Exploring the intricacies of plasma cutters and TIG welders reveals fascinating distinctions in their applications and outputs. You might be intrigued by how plasma cutters deliver rapid, precise cuts on thicker metals while TIG welders excel in crafting flawless welds on thinner materials. The edge quality achieved by these tools plays a pivotal role in design and function. Curious about costs, performance, and the nuances of each tool? There’s more to uncover.

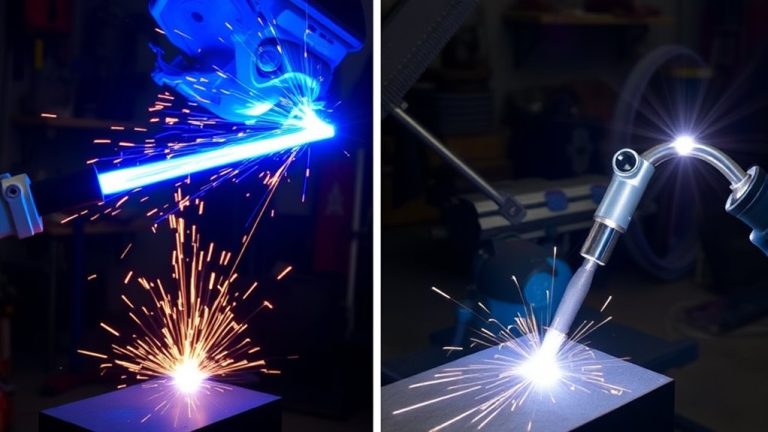

Understanding Plasma Cutters and TIG Welders

When delving into the world of metalworking, understanding the distinct functionalities of plasma cutters and TIG welders is essential.

Plasma cutters, operating at 250-300V open circuit voltage, excel in applications requiring rapid and clean cuts, particularly on metals up to 50 mm thick. They leverage higher voltage for efficient performance, producing minimal heat-affected zones, thereby reducing material warping.

Plasma cutters excel with rapid, clean cuts on metals up to 50 mm, minimizing heat-affected zones.

In contrast, TIG welders, employing a non-consumable tungsten electrode with argon or helium shielding gas, are crafted for high-precision applications. They’re ideal for welding thin materials like aluminum and titanium, offering superior control over heat input and producing aesthetic welds.

From a technology comparison standpoint, plasma cutters are more suited for tasks demanding speed and minimal material distortion. Meanwhile, TIG welders are your go-to for projects prioritizing precision and weld quality.

Consider the investment: plasma cutters range from $1,400 to $50,000, while TIG welders cost between $2,200 and $16,000.

Key Differences in Functionality

While both plasma cutters and TIG welders are pivotal in metalworking, they serve distinct functional purposes driven by their operational characteristics.

In a functionality comparison, plasma cutters operate at higher voltages (250-300V) compared to TIG welders (60-80V), resulting in significant operational differences. Plasma cutting employs a constricted arc with air or other gases, allowing rapid severance of thick materials up to 50 mm. This contrasts sharply with TIG welding, which uses a non-consumable tungsten electrode and inert argon gas, focusing on precision tasks for thin materials up to ½ inch.

Operational differences also extend to equipment setup. TIG welding demands argon for shielding, while plasma cutting involves an air compressor, underscoring their distinct requirements.

Additionally, safety protocols differ: TIG welding prioritizes reducing contamination and achieving clean aesthetics, whereas plasma cutting necessitates protection from noise, fumes, and intense light.

Each tool’s functionality is tailored to its unique applications and operational demands.

