee welding safety through effective heat resistance.

Exceptional thermal protection ensures welding safety with effective heat resistance for optimal performance in demanding tasks.

Key features include:

- Low thermal conductivity of 0.13 W/(m-K).

- Temperature tolerance up to 600°F, maximizing safety during high-heat tasks.

- Versatile usage for equipment coverage and ground protection against sparks and slag.

- Ideal for insulation, flame retardant needs, and soldering copper pipes efficiently.

In essence, these blankets serve as essential tools for professionals seeking reliable safety and performance in demanding environments, safeguarding both personnel and equipment.

Durability and Longevity of the Welding Blanket

Durability is a critical factor when evaluating the longevity of HVAC tools welding blankets, as their performance relies heavily on the materials used in their construction.

The 5mm heavy-duty carbon felt considerably enhances durability, outperforming standard 2-3mm mats. This superior material not only offers exceptional heat resistance, withstanding temperatures up to 600°F, but also guarantees user comfort due to its soft, non-irritating nature.

Such features make it ideal for protection against heat, sparks, and slag in various applications. With its robust design and adaptability, this welding blanket promises reliable performance, providing lasting protection for both personnel and equipment.

Frequently Asked Questions

How Do I Clean and Maintain the Welding Blanket?

Cleaning techniques involve gentle wiping with a damp cloth and mild detergent. Maintenance tips include storing the blanket in a dry place, avoiding excessive heat exposure, and inspecting regularly for wear to prolong its life.

Can the Blanket Be Used Outdoors in Wet Conditions?

The blanket exhibits limited water resistance, making it suitable for outdoor use in dry conditions. However, its outdoor durability may diminish when exposed to prolonged moisture, potentially affecting its effectiveness in protecting against heat and sparks.

Is the Welding Blanket Safe for Use Near Open Flames?

The welding blanket demonstrates notable fire resistance, providing effective heat protection near open flames. Its high-quality construction guarantees safety, allowing users to operate confidently while minimizing risks associated with intense thermal environments during welding tasks.

What Are the Dimensions of the Welding Blanket?

The welding blanket’s dimensions may vary, typically aligning with standard sizes. A dimensions comparison reveals its adaptability, enabling effective coverage and protection, appealing to those seeking liberation from constraints typically imposed by conventional protective gear.

Does the Blanket Come in Different Colors or Styles?

The blanket is available in various color options and styles, catering to diverse preferences. This flexibility allows users to select a design that aligns with their aesthetic, promoting both functionality and personal expression in their workspaces.

Conclusion

In conclusion, the HVAC Tools Welding Blanket stands as a formidable ally in high-heat environments, much like a steadfast guardian shielding against the flames of a blacksmith’s forge. With its impressive heat resistance of up to 600°F and durable 5mm thickness, this blanket offers both flexibility and protection. The thoughtful design, featuring cut-out openings and snap buttons, enhances usability, ensuring this tool remains an essential component for professionals seeking reliability in demanding tasks.