Before you strike an arc, you verify airflow, inspect leads and consumables, and clear combustibles. You set amperage to match thickness, confirm clean, dry air, and establish a consistent standoff. You position the work for stable movement, trace the path, and plan starts and exits. You anchor your off-hand for control, hold a steady arc length, and watch travel speed to limit dross. You suit up with proper PPE and ventilation—then you address the pitfalls that ruin cuts.

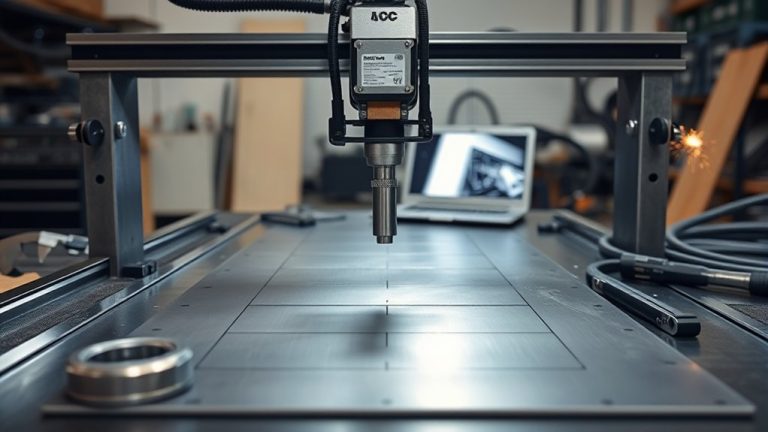

Preflight Checks and Equipment Setup

Before you power up the plasma cutter, complete a disciplined preflight check. Start with preflight inspections of the power cord—look for cuts, burns, or loose strain reliefs—and confirm the power supply matches the machine’s rating.

Verify the ground clamp is secure on a clean, bare section of the workpiece to guarantee a reliable circuit and stable arc.

Check the air system next. Confirm adequate airflow and pressure per the owner’s manual. If your setup lacks conditioning, install an air filter/dryer to remove moisture and particulates that degrade cut quality and consumables.

Confirm all consumables are correctly installed, tight, and appropriate for the material and thickness. Review the owner’s manual to align settings and procedures with manufacturer requirements.

Prioritize equipment maintenance. Inspect torch leads, cables, and connections for wear, heat damage, or looseness; replace as needed.

Maintain tidy cable routing to prevent strain and trip hazards. Document findings and corrective actions to support consistent performance and safe operation.

Selecting the Right Plasma Cutter and Consumables

Although many models can make a spark, choose a plasma cutter by matching its output and duty cycle to your material and production demands. Select plasma cutter types by verified cut capacity: a Spectrum 375 X-TREME handles up to 3/8 in mild steel; a Spectrum 625 X-TREME reaches up to 5/8 in. For continuous work, verify the duty cycle meets your production rate to avoid thermal trips and inconsistent cut quality.

Pick consumable materials by amperage and thickness. Use higher-amp tips and matched electrodes for thicker stock; low-amp tips protect edge quality on thin sheet. Confirm part numbers for model compatibility and install per the manufacturer’s torque and orientation to prevent arc instability.

- Inspect tips and electrodes routinely; replace at the first signs of orifice ovaling or pitting.

- Control moisture; contamination accelerates wear and causes double-arcing.

| Selection Factor | Specification Guidance |

|---|---|

| Output capacity | Match to max thickness (3/8 in vs 5/8 in) |

| Duty cycle | Align with expected arc-on time |

| Consumables | Amperage-rated, model-specific |

| Maintenance | Dry air, scheduled inspection and replacement |

Dialing In Amperage, Air, and Torch-to-Work Distance

Set amperage to match material thickness—higher for thick plate, lower for thin sheet—to control heat input and prevent burn-through.

Maintain clean, dry air at the manufacturer’s specified pressure (typically 60–80 psi) to stabilize the arc and cut quality.

Hold a consistent 1/16–1/8 in standoff, adjusting slightly for thicker stock, and monitor arc length to minimize dross and protect consumables.