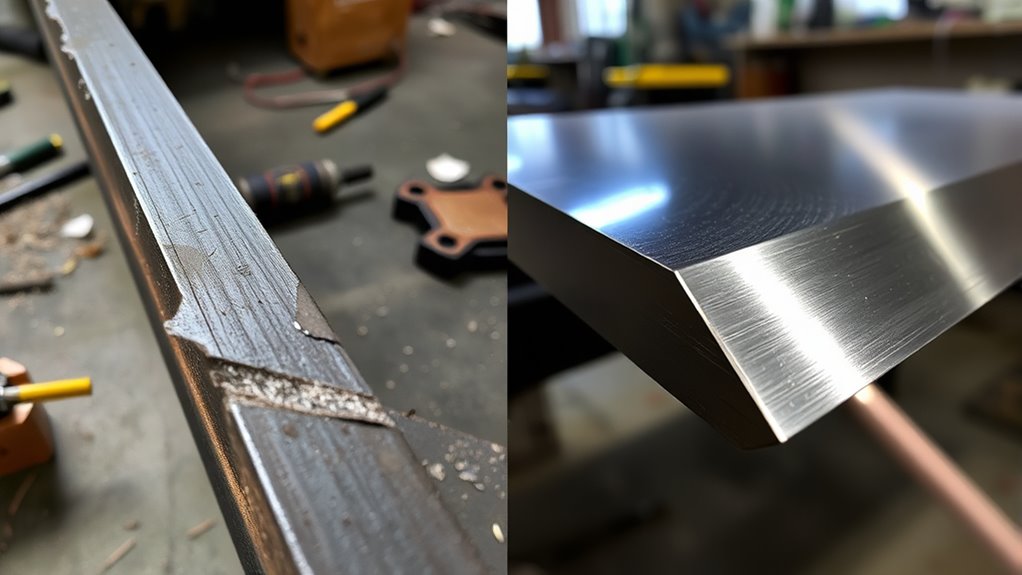

Analyzing Edge Quality and Finish

When evaluating edge smoothness, you’ll notice that plasma cutting often yields cleaner edges with minimal dross on materials up to 50 mm thick, especially beneficial for intricate designs.

In contrast, TIG welding excels in producing superior finish quality with smooth, aesthetically pleasing welds, essential for applications involving metals like aluminum and titanium.

While plasma cutting is efficient for thicker materials, TIG welding provides consistent high-quality edges across various thicknesses, ensuring minimal post-process cleanup.

Edge Smoothness Comparison

Edge smoothness is a critical factor when analyzing the quality and finish of metalworking processes, especially in applications where precision and aesthetics are paramount. When choosing between plasma cutting and TIG welding, consider the edge durability and aesthetic preferences. Plasma cutting delivers minimal dross and smoother finishes ideal for intricate designs, but edges might need refinement for a TIG-like finish. TIG welding, with its precise heat control, offers polished edges, essential in high-precision tasks.

| Method | Edge Quality | Ideal For |

|---|---|---|

| Plasma Cutting | Minimal dross, smooth | Intricate designs |

| TIG Welding | Highly polished | Aesthetic applications |

| Plasma Cutting | Variable with thickness | Sheets up to 50 mm |

| TIG Welding | Clean, uniform | Thin-gauge metals |

Ultimately, project requirements dictate the best method.

Finish Quality Assessment

Consider how finish quality greatly impacts the final appearance and functionality of metalwork. When evaluating plasma cutting and TIG welding, you need to weigh aesthetic preferences and finish durability.

Plasma cutting excels in speed and efficiency, offering cleaner edges with minimal dross for materials up to 50 mm. However, it can produce a rougher edge due to its high-speed process, requiring additional finishing for aesthetic preference.

- Plasma Cutting: Ideal for intricate designs, yet may need post-processing for smoother finishes.

- TIG Welding: Provides high-quality, contamination-free welds, especially on delicate materials, with a naturally smoother finish.

- Heat-Affected Zone (HAZ): Plasma cutting’s smaller HAZ minimizes warping, enhancing finish durability.

Operator skill heavily influences the quality in both methods, demanding precision for best results.

Cost Implications and Budget Considerations

When considering initial investment costs, you’ll find that plasma cutters require additional infrastructure, like an air compressor, which can elevate setup expenses markedly compared to TIG welders.

Maintenance and upkeep are critical, with ongoing consumable expenses for both tools, such as gas, electrodes, and wires, impacting your budget notably over time.

Evaluating the cost-effectiveness of used equipment, especially in the TIG welder market, can offer substantial savings and reduce depreciation losses.

Initial Investment Costs

While choosing between a plasma cutter and a TIG welder, you’ll encounter varied initial investment costs that greatly impact budget planning. A precise cost comparison reveals plasma cutters range from $1,400 to $50,000, whereas TIG welders cost between $2,200 and $16,000. This disparity necessitates careful evaluation of machine capabilities relative to your budget.

Key considerations include:

- Plasma cutters: Factor in an air compressor (minimum 20 gallons) to guarantee peak performance.

- Energy efficiency: Plasma cutters can offer higher operational efficiency, potentially reducing energy expenses.

- Used equipment: Opting for dependable used models, like the Miller Syncrowave, may considerably lower initial investment, priced around $900 to $1,500.

Carefully assess these elements to strategically align your investment with technical requirements.

Maintenance and Upkeep

Maintaining your plasma cutter and TIG welder is essential to ensuring their longevity and efficiency. Regular upkeep involves adhering to strict safety practices and mastering troubleshooting techniques.

For plasma cutters, replace consumables like electrodes and nozzles, costing $50-$200 annually based on usage. TIG welders demand periodic tungsten electrode inspections and gas line replacements, with costs ranging from $100 to $300 per year.

Routine cleaning and calibration of both machines are vital to avoid costly repairs and enhance lifespan. Consider the higher initial investment of TIG welders ($2,200 – $16,000) versus plasma cutters ($1,400 – $50,000), alongside ongoing maintenance expenses.

