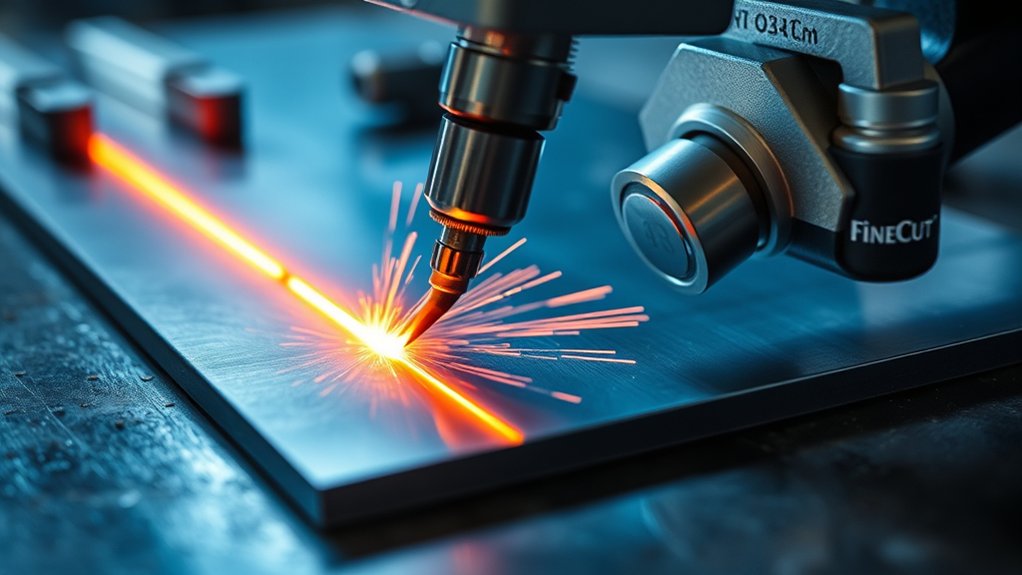

Blue-white arc snaps across sheet metal as you chase a tight contour, and the panel oil-cans from heat load. You want crisp kerfs in 0.5–1.5 mm steel without potato-chipping, so you’ll tune amperage down, push traverse near 350 IPM, lock in FineCut consumables, and hold torch height tight with THC. Pair that with proper air quality, fixturing, and water-table cooling. Get these fundamentals right, and the next moves—lead-ins, pierce timing, and pathing—decide the outcome.

Why Thin Steel Warps and How Plasma Heat Affects It

Because thin steel has low mass and stiffness, it heats and moves quickly under a plasma arc. You’ll see it warp when localized melt pools form and cool unevenly. You’re managing a concentrated energy source that expands the heat-affected zone (HAZ); as the HAZ contracts, residual stresses drive heat distortion and bowing.

Thin sheet heats fast; uneven cooling and HAZ contraction drive warping, bowing, and distortion under a plasma arc.

If the sheet isn’t fixtured or your traverse speed lags, the puddle grows, edge collapses, and panels potato-chip.

Use process control to limit input energy. Apply cutting techniques that prioritize high travel speed, correct amperage, and tight kerf to shrink the thermal footprint. Stabilize standoff with Automatic Torch Height Control (THC) to maintain consistent arc voltage and avoid arc stretch, which spikes heat.

Fixture the sheet with clamps or magnets to resist movement. Employ a water table or water film to quench below the kerf, extracting heat and suppressing distortion. Sequence cuts from inside features outward, skip around to distribute heat, and allow brief dwell for thermal equalization.

Choosing the Right Plasma Cutter for 0.5–1.5 Mm Steel

You’ll size the machine by duty cycle to match workload—occasional cuts suit a 30–35% unit like a Viper 30 XP, while continuous production calls for 100% duty cycle such as a Viper 65.

For precision and kerf control on 0.5–1.5 mm sheet, spec FineCut consumables and maintain high traverse speeds (e.g., ~350 IPM on 22 ga) to limit heat input.

Match power and consumables to torch height control and a water table to stabilize the sheet, tighten kerf, and suppress warping.

Duty Cycle Needs

Although thin sheet cuts quickly, duty cycle still governs throughput and uptime when you’re processing 0.5–1.5 mm steel. Quantify duty cycle impact against your takt time and nest size before selecting models.

A handheld unit like the Hypertherm Viper 30 XP at 35% duty cycle suits intermittent cutting, short nests, and job-shop duty. For longer runs and higher utilization, an industrial platform such as the Hypertherm Powermax 85 SYNC at 60% duty cycle sustains more arc-on time per hour.

Match amperage to thickness to avoid unnecessary heat input; on 0.5 mm stainless, run lower amps and faster travel (e.g., ~350 IPM on 22 ga) to limit thermal load and pause frequency.

