You’re evaluating a 60A plasma cutter for material thickness and speed, so start with rated vs max capacity and power input. At 240V, expect clean cuts on 3/4–7/8 in mild steel near 15 ipm; at 120V, capacity and speed drop sharply. Stainless and aluminum of similar thickness run slower as amperage nears limits. Gas flow, duty cycle, and torch start type also dictate cut quality—now confirm air requirements and travel speed targets.

Understanding 60 Amp Plasma Cutter Capabilities

Precision defines a 60 A plasma cutter: expect clean cuts on steel up to about 7/8 inch, with practical capacities tied to input power and duty cycle. You should benchmark performance by rated amperage, torch design, and gas flow.

Typical travel speed is around 15 inches per minute on mild steel under ideal parameters, which you’ll validate with kerf width and dross grade. Non-touch pilot arc improves cutting efficiency on painted, rusty, or expanded metals by maintaining arc stability without standoff contact, reducing nozzle wear and starts.

Expect ~15 ipm on mild steel; validate with kerf/dross. Non-touch pilot arc boosts stability and reduces wear.

Duty cycles commonly fall between 60% and 80%; plan work intervals to prevent thermal shutdown and keep cut quality consistent.

Apply consistent standoff, correct consumable selection, dry air at specified pressure, and square torch angle—these user techniques directly influence edge squareness and heat-affected zone. Calibrate speed to amperage and thickness to avoid lag lines. Document parameters per job to standardize repeatability and throughput.

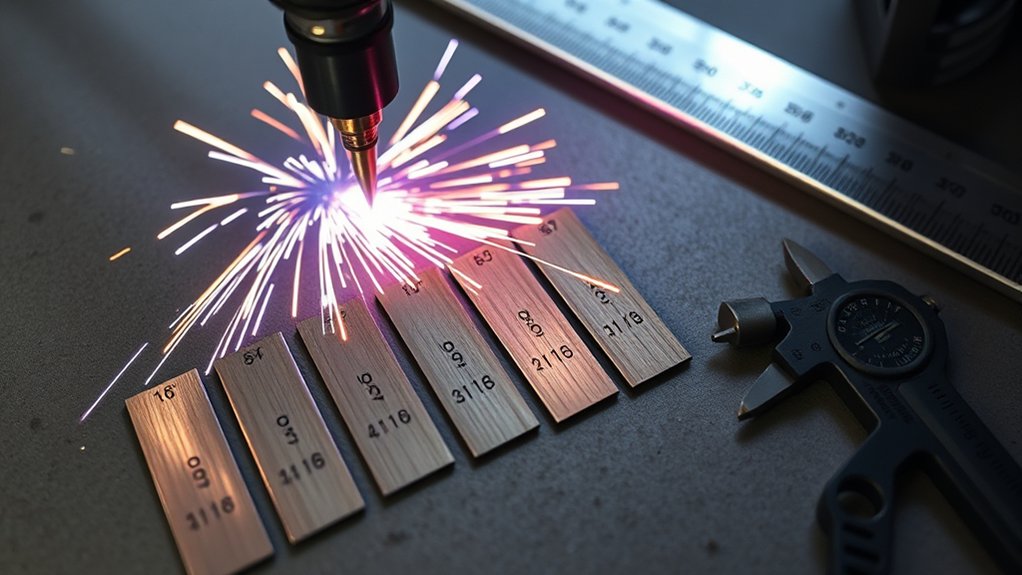

Material Thickness Ranges at 120V Vs 240V

Although both inputs can run a “60 A” class machine, line voltage sets the real thickness window: at 120V you’re typically limited to ~20–35 A output and light-gauge work (about 3/16 in on some units; up to 1/2 in on stronger designs like the RBC6000D), while 240V releases the full 55–60 A output and consistent cuts in the 5/8–7/8 in range (and up to ~1 in on high-spec models like the CUT‑60HF).

When you evaluate 120V performance, consider amperage ceiling and duty cycle. Examples: PrimeWeld CUT60 operates at 20–30 A on 120V; some users report heavy-section capability, but practical, controlled results trend toward thin stock and occasional 1/2 in on robust designs.

The Eastwood Versa-Cut 60 is constrained to ~3/16 in at 120V.

Switching to 240V advantages expands both thickness and productivity. The RBC6000D reaches 5/8 in at 60 A. Eastwood reliably handles 7/8 in.

The Amico CUT‑60HF delivers up to ~1 in on stainless and sustains an 80% duty cycle, enabling steady production on thicker material.

Rated Vs Maximum Cutting Thickness Explained

You should treat rated thickness as the machine’s validated cut at a specified amperage (e.g., 60 A ≈ 7/8 in mild steel) with standard speed and quality targets.

