Imagine you’re an artist with both a chisel and a brush at your disposal. A plasma cutter is akin to the chisel, perfect for precision and detail when shaping metal. On the other hand, a MIG welder resembles the brush, adept at seamlessly blending pieces together. The key is to know when to sculpt and when to paint, as both tools offer unique advantages and challenges depending on your project’s needs. Consider what’s next in your toolkit.

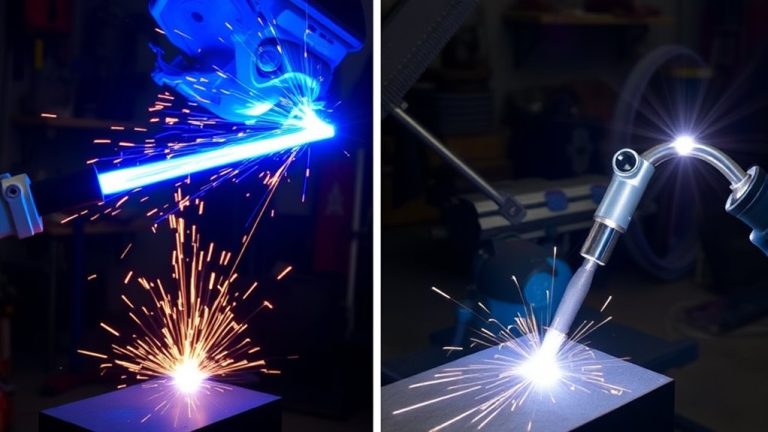

Understanding Plasma Cutting and MIG Welding

When delving into the world of metalworking, understanding the distinct roles of plasma cutting and MIG welding is vital.

Plasma cutting utilizes plasma properties by converting gas into plasma through an electric arc, reaching temperatures around 25,000°C. This allows for precision cuts on metals up to 1/4 inch thick, producing clean edges that require minimal post-processing. The high temperatures and precision make plasma cutting ideal for intricate designs and curved metalwork.

Conversely, MIG welding employs MIG techniques, utilizing a continuously fed wire electrode and an electrical arc to join metal pieces. Operating at lower temperatures of approximately 6,000°C, MIG welding is adept at joining thicker materials up to 1/2 inch in a single pass.

This technique is user-friendly, making it accessible for beginners. Understanding these processes’ technical aspects and operational parameters is essential for selecting the appropriate method based on your fabrication requirements.

Key Differences in Function and Application

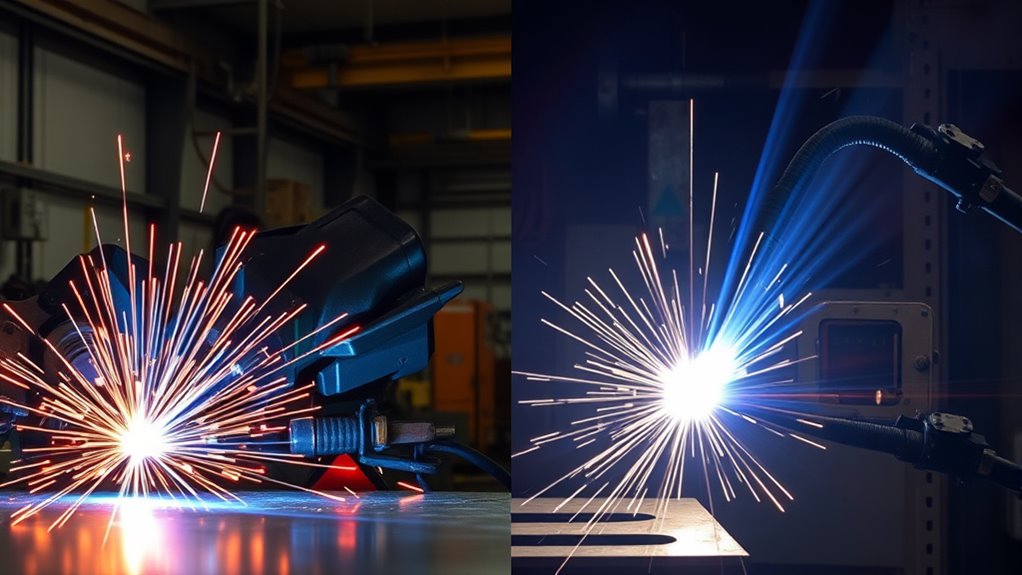

When you’re evaluating the roles of plasma cutters and MIG welders, it’s essential to recognize their distinct functions in metalworking.

