You don’t need guesswork to match plasma amperage to thickness—you need a standard-driven quick reference. You’ll map amps to inches based on five variables: material, cut speed, duty cycle, pierce method, and consumables. Typical air plasma ranges cover 1/4″–1″ with 45–105 A, but mild steel, stainless, and aluminum each shift the target. We’ll pin exact ranges, note pierce vs. edge starts, and flag setup choices that tighten kerf and cut quality—before you waste consumables.

The Five Variables That Determine Thickness

Although material thickness is often equated to amperage, five interdependent variables set your real cutting limit: output amperage (arc energy density), process gas selection (air/oxygen/nitrogen blends matched to material), torch height control accuracy (arc-voltage–based standoff control), air supply quality (dry, oil‑free, stable pressure/flow), and base material type/alloy and condition.

You’ll match amperage to thickness to maintain plasma efficiency—higher current increases energy density and supports thicker sections—but you must coordinate cutting techniques with gas choice. Air is versatile; oxygen improves mild‑steel speed and edge; nitrogen stabilizes stainless and aluminum at certain thicknesses.

Maintain THC within specified arc‑voltage windows to keep kerf geometry and compensate for warp. Verify air dryness and oil content per ISO 8573-1 class targets; contamination accelerates nozzle wear and destabilizes the jet.

Finally, consider metallurgy and plate condition; mill scale, coatings, and temper alter heat input needs. Optimize these variables together to define your practical thickness limit.

Quick Reference: Typical Air Plasma Ranges

You’ll match power class to thickness using typical air plasma ranges: 45–65 A for 1/4″–1/2″ mild steel, 85–130 A to reach ~1″ at reduced speeds.

You’ll factor gas choice because air favors mild steel, while nitrogen or specialty mixes improve stainless and aluminum edge quality and dross control, especially on thicker sections.

You’ll distinguish quality cut ratings from sever limits—quality prioritizes edge finish and speed with dry, oil-free air; sever is possible at higher amperage but with slower travel and compromised edges.

Power Class Ranges

Power classes for air plasma cutters cluster between 45 A and 130 A, with amperage dictating arc energy density and practical thickness capacity. When you set a power class, base your amperage selection on target material and thickness.

For mild steel, 45–65 A supports 1/4–1/2 in with efficient travel speeds and acceptable kerf. Move to 105–130 A for up to 1 in; expect slower speeds and tighter pierce limits.

Stainless cuts remain viable with air, but performance tightens as amperage rises—optimize consumables to maintain edge integrity.

Aluminum typically benefits from higher amperage to offset heat input and expansion; guarantee duty cycle headroom.

Always match consumables to the selected amperage and process parameters to stabilize arc, minimize dross, and preserve cut quality.

Gas Choice Impacts

With amperage classes set, gas selection defines cut quality, speed, and consumable life within those ranges.

Use air plasma for economical cutting on mild steel; expect acceptable edges and moderate speed.

Switch to oxygen (O₂) on mild steel when you need faster travel and cleaner kerfs.

For stainless and aluminum, air works, but nitrogen (N₂) improves edge appearance and limits dross, especially at higher amperage on thicker sections.

Match gas to torch consumables and rated current to preserve nozzle orifice integrity and maintain cut consistency.

- Apply gas selection strategies by material: O₂ for mild steel speed, N₂ for stainless/aluminum quality.

- Conduct cutting efficiency analysis: track inches-per-minute, dross, and consumable wear across gases.

- Verify manufacturer gas/amperage/cone specs to prevent premature wear and unstable arcs.