View maximum thickness as a marketing-limit context—possible (≈1 in+) under ideal conditions, but with slower travel, rougher kerf, and more dross.

Expect speed and quality to drop sharply at the max and verify against duty cycle limits and material type (stainless, aluminum) to avoid overheating and productivity loss.

Rated Thickness Meaning

Clarity starts with defining rated versus maximum cutting thickness for a 60-amp plasma cutter.

Rated thickness meaning: the material thickness you can cut efficiently, at the machine’s specified current, under ideal conditions. Expect stable arc, faster travel speeds, and clean kerf. That’s why rated thickness applications include production cuts, tight tolerance parts, and repeatable quality.

Typical rated thickness limitations: once you exceed the rating, speed drops and edge quality degrades.

For example, a unit rated at 7/8 inch delivers precise cuts at that size; it may sever 1 inch, but you’ll see slower progress and rougher edges.

Data points: PrimeWeld CUT60 efficiently handles steel to 7/8 inch; Amico CUT-60HF can reach 1.2 inches in specific setups.

Use ratings to match projects, materials, and performance targets.

Maximum Claim Context

Rated thickness sets your baseline for quality and speed; maximum thickness defines the outer limit a 60‑amp cutter can physically sever. Treat rated as the spec for repeatable outcomes: defined travel speed, clean kerf, minimal dross, and stable arc.

For example, a CUT60-class unit can rate at 7/8 in steel with consistent edge quality. Maximum thickness is the marketing ceiling—achievable, but at slower travel, higher dross, and greater arc instability risk.

Use model data: PrimeWeld CUT60 is solid at 7/8 in rated; Amico CUT-60HF lists 1.2 in maximum thickness. Expect reduced cutting efficiency at the maximum claim.

Monitor duty cycle to prevent thermal overload and consumable burn. For production planning, base schedules and QA on rated capacity; reserve maximum for infrequent, non-critical severing.

Speed and Quality Tradeoffs

Although a 60‑amp plasma cutter can sever near its maximum claim, the cut quality and travel speed drop as thickness increases. Rated thickness defines continuous-duty performance with clean kerfs, minimal dross, and predictable travel rates; maximum thickness identifies the upper limit under ideal conditions, not a production target.

For example, at 1/2 inch steel, you can maintain about 15 ipm with consistent arc stability. Near 7/8 inch, you’ll slow considerably, accept more bevel and dross, and consume tips faster.

For speed optimization and quality assurance, operate at or below the rated thickness. You’ll extend consumable life, maintain perpendicularity, and reduce secondary grinding.

Use steady travel, correct standoff, and proper gas flow. Select duty cycle and amperage to match thickness, prioritizing repeatable, standards‑level cut quality.

Travel Speed Benchmarks at Common Thicknesses

For 1/4-inch mild steel, you should target roughly 25 ipm with a 60 A machine, adjusting ±10% based on cut quality and kerf width.

For 1/2-inch stainless or aluminum, set a guideline of 10–15 ipm, verifying with test cuts to keep dross and bevel within tolerance.

Use pilot arc capability to hold those speeds on painted, rusty, or expanded surfaces for consistent results.

1/4-Inch Speed Targets

Set clear travel speed targets to match material and thickness for a 60 Amp plasma cutter. Use data-driven cutting techniques and disciplined plasma maintenance to hold cut quality and kerf integrity.

For 7/8 inch steel, target about 15 ipm. At 5/8 inch steel on 240V, run near 20 ipm. For 1/4 inch steel, set 30–40 ipm, contingent on torch design and arc density. For 1/2 inch aluminum, hold 12–15 ipm; stainless at similar thickness may trend slightly lower.

Validate speeds by monitoring dross type, bevel angle, and arc lag. If top-edge rounding or heavy bottom dross appears, reduce ipm; if bevel widens and arc trails, increase ipm incrementally.

Note that advanced inverter models can sustain higher speeds while maintaining cut squareness and minimal heat-affected zones.

1/2-Inch Ppm Guidelines

When you benchmark travel speed in inches per minute (ipm) for a 60 Amp plasma cutter, anchor targets to thickness and alloy while holding air at 40–75 PSI.

Use inch ppm comparison to standardize: mild steel 1/2 inch at ~20 ipm; 7/8 inch at ~15 ipm. Stainless tops out near 1 inch at ~12 ipm. Aluminum at 5/8 inch runs ~10 ipm.

Validate cut quality with kerf symmetry and minimal dross; adjust travel ±10% to stabilize arc lag and edge squareness.

For inch ppm efficiency, prioritize steady standoff, dry air, and correct nozzle/orifice.

If edges bevel, slow slightly; if top spatter rises, increase speed or pressure within the band.