Plasma cutters excel in precision and efficiency, especially for intricate designs on thin materials, while MIG welders are better suited for joining thicker materials with strong, high-quality welds.

Understanding tool-specific material compatibility will guide your decision, ensuring peak performance for your particular application.

Distinct Metalworking Roles

While both plasma cutters and MIG welders are essential in metalworking, their distinct roles highlight their specialized functions and applications.

Plasma cutters excel in cutting techniques, utilizing a high-temperature electric arc to transform gas into plasma, achieving precise cuts with cleaner edges. They’re ideal for intricate designs and thin materials, operating at temperatures up to 30,000°C for deeper penetration.

In contrast, MIG welders employ welding methods, using a wire electrode fed into a welding pool to join metals. This approach suits thicker materials and high-volume projects, with maximum temperatures around 6,000°C, allowing for fine-tuning of penetration depth.

Consequently, plasma cutters and MIG welders serve complementary functions, with plasma cutting favored in aerospace and MIG welding prevalent in automotive manufacturing.

Tool-Specific Material Compatibility

A crucial aspect of metalworking involves understanding the material compatibility of plasma cutters and MIG welders, as their functional distinctions dictate their best applications.

Plasma cutters shine in cutting electrically conductive materials, particularly when precision is needed for thin metals up to 1/4 inch. Their high operational temperature, reaching up to 30,000°C, guarantees clean, intricate cuts with minimal cleanup.

However, when joining thicker materials, MIG welders are superior, handling up to 1/2 inch in a single pass. Their continuous wire feed and shielding gas system make them ideal for high-volume tasks, especially with steel and aluminum.

The material suitability of each tool, combined with their thickness limitations, highlights their complementary roles in achieving ideal metalworking results.

Precision and Efficiency Balance

Understanding the balance between precision and efficiency is crucial in selecting the appropriate tool for metalworking tasks. Plasma cutters and MIG welders offer distinct precision techniques and efficiency strategies.

Plasma cutting excels in crafting intricate cuts with exceptional precision, ideal for thin materials. It operates at temperatures up to 30,000°C, providing deep penetration for complex designs.

Conversely, MIG welding shines in efficiency, particularly in high-volume productions, offering robust welds with a continuous wire feed.

- Plasma cutting achieves cleaner edges, reducing post-process cleanup.

- MIG welding’s operational efficiency suits automotive manufacturing, enhancing productivity.

- Plasma cutting’s precision is essential in automated setups for specialized tasks.

- Ease of use favors MIG welding for beginners, balancing skill requirements and output quality.

Choose based on task demands and desired outcomes.

Material and Thickness Considerations

Considering the material and thickness is essential when deciding between plasma cutting and MIG welding. Material thickness plays a significant role in equipment selection. For instance, plasma cutting is ideal for materials up to 1/4 inch thick, offering precision for intricate designs. It’s particularly advantageous with electrically conductive metals, making it perfect for tasks requiring clean and detailed cuts.

Plasma cutting excels at precision for intricate designs on materials up to 1/4 inch thick.

Conversely, MIG welding excels with materials up to 1/2 inch thick in a single pass, efficiently joining thicker sections. This method is particularly effective for steel and aluminum, often used in automotive applications.

When dealing with thicker plates, such as 4-5mm and above, plasma cutters provide time-saving advantages and produce cleaner cuts than traditional grinding. However, be mindful of plasma-cut edges, as they can exhibit hardness due to martensite formation, complicating subsequent welding processes.

As a result, understanding both the thickness and properties of your material is vital in determining the appropriate method.

Cost and Investment Analysis

When evaluating the cost and investment of plasma cutters versus MIG welders, it’s vital to take into account both upfront and ongoing expenses. MIG welders usually present a lower initial investment, starting at around $500, while plasma cutters begin at approximately $1,000.

Despite the higher cost, plasma cutters often offer enhanced investment longevity due to their robust resale value, making them advantageous in the long term. However, consider the ongoing costs: MIG welding requires consumables like welding wire and shielding gas, whereas plasma cutting necessitates electrodes and nozzles, leading to potentially greater maintenance costs.

Given these factors, a detailed cost comparison is important:

- Initial purchase cost: MIG welders are generally more affordable.

- Ongoing maintenance: Plasma systems may incur higher costs.

- Time efficiency: Plasma cutters excel in intricate and thick material applications.

- Resale value: Plasma cutters maintain strong market value, enhancing long-term investment potential.