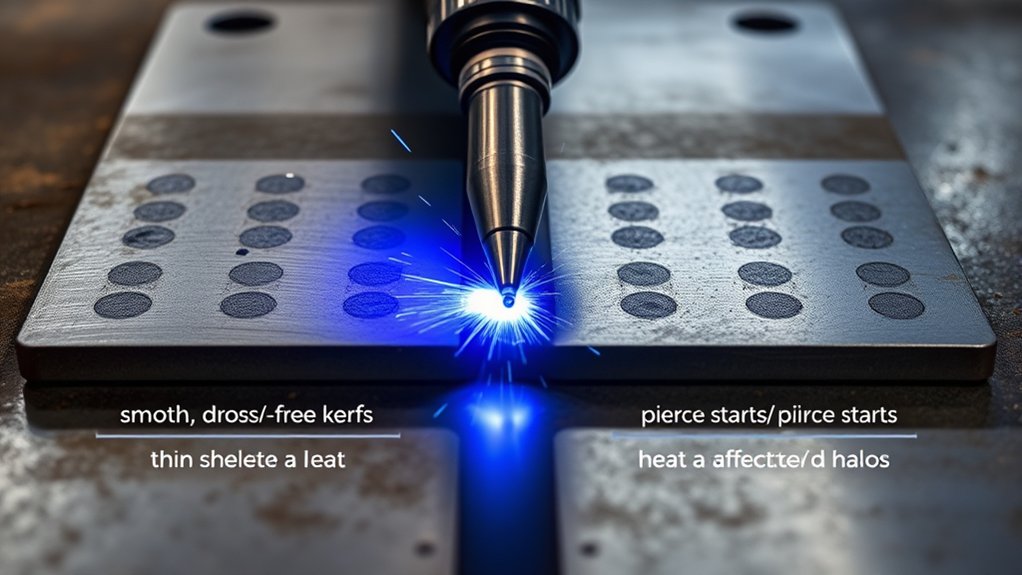

Quality vs. Sever Limits

Although a plasma torch can sever beyond its “rated” thickness, quality falls off as thickness increases and speed drops. Define your target by distinguishing cut quality from sever standards.

For mild steel, typical air plasma ranges specify 45–65 A for 1/4″–1/2″ and 85–105 A for 3/4″–1″. Those currents maintain acceptable kerf geometry, minimal dross, and square edges. If you push to sever limits, expect wider kerf, taper, more dross, and heat tint.

Apply quality considerations: match amperage and tip size to maintain consistent kerf thickness; don’t exceed the nozzle’s flow and current rating.

For stainless and aluminum, nitrogen or optimized mixes improve edge appearance at higher thickness. When speed must drop to maintain the arc, monitor bevel and dross as objective quality indicators.

Material-Specific Guidance: Mild Steel (A36 and Similar)

Mild steel (A36 and similar) responds predictably to amperage scaling, so match current to thickness for clean kerfs, acceptable dross, and economical cycle times. Leverage material properties to set realistic speeds and choose cutting techniques that control heat input and taper.

Match amperage to steel thickness for clean kerfs, controlled dross, and efficient, predictable cutting.

For 1/4″–1/2″, run 45–65 A to balance edge quality and cost. Step up to 65–85 A for 1/2″–3/4″ to hold squareness and minimize secondary grinding. For 3/4″–1″, use 85–105 A; expect slower travel to maintain pierce reliability. At 1″, 105–130 A is valid, but feed rates drop as section thickness rises. Oxygen process gas increases speed and improves edge fidelity versus air.

- Verify torch rating, duty cycle, and consumable class at the selected current.

- Tune arc voltage and cut height; maintain 0.06–0.08 in standoff for consistent kerf geometry.

- Calibrate lead-in length and pierce delay to match thickness and gas type for minimal top dross.

Material-Specific Guidance: Stainless Steel (304/316)

For 304/316 stainless, you’ll typically run 45 A at 1/4 in and up to ~85 A at 3/4 in with air plasma, but switching to N₂ or specialty mixes measurably improves edge color and reduces dross.

Expect air cuts to show a nitride tint, whereas N₂-based processes produce cleaner, more uniform edges with less secondary cleanup.

Maintain specification travel speeds and dry, oil‑free air to stabilize the arc, minimize heat input, and preserve consumable life.