Matching Amps to Thickness

Two settings govern clean, safe plasma cuts: amperage that matches thickness and air/stand-off that stabilize the arc. Start with cutting thickness, then make a precise amperage adjustment. As a rule of thumb, use about 1 amp per 0.001 inch. For 1/4 inch steel, set ~40 A. Verify with your owner’s manual for material-specific ranges. Match travel speed to amps: if you must move faster to stay ahead of the kerf, increase current; if dross builds, you’re too slow or too hot.

| Thickness (in) | Target Amps | Notes |

|---|---|---|

| 0.063 (1/16) | ~60 | Fine kerf; moderate speed |

| 0.125 (1/8) | ~125 | Watch edge angularity |

| 0.250 (1/4) | ~40 | Typical shop cut |

| Consult manual | As listed | Overrides rule |

Keep air 60–80 psi and maintain 1/16–1/8 inch stand-off for arc stability and consumable life.

Optimizing Standoff and Air

With amperage matched to thickness, tighten control of torch-to-work distance and air. Use standoff adjustment to hold 1/16–1/8 inch off the work. Don’t drag the tip—contact widens the kerf, skews bevel, and burns consumables. Verify your air pressure is within the machine’s specification, typically 60–80 psi at the torch while flowing, to stabilize the arc and reduce dross.

- Set amperage for thickness, then fine-tune voltage via torch-to-work distance; consistent standoff yields uniform bevel and minimal distortion.

- Perform a flowing-air check: confirm 60–80 psi at the torch, adjust regulator, and drain moisture traps.

- Use a drag shield or spacer for repeatable standoff adjustment; inspect tip wear frequently.

- Test-cut coupons: evaluate kerf angle, dross, and edge hardness, then adjust air pressure and standoff in small increments.

Path Tracing and Workpiece Positioning

Before striking an arc, perform a dry run along your marked path to verify torch reach, lead routing, and visibility.

Clamp guides and securely support the workpiece to prevent movement, maintain straight or bevel cuts, and keep your body clear of potential kick or tip hazards.

Set start and finish points with allowances for lead‑in/lead‑out, pierce clearances, and kerf exit to meet cut-quality and safety requirements.

Dry Run Tracing

One essential step for clean, accurate cuts is a dry run—tracing the planned path without firing the torch to refine motion and verify setup.

Dry run benefits include confirming reach, sightlines, and travel stability while building muscle memory for consistent speed and torch angle. Mark the cut line with a fine marker or chalk for high-contrast visibility, and use a straight edge or template for linear sections; freehand curves to validate smoothness.

1) Stand square to the work, elbows lightly anchored; simulate arc length and standoff consistently.

2) Trace the full path, including lead-ins/lead-outs; note tight spots where cable drag or obstructions occur.

3) Maintain uniform travel speed; count or pace to standardize timing across segments.

4) Verify workpiece stability and fixture integrity; re-check alignment after repositioning.

Clamp and Support

Clamping and support set the foundation for accurate cuts and safe operation. Secure the ground clamp to a clean, bare-metal area on the workpiece to complete the circuit; inspect for paint, rust, or scale and reposition if resistance is high.

Select clamp types that match the geometry and load: C-clamps for flat stock, locking pliers for irregular shapes, and toe clamps or fixtures for repeatability. Use support methods that prevent chatter and sag—blocks, slats, or a cutting grate—while keeping the kerf path clear.

Position the workpiece so it can’t shift under drag forces. Before initiating the arc, practice path tracing along the layout line to verify clearance and torch access.

During cutting, maintain a 1/16–1/8 inch standoff and use your non-cutting hand as a steady rest.

Start/Finish Positioning

Two preparations determine clean starts and square finishes: path tracing and secure positioning.

Dry-run the torch along your layout before energizing. This confirms reach, torch angle, and body stance, so you don’t fight cables or induce waviness. Mark the start point and end point with high-contrast chalk for visibility through sparks and fumes. Set the work at elbow height; clamp it rigidly to prevent drift.

- Trace the full path cold, checking for obstructions and verifying that your hand can clear corners without twisting.

- Place the start point near the base metal edge to let the arc pierce cleanly and reduce dross.

- Use two clamps or fixtures minimum, located outside the cut line.