Your choice should align with specific job requirements and metalworking needs.

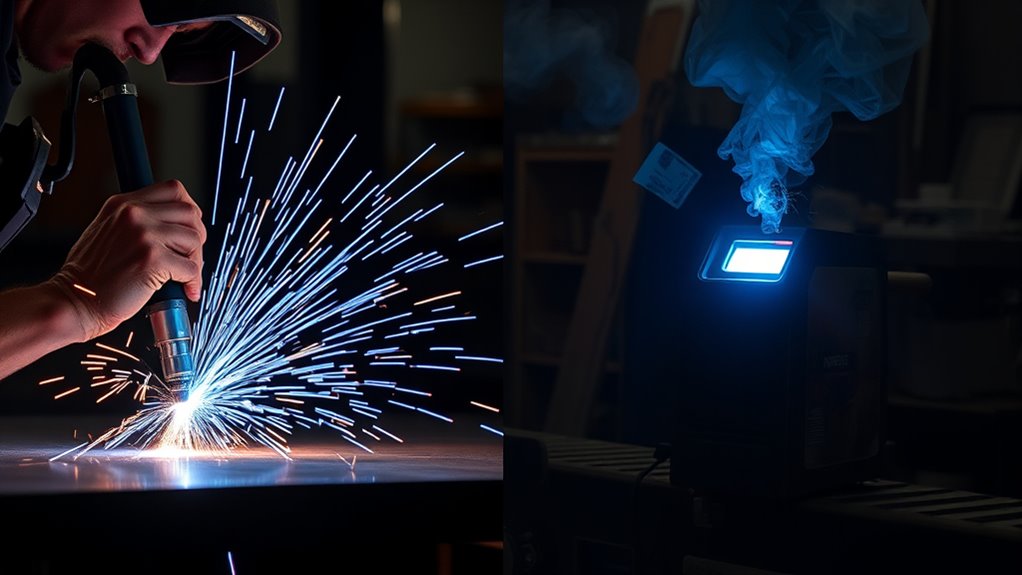

Skill Requirements and Safety Measures

When operating a plasma cutter, you’ll need a more advanced skill set and precise control due to the complex arc behavior and cutting techniques involved.

In contrast, MIG welding is more accessible for beginners, requiring less intensive training and simpler setups, though both processes mandate strict adherence to safety protocols.

Ensuring proper personal protective equipment and ventilation is critical, with plasma cutting demanding additional precautions due to its higher temperature and specific hazards.

Skill Level Varies

While both plasma cutting and MIG welding are valuable techniques in metal fabrication, they demand varying skill levels and safety considerations.

Plasma cutting requires more intensive training methods due to its complexity. You’ll need precise control over the arc and a deep understanding of its behavior, which makes skill progression challenging.

In contrast, MIG welding is more accessible for novices. Its continuous wire feed simplifies operations, allowing you to focus on improving technique with less technical expertise.

- Plasma Cutting:

- Demands formal instruction for mastery.

- Requires precise arc control.

- Involves complex operational setup.

- Presents high-temperature hazards.

- MIG Welding:

- Easier for self-teaching.

- Simplified, adaptable setups.

- Continuous wire feed aids learning.

- Requires understanding of shielding gas handling.

Safety Gear Necessity

Advancing from skill levels to safety considerations, it’s vital to understand the necessity of appropriate safety gear in plasma cutting and MIG welding. Safety equipment, including helmets, gloves, and protective clothing, is important to protect against burns, sparks, and dangerous fumes. Plasma cutting demands heightened precision and training, necessitating a thorough understanding of arc behavior and gas handling. Guarantee a clean, dust-free environment and stable power for safe arc generation. MIG welding, while more forgiving, still requires vigilance. Both methods benefit from regular maintenance checks to guarantee operational integrity.

| Safety Concern | Plasma Cutting | MIG Welding |

|---|---|---|

| Skill Requirement | High precision needed | Forgiving for beginners |

| PPE Necessity | Vital: gloves, helmets | Vital: gloves, helmets |

| Workspace Safety | Dust-free, stable power required | Less sensitive to drafts |

| Training Intensity | Intensive | Moderate |

| Maintenance | Regular checks important | Regular checks important |

Industry-Specific Applications

Although each tool offers unique advantages, understanding the industry-specific applications of plasma cutters and MIG welders is essential for optimizing their use.