Air vs. Nitrogen

While air plasma will cut 304/316 reliably, it often leaves a nitride-tinted edge and more dross than nitrogen-based processes; switching to N₂ (or N₂‑rich mixes) improves edge color, reduces cleanup, and becomes increasingly advantageous as thickness grows.

If you’re targeting standards-grade appearance on stainless, nitrogen benefits become clear beyond 1/4 in. Pair gas choice with amperage: run 45–65 A for 1/4–1/2 in, and 65–85 A for 1/2–3/4 in.

Maintain proper standoff and guarantee a dry, oil‑free supply—contamination degrades arc stability and surface finish. On thicker plate, nitrogen’s inert profile limits nitriding and reduces post‑process finishing time.

- Use N₂ when aesthetics matter or thickness ≥ 3/8 in

- Keep standoff consistent; verify with feeler gauges

- Dry, oil‑free gas verifies repeatable quality

Edge Quality and Dross

Nitrogen’s edge-color advantage over air ties directly to edge quality and dross on 304/316. You’ll see cleaner kerfs, lower heat tint, and measurable dross reduction when you run N₂ or specialty mixes versus air, which often leaves a nitride tint. For 1/8″–1/4″, target 45–65 A; step to ≥85 A as thickness increases. Maintain a consistent standoff to stabilize the arc, prevent bevel, and support edge enhancement. Replace consumables on schedule to keep stream coherence and minimize dross.

| Parameter | Stainless 304/316 Guidance |

|---|---|

| Gas | N₂ or specialty mix for edge enhancement |

| Amperage | 45–65 A (1/8″–1/4″), ≥85 A thicker |

| Standoff | Constant, per torch spec, to limit heat distortion |

| Maintenance | Replace consumables regularly to sustain cut quality |

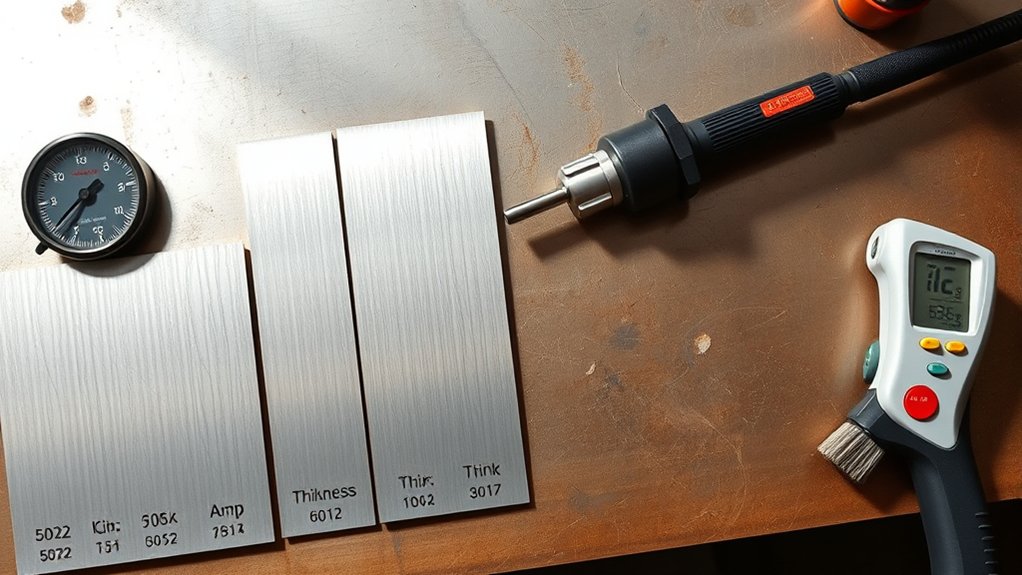

Material-Specific Guidance: Aluminum (5052/6061)

Most aluminum jobs—especially 5052 and 6061—cut cleanly with air plasma, but thicker plate benefits from nitrogen (N₂) to tighten the edge and reduce oxidation.