Use FineCut consumables to maintain arc stiffness at high speed. Incorporate water tables to buffer heat during extended cycles.

Precision and Kerf

For thin-gauge steel, prioritize a plasma platform that delivers tight kerf control and repeatable cut geometry.

You need a system optimized for precision cutting, with predictable kerf width across 0.5–1.5 mm stock. Specify a torch that supports FineCut consumables; they generate a narrower kerf and reduce edge bevel, improving feature fidelity on intricate profiles.

Integrate closed-loop torch height control (THC) to lock in stand-off, stabilize arc voltage, and hold cut width tolerance over minor surface variance.

Run fast traverse and cut speeds—around 350 IPM on 0.5 mm—to limit heat input, suppress warping, and sharpen corner definition. Pair this with a water table to pull heat from the kerf line and clean the edge.

Calibrate amperage to thickness; lower current tightens arc column and enhances edge quality.

Power and Consumables

Tight kerf control starts with the right powerplant and consumables package. For 0.5–1.5 mm steel, spec a 30–40 A inverter that supports fine cut consumables; they tighten the arc column, yield narrow kerfs, and deliver cleaner edges.

Target a unit with stable low-current performance and a consistent arc start to leverage modern plasma technologies and cutting innovations.

Run at 30 A with a 35% duty cycle as typical for light fabrication—Hypertherm Powermax 30 XP fits, offering reliable output for thin-gauge work.

Program fast traverse: about 350 IPM to limit heat input and mitigate warping. Pair with a water table or submerged cutting to sink heat and suppress distortion.

Maintain tip standoff precisely, monitor swirl ring condition, and replace nozzles/electrodes on schedule to preserve cut quality.

Essential Setup: Air, Power, and Torch Height Control

Every reliable thin-steel plasma setup starts with clean, dry air, adequate power, and precise torch height control.

Start with air management: spec an oil‑free compressor with a refrigerated dryer or desiccant stage, add multi-stage air filtration at the plasma inlet, and schedule compressor maintenance to purge condensate and verify regulator setpoints. Dry air suppresses dross and protects valves and solenoids.

Power next: match machine output and duty cycle to your cut plan. A compact unit like the Hypertherm Viper 30 XP handles thin sheet efficiently, but watch its 35% duty cycle—stage jobs, allow cooldown, and size circuits to prevent voltage sag.

Torch height control (THC) closes the loop on arc voltage to maintain standoff, stabilizing kerf width and minimizing warp. Pair THC with speed and amperage tuned to gauge.

1) Verify line pressure/CFM under load; leak-test hoses and fittings.

2) Calibrate THC: pierce height, cut height, and voltage.

3) Use a water table to dissipate heat and suppress fumes.

FineCut and Other Consumables for Narrow Kerf and Clean Edges

FineCut consumables are your go-to when you need a narrow kerf, low heat input, and crisp edges on thin steel. You’ll leverage tighter arc constriction, a reduced nozzle orifice, and tailored swirl rings to shrink the heat-affected zone and limit distortion—key FineCut advantages for sheet work.

Match the cartridge/nozzle/electrode set to the material gauge; select amperage appropriate to thickness to hold kerf width and edge squareness. Validate with a straight-line test coupon, inspecting dross type (top vs. bottom) and edge bevel.

Match consumables to gauge, set amperage for kerf and squareness, then verify with straight-line dross and bevel checks.

Drive quality by optimizing travel speed—faster feeds with FineCut typically polish the edge and shed dross. Run dry, clean air, correct standoff, and a stable torch height to keep the arc column centered.

Consumable maintenance is non‑negotiable: monitor nozzle orifice growth, electrode pit depth, and shield wear; replace at spec limits. A worn tip destabilizes the arc, widens kerf, and heats the panel, increasing warp risk.

Log parts life and results for repeatability.

Speed and Amperage Settings to Minimize Heat Input

With consumables sorted for a narrow, stable arc, you’ll lock in heat control with the right speed/amperage pairing.

Target cutting efficiency by driving fast travel and conservative amperage adjustments. On 22 ga steel, run near 350 IPM to shed heat quickly while maintaining full penetration; the FineCut kerf keeps the arc stiff and localized, limiting thermal spread.

For 0.5 mm stainless, prioritize velocity—faster IPM reduces dwell, curbing distortion. Undershoot amperage on thin stock to avoid over-energizing the puddle; increase only until dross tails disappear.

1) Set baseline:

– 22 ga: start ~350 IPM with FineCut; dial amperage at the low end of the torch’s thin-sheet range; verify a clean, narrow kerf.

2) Tune amperage adjustments:

– Bump current in 2–5 A steps until the cut clears; back off if edges blue or top spatter appears.

