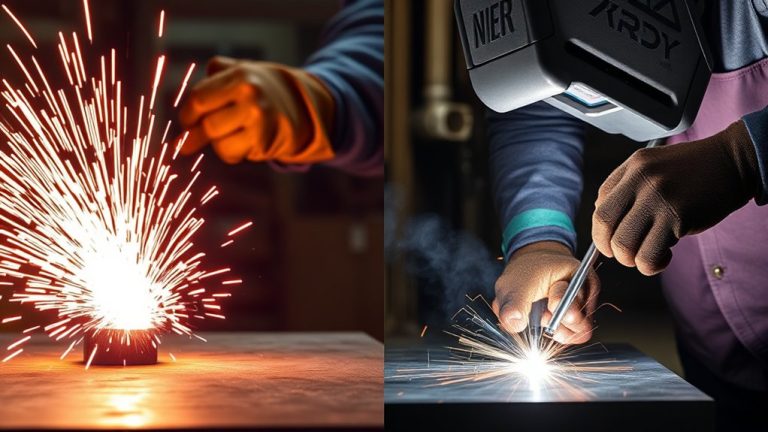

When you think of metalworking, do plasma cutters and welding machines spark the same image in your mind? They’re often mixed up, yet each serves a unique role. Plasma cutters slice through metal with precision, while welding machines forge bonds by melting and fusing materials. Knowing their differences, applications, and safety protocols is essential for any professional in the field. But what makes plasma cutting both advantageous and challenging?

Understanding Plasma Cutters and Welding Machines

How do plasma cutters and welding machines differ in their fundamental operations?

With plasma technology, plasma cutters excel in cutting precision by using a high-velocity jet of ionized gas to slice through electrically conductive materials. In contrast, welding machines focus on joining metals by melting and fusing them together using an electric arc.

Plasma cutters operate at temperatures up to 40,000°F, efficiently melting and expelling material, which results in clean, precise cuts with minimal kerf and dross. This makes them particularly effective for a variety of metals such as stainless steel, aluminum, brass, and copper.

Safety is paramount when using these tools. Plasma cutting generates intense light and harmful fumes, requiring proper ventilation and eye protection. Meanwhile, welding demands precautions against heat, sparks, and electric shock.

Key Differences Between Plasma Cutters and Welding Machines

When you’re comparing plasma cutters to welding machines, focus on their distinct functions and purposes.

Plasma cutters excel in slicing through conductive metals with precision using ionized gas, while welding machines specialize in joining materials through electrical arcs.

Consider also the operational requirements; plasma cutters need compressed air and electrical power, whereas welding relies solely on electricity, yet both demand rigorous safety precautions tailored to their specific hazards.

Function and Purpose

While both plasma cutters and welding machines are essential tools in metalworking, their functions and purposes differ considerably.

Plasma cutters excel in cutting techniques, using a high-velocity jet of ionized gas to slice through metals like mild steel, stainless steel, and aluminum. They operate at temperatures up to 40,000°F, ensuring clean cuts with minimal slag.

In contrast, welding machines focus on joining methods. They melt and fuse metals to create strong bonds, requiring lower temperatures than plasma cutting. Welding allows for versatility in joining different metals, though specific techniques may be necessary depending on the material.

Safety is paramount: plasma cutting demands protection from intense light and electricity, while welding emphasizes shielding against sparks and ensuring proper ventilation.

Technology and Operation

Understanding the technology and operation of plasma cutters and welding machines reveals their distinct roles in metalworking.

Plasma technology harnesses a high-velocity jet of ionized gas to slice through metals like steel and aluminum with precision. The operation principles involve creating plasma at temperatures up to 40,000°F, allowing for rapid, clean cuts with minimal slag. You need compressed gas, typically air, for effective plasma cutter operation.

In contrast, welding machines focus on creating strong metal bonds by melting and joining metals through an electric arc. The operation principles here involve generating heat via electrical current and sometimes using filler materials to enhance the bond.

Welding can be slower and may require post-process cleaning. Each method’s unique technology and operation principles define its specific metalworking applications.

Material Compatibility

Though plasma cutters and welding machines both serve essential roles in metalworking, their material compatibility highlights key differences in their applications.

Plasma cutters excel in handling electrically conductive material types like mild steel, stainless steel, aluminum, brass, and copper. This versatility allows them to tackle non-ferrous metals efficiently, minimizing compatibility issues. Plasma cutting is ideal for achieving precise, clean cuts up to 1 inch thick.

In contrast, welding machines are tailored for joining metals by melting and fusing. Their compatibility often depends on the welding technique—MIG, TIG, or stick—which dictates the specific materials you can work with.

While welding can bond much thicker pieces, it may face compatibility issues with certain material types, limiting flexibility. Understanding these distinctions is fundamental for safe, effective metalworking.

Common Uses of Plasma Cutters

When you’re involved in metal fabrication, plasma cutters offer precise and efficient cutting capabilities on materials like steel and aluminum, essential for maintaining high-quality standards.

In automotive repair, you can rely on plasma cutters for their ability to cut through rusty or painted metals without extensive preparation, reducing labor time and ensuring safety.

These tools enhance productivity in both fields by providing quick, clean cuts while minimizing material distortion.

Metal Fabrication Applications

While plasma cutters aren’t welding machines, they play an essential role in metal fabrication by offering efficient cutting solutions for a variety of conductive materials.

By employing precise fabrication techniques, plasma cutters handle varying metal thicknesses with ease, from delicate aluminum to robust structural steel. They’re perfect for crafting intricate designs and patterns, enhancing both artistic metalwork and custom projects.

In construction, plasma cutters streamline processes by swiftly slicing through structural steel beams and metal decking, reducing labor time and improving workflow efficiency.