Use data-driven cutting techniques to match amperage to thickness and maintain a consistent edge finish. For 5052, target 45–65 A for 1/4″–1/2″ and 65–85 A for 1/2″–3/4″. For 6061, step up to 85–105 A for 3/4″–1″.

Match amperage to thickness for consistent edges: 5052 at 45–85 A, 6061 at 85–105 A.

Set pierce delay conservatively—aluminum’s high thermal conductivity and expansion punish over-delays with excessive hole size and spatter. Maintain precise torch height; verify arc voltage calibration and THC response to prevent bevel and top-edge rounding.

Guarantee clean, dry air; moisture and oil degrade edge quality and shorten consumable life.

- Verify flow rates and gas purity; switch to N₂ on thicker plate to stabilize arc and improve edge finish.

- Align cut speed with amperage; avoid overburn on corners with deceleration tables.

- Inspect kerf and dross; adjust height, speed, or gas accordingly.

Choosing a Power Class for Your Work Mix

After dialing in gas selection and torch control for alloys like 5052 and 6061, capacity planning becomes the gatekeeper of repeatable results.

Start with your maximum routine thickness, not the occasional outlier. Select a system whose rated cut matches that thickness, then move one power class up to stabilize arc energy, maintain kerf geometry, and elevate cutting efficiency. This power selection buffer reduces dross, minimizes bevel error, and preserves travel speed.

Use common classes—45 A, 65 A, 85 A, 105 A, 130 A—as discrete steps. If you routinely cut 3/16–1/4 in, a 45–65 A unit is appropriate; for 3/8–1/2 in, consider 65–85 A; for 5/8–3/4 in, 105–130 A.

Audit daily throughput and duty cycle to prevent thermal limits from throttling productivity. If heavier plate appears in your mix, verify sever capability for those thicknesses so you can complete non-standard cuts without compromising quality.

Size for routine work; validate for extremes.

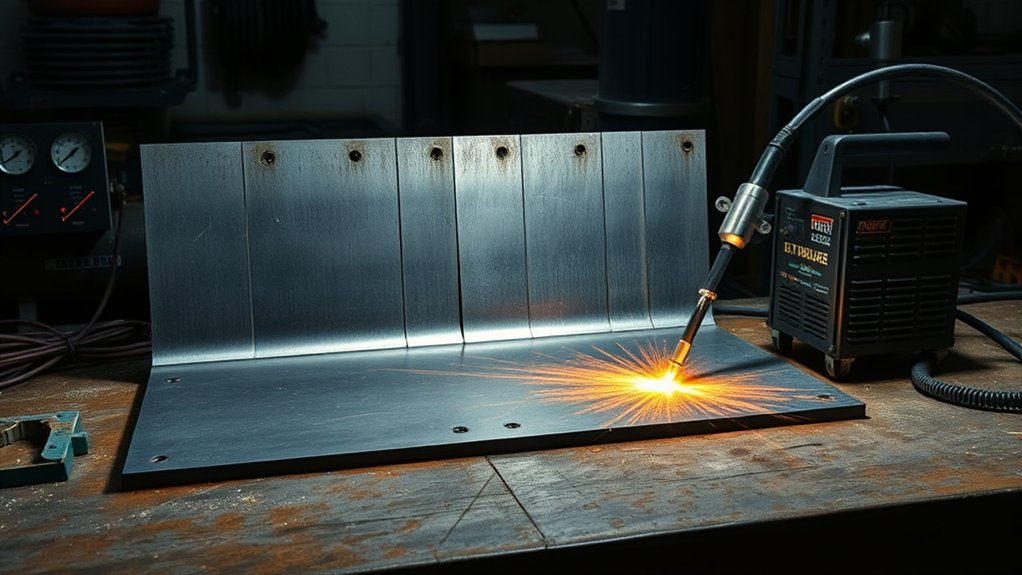

Piercing vs. Edge-Starting

You should compare heat load profiles: piercing concentrates energy at a point for thick sections, while edge-starting spreads heat and often produces a wider kerf.

