MIG welding tools are essential for achieving high-quality welds in various projects. These tools include heat-resistant leather gloves, which protect hands from extreme temperatures, and heavy-duty magnets that help maintain precise angles during assembly. Additionally, welpers pliers facilitate easy handling of components, while a MIG nozzle reamer guarantees optimal gas flow for effective welding. Understanding these tools’ specifications and benefits can greatly enhance a welder’s efficiency and safety. Discover how each tool contributes to a successful welding experience.

Key Takeaways

- MIG welding tools, including gloves and pliers, enhance the welding process, ensuring high-quality and durable results.

- Leather welding gloves provide heat resistance and comfort, protecting hands while allowing for dexterity during welding tasks.

- Heavy-duty magnets assist in maintaining precise angles, improving alignment and efficiency in welding projects.

- Chipping hammers effectively remove slag, promoting cleaner weld surfaces for stronger bonds in metal fabrication.

- Regular maintenance of tools like MIG nozzle reamers and welpers pliers is essential for optimal performance and improved welding outcomes.

Overview of MIG Welding Tools

The world of MIG welding tools encompasses a variety of essential instruments designed to enhance the welding process and guarantee high-quality results.

MIG welding techniques benefit immensely from tools like leather welding gloves, which protect hands from heat, and heavy-duty magnets that secure precise angles. Additionally, the multi-purpose welpers pliers facilitate easy handling of components, while the MIG nozzle reamer guarantees maximum gas flow.

Safety remains paramount, underscoring the need for quality equipment. With tools like a wire brush for cleaning and a soapstone holder for marking, welders can achieve effective results while prioritizing welding safety and efficiency in their craft.

The Importance of a Chipping Hammer

A chipping hammer serves as an indispensable tool in the MIG welding process, designed specifically to enhance efficiency when removing welding slag. Its effective use of chipping techniques guarantees a cleaner weld surface, promoting stronger bonds.

The chipping hammer’s features include:

The chipping hammer boasts high carbon steel construction, heat-treated durability, and a precision chisel for efficient slag removal.

- Constructed from high carbon steel for durability

- Heat-treated for increased resistance to wear

- Measures 10-1/2 inches in length for comfortable handling

- Chisel width of 1-1/16 inches for precision slag removal

Utilizing this tool not only expedites slag removal but also contributes to the overall quality of the welding project, making it an essential item in any welder’s toolkit.

Essential Features of Welding Gloves

When selecting welding gloves, several essential features contribute to both safety and comfort during the welding process. A key characteristic is heat resistance, which protects hands from high temperatures and sparks.

Gloves made from leather, often measuring 13.5 inches, provide durability and flame resistance. Additionally, a comfort fit is vital for maneuverability, allowing welders to maintain dexterity while working.

Cotton lining enhances comfort, reducing fatigue during extended use. Fully welted seams guarantee durability, preventing wear and tear.

Utilizing Welding Magnets and Soapstone Holders

Maximizing efficiency and precision in welding projects can be greatly enhanced by the use of welding magnets and soapstone holders.

Enhance your welding projects’ efficiency and precision with the essential tools of welding magnets and soapstone holders.

These tools provide essential support, ensuring magnetic stability and maintaining accurate angles.