3) Stabilize thermal input:

– Use a water table to quench the kerf zone, flattening heat gradients and sharpening edges without sacrificing speed.

Fixturing and Clamping Techniques for Flat, Stable Sheets

Flatness is your control variable, and fixturing is how you lock it down before the arc ever fires. Start by screening stock; if a sheet’s crowned or oil-canned, cold-straighten it with rollers or press blocks before loading. Select fixturing materials with low thermal growth and good rigidity—blanchard-ground steel slats or MIC-6 plate—so the sheet stays planar under heat. Use clamping options that apply uniform, low-profile pressure: edge dogs, toggle clamps, or a vacuum table for full-surface hold-down. Keep clamp hardware outside the toolpath and pierce plume.

- Establish a grid: 150–200 mm clamp spacing on thin gauges.

- Use a torch height controller to hold standoff; flat support enables consistent arc voltage.

- Verify with feeler gauges; shim where needed to zero runout.

| Component | Purpose | Notes |

|---|---|---|

| Vacuum table | Full-area restraint | Minimizes micro-buckle |

| Edge clamps | Shear resistance | Low profile |

| Fixturing materials | Stable support | Low warp, ground |

| Height controller | Consistent standoff | Clean kerf, less heat |

Using Water Tables and On-Workpiece Cooling Methods

You’ll use a water table to sink heat and capture plume, keeping thin sheet stable and minimizing warp while cutting.

Augment with on-piece cooling—submersion, a controlled water stream, or mist—paired with THC for constant standoff to preserve edge quality.

Run high traverse and ideal amperage/nozzle to limit heat input, manage kerf, and maintain geometry.

Water Table Benefits

Although thin-gauge steel is prone to heat distortion, a water table stabilizes the thermal profile at the cut zone and preserves flatness.

By leveraging heat absorption and quenching right beneath the arc, the water table limits heat-affected zone growth, suppresses warp on 0.5 mm stainless, and improves edge fidelity.

You’ll also see lower dross because steam scrubs molten ejecta before it solidifies.

- 1) Submerged cutting: Keep the sheet just below the surface to manage heat accumulation, reduce plume energy, and maintain dimensional stability without degrading arc integrity.

- 2) Pair with THC: Automatic Torch Height Control preserves standoff as sheet stresses relax, locking in kerf consistency and surface finish.

- 3) Speed synergy: Run high traverse speeds; the water bath removes residual heat, preventing propagation and cumulative distortion across small features.

Maintain clean water and correct table depth for repeatability.

On-Piece Cooling Techniques

Building on water table control of the heat-affected zone, on-piece cooling pushes thermal management directly onto the sheet to lock down flatness and kerf quality on thin steel.

Use on workpiece cooling to deliver immediate heat reduction at the cut front. Dribble a controlled water stream ahead of the torch to quench nascent heat, suppress oxide color, and stabilize the kerf.

For stainless, submerge the panel just below the surface; the water jacket strips latent heat and mitigates distortion from cumulative passes.

Pair cooling with Automatic Torch Height Control to hold standoff as the sheet relaxes; consistent arc length preserves energy density and improves quench efficiency.

Run brisk feed rates to minimize dwell and thermal soak. Monitor steam, adjust flow, and maintain uninterrupted coolant contact through the toolpath.

Heat Management Best Practices

When thin stainless wants to potato-chip under arc heat, manage the thermal budget with water and speed. Use a water table as your primary heat absorption technique: the bath wicks energy from the kerf, stabilizes 0.5 mm sheet, and suppresses distortion.

Pair it with high traverse—around 350 IPM on 22 ga—to minimize dwell and keep edges crisp. Add on-workpiece cooling methods—light pour or fine mist—to quench localized hotspots without shocking the cut.

1) Configure: Set water level just under the plate or partially submerge for maximum heat absorption techniques; guarantee drainage to avoid steam bursts.

2) Execute: Enable THC to lock standoff, preventing arc stretch that dumps extra heat.

3) Verify: Inspect kerf tint, dross line, and flatness; adjust speed, amperage, and water exposure.

Cutting Strategies: Lead-Ins, Pierce Delays, and Path Planning

Even before you strike an arc, lock in your cutting strategy to control heat, kerf, and edge quality on thin steel. Apply lead in techniques to enter off-part, then traverse into geometry; this shifts the pierce crater away from the feature and stabilizes the arc. Pair that with pierce optimization: set pierce delay just long enough to fully penetrate without overheating. Too short blooms heat at the surface; too long undercuts the start and weakens the edge.