Record heat input (ipm vs thickness) to keep repeatable, code-ready settings across materials.

Air Supply Requirements and Their Impact on Cut Quality

Although amps and travel speed get most of the attention, your 60‑amp plasma cutter’s cut quality ultimately hinges on air that’s clean, dry, oil‑free, and delivered within spec.

Specify an air supply pressure of 30–90 PSI at the torch, verified under flow. Target 5–7 CFM continuous delivery; higher CFM reserves stabilize the arc on thicker sections.

Moisture or oil aerosols destabilize the plasma column, widen kerf, and pit edges, so install a multi‑stage filter train: particulate (5 µm), coalescing (0.01 µm), and an automatic drain.

Use a precision regulator and gauge at the machine inlet to hold pressure within ±2 PSI during cutting.

If pressure sags, you’ll see arc flutter, dross accumulation, bevel error, and accelerated nozzle/electrode wear.

On rusty or dirty plate, consistent, dry airflow improves slag ejection and edge smoothness.

Validate system performance with a flowmeter and periodic filter differential checks, and size hoses and quick‑connects to minimize pressure drop.

Duty Cycle Considerations for Continuous Cutting

With clean, stable air sorted, you still have to manage thermal limits: the duty cycle defines how long your 60‑amp unit can sustain output in a 10‑minute window before a cooldown.

You should plan continuous cutting with the rated percentage in mind because thicker sections extend arc-on time and elevate heat load. At 60% duty cycle, expect 6 minutes on/4 minutes off at max output. Higher ratings—80% or 100%—support longer production runs and reduce thermal cycling, improving reliability.

1) Quantify runtime: Match material thickness and travel speed to the rated percentage. If your cut requires >6 minutes at 60%, schedule a mid-pass pause or reduce current.

2) Apply cooling management: Maintain unobstructed airflow, keep filters clean, and operate within ambient temperature limits to avoid derating.

3) Monitor temperature: Use panel indicators and timed intervals; stop when thermal protection triggers to prevent damage.

4) Understand duty cycle implications: Selecting higher-duty models minimizes downtime, supports heavy-duty tasks, and extends component life through reduced overheating.

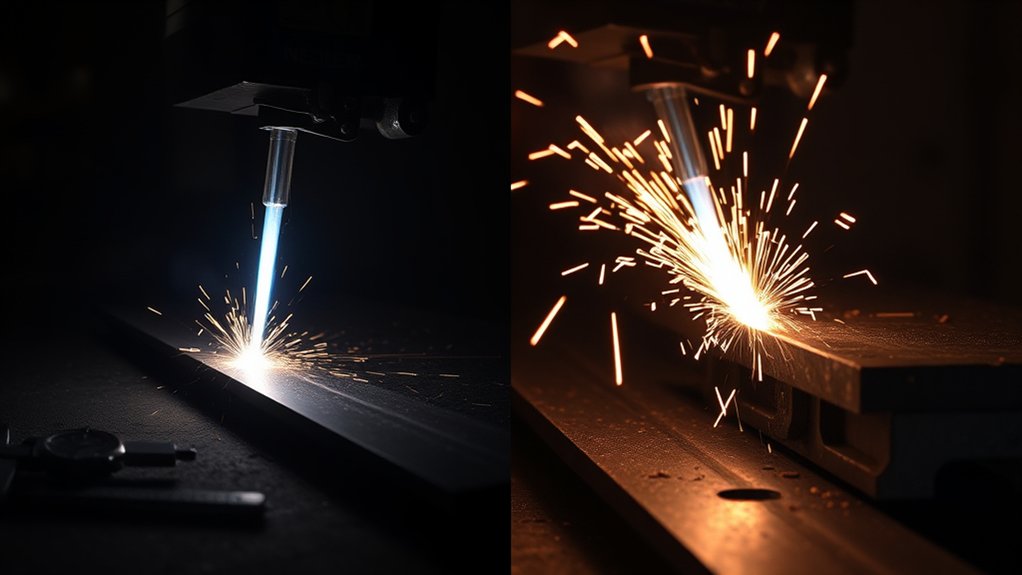

Torch Technology: Pilot Arc, Blowback, and Start Types

A modern 60‑amp plasma torch uses distinct start and arc-management systems that govern reliability, cut quality, and consumable life. You’ll see three core elements: pilot arc, blowback technology, and start modes that support repeatable, continuous cutting.

Pilot arc initiates off-material, stabilizing the arc on rough, dirty, or rusty plate and reducing nozzle/electrode erosion. Blowback technology uses a retracting electrode to create an interference-free HF-free start, essential for CNC environments and cutting expanded or perforated metals without contact.

