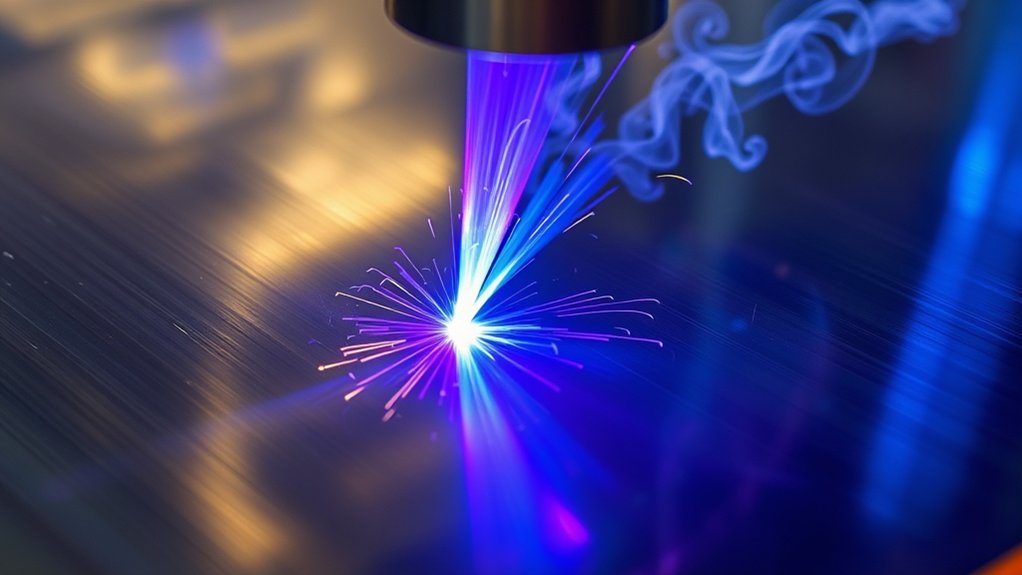

Imagine you’re tasked with plasma cutting a 1/8 inch aluminum sheet, aiming for precision and minimal dross. You’d need to set your plasma cutter to 45 amps and maintain a speed of 70-75 inches per minute. The choice of nitrogen as both plasma and shield gas will minimize oxidation. Ensuring the correct torch height is vital for stability. There’s more to uncover about optimizing your settings for flawless results.

Importance of Correct Settings for Aluminum

When cutting aluminum with a plasma cutter, getting the settings right is essential for achieving high-quality results.

Start by confirming the correct amperage; for plasma cutting aluminum at 1/8 inch thickness, 45 amps is ideal to guarantee effective penetration and superior cut quality.

Maintain a cutting speed between 70-75 inches per minute to prevent dross formation and achieve a clean edge. The standoff distance is critical; keep it consistent to stabilize arc voltage, enhancing the cut quality.

Using nitrogen as both the plasma and shield gas minimizes oxidation, guaranteeing cleaner cuts, especially for aluminum under 5 mm thick.

Regularly consult the manufacturer’s cut charts to adjust settings for varying material thicknesses, optimizing performance.

Managing feed rate and standoff distance meticulously will enhance your ability to produce smooth, accurate cuts without excess dross.

Precision in these settings directly correlates with achieving professional-grade results in aluminum cutting tasks.

Selecting the Right Equipment and Consumables

Achieving professional-grade results in aluminum cutting doesn’t stop at settings; choosing the right equipment and consumables is equally important.

Opt for a high-frequency plasma cutter to guarantee clean, effective cuts. It’s crucial to match the amperage settings to the thickness of aluminum; higher amperages are necessary for thicker materials to maintain the best cut quality.

Selecting the right consumables is essential. Verify they’re compatible with your plasma cutter model; .9mm consumables might be ideal for certain setups.

Regularly changing consumables can greatly enhance cutting efficiency and minimize dross production. For aluminum up to 5 mm thick, using nitrogen as both plasma and shield gas achieves cleaner cuts and reduces oxidation, creating a superior finish.

Optimal Speed and Amperage for Aluminum Cutting

To achieve ideal results in plasma cutting aluminum, precise control over speed and amperage is essential. Start by setting your plasma cutter to an amperage setting of 45 amps for 1/8 inch aluminum. This helps prevent excessive dross formation while guaranteeing efficient cuts.

