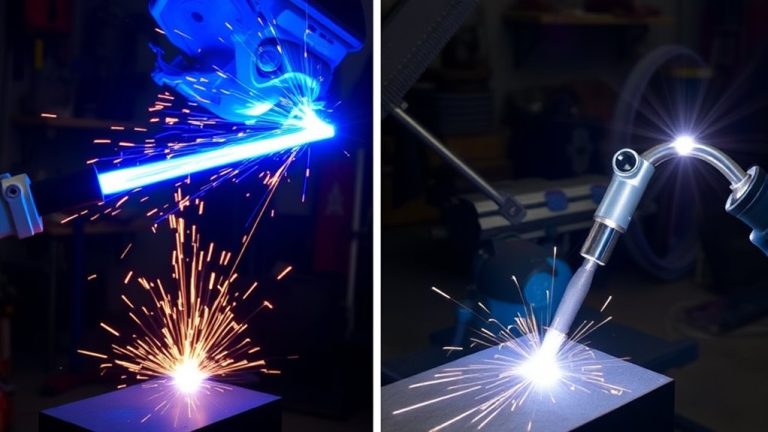

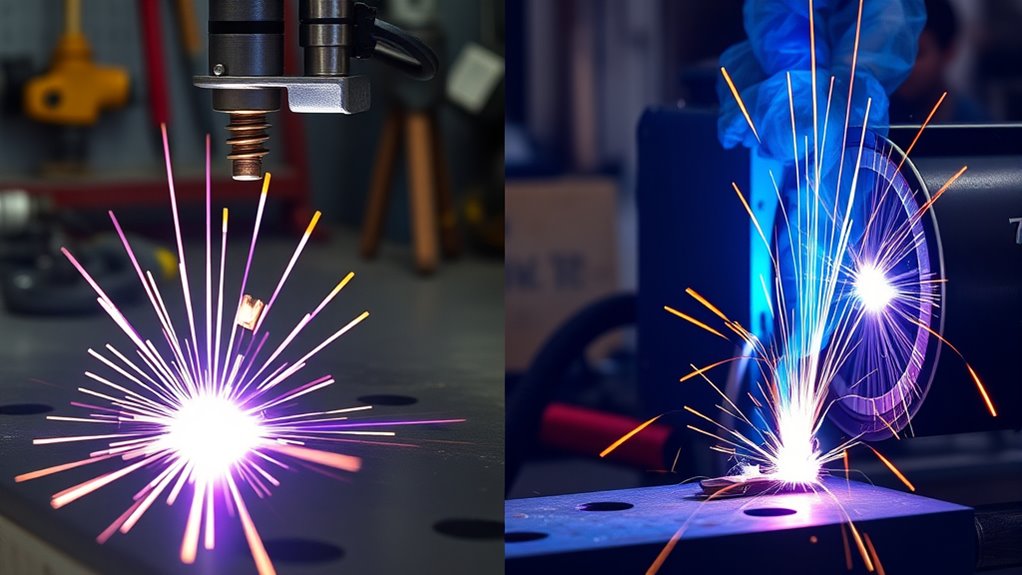

When comparing laser and plasma welding, consider speed, penetration, and cost. Laser welding offers unmatched speed, exceeding 200 inches per minute, ideal for high-volume production. Its penetration depth excels with a 12:1 depth-to-width ratio, perfect for thin materials. Although plasma welding systems are initially cheaper, laser welding provides long-term savings. Are you ready to explore which method truly aligns with your precision needs and budgetary constraints?

Speed and Efficiency Comparison

When comparing the speed and efficiency of laser welding to plasma welding, laser welding stands out with its ability to achieve welding speeds of several meters per minute.

Laser welding’s speed advantages are particularly evident in high-volume applications, such as automotive manufacturing, where you might see speeds exceeding 200 inches per minute. This impressive speed translates into quicker production cycles, enhancing operational efficiency.

In contrast, plasma welding operates at a relatively slower pace due to its inherent heating and cooling processes, resulting in longer processing times for similar tasks.

You’ll find that laser welding systems excel in efficiency metrics, offering faster cycle times thanks to their non-contact nature and precise energy delivery. This minimizes the need for extensive preheating.

While setup and programming might offset these advantages in short runs, the efficiency gains of laser welding in high-volume operations are substantial compared to plasma welding.