Select 2T/4T with a trigger lock to minimize hand fatigue on long cuts while maintaining consistent arc-on time. Continuous pilot arc (auto-restrike) bridges kerf gaps, keeping travel uninterrupted across holes and edges.

For manual work, a touch-and-go drag start lets you rest the shield and move with controlled standoff, improving cut edge straightness and kerf uniformity. Properly combining these systems yields cleaner starts, fewer restarts, and longer consumable life at 60 amps.

Real-World Applications by Material and Thickness

Even before you choose consumables, map your 60‑amp class cutter’s capability to material and thickness so you can set realistic speeds and duty-cycle expectations.

In plasma cutting, match amperage, travel speed, and duty cycle to material types (mild steel, stainless, aluminum) and project class.

1) Automotive restoration (mild steel 10–3/16 in): A 60A unit like the PrimeWeld CUT60 or Eastwood Versa-Cut 60 delivers clean cuts in body panels and frame tabs; both reach 7/8 in max, but you’ll run faster and cleaner at ≤3/8 in.

2) Custom fabrication (3/16–1/2 in steel and stainless): Expect continuous production with the Versa-Cut 60’s 60% duty cycle; optimize dross by holding travel speeds in the 15–30 ipm range.

3) Metal art and farm repair (1/8–5/8 in mixed alloys): The Reboot 60A at 240V handles up to 5/8 in, balancing precision and portability for field work.

4) Heavy-duty industrial (3/4–7/8 in mild steel, up to 1.2 in capability): Spectrum 875 sustains ~15 ipm at 7/8 in; Amico CUT-60HF extends to 1.2 in across conductive metals when edge-starting.

Safety, Power, and Protection Features for Reliable Operation

Matching amperage and travel speed to thickness only pays off if the cutter protects itself and you under load. At 60 A, you should verify compliance with applicable safety standards and confirm the machine’s power management architecture.

Inverter-based supplies stabilize output, damp voltage ripple, and mitigate line sag, reducing nuisance trips and arc instability during long cuts.

Look for overcurrent and overtemperature protections that derate or shut down before component stress exceeds limits. Surge suppression guards against power spikes common in shop circuits.

A continuous pilot arc maintains reliable ignition across painted, rusty, or expanded metals, lowering misfire risk and reducing tip wear.

Specify adjustable air post-flow (0–60 s) to cool the torch and extend consumable life; validate actual flow time against spec.

Automatic solenoid valves and integrated air filtration guarantee clean, dry air, preventing contamination that degrades arc quality.

Monitor duty cycle indicators, verify cooling airflow, and keep cables and work leads within rated lengths to sustain reliable operation.

Frequently Asked Questions

Can I Use a Generator to Power a 60A Plasma Cutter?

Yes, if the generator meets power requirements. Verify generator compatibility: continuous wattage ≥8–10 kW, 240V output, proper receptacle, low THD (<5%), sufficient surge capacity, and stable frequency (60 Hz). Use correct gauge cords and follow manufacturer specifications.

What Consumable Lifespan Should I Expect at 60 Amps?

Expect 40–100 starts per tip at 60 amps. Like a candle’s wick, consumable wear scales with cutting frequency, duty cycle, pierce depth, air quality, and arc voltage. You’ll extend life by maintaining 90–120 psi, clean, dry air.

How Noisy Is a 60A Plasma Cutter During Operation?

You’ll typically experience 90–105 dBA noise levels at the torch, rising to 110+ dBA with high airflows. Use sound reduction measures: compliant enclosures, downdraft tables, PPE (NRR 25–33), optimized gas flow, and stand-off per ISO/OSHA guidelines.

Will a CNC Table Require Different Torch Leads or Interfaces?

Yes—CNC tables often need different torch leads and interfaces. Verify torch lead compatibility (machine vs. hand torch), CNC interface requirements (start/OK‑to‑move signals), voltage-sensing or divided voltage, and connector standards (CPC/14‑pin). Check manufacturer pinouts, amperage ratings, strain relief.

How Does Altitude Affect Plasma Cutter Performance and Settings?

Altitude reduces air density, weakening arc energy. You’ll apply altitude adjustments: increase gas pressure/flow ~1–2% per 1,000 ft, verify duty cycle derating, recalibrate torch height control, and perform performance optimization via test cuts, nozzle inspection, and voltage setpoint tuning.

Conclusion

You’ll get the best from a 60 A plasma cutter by matching thickness to rated capacity and holding travel speed. Expect ~15 ipm on 7/8 in mild steel with clean edges when air is dry, 90–120 psi supply, and duty cycle observed. For example, on a 240V line, you section 3/4 in A36 plate at 16 ipm using pilot arc, 0.9 mm nozzle, 65–75 psi tip pressure, achieving <1.0 mm kerf variance and minimal dross, versus sluggish 1 in stainless.