Run fast traverse and cut speeds to evacuate heat, leveraging fine cut consumables for a tighter kerf and higher arc density. Sequence parts to minimize cross-sheet travel and avoid revisiting hot zones. Start with small internal features, progress outward, and finish with perimeter cuts last.

| Control | Setpoint Guidance | Result |

|---|---|---|

| Lead-in length/angle | 0.1–0.2 in, 30–60° | Clean entry, off-feature crater |

| Pierce delay | Just to break through | Stable start, minimal heat |

| Cut speed | High, per chart + test | Reduced HAZ, less warp |

| Path order | Inside-out, cool zones | Thermal balance, accuracy |

Post-Cut Cleanup: Minimizing Dross and Edge Finishing

Although a clean cut starts at the torch, post-cut cleanup locks in finish quality by managing dross and refining edges with minimal rework. Start by verifying cut parameters—amperage, arc voltage, and traverse speed—to limit molten rollover.

Faster travel and fine cut consumables narrow kerf width, reducing secondary dross removal and simplifying edge refinement. A water table helps quench the plume, trap particulate, and contain slag for cleaner post-cut handling.

Use a methodical sequence:

1) Bench prep: Deburr lightly with a scraper or chisel to knock off brittle dross without gouging the heat-affected zone.

2) Mechanical finish: Run a flap disc on an angle grinder, following the cut path to blend micro-notches and normalize edge land. Keep passes light to avoid heat-loading.

3) Final spec check: Inspect edge squareness, kerf taper, and surface profile; re-touch high spots and verify fit-up.

Dialing in settings upstream minimizes cleanup time; disciplined grinding delivers consistent cosmetic and dimensional results.

Safety Practices for Handling Thin, Sharp, and Hot Parts

With edges dressed and parts inspected, shift your focus to handling hazards that follow a clean cut. Enforce safety training so you and your crew apply protective gear and handling protocols every time.

Don heavy‑duty gloves to defeat lacerations from razor‑sharp edges and burr-laden corners. Fit safety glasses or a face shield to block sparks and micro-debris. Wear reinforced boots and flame-resistant apparel; recently cut thin steel retains heat and transfers it quickly through contact.

Stage parts on heat-tolerant surfaces and confirm temperature with a contactless thermometer before moving. Use tongs, magnets with rated lift, or edge clamps to keep hands clear. Apply proper lifting mechanics—neutral spine, close load, team lift or mechanical assist for large plates—to prevent strains.

Maintain a clear deck: purge clutter, route leads overhead, and mark hot zones with signage. Brief all personnel on sharp and hot material hazards, and validate compliance with documented checklists.

Frequently Asked Questions

Can I Cut Painted or Coated Thin Steel Without Damaging the Finish?

Yes, but you’ll protect the finish with specific process controls. Mask edges, control amperage, increase standoff, and use fine-cut consumables. Consider coating considerations; pre-score lines, mitigate heat-affected zone, and apply localized cooling. If necessary, employ paint removal techniques post-cut.

How Do Ambient Temperature and Humidity Affect Thin-Sheet Plasma Cutting?

Ambient temperature and humidity directly influence cut quality. You’ll stabilize arc voltage, prevent condensation, and maintain dry air. Control ambient conditions; moisture effects cause nozzle sputter, porosity, double-arcing, dross. Preheat cold stock, dehumidify intake air, use desiccant dryers, verify dew point, recalibrate amperage.

What File Formats and CAM Settings Work Best for Tiny Features?

Use DXF/SVG file types with simplified nodes. Configure CAM settings: kerf compensation, lead-ins 0.02–0.05″, pierce delay minimal, cut height 0.06″, feed rate tuned to amperage, corner slowdown 30–50%, micro-tabs 0.02″, optimize toolpath order.

How Loud Is Thin-Sheet Plasma Cutting, and What Hearing Protection Is Ideal?

It’s loud—Noise levels typically hit 95–115 dBA at torch, 85–100 dBA operator-side. You deploy double protection: foam earplugs (NRR 32) plus over-ear muffs (NRR 25–30). Verify seal, fit-test, and monitor exposure with dosimetry.

Can I Safely Stack-Cut Multiple Thin Sheets, and How to Separate Them?

Yes; you can stack cutting thin sheets if you clamp, tack corners, and use dry, flat, de-burred stock. Employ interleaf shims to control arc blow. For sheet separation, wedge and pry, then flex, slide putty knives, and deburr.

Conclusion

You’ve got the recipe now: dial amperage low, push traverse high, ride the arc on-height, and let FineCut tips slice a razor kerf. Lock the sheet, flood the heat with water or air, and choreograph toolpaths with crisp lead-ins and tight pierce delays. Keep consumables fresh, gas dry, and THC responsive. Do this, and thin steel behaves—no potato-chip warp, just laser-straight edges. You’re not cutting metal; you’re conducting heat—precisely, repeatably, like a metronome on steel.