In the automotive sector, MIG welding techniques are favored for assembling car body panels and frames due to their efficiency in joining thicker materials. Plasma cutting methods excel in creating precise cuts for custom designs.

In aerospace, plasma welding is ideal for high-quality welds on thin aluminum, while MIG welding provides robust joints for structural components.

Construction projects benefit from MIG welding in steel framework assembly, whereas plasma cutting is preferred for intricate shapes in metal sheets.

Manufacturing sectors utilize MIG welding for high-volume production, with plasma cutting providing precision in small-batch or custom projects.

- Automotive Industry: MIG welding for body panels; plasma cutting for custom designs.

- Aerospace: Plasma welding on aluminum; MIG welding for structural joints.

- Construction: MIG welding for frameworks; plasma cutting for detailed cuts.

- Manufacturing: MIG welding for volume; plasma cutting for precision.

Technological Innovations and Future Trends

As the welding industry evolves, technological innovations are reshaping the landscape, setting the stage for future trends. The global welding market is on track to hit $28 billion by 2028, fueled by technological advancements. Virtual reality (VR) and augmented reality (AR) are transforming training programs, enhancing skill development and operational efficiency. Hybrid welding systems, such as laser-MIG and plasma-MIG, are becoming essential for their superior results and efficiency.

| Trends | Details |

|---|---|

| Market Growth | Projected to reach $28 billion by 2028 |

| Training Innovations | VR and AR integration |

| Hybrid Systems | Laser-MIG and plasma-MIG |

Automation is set to redefine the field, with robotic welding automating 50% of jobs by 2030, leveraging AI for real-time adjustments. Future innovations include nano-enhanced filler metals and smart welding helmets with sensors, optimizing quality and safety. These technological advancements are imperative for a competitive edge in metalworking.

Making the Right Choice for Your Project

How do you determine the best tool for your welding or cutting project? Start by evaluating project suitability and material selection.

If your project involves precision cutting of thin, electrically conductive materials, a plasma cutter is your go-to choice. It’s ideal for intricate designs and automated setups where precision is paramount, such as in aerospace applications.

Conversely, if you’re joining thicker materials, particularly steel or aluminum, opt for MIG welding. It’s faster and suitable for high-volume tasks like automotive manufacturing.

Consider these factors to refine your decision:

- Material Type: Plasma cutters excel with conductive metals; MIG welders are versatile for steel and aluminum.

- Thickness Requirements: Plasma is best for thin materials, while MIG handles up to 1/2 inch.

- Skill Level: MIG welding is more beginner-friendly; plasma cutting requires advanced skills.

- Workspace Conditions: Plasma cutting needs a stable, clean environment; MIG welding is more forgiving.

Select the tool that aligns with your project’s specific needs.

Frequently Asked Questions

How Do Plasma Cutters Affect Metal Fatigue?

When using a plasma cutter, you’ll minimize metal fatigue if you utilize precise cutting techniques. Poor technique induces stress concentrations, leading to fatigue cracks. Guarantee ideal speed and torch angle to reduce the risk of compromising metal integrity.

Can MIG Welders Be Used in Outdoor Environments?

Certainly, MIG welders are like a jack-of-all-trades, adaptable to outdoor conditions if you shield the weld pool from wind. Master various welding techniques, use suitable equipment, and guarantee safety for effective outdoor welding.

What Maintenance Is Required for Plasma Cutters?

You should regularly replace electrodes and clean the nozzle to guarantee efficient plasma cutter performance. Check for wear, inspect connections, and maintain air filters. This maintenance minimizes downtime and prolongs the lifespan of your equipment.

Are There Eco-Friendly Options for MIG Welding?

Oh, you’re worried about the planet while welding? That’s cute. But yes, you can use sustainable materials and focus on energy efficiency. Just remember, your eco-guilt won’t fix that metal seam. Happy welding!

How Do Plasma Cutters Handle Non-Metal Materials?

Plasma cutters, known for their versatility, primarily excel with metals. However, they can handle some non-metal applications like plastics and wood, but effectiveness decreases due to material composition and risk of combustion or damage. Use cautiously.

Conclusion

When deciding between plasma cutting and MIG welding, remember: it’s not just your project’s needs; it’s also the sheer joy of choosing the wrong tool and embracing chaos. After all, who wouldn’t want to attempt intricate cuts with a MIG welder? Understanding the nuances of material and thickness, cost, and skill requirements ironically guarantees efficiency. So, make informed choices, or don’t, and learn the hard way—it’s a journey in mastering chaos and precision.