- Heavy-duty welding magnets support precise angles of 45°, 90°, and 135°

- Soapstone holders allow for clear, removable markings

- Soapstone replacements include 5 flat and 45 round pieces

- The combination facilitates accurate alignment during the welding process

The Role of Welpers Pliers and MIG Nozzle Reamer

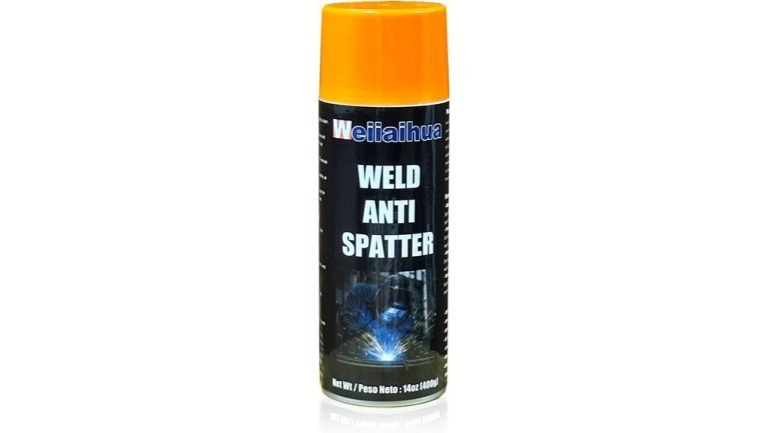

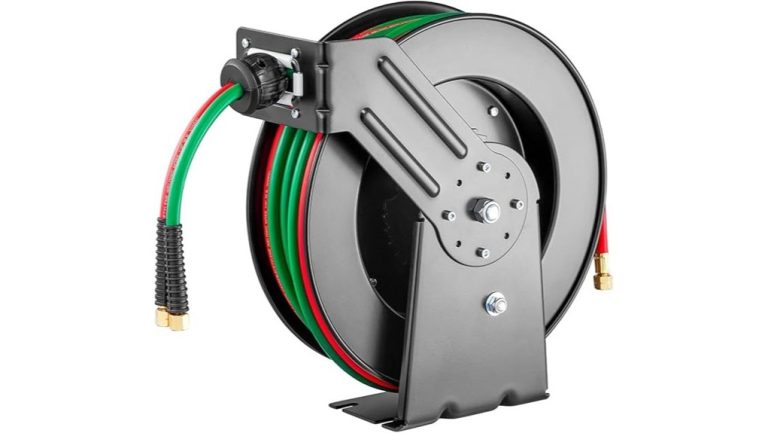

Welpers pliers and the MIG nozzle reamer serve crucial functions in enhancing the overall efficiency of MIG welding operations. These tools are essential for maintaining peak performance and guaranteeing seamless welding experiences.

| Tool | Function | Benefits |

|---|---|---|

| Welpers Pliers | Multi-purpose tool for gripping, cutting, and installing tips | Improves welding efficiency, guarantees secure holds |

| MIG Nozzle Reamer | Cleans nozzles and removes metal spatter | Enhances gas flow, prolongs nozzle life |

Regular tool maintenance using these instruments not only boosts welding quality but also contributes to a more liberated and proficient welding practice.

Frequently Asked Questions

How Do I Maintain My MIG Welding Tools?

To maintain MIG welding tools, regular tool cleaning prevents buildup and enhances performance. Proper equipment storage protects tools from damage, ensuring longevity and efficient usage. Following these practices empowers welders to work effectively and confidently.

What Safety Gear Should I Wear While MIG Welding?

To guarantee safety while MIG welding, one must wear a welding helmet to protect the face and eyes, alongside durable protective clothing that shields against heat, sparks, and harmful radiation, fostering both safety and freedom in expression.

Can I Use These Tools for Other Types of Welding?

Welding tools exhibit remarkable versatility; approximately 70% of tools designed for MIG welding also support other welding processes. This compatibility empowers welders to explore diverse techniques, enhancing their craft and liberating their creative potential.

Are There Specific Brands Recommended for MIG Welding Tools?

Several reputable MIG welding brands are known for their high-quality tools. These brands prioritize durability and performance, ensuring welders have reliable equipment that enhances their craft and supports their quest for skill and independence in welding.

How Often Should I Replace My Welding Gloves and Other Tools?

Like fleeting shadows in a forge, welding gloves require replacement every six months to a year, while tools should be assessed regularly. Their lifespan and replacement frequency guarantee safety and efficiency in the welding dance of creation.

Conclusion

In summary, the right MIG welding tools are the backbone of a successful welding project. Each tool, from leather gloves that shield against heat to heavy-duty magnets that secure components, plays a crucial role in ensuring safety and precision. The chipping hammer contributes to cleaner weld surfaces, while versatile welpers pliers and the MIG nozzle reamer enhance efficiency and control. By investing in these essential tools, welders can elevate their craft and achieve exceptional results with confidence.