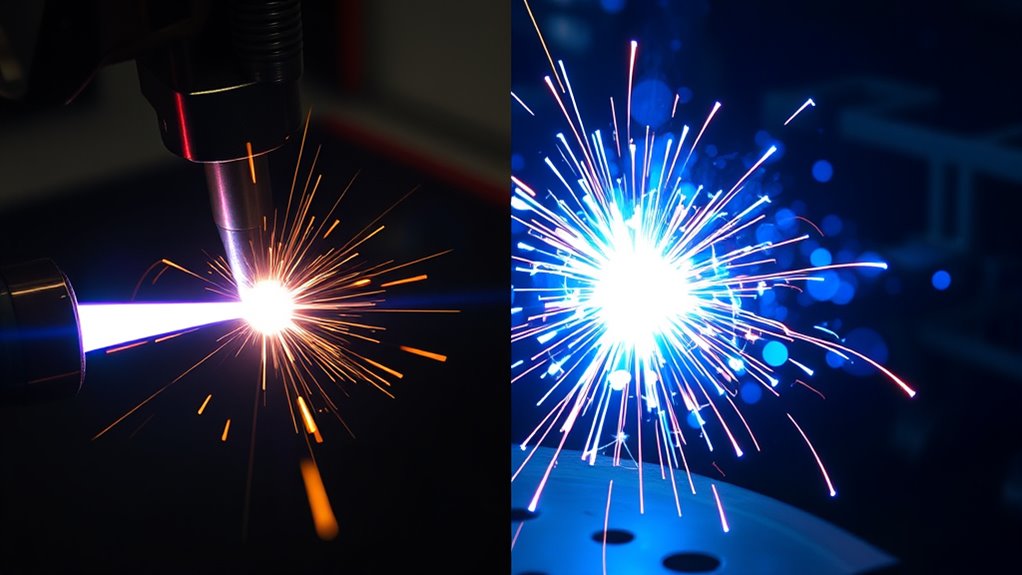

Penetration Capabilities and Depth Ratios

When considering penetration capabilities, laser welding’s depth-to-width ratio of 12:1 stands out, enabling deep penetration with minimal heat-affected zones, particularly in thin materials.

In contrast, plasma welding’s 3:1 ratio is better suited for thicker materials, though it creates a larger heat-affected zone.

Your choice between these methods should align with the specific material thickness tolerance and the desired precision in joining.

Depth-to-Width Comparison

Although both laser and plasma welding techniques offer distinct advantages, laser welding outshines plasma welding with respect to depth-to-width ratio, achieving approximately 12:1 compared to plasma’s 3:1.

The refined weld profile of laser welding is a demonstration of its superior energy efficiency, as it harnesses high energy density (10⁶-10⁷ W/cm²) to penetrate materials deeply while maintaining narrow, precise welds. This capability is particularly beneficial when working with thin materials, where minimal heat-affected zones are essential.

In contrast, plasma welding, with a lower energy density (10⁵-10⁶ W/cm²), results in wider welds and is more suited for medium to thick plates.

Its lower depth-to-width ratio often necessitates multiple passes to achieve the same penetration, impacting overall efficiency.

Material Thickness Tolerance

In comparing laser and plasma welding, understanding their material thickness tolerance offers key insights into their practical applications.

Laser welding, with its superior depth-to-width ratio of 12:1, is ideal for thin materials, ensuring precise penetration and a minimal heat-affected zone (HAZ). This is essential when material compatibility demands minimal thermal distortion. You’ll find it’s best suited for welding applications up to 10 mm thick, where tight gap tolerances of 0.1 mm are required.

Conversely, plasma welding’s 3:1 ratio makes it more effective for thicker sections, handling materials up to 38 mm thick.

It’s more forgiving with gap tolerances between 0.3 and 0.5 mm, although it results in a larger HAZ. This makes plasma welding preferable for applications demanding robust material compatibility at scale.

Cost Analysis and Investment Considerations

When evaluating laser welding and plasma welding systems, you’ll notice that laser systems demand a higher initial investment, typically exceeding $200,000, compared to plasma systems that range from $10,000 to $50,000.

However, laser welding’s long-term cost efficiency becomes evident through reduced labor and maintenance expenses, offering potential payback in 1-3 years for high-volume operations.

To determine the most economically viable option, consider the total cost of ownership, including equipment, maintenance, consumables, and labor savings.

Initial Investment Comparison

Why is the initial investment so critical when choosing between laser welding and plasma welding systems? The choice depends on your budget, production needs, and risk tolerance.

While laser welding systems demand a higher initial outlay, typically starting at $200,000, they offer potential long-term benefits. On the other hand, plasma welding systems, ranging from $10,000 to $50,000, are more accessible for smaller operations but come with their own investment risks.

Analyze these factors:

- Initial Costs: Laser systems require higher initial investment.

- Risk Assessment: Evaluate the financial risk of each option.

- Maintenance: Plasma systems incur higher maintenance costs.

- Payback Period: Laser systems might’ve a payback period of 1 to 3 years.

Your decision should balance these considerations for ideal investment.

Long-term Cost Efficiency

Although the initial costs for laser welding systems might appear intimidating, their long-term cost efficiency often outweighs the upfront investment.

Investing in a laser welding system, typically starting at $200,000, can lead to substantial long term savings. This technology’s efficiency in high-volume production greatly reduces labor and operational expenses. With processing rates of several meters per minute, laser welding minimizes production time, speeding up return on investment.

In contrast, plasma welding systems, though initially cheaper, incur higher maintenance costs due to frequent consumable wear. Laser systems, requiring only occasional cleaning and recalibration, offer lower maintenance expenses.