- Reconfirm the end point and provide over-travel room to avoid a hooked finish.

Hand Technique, Standoff, and Travel Speed Control

Although the arc does the cutting, your hands dictate quality and safety. Prioritize hand stability and torch control.

Although the arc cuts, your hands decide quality and safety—stability and torch control come first.

Dry-run the path without triggering to program smooth motion and eliminate hesitations. Use your non-cutting hand as a guide or bridge on the work surface to steady the torch, especially on long cuts or tight radii. Pull the torch rather than push; it gives better visibility, control, and edge quality.

Hold the torch perpendicular to the workpiece for standard cuts; tilt only when intentionally beveling. Maintain a consistent standoff of 1/16 to 1/8 inch to protect consumables and sustain ideal plasma flow. Use a drag shield if supplied; otherwise, gauge the gap visually or with a standoff guide.

Match travel speed to material thickness using a reference chart. On softer metals like aluminum, reduce speed to prevent dross trails and arc lag.

Watch the kerf and sparks: a vertical, narrow stream indicates correct speed; forward-leaning sparks signal you’re moving too fast.

Essential Safety Practices and PPE

Good hand control means nothing if you’re unprotected. Follow PPE guidelines and lock in safe habits before striking an arc.

Wear a fire-resistant jacket, closed-toed leather shoes, flame-resistant gloves, and a welding helmet with the correct minimum shade for plasma intensity. Confirm workspace ventilation removes fumes at the source; supplement with local exhaust or a rated respirator when extraction is insufficient. Keep combustibles out of the hazard zone and maintain clear egress.

- Inspect before use: check torch leads, power cord insulation, and strain relief; verify air supply pressure/flow and filter/dryer function; confirm torch consumables are seated.

- Control the environment: enforce a safe perimeter, shield bystanders from UV and spatter, and stage a Class ABC fire extinguisher within arm’s reach.

- Operate by the manual: apply manufacturer-specific settings, handling cautions, and emergency shutdown procedures.

- Ventilate and position: orient cutting to pull fumes away from you; never cut in confined spaces without engineered workspace ventilation.

Frequently Asked Questions

How Do I Minimize Warping on Thin Sheet Metals?

Minimize warping by staggering welds, using back-step and skip sequences, clamping with heat sinks, and controlling interpass temperature. Match parameters to metal thickness considerations, employ heat control techniques, shorten arc time, allow cooling intervals, and verify flatness with calibrated straightedges.

What Are Best Practices for Cutting Painted or Galvanized Steel?

You strip coatings before cutting and ventilate aggressively. After thorough paint removal and surface preparation, test a small section. For example, you halted a line job to remove galvanization, used fume extraction, monitored zinc exposure, and documented compliance.

How Can I Manage Distortion When Cutting Long Continuous Seams?

Stagger cuts, skip around, and clamp strategically to maintain distortion control. Use balanced sequencing, minimal heat input, and intermittent stops. Verify seam alignment with fixtures, shims, and straightedges. Allow cooling pauses, pre-set counter-bow, and measure continuously to meet tolerance and safety requirements.

What Maintenance Schedule Extends Torch and Consumable Lifespan?

Schedule weekly torch cleaning, daily inspection, and interval-based consumable replacement per manufacturer specs. Like dialing a rotary phone, you verify airflow, electrode/nozzle wear, coolant/filters, leads, and O-rings. Keep logs, torque-check assemblies, and isolate power before service for safety.

How Do I Safely Use CNC Templates With Manual Guide Fixtures?

Use rigid fixtures and check template alignment with scribed reference marks. Clamp securely, verify clearance, and follow CNC safety: guarded torch, dry work area, PPE, fume extraction. Test on scrap, control standoff, maintain lead-ins, stop if vibration occurs.

Conclusion

By now, you’ve checked your gear, tuned amperage and air, and set a respectful torch-to-work distance. You’ll trace the path with a steady hand, keep travel speed honest, and let dross be a polite reminder to adjust. You’ll mind the airflow, clear the clutter, and suit up so surprises remain merely “events.” Hold standards tight, protect your consumables, and you’ll cut clean, repeatable lines—on spec, on schedule, and with nothing more dramatic than a tidy spark show.