Opt for high-quality consumables to minimize downtime and optimize operational efficiency, ultimately reducing the total cost of ownership.

Consumable Expenses

Steering through the consumable expenses of plasma cutters and TIG welders demands a meticulous budgeting approach. Understanding consumable longevity and cost comparison is essential.

Plasma cutters incur higher costs due to frequent replacement of cutting tips, electrodes, and gas supplies. Expect to spend $50 to $150 monthly, particularly in high-volume operations.

Conversely, TIG welders benefit from consumable longevity with tungsten electrodes and filler rods, averaging $20 to $100 per month.

- Plasma cutters: Higher consumable costs due to frequent parts replacement.

- TIG welders: Lower expenses thanks to reusable tungsten electrodes.

- Gases: Argon for TIG costs around $40 per cylinder; plasma uses cheaper compressed air but needs maintenance.

Accurate budgeting guarantees cost-efficiency in choosing the right tool for your needs.

Material Compatibility and Versatility

Although both plasma cutters and TIG welders excel in their respective domains, understanding their material compatibility and versatility is essential for ideal application.

Plasma cutters shine with their ability to efficiently slice through metals like stainless steel, aluminum, and mild steel with cutting thickness up to 50 mm. This makes them highly adaptable for diverse, high-volume production scenarios. Their precision in creating clean cuts with minimal heat-affected zones is unmatched, though they falter in intricate welding tasks.

Conversely, TIG welders are the champions of welding precision, excelling in non-ferrous metals such as aluminum, stainless steel, and copper. They particularly thrive in handling thin-gauge sections, where control and minimal impurities are critical, a common requirement in aerospace applications.

TIG welding produces aesthetically superior and structurally sound welds. Both processes demand specific gas shielding—plasma cutting with air or other gases, and TIG welding with inert gases like argon or helium.

Speed and Efficiency in Operation

When evaluating speed and efficiency, plasma cutters clearly outpace TIG welders, particularly in high-demand production environments.

Plasma cutters excel due to their superior cutting speed, reaching up to 20 inches per minute on materials as thick as 1 inch. This rapid pace considerably enhances operational efficiency and is ideal for large-scale production. The minimized heat-affected zones guarantee material integrity, reducing the risk of warping and distortion.

Superior cutting speed improves efficiency and maintains material integrity, making plasma cutters ideal for large-scale production.

In contrast, TIG welders, while precise, operate more slowly. They require meticulous control to maintain a stable arc and achieve weld quality, which limits their cutting speed to just a few inches per minute, particularly on thicker materials. Consequently, TIG welding is less suited for high-volume tasks.

Key advantages of plasma cutters include:

- High cutting speed: Up to 20 inches/minute

- Operational efficiency: Lower labor costs

- Minimal material distortion: Reduced heat-affected zones

These factors make plasma cutters the preferred choice for efficiency-driven operations.

Skill Level and Training Requirements

While plasma cutters speed through tasks with efficiency, they demand specialized knowledge for ideal operation. You’ll need to master training methods that emphasize safety and performance, especially in handling high voltage and gas flow rates.

Skill progression in plasma cutting involves learning to troubleshoot and manage equipment complexities, which guarantees peak functionality and safety.

On the other hand, TIG welding requires a higher skill level due to its precision demands. Controlling heat input and maintaining a stable arc are critical skills, necessitating hands-on training.

Beginners will benefit from structured training methods focusing on pedal control for heat adjustments and understanding material-specific welding characteristics. The learning curve is steeper here, demanding more practice to achieve high-quality welds.

Both processes involve safety training to mitigate risks from intense light, noise, and fumes, necessitating proper protective gear and a thorough understanding of operational hazards.

Industrial Applications and Use Cases

In industrial settings where speed and efficiency are paramount, plasma cutters are indispensable for their ability to slice through thick metals like stainless steel and aluminum with precision.

These machines are essential in plasma applications where cutting efficiency and reduced heat-affected zones are necessary to prevent material distortion. Plasma cutters shine in fabrication shops, offering lower operational costs and the ability to handle metals up to 50 mm thick.

Plasma cutters excel in efficient cutting, minimizing heat distortion, and handling metals up to 50 mm thick.

On the other hand, TIG applications are prized in industries like aerospace and automotive, where precision and control over welding thin-gauge metals and exotic materials are vital.

TIG welders deliver aesthetically superior results, a fundamental requirement for high-end products and components.

- Plasma Applications: Fast, precise cutting of thick materials; low operational costs.

- TIG Applications: High precision welding for thin and exotic materials; aesthetic quality.

- Industry Preferences: Plasma for speed and cost; TIG for precision and appearance.

Equipment Setup and Maintenance Needs

Setting up a plasma cutter necessitates integrating a 20-gallon air compressor to guarantee peak performance, while TIG welders demand meticulous adjustments for current and proper gas flow, typically using argon or helium, to maintain weld integrity.