Their versatility extends to HVAC applications, where they create clean, accurate cuts in ductwork for seamless assembly.

Always prioritize safety by wearing protective gear and ensuring proper ventilation, as plasma cutting produces intense heat and fumes.

Automotive Repair Efficiency

Plasma cutters aren’t just valuable in metal fabrication; they’re also indispensable in the domain of automotive repair, where efficiency and precision are paramount.

Using a plasma cutter, you can swiftly cut through metals like mild steel, aluminum, and stainless steel, which are integral to vehicle construction. This tool excels in repair techniques by allowing quick removal of damaged parts like body panels and exhaust systems, ensuring minimal distortion and clean edges for perfect fitting and welding of replacements.

For automotive modifications, plasma cutters facilitate the customization of metal parts, making it easier to fabricate unique components.

Their ability to cut through thick materials, even up to 1 inch, is ideal for heavy-duty applications such as frame repairs. This efficiency considerably boosts workshop productivity.

Essential Safety Measures for Plasma Cutting

Although operating a plasma cutter can greatly enhance your metalworking capabilities, it’s vital to follow essential safety measures to protect yourself and those around you.

Start by adhering to robust safety protocols, which include wearing flame-resistant clothing, gloves, and a welding helmet to protect against burns and arc rays. Equally important is the daily equipment inspection. Check cables and grounding connections meticulously to prevent electrical hazards and guarantee the equipment operates safely.

Guarantee your workspace has proper ventilation to mitigate the inhalation of harmful fumes and gases. If ventilation is inadequate, use air-supplied respirators.

Additionally, be vigilant about fire risks; keep flammable materials away and maintain a tidy area free of debris. Training is essential; familiarize yourself with all safety protocols, learn to recognize potential hazards, and maintain a steady hand during operation.

This disciplined approach will minimize risks and enhance safety during plasma cutting tasks.

Advantages of Using Plasma Cutters

You’ll find that one of the primary advantages of using plasma cutters is their ability to operate at temperatures soaring up to 40,000°F, allowing them to slice through materials like steel, aluminum, and brass with remarkable speed and accuracy. This high temperature contributes to plasma efficiency, enabling cleaner cuts with minimal slag and a narrower kerf. You won’t need to preheat materials, which boosts cutting speeds and reduces operational time, particularly beneficial for thin metal applications.

Moreover, plasma cutters deliver superior cut quality, handling various metal types and thicknesses with ease. Their versatility makes them indispensable in industries like manufacturing and automotive repair. Importantly, they provide a safer work environment by eliminating explosive gases and open flames common in traditional methods.

| Advantage | Description | Benefit |

|---|---|---|

| High Temperature | Up to 40,000°F operation | Quick, precise cuts |

| Clean Cuts | Minimal slag, narrow kerf | Enhanced product quality |

| No Preheating | Immediate cutting capability | Reduced time, increased efficiency |

| Versatility | Handles various metals and thicknesses | Broad application range |

| Safety | No explosive gases, no open flames | Reduced workplace hazards |

Challenges and Limitations of Plasma Cutters

While plasma cutters offer impressive capabilities, they’re not without their challenges and limitations. Cut quality begins to suffer when you’re dealing with materials thicker than 50 mm, making it less effective for heavy-duty tasks. This degradation means additional post-cutting work, such as deburring and cleaning, is often required to achieve the desired finish.

The operational complexity of plasma cutting adds another layer of difficulty; operators must be well-trained to set up and run these machines efficiently, which can be time-consuming and costly.

The initial investment for plasma cutting equipment is substantial, potentially deterring smaller shops from adopting this technology. Additionally, the process generates excessive noise, intense light, and harmful fumes. Proper safety measures, including effective ventilation and personal protective equipment, are essential to safeguard operators.

Finally, dross production, though reduced compared to other cutting methods, still occurs, necessitating further cleanup, especially on thicker cuts.

Frequently Asked Questions

Can Plasma Cutters Be Used on Non-Metal Materials?

You can’t use plasma cutters on non-metal materials due to their reliance on electrical conductivity. Despite plasma cutter versatility, their primary application remains metal. Always guarantee safety protocols are followed to prevent accidents during cutting operations.

How Do I Maintain a Plasma Cutter for Longevity?

To maintain a plasma cutter for longevity, regularly clean the torch and nozzle with proper cleaning techniques. Inspect and replace worn parts promptly. Follow maintenance tips in the manual, emphasizing safety protocols to prevent malfunctions and guarantee durability.

Are Plasma Cutters Suitable for Hobbyists and Beginners?

Plasma cutters are perfect for passionate hobbyists. They offer precision and versatility for various projects. You’ll appreciate the clean cuts and creative control they provide. Make sure you’re familiar with safety procedures to protect yourself while perfecting your skills.

What Is the Cost Range for Plasma Cutter Equipment?

Plasma cutter pricing varies from $300 to $3,000, depending on the model’s capabilities and features. When making an equipment investment, analyze your needs and prioritize safety features to guarantee efficient and secure operation in your projects.

Can Plasma Cutters Be Used Underwater for Cutting Tasks?

Yes, you can use plasma cutters underwater, enhancing cutting efficiency for specialized applications. Make certain you follow stringent safety protocols, as water increases electrical hazards and affects equipment performance. Proper training and protective gear are essential for safe operation.

Conclusion

In your metalworking journey, distinguishing between plasma cutters and welding machines is essential. Plasma cutters, with their precision, can slice through metal up to six inches thick, showcasing their power and versatility. Always prioritize safety: wear protective gear and guarantee proper ventilation. By understanding their unique functions and applications, you can optimize your projects. The right tool, used safely, transforms metal manipulation into an art form, making your work both efficient and groundbreaking.