Plan lead-in strategies accordingly—edge starts need longer lead-ins and clearance, whereas piercing supports tighter nesting with minimal lead-in.

Protect the torch by setting pierce height at 1.5–2.0× cutting height to deflect spatter, extend consumable life, and maintain cut quality.

Heat Load Differences

Although both methods achieve full penetration, piercing and edge-starting impose very different heat loads that affect amperage selection, consumable life, and cut quality.

Piercing concentrates heat load at a single point, delivering piercing advantages on thick plate but driving a larger HAZ and higher thermal stress on the torch. Set pierce height to 1.5–2× cutting height to deflect molten metal and protect consumables; otherwise, expect premature nozzle and shield failure.

Edge-starting spreads heat along the boundary, reducing peak load, warping risk, and dross on thin stock, though it can slow initiation and travel speed.

- Use higher amperage and shorter duty cycles for piercing; monitor torch temperature.

- For edge-starting, select moderate amperage and prioritize edge quality.

- Adjust charted amperage by thickness and starting method.

Lead-In Strategies

Because lead-in strategy governs heat input and nozzle exposure at the start of the cut, select piercing or edge-starting based on thickness, geometry, and cut quality targets.

Use piercing when you must start inside the profile or when cutting thicker plate; concentrated energy initiates penetration reliably. For thin stock with available edges, edge-starting reduces thermal load and cycle time.

Apply lead in techniques with precise torch positioning and height control. Set pierce height to 1.5–2× cutting height to limit molten ejecta and stabilize the arc.

Use a short linear or arc lead-in for thin materials; increase length and angle on thicker sections to move dross away from the cut path. Avoid edge-starts on nested parts; piercing provides placement flexibility while maintaining cut quality and efficiency across materials.

Torch Protection Tips

From a torch-protection standpoint, select piercing for thick sections and internal features, and reserve edge-starts for thin stock with accessible edges. Piercing concentrates heat in a controlled zone, ejects molten metal efficiently, and supports torch longevity on heavy plate and nested parts.

Set pierce height at 1.5–2.0× cutting height; this limits blowback, preserves consumables, and stabilizes arc initiation for quality cuts. For edge-starts, program a lead-in to shield the nozzle, then shift to nominal cutting height and speed. Monitor heat input to minimize warping, especially on thin sheet.

- Verify pierce height, amperage, and gas per material thickness; adjust per cut charts.

- Replace worn electrodes/nozzles early to reduce scrap and rework.

- Use appropriate lead-ins/lead-outs to protect the torch and maintain kerf consistency.

Tip Size, Kerf Width, and Air Settings

While amperage dictates arc energy, tip size, kerf width, and air settings determine how that energy translates into cut quality and efficiency. Treat tip selection as an amperage-matched specification: larger orifices support higher current and flow.

Example: a 60 A tip typically uses a ~1.1 mm orifice for 51–60 A duty. Undersizing the tip starves the arc; oversizing broadens the jet and wastes material.

A 60 A tip uses ~1.1 mm orifice; undersize starves the arc, oversize wastes material.

Kerf management follows: kerf width rises with amperage and orifice size, so expect thicker kerfs and more heat input at higher settings.

Match air pressure to tip rating. As a baseline, run 55–60 psi for 30 A tips and 65–75 psi for 50 A tips. Too little pressure leaves slag and incomplete penetration; too much lifts the arc and promotes dross.

Align amperage to thickness targets: 45–65 A for 1/4–1/2 in mild steel; 105–130 A for 1 in. Verify cut face, dross line, and kerf width, then adjust in small increments.

Setup Details That Move the Needle

Even small setup choices—amperage, gas selection, tip/orifice, standoff, and air pressure—swing cut quality, speed, and consumable life more than anything else.