Economic analyses show that laser welding systems’ payback periods range from 1 to 3 years, underscoring their cost-effectiveness in suitable applications.

Maintenance and Operational Requirements

Considering the technical demands of maintaining and operating welding systems, it’s important to recognize the stark differences between laser and plasma welding.

Recognizing the stark differences between laser and plasma welding is crucial for effective system maintenance and operation.

With advancements in welding technology, laser systems require less frequent maintenance, primarily involving cleaning and recalibration. Meanwhile, plasma welding systems need a more rigorous maintenance schedule due to consumable wear and larger gas consumption.

Here’s a concise comparison:

- Maintenance Frequency: Laser welding needs occasional attention, while plasma welding demands frequent checks due to its consumable parts.

- Operational Cost: Despite a higher initial investment (over $200,000), laser welding offers lower downtime and long-term savings. Plasma systems, though cheaper initially ($10,000-$50,000), incur more frequent operational costs.

- Efficiency: Laser systems boast higher processing rates, enhancing operational efficiency.

- Setup Precision: Plasma welding requires stricter attention to gap tolerances (0.3-0.5 mm), whereas laser welding is more forgiving (0.1 mm).

Understanding these nuances guarantees you maximize efficiency and longevity in your welding operations.

Material Versatility and Limitations

Having explored the maintenance and operational requirements, let’s turn our attention to the material versatility and limitations inherent in laser and plasma welding. Laser welding stands out with its material adaptability, accommodating a broad spectrum of metals, including aluminum and titanium, as well as reflective materials and some non-metals. In contrast, plasma welding is constrained to conductive materials but excels in welding environments involving thicker plates up to 38 mm.

Here’s a comparison of key attributes:

| Attribute | Laser Welding | Plasma Welding |

|---|---|---|

| Material Adaptability | High | Moderate |

| Thickness Suitability | Up to 19 mm | Up to 38 mm |

| Precision | Spot sizes as small as 0.1 mm | Larger spot sizes |

| Gap Tolerance | Tighter (0.1 mm) | More relaxed (0.3-0.5 mm) |

| Stability in Complex Geometries | Moderate | High |

Laser welding’s high energy density allows for precise, deep penetration, while plasma welding’s versatility in handling thicker plates makes it invaluable in certain industrial scenarios.

Heat-Affected Zone and Distortion Control

When analyzing the heat-affected zone (HAZ) and distortion control, laser welding’s precision becomes evident. Its precise heat distribution results in a micron-level HAZ, minimizing potential damage and reducing distortion risk. This is vital for maintaining dimensional accuracy, particularly in industries like aerospace and medical devices.

Here’s a breakdown of why laser welding excels:

- Minimal Heat Input: Laser welding’s heat input is 10-100 times lower than traditional methods, aiding in superior thermal management and minimizing distortion.

- Precision Control: The small HAZ allows for tight control over the welding process, guaranteeing high precision in component fabrication.

- Reduced Distortion: Unlike plasma welding, which induces more thermal expansion, laser welding minimizes distortion, making it ideal for thin materials.

- Dimensional Accuracy: Effective distortion control guarantees the production of high-precision components, essential where accuracy is non-negotiable.

Frequently Asked Questions

What Are the Safety Measures for Laser and Plasma Welding?

Guarantee safety protocols by wearing protective gear, including goggles and gloves. Handle equipment correctly to prevent accidents. Maintain proper ventilation to minimize fume exposure. Regularly inspect tools to guarantee safe operation. Always follow manufacturer guidelines accurately.

How Do Laser and Plasma Welding Impact Environmental Sustainability?

You’ll find laser welding typically offers higher energy efficiency, leading to a lower carbon footprint. Plasma welding may consume more energy, potentially increasing environmental impact. Analyzing both processes helps you choose a more sustainable option for your needs.

Can Laser Welding Be Used for Artistic Metalwork Projects?

Imagine the precision of a laser beam sculpting intricate designs. You can absolutely use laser welding for artistic metalwork projects. This technique offers unparalleled control and versatility, allowing for complex, detailed artistic applications with impeccable precision.

Are There Specific Training Requirements for Operating Laser Welding Machines?

Yes, you need specific training and certification requirements for operating laser welding machines. You must develop precise operator skills, including understanding machine settings, safety protocols, and material compatibility, ensuring efficient and high-quality welds in various applications.

How Does Plasma Welding Perform in Outdoor Environments?

Imagine seamless metal under blue skies; plasma welding excels outdoors with impressive efficiency. Its weather resistance guarantees consistent performance despite environmental challenges, allowing you to achieve precise, reliable results even when conditions aren’t ideal.

Conclusion

When deciding between laser and plasma welding, think of laser welding as a finely tuned sports car—fast, precise, and efficient, ideal for high-volume and precision-demanding projects. It offers unmatched speed and penetration, like a blade slicing effortlessly through paper. While plasma welding might initially be the budget-friendly choice, laser welding shines with long-term savings in labor and maintenance. Consider your project’s demands carefully; laser welding’s precision and efficiency might just be the investment your operation needs.