Routine maintenance for plasma cutters includes regularly checking consumables like electrodes and nozzles, as well as verifying the air system’s integrity to avoid operational disruptions.

TIG welders require consistent evaluation of the tungsten electrode‘s condition and sharpness, which is critical for sustaining stable arcs and high-quality welds.

Setup Requirements Overview

When setting up plasma cutters, you’ll need a high-voltage power source and a specific air supply system, typically involving a compressor, to guarantee clean and efficient cuts across various metal thicknesses.

The setup complexities involve fine-tuning equipment configurations to secure ideal performance. Precision in adjusting parameters like gas flow and arc length is vital.

- High-voltage power source: Essential for driving the plasma arc through metal surfaces.

- Air supply system: Requires a dedicated compressor to provide clean, dry air.

- Parameter calibration: Critical for achieving desired cut quality and efficiency.

For TIG welders, precise current control systems, tungsten electrodes, and inert gas supplies are paramount.

Intricate adjustments for precision make this process slightly more demanding regarding equipment configurations compared to plasma cutting.

Routine Maintenance Essentials

Although maintaining your equipment might seem tedious, it’s essential for ensuring both plasma cutters and TIG welders perform at their peak. Routine maintenance is vital for equipment longevity.

For plasma cutters, regularly check and replace consumables like electrodes and nozzles to uphold cutting performance. Inspect electrical connections and hoses for leaks to avoid interruptions.

TIG welders demand periodic tungsten electrode inspection, maintaining ideal gas flow rates, and ensuring shielding gas purity to avert contamination. Adjust your gas flow, current settings, and keep a clean workspace to prevent defects.

Clean the torch and work surface routinely, as contaminants can compromise edge quality. Finally, test TIG cables for insulation integrity and secure connections, ensuring flawless operational readiness.

Future Trends and Technological Advancements

As the welding industry advances, automation and intelligent systems are at the forefront of future technological trends, particularly in TIG and plasma welding. Automation trends are enhancing precision and consistency by integrating intelligent systems that monitor parameters in real-time.

Automation in welding enhances precision with real-time parameter monitoring through intelligent systems.

You’ll find that these smart technologies adjust settings to accommodate various materials and thicknesses efficiently.

Key advancements in the field include:

- Multi-component fluxes: These improve weld penetration and efficiency, vital for lightweight material applications.

- Energy-efficient plasma cutting: Innovations here reduce operational costs, making them ideal for high-volume production.

- User-friendly interfaces: With smartphone apps, these simplify setup and cut down on operator training time.

These trends guarantee that as technology evolves, your welding processes become more precise and cost-effective. Embracing these innovations will allow you to stay competitive in a rapidly changing industry landscape, where efficiency and adaptability are paramount.

Frequently Asked Questions

Are There Any Safety Concerns With Using Plasma Cutters or TIG Welders?

Yes, you’ve got safety concerns with both. Wear appropriate safety gear to protect from sparks and UV radiation. Plasma cutters present fire hazards, so maintain a clean workspace. TIG welders require precise handling to avoid electrical risks.

How Do Environmental Factors Affect the Performance of Both Tools?

Imagine a dance where humidity and temperature effects lead. They can impact arc stability and cutting precision. High humidity causes oxidation, while extreme temperatures affect metal expansion. Monitor conditions meticulously to guarantee ideal tool performance and precise results.

Can Plasma Cutters and TIG Welders Be Used Underwater?

Yes, you can use plasma cutters and TIG welders underwater with specialized techniques. Underwater applications require precise control, and you must guarantee equipment is waterproofed. Such welding techniques demand expertise, increased safety measures, and specific electrode configurations.

What Are the Noise Levels Associated With Each Tool?

You might wonder if plasma cutters are noisier than TIG welders. Plasma cutters typically produce higher sound levels, around 90-120 dB, whereas TIG welders operate quieter, around 70-80 dB. This noise comparison highlights precision-focused considerations.

How Do Power Consumption Rates Compare Between the Two Tools?

You’ll find plasma cutters generally consume more power, affecting energy costs unfavorably. In contrast, TIG welders often show better power efficiency. Analyzing both tools’ specifications, TIG welders usually offer lower power consumption, enhancing operational cost-effectiveness.

Conclusion

In the domain of metal fabrication, choosing between plasma cutters and TIG welders hinges on your project’s nuances. Plasma cutters slice through thick materials with surgical precision, ideal for intricate designs. Conversely, TIG welders provide a polished touch, perfect for delicate, aesthetically-driven tasks. While initial investments and upkeep vary, each tool offers unique benefits. By understanding your material and project requirements, you can navigate this decision-making labyrinth with finesse, ensuring your craftsmanship reaches its full potential.