The best feed rate, typically between 70-75 inches per minute (ipm), balances cut speed with the desired cut quality. Remember, higher amperage allows for increased cut speeds, but you must account for the thickness of the aluminum to avoid distortion.

Maintaining tight tolerances during the plasma cutting process involves consistent torch height and adherence to manufacturer guidelines.

Should you encounter issues like dross on the top of cuts or the torch “cutting out,” experiment with slightly slower feed rates. This approach can refine the cutting process and enhance the overall cut quality.

Precision adjustments in speed and amperage settings guarantee superior results and minimized warpage.

Gas Types and Their Impact on Cut Quality

While precise speed and amperage settings are essential for ideal aluminum cuts, the choice of gas greatly affects cut quality. When you cut aluminum, selecting appropriate gas types is critical.

For materials less than 5 mm thick, nitrogen is the preferred plasma gas due to its ability to provide cleaner cuts with minimal oxidation, which is often an issue with air plasma.

As aluminum thickness increases beyond 6 mm, combining nitrogen with water as a shield gas enhances cut quality and minimizes dross. This setup is particularly beneficial for thicker materials, maintaining torch efficiency and reducing consumable wear.

For aluminum exceeding 12 mm, an argon-hydrogen mixture excels, mitigating rough surfaces and ensuring superior cut quality.

Air plasma cutting is prone to oxidation; consequently, nitrogen remains a superior choice. The significance of shield gas selection can’t be overstated, as it prevents torch overheating during plasma cutting.

Troubleshooting Common Issues in Aluminum Plasma Cutting

When tackling common issues in aluminum plasma cutting, identifying and addressing dross formation is crucial. Adjust your feed rate to around 70-75 IPM and maintain the amperage at 45 amps to mitigate dross.

Unlike mild steel, aluminum cutting demands precision with cutting speed and torch height. Confirm your torch height aligns with the standoff distance recommended by the manufacturer to prevent arc instability.

A solid ground clamp connection is essential; inadequate grounding can cause the torch to “cut out” mid-operation. If you’re facing excessive dross, consider using nitrogen as a secondary gas, particularly for thinner aluminum, to enhance cut quality.

Experimenting with slower feed rates might also yield better results. Document your processes and refine these cutting settings based on outcomes. This won’t only troubleshoot current issues but also improve future aluminum plasma cutting performance, making your operations more efficient and precise.

Frequently Asked Questions

Can You Cut Aluminum on a Plasma Cutter?

Yes, you can cut aluminum on a plasma cutter. Guarantee proper material preparation, select the right nozzle size, and set amperage. Adjust cutting speed for your aluminum thickness, maintain arc stability, and follow cooling methods and safety precautions.

What Should a Plasma Cutter Be Set At?

Visualize the crackling arc: Set your plasma cutter with 45 amps for 1/8-inch aluminum. Maintain cutting speed at 70-75 ipm. Match nozzle diameter to material thickness, guarantee arc stability, adjust voltage, and prioritize safety for ideal results.

What Gas for Plasma Cutting Aluminum?

Use nitrogen or an argon mix for best results when plasma cutting aluminum. Adjust cutting speed, nozzle diameter, and power settings for ideal performance. Maintain proper gas pressure, cooling system, and electrode material according to thickness range. Always follow safety precautions during operation.

What Are the Fumes From Plasma Cutting Aluminum?

Imagine fumes as silent serpents; their composition includes aluminum oxide particles, posing health risks. Emphasize safety precautions with fume extraction, ventilation requirements, and proper respiratory protective equipment (PPE). Cutting quality and material properties affect environmental impact—prioritize safety.

Conclusion

Think of plasma cutting aluminum as maneuvering a precise dance, where each step must be in harmony. By setting the amperage to 45 amps and maintaining a cutting speed of 70-75 inches per minute, you guarantee a flawless performance. Use nitrogen as your partner to minimize oxidation, and keep a consistent standoff distance to stabilize the arc voltage. Always consult manufacturer cut charts for guidance, confirming your torch height is perfect to avoid dross and achieve peak results.