Make deliberate amperage adjustments tied to thickness and alloy: 45–65 A for 1/4″–1/2″ mild steel; 105–130 A for 1″ mild steel. For stainless, run 65–85 A at 1/2″–3/4″ and 85–105 A up to 1″, pairing N₂ to tighten the arc and clean edges.

For aluminum, start 45–65 A at 1/4″–1/2″ and scale carefully to control heat and expansion. Lock in pressure settings at the torch, not just the compressor; low pressure risks uncut sections, high pressure elevates dross.

Verify standoff with a gauge, and match tip/orifice to amperage to prevent double-arcing.

- Calibrate line pressure at the torch under flow; record psi for each thickness.

- Test on scrap to confirm kerf, dross, and speed before production.

- Document settings (amps, gas, tip, standoff, pressure) per material/thickness.

Practical Thickness Targets by Shop Type

Different shop profiles drive distinct amperage and thickness targets, and you should set ranges by workload and material.

Tailor amperage and thickness targets to your shop’s workload and specific materials.

In automotive body shops, specify 30–50 A for sheet under 7 gauge to preserve cutting precision, minimize HAZ, and avoid panel distortion.

For mild steel fabrication, standard fabrication techniques align with 45–65 A for 1/4″–1/2″; step up to 85–105 A for 3/4″–1″ to maintain kerf quality and throughput.

Custom interior design applications using stainless benefit from 65–85 A up to 3/4″. Pair with optimized gas mixtures to tighten edge angularity and reduce secondary finishing.

For aluminum, target 45–65 A to 1/2″; prefer nitrogen as process gas to lower dross and improve edge integrity.

High production environments prioritize rate and repeatability: deploy 105–130 A for sections over 1″, using mechanized motion, proper standoff, and verified consumable life.

Calibrate amperage to thickness, process gas, and travel speed to hold tolerance and consistent cut face.

Frequently Asked Questions

How Do Duty Cycle and Amperage Affect Continuous Production Cutting?

Like an engine’s redline, you balance heat and time: a higher duty cycle sustains continuous cutting, boosting production efficiency; matched amperage maintains kerf quality and speed. Overdrive either, and you’ll trigger thermal shutdowns, inconsistent edges, and downtime.

What Safety Gear Is Essential When Increasing Amperage for Thicker Materials?

You need safety goggles with ANSI Z87.1+ impact/IR protection, a welding helmet with shade 8–12 for higher amperage, welding gloves rated for heat, FR jacket, leather boots, hearing protection (≥25 dB NRR), and respirator per OSHA/NIOSH.

How Does Input Power Voltage (120/240v) Limit Maximum Amperage Settings?

Input voltage dictates available current: at 120V, you’re typically capped near 20–30A; at 240V, you access 40–60A or more. Voltage impact sets duty-cycle and cut capacity; Amperage limitations follow circuit rating, PSU design, and standards.

Can CNC Cutting Speeds Be Estimated From Amperage and Thickness Charts?

Yes—you can derive CNC cutting speed estimation from amperage/thickness charts, though you’ll adjust for gas, material, consumables, and duty cycle. You’ll reference manufacturer kerf data, specify pierce height, arc voltage, and feedrate, then validate with cut-quality metrics.

How Do Altitude or Humidity Changes Affect Plasma Arc Performance?

They alter plasma stability and arc length. At high altitude, lower density reduces cooling and ionization; you’ll derate current, shorten standoff, and verify gas flow. High humidity adds quenching vapor; you’ll dry gas, adjust flow, and monitor voltage.

Conclusion

You’ve now got a calibrated compass for amps vs. inches—so you can steer clean cuts, not guess. Match amperage to thickness, material, and start type, and you’ll hold tolerances like a mic. Dial tip size, air flow, and kerf to spec, and you’ll cut like a laser with air. Separate pierce from edge-start limits, and set realistic shop targets. When data leads, your arc sings: faster, squarer, cooler—within standards, on